A method for controlling the grain size of equiaxed superalloy turbine blades

A technology of turbine blades and superalloys, applied in the field of precision casting, can solve the problems of blade inclusions, low pouring temperature, difficulty in meeting the metallurgical quality requirements of castings, etc., and achieve the effect of sufficient feeding and good mold filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

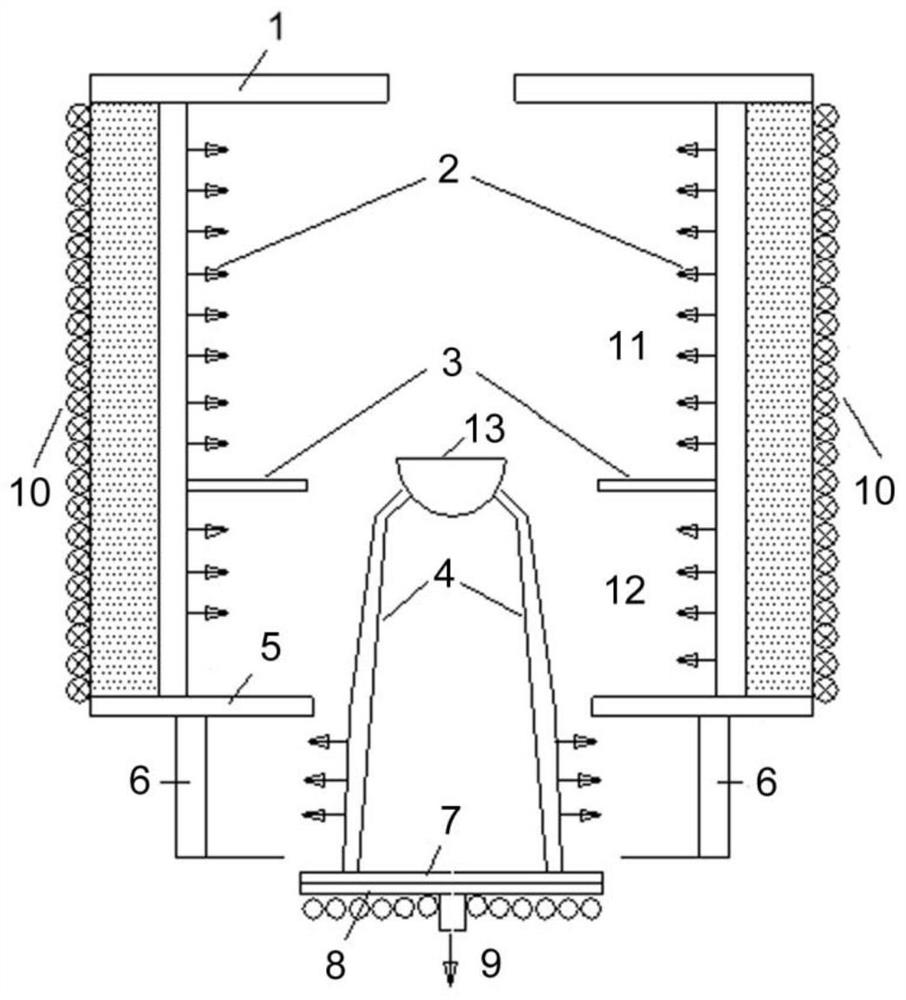

Method used

Image

Examples

Embodiment 1

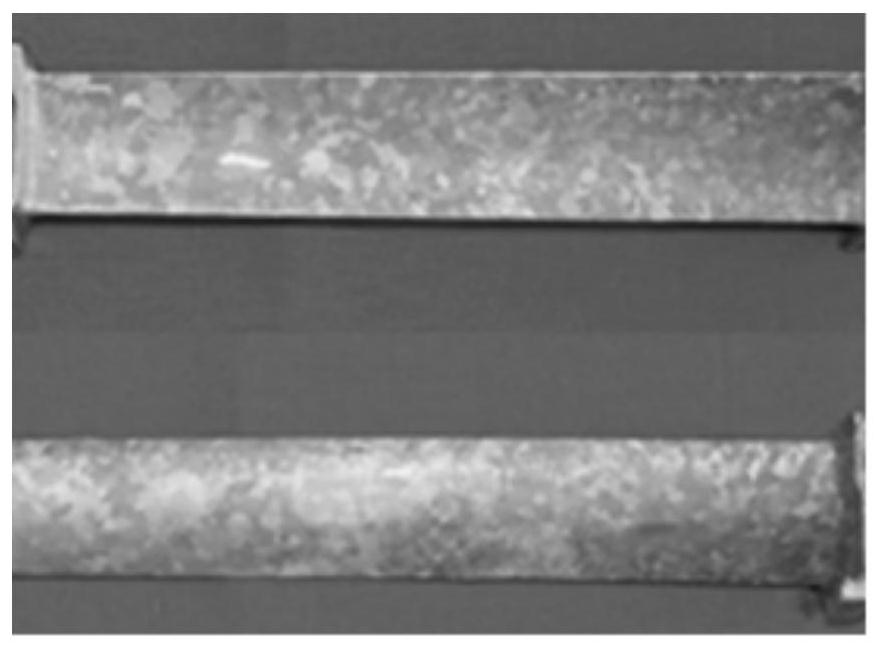

[0038] Development of working blades of a low-pressure three-stage turbine for an engine. The blade is a crowned solid blade with a slender shape and a length of about 250mm. The maximum thickness of the blade body is about 3mm, the thickness of the exhaust edge is about 0.8mm, and the weight of a single blade blank is about 380g. It is made of equiaxed nickel-based superalloy K465 (solid The phase line temperature is 1300°C, the liquidus line temperature is 1340°C), and the grain size is required to be 4-7 on the blade body (according to HB 20057). Chilled crystals and vertical columnar crystals are not allowed. In the initial stage of the test, ordinary casting technology was adopted, 4 pieces / group, thick risers were set at both ends of the blade crown and tenon for feeding, and a tall sprue cup was used to form a sufficient pressure head, and the material used for each furnace was 7Kg . In addition, measures such as heat preservation of the sprue and sprue cup wrapped cer...

Embodiment 2

[0041] Development of working blades of a low-pressure five-stage turbine for an engine. The blade is a crowned solid blade with a slender shape and a length of about 230mm. The maximum thickness of the blade body is about 2mm, the thickness of the exhaust edge is about 0.8mm, and the weight of a single blade blank is about 200g. The phase line temperature is 1281°C, the liquidus line temperature is 1327°C), and the surface grain refinement process is adopted, and the grain size requirement is 1-3. In the initial stage of the test, ordinary casting technology was used, 4 pieces / group, and the material used in each furnace was 7Kg. The proportion of blades scrapped due to excessive grain size such as columnar crystals exceeded 30%, and the blade body was seriously loose (exceeding ASTME1921 / 8" Photo 5).

[0042] Adopt above-mentioned steps of the present invention to prepare this kind of engine low-pressure five-stage turbine working blade, at first simplifies pouring system, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com