Fluo-copolymer/polyacrylate blending emulsion and its production and use

A technology of polyacrylate and acrylic emulsion, which is applied in the direction of coating, etc., and can solve the problem of lack of composite coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The method for preparing the fluorocopolymer / polyacrylate blend emulsion of the present invention generally comprises: mixing the fluorocopolymer aqueous dispersion of about 1-95 parts by weight with the acrylic acid emulsion of about 99-5 parts by weight to obtain a stable Fluorine copolymer / polyacrylate blend emulsion.

[0045] When mixed, the fluorocopolymer may be added in the form of an aqueous dispersion in which the concentration of the fluorocopolymer is usually about 10-60%.

[0046] Mixing can be carried out at normal temperature and pressure, using conventional mixing equipment and methods in the art. Preferred conditions are a temperature of about 20°C and a pressure of about 1 atmosphere.

[0047] When using polymerized monomers to replace polyacrylate emulsions, or to additionally use polymerized monomers in addition to polyacrylate emulsions, usually about 10-95 parts by weight of acrylate mixed monomer emulsions are added or acrylate monomers The body mi...

Embodiment 1

[0058] Preparation of Blend Emulsion 1-3

[0059] Add 5g, 10g or 20g THV 340C (terpolymer of TFE / HFP / VDF, a kind of fluororesin aqueous dispersion purchased from 3M Company) to 100g AC261 pure acrylic emulsion (purchased from Rohm & Hass Company, PA state, USA) liquid with a solid content of 50%, a pH of 9.5, and a density of 1.32 g / cm 3 , with a viscosity of 76mPa·S), and then mixed uniformly to obtain stable fluorocopolymer / polyacrylate blend emulsion 1-3.

Embodiment 2

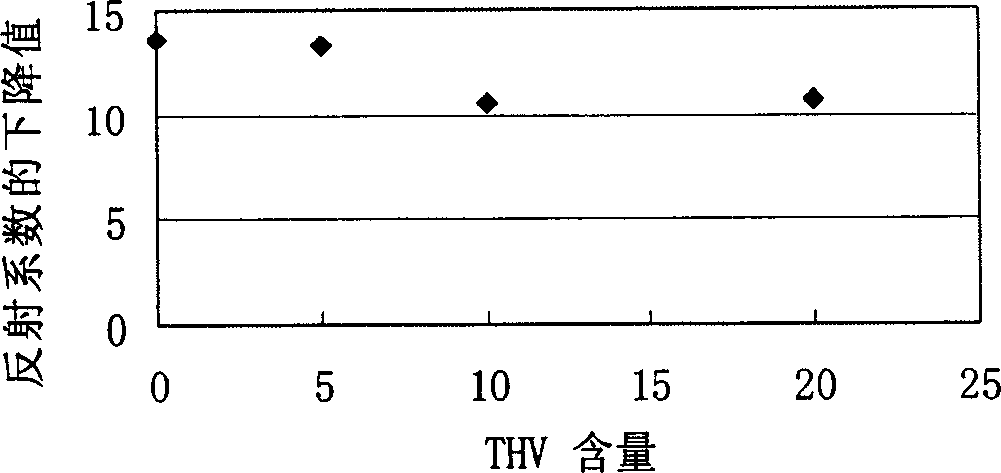

[0061] Determination of water contact angle

[0062] The blended emulsions 1-3 prepared in Example 1 were respectively coated on the glass surface to form a film with a thickness of about 10 μm, and the contact angle of water droplets on the surface was measured. The results are listed in Table 1:

[0063] control

[0064] From the results in Table 1, it can be clearly seen that after adding the fluorocopolymer, the water contact angle of the blended emulsion is significantly increased, thereby greatly improving the stain resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com