Local heating method and system used after storage battery dispensing and cover closing

A technology of local heating and gluing cover, applied in the field of local heating and heating after the battery is glued and glued, it can solve the problems of large loss and low heat utilization efficiency, and achieve the effect of increasing the speed, avoiding heat loss and improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

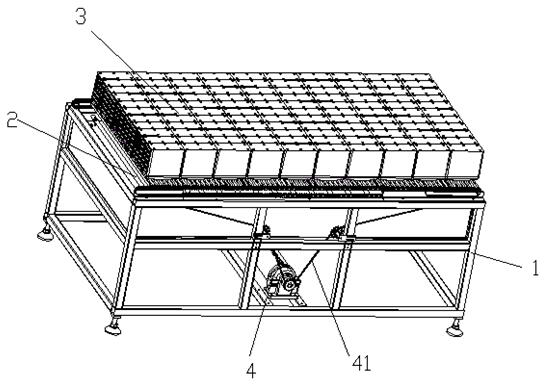

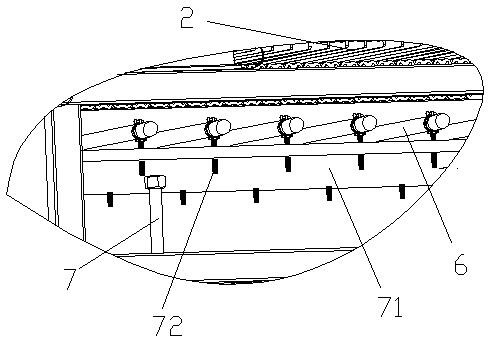

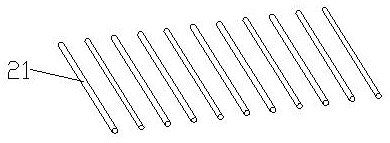

[0038] like figure 1 Shown, spot gluing A battery cover after local heating system, includes a frame 1, in this embodiment, the frame 1 as a whole has a rectangular parallelepiped configuration, with a conveying plate 2 is provided on a surface of the cuboid structure, spot gluing cap after the battery 3 is moved from one end of the conveying plate 2 to the other end of the conveying plate 2. like figure 2 , The heat source 2 is provided below the transfer plate 6, a plurality of heating pipes in the embodiment, the heat source 6 is arranged to the conveying direction of the plate width 2 of the present embodiment, equally spaced laying underneath the transport plate 2, and the conveying plate 2 to be covered baked cell 3 corresponding to the entire surface of the bottom, while ensuring entering the baking zone of the entire row of cells 3 heat evenly, glue substantially the same clotting time in the battery cover. A rack positioned on the transport plate portion 2 is provided bel...

Embodiment 2

[0042] This embodiment substantially the same preceding embodiments, except that, as Figure 4 , The upper plate 2 transport structure 3 supporting the battery manner using support rods 22 and the connecting strip 23, the width direction of the plurality of support rods 22 disposed along the conveying plate 2, the connection between two adjacent support bars 22 using bar 23 is connected, at this time, the conveying plate has an annular structure 2 as a whole, 2 the overall movement of the motor 4 driven endless conveyor plate 3 relative to stimulate cell proceeds. The conveying motor 4 is connected between the plate 2 and the frame 1 and the transport connection between the plate 2 may be employed in a conventional manner. In this configuration, the connecting bar 23 requires the use of insulating materials or heat insulating material covering the contact portion 23 on the connector strip and the battery 4.

Embodiment 3

[0044] This embodiment according to the second embodiment substantially the same, except that, as Figure 5 As shown in this example embodiment of the support rod 22 by pairwise connecting structure, each of the two support rods 23 connected by a connecting bar 22, in this embodiment, the connecting bar 23 is disposed below the support rod 22, in which case , the battery on the contact surface portion 23 of the connecting bar 3 must be a thermal insulator, such Image 6 Shown, may be employed on the metal surface of the insulating layer structure of the sleeved. The support rod 22 is connected to the frame 1 may be employed in a conventional manner, such as connection hole 25 provided at both ends of the support rod 22 by a chain 22 connected to all the support rod 41 is provided with the connecting hole 25. Of course, the strength of the support rod 22 is sufficiently large, the connecting bar 23 can be canceled. Alternatively, each support rod 22 is provided individually, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com