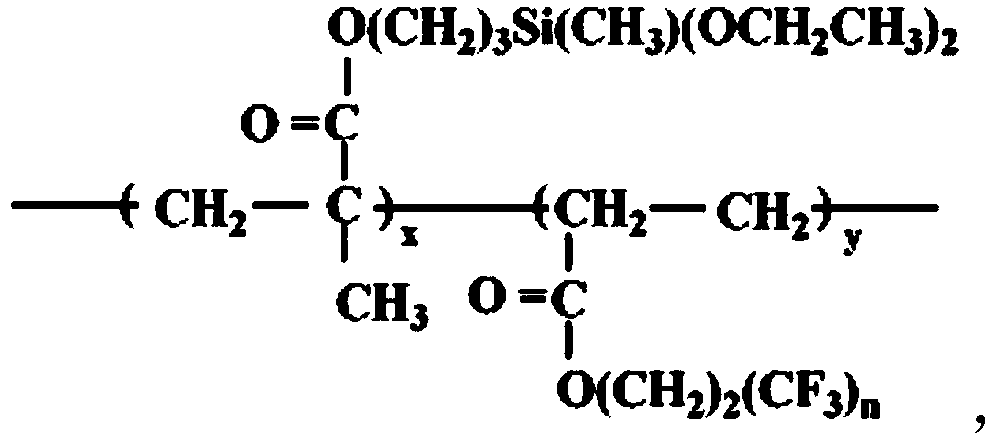

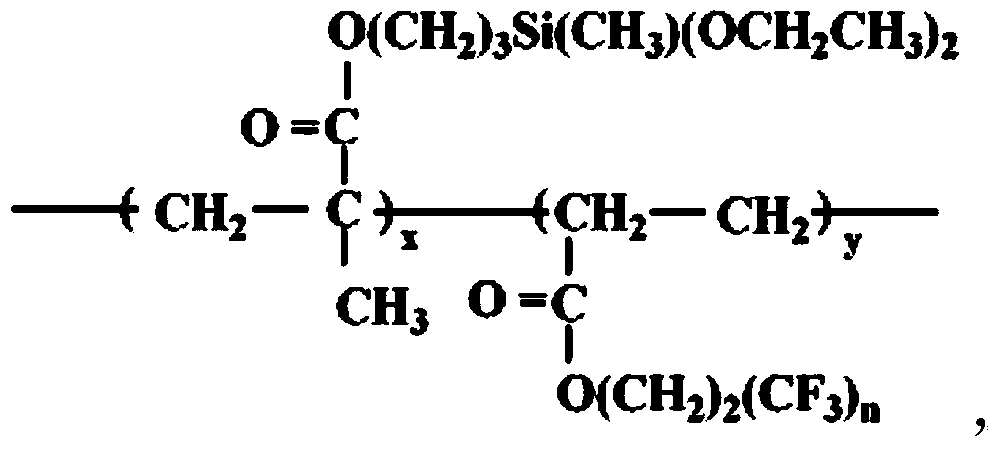

Silicon and fluorine-containing antifouling easy-cleaning agent

A technology of silicon fluoride and detergent, applied in coating and other directions, can solve the problems of high price and complicated production process, and achieve the effects of low price, simple and easy-to-obtain raw materials, and excellent water and oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Dissolve 50g of perfluorooctyl ethyl acrylate and 2g of γ-methacryloxypropylmethyldiethoxysilane in 150ml of 2-butanone, add 0.2g of AIBN, and keep the reaction at 80°C for 4 hours. The solvent of the product after the reaction is completed, and the random silicon-fluorine copolymer A is obtained. Then, add 5000g of FF31 solvent into the silicon-fluorine copolymer A, stir until uniform, and obtain the antifouling and easy-cleaning agent. The anti-fouling and easy-cleaning agent was sprayed on the surface of the glass slide, and after standing at ambient temperature for 8 hours, the water contact angle reached 121.3°, and the hexadecane contact angle reached 82.6°.

Embodiment 2

[0018] Dissolve 50g of perfluorohexyl ethyl acrylate and 1g of γ-methacryloxypropylmethyldiethoxysilane in 150ml of 2-butanone, add 0.3g of AIBN, and incubate at 75°C for 5 hours. The solvent of the finished product is recycled to obtain the random silicon-fluorine copolymer B. Then add 10000g of FF31 solvent to the silicon-fluorine copolymer B, and stir until uniform to obtain the antifouling and easy-cleaning agent. The anti-fouling and easy-cleaning agent was sprayed on the surface of the glass slide, and after standing at ambient temperature for 8 hours, the water contact angle reached 119.6°, and the hexadecane contact angle reached 83.2°.

Embodiment 3

[0020] Dissolve 50g of perfluorobutyl ethyl acrylate and 2g of γ-methacryloxypropylmethyldiethoxysilane in 150ml of 2-butanone, add 0.3g of AIBN, and keep the reaction at 80°C for 4 hours. After the reaction is completed, the solvent is recovered to obtain the random silicon-fluorine copolymer C. Then, add 50000g of FF31 solvent into the silicon-fluorine copolymer C, stir until uniform, and obtain the antifouling and easy-cleaning agent. The anti-fouling and easy-cleaning agent was sprayed on the surface of the glass slide, and after standing at ambient temperature for 8 hours, the water contact angle reached 117.4°, and the hexadecane contact angle reached 81.5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com