Waterborne polyester modified epoxy polyurethane anticorrosive paint and preparation method thereof

A technology of epoxy polyurethane and water-based polyester, applied in the field of coatings, can solve the problems of limited use in the field of anti-corrosion, insufficient anti-corrosion performance, slow curing speed, etc., and achieve the effects of low cost, slow down corrosion reaction, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

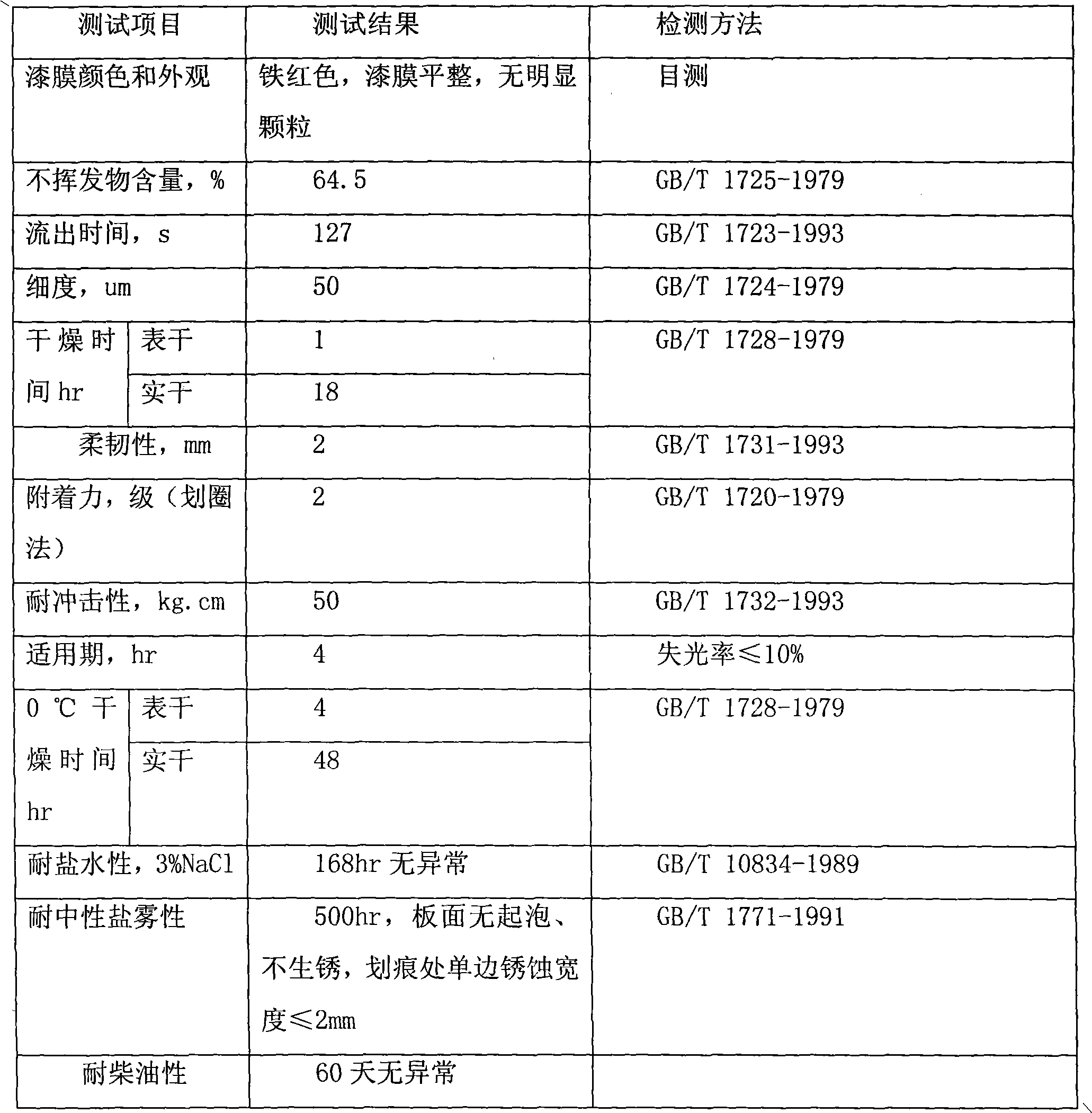

Embodiment 1

[0060] Weigh the following raw materials by weight: 25 water-based polyester modified epoxy resin dispersions; 12 iron oxide red; 10 zinc phosphate; 8 aluminum tripolyphosphate; 5 talcum powder; 5 barium sulfate; dispersant (BYK 190) 2 ; Defoamer (BYK019) 1; Leveling agent (BYK 346) 1; Thickener water-based bentonite 1.0; Drier (containing 1% T-12) 1.0; Anti-flash rust agent (RAYBO 60) 0.5; Cosolvent Propylene Glycol Methyl Ether Acetate 2.0; Deionized Water 20 (prepared according to the following method and packaged separately, namely A component, the same below); curing agent component water-based isocyanate dispersion (ie B component, separately packaged, the same below) .

[0061] Under the stirring condition of 300r / m-500r / m, add the dispersant, co-solvent, thickener, half of the defoamer, and water-based polyester modified epoxy dispersion to half of the deionized water in turn, and stir for 5 minute. Under the stirring condition of 800r / m-1500r / m, add anti-rust pigmen...

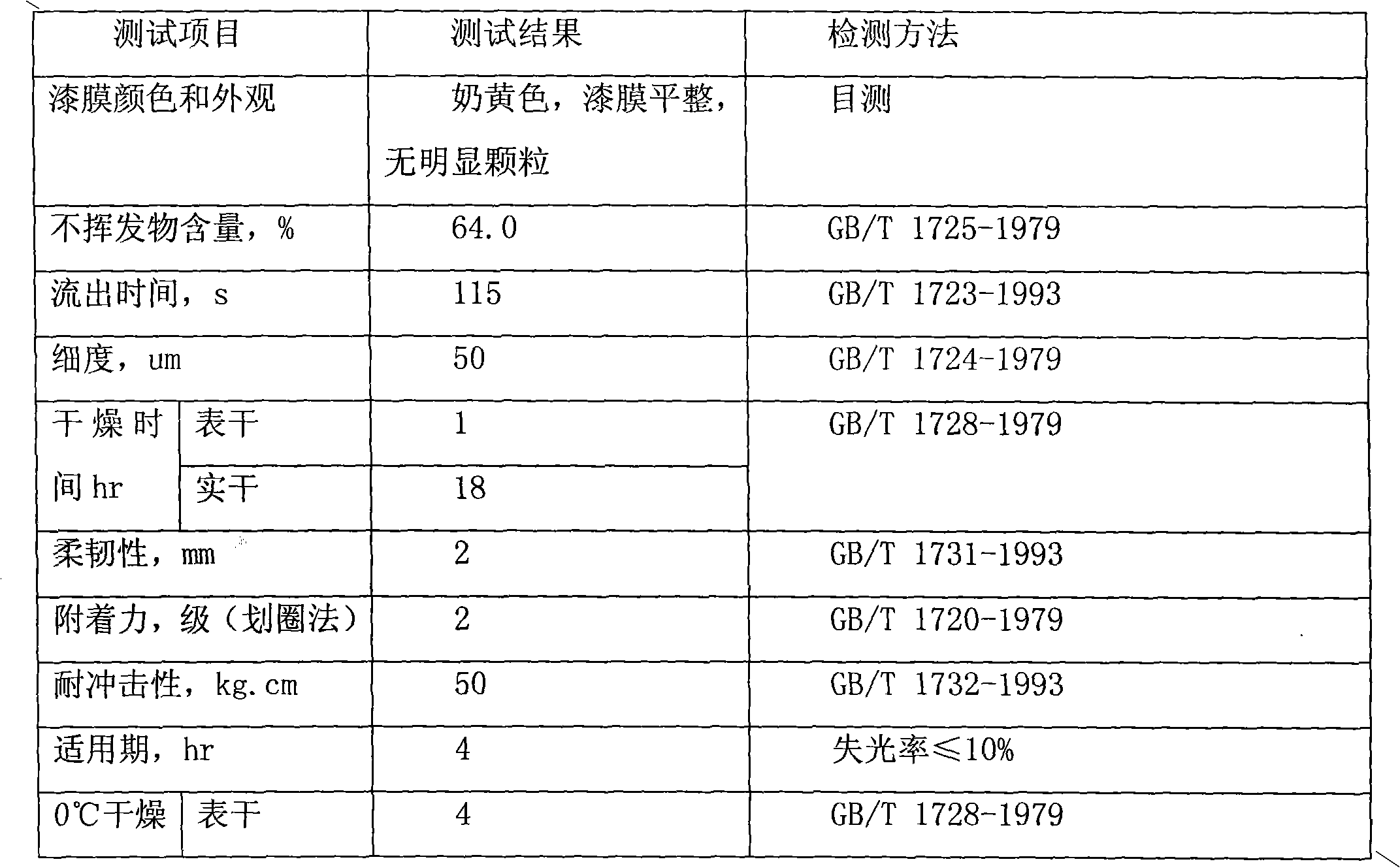

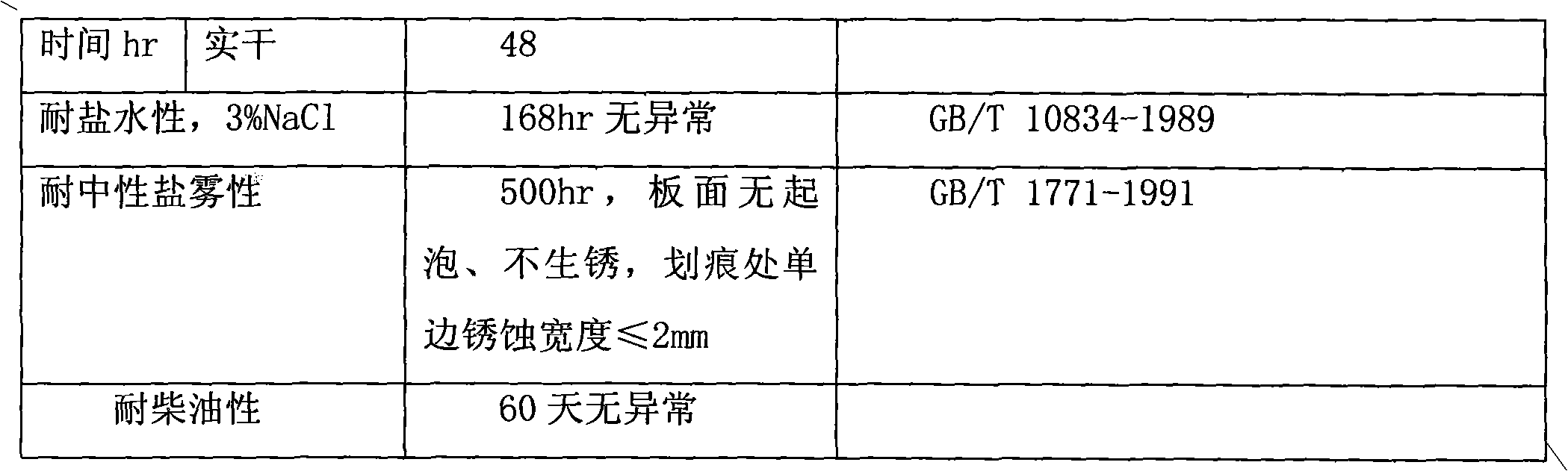

Embodiment 2

[0066] Weigh the following raw materials according to weight ratio: water-based polyester modified epoxy resin dispersion 25; anatase titanium dioxide 12; zinc chrome yellow 8; talcum powder 15; barium sulfate 5; dispersant (BYK 190) 1; defoaming agent (BYK 019) 0.8; leveling agent (BYK 346) 0.8; thickener water-based bentonite 0.8; drier (containing 1% T-12) 1; anti-flash rust agent (RAYBO 60) 0.5; cosolvent propylene glycol methyl Ether acetate 3.5; deionized water 15; curing agent component aqueous isocyanate dispersion.

[0067] Under the stirring condition of 300r / m-500r / m, add the dispersant, co-solvent, thickener, half of the defoamer, and water-based polyester modified epoxy dispersion into 2 / 3 deionized water in turn, and stir 10 minutes. Under the stirring condition of 800r / m-1500r / m, add anti-rust pigment and filler in turn, disperse for 30 minutes and grind until the fineness is below 50 microns. Then, under the stirring condition of 300r / m-500r / m, add leveling a...

Embodiment 3

[0073] Weigh the following raw materials by weight: water-based polyester modified epoxy resin dispersion 30; anatase titanium dioxide 12; zinc phosphate 7; aluminum tripolyphosphate 8; talcum powder 3; barium sulfate 4; dispersant (BYK 190 ) 1.5; defoamer (BYK 019) 0.6; leveling agent BYK 3460.5; thickener water-based bentonite 0.6; drier (containing 1% T-12) 1.5; anti-flash rust agent (RAYBO 60) 0.6; cosolvent Propylene glycol methyl ether acetate 4; deionized water 13; curing agent component aqueous isocyanate dispersion.

[0074] Under the stirring condition of 300r / m-500r / m, sequentially add the dispersant, co-solvent, thickener, half of the defoamer and water-based polyester modified epoxy dispersion into the deionized water, and stir for 20 minutes. Under the stirring condition of 800r / m-1500r / m, add anti-rust pigment and filler in turn, disperse for 40 minutes and grind until the fineness is below 50 microns. Then, under the stirring condition of 300r / m-500r / m, add le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com