Effective method for improving feeding efficiency of sand mold casting

A technology of sand casting and shell casting, which is applied in the field of improving the feeding efficiency of sand casting. It can solve the problems of large shrinkage of molten steel, inability to feed, and difficult feeding of products, so as to improve internal quality, reduce shrinkage and porosity. Reduce the effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]An effective method of improving sand casting replenishment efficiency, including the following steps:

[0023](1) Casting process:

[0024]A, the shell casting, all of the shapes have a coating sand mold, in order to ensure surface roughness, and the coating can produce a certain amount of cooling effect on castings;

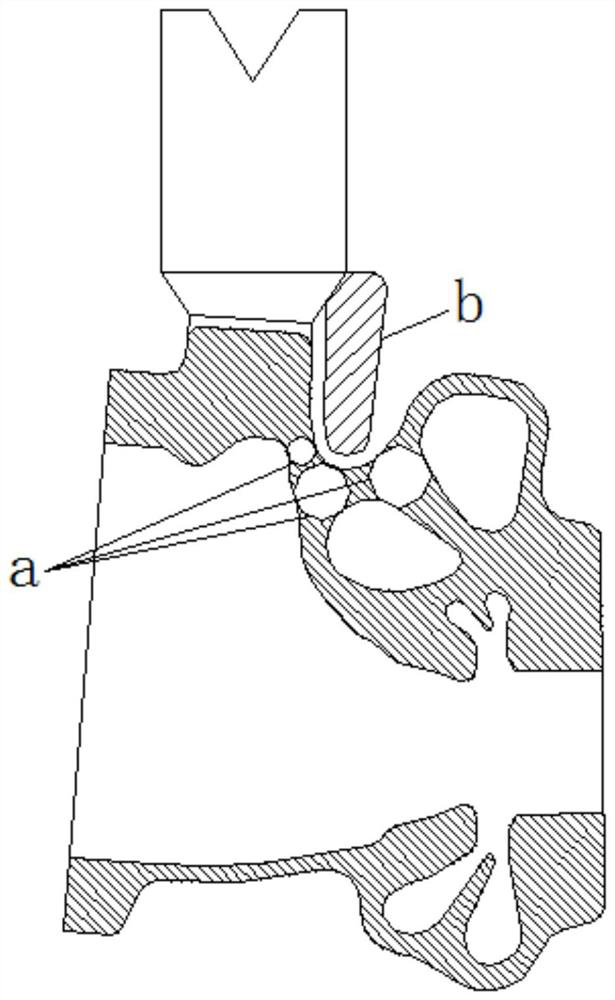

[0025]b, arrange the riser and cold iron in the product plane position, controlling its cooling speed, ensuring the order of order;

[0026]C. When pouring, a small metal solution B is introduced synchronously, wherein the metal solution B is separated from the surface of the product, further, a film covers isolation between the metal fluid B and the product surface. Further, the film is used as a polytetrafluoroethylene iron-proof dragon PTFE film;

[0027](2) Product testing:

Embodiment 2

[0031]An effective method of improving sand casting replenishment efficiency, including the following steps:

[0032](2) Casting process:

[0033]A, the shell casting, all of the shapes have a coating sand mold, in order to ensure surface roughness, and the coating can produce a certain amount of cooling effect on castings;

[0034]b, arrange the riser and cold iron in the product plane position, controlling its cooling speed, ensuring the order of order;

[0035]C. When the pouring is pouring, a small metal solution B is introduced synchronously, wherein the metal solution B is isolated from 5 mm from the surface of the product, and the film B and the surface of the product are covered with a film. Further, the film is used as a polytetrafluoroethylene iron-proof dragon PTFE film;

[0036](2) Product testing:

[0037](1) cutting cutting on the product line;

Embodiment 3

[0040]An effective method of improving sand casting replenishment efficiency, including the following steps:

[0041](3) Casting process:

[0042]A, the shell casting, all of the shapes have a coating sand mold, in order to ensure surface roughness, and the coating can produce a certain amount of cooling effect on castings;

[0043]b, arrange the riser and cold iron in the product plane position, controlling its cooling speed, ensuring the order of order;

[0044]C. When pouring, a small metal solution B is introduced synchronously, wherein the metal fluid B is isolated from the surface of the product, further, the metal solution B and the surface of the product are covered with a film cover. Further, the film is used as a polytetrafluoroethylene iron-proof dragon PTFE film;

[0045](2) Product testing:

[0046](1) cutting cutting on the product line;

[0047](2) Cut surface dyeing test.

[0048]In summary, the traditional casting process (not introduced into the metal solution), due to the product structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com