Anti-aging, waterproof and oil-rub-resistant leather surface treating agent and preparation method thereof

A surface treatment agent and anti-oil technology, which is applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve the impact of leather products, influence Appearance aesthetics, use effect and service life, no anti-ultraviolet and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

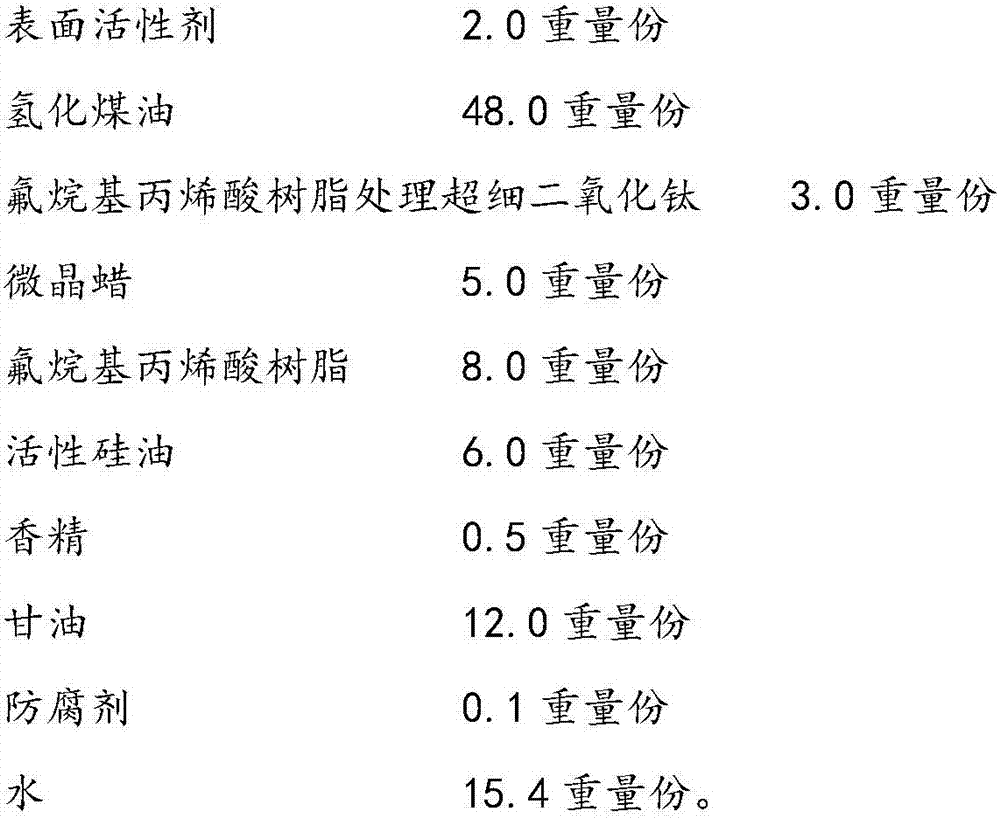

Examples

Embodiment Construction

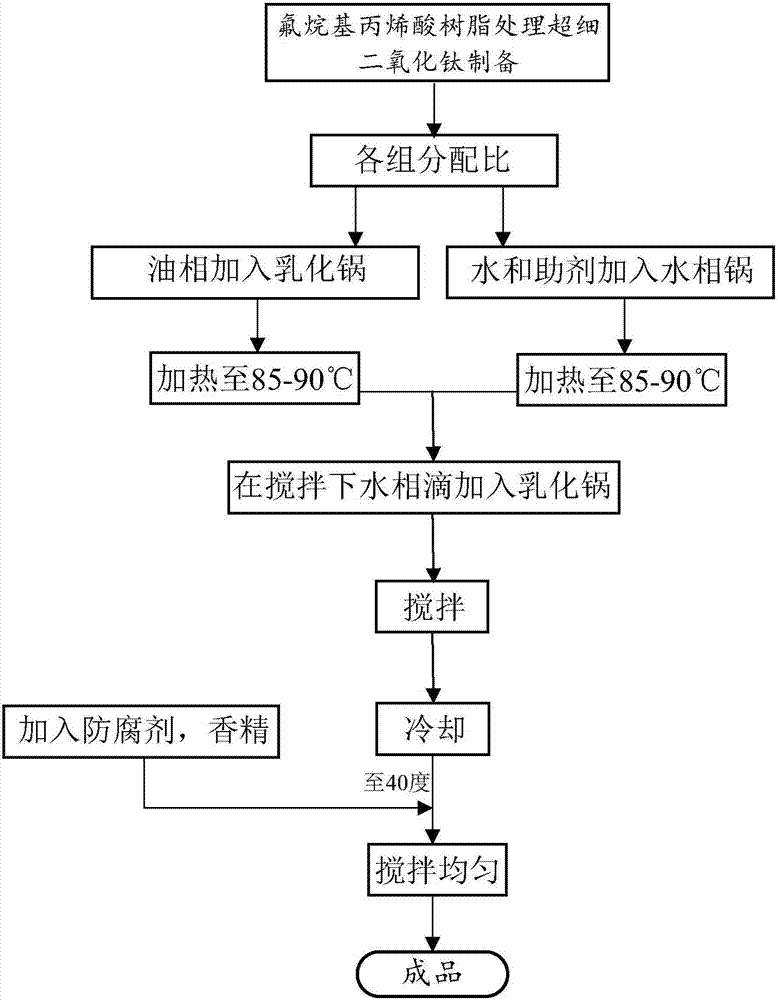

[0036] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

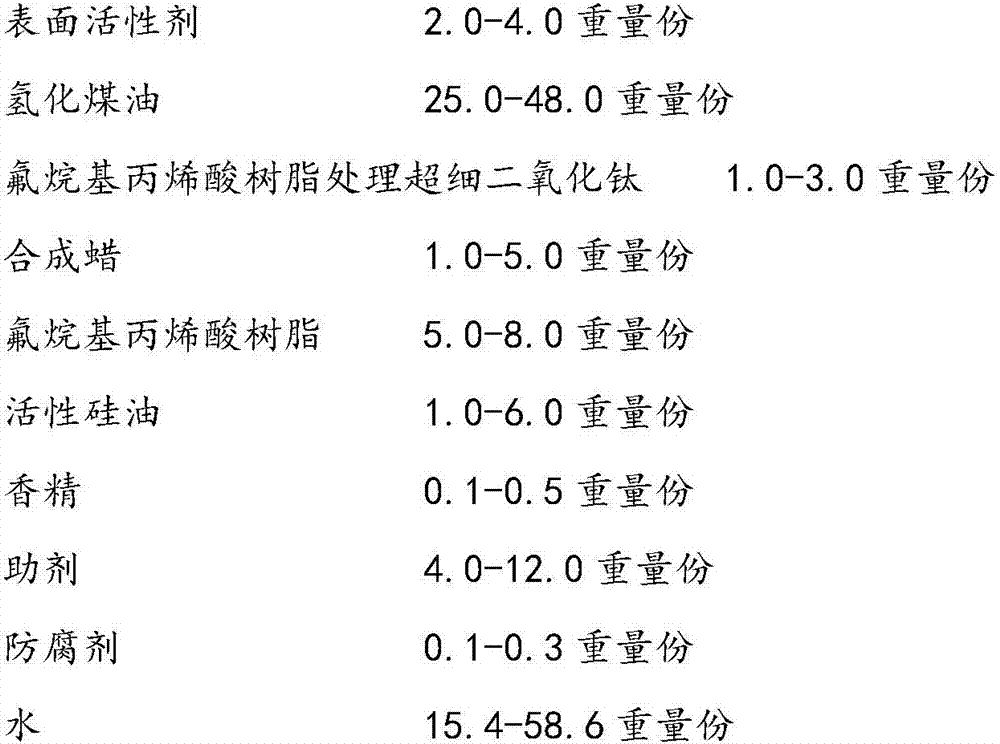

[0037] An anti-aging, water-resistant and oil-resistant leather surface treatment agent, the parts by weight of each component are as follows:

[0038]

[0039] Wherein the surfactant is a water-in-oil emulsifier;

[0040] The fluoroalkyl acrylic resin treated ultrafine titanium dioxide is prepared by the following method:

[0041] Select rutile-type titanium dioxide coated with alumina and silicon oxide as the initial raw material, and use a supersonic airflow mill to depolymerize the powder of the titanium dioxide in a high-speed airflow. 2-5% of the weight of titanium dioxide is atomized with fluoroalkyl acrylic resin, and it is impacted and mixed under high-speed airflow, so that the powder particles of the highly dispersed titanium dioxide are coated with atomized fluoroalkyl acrylic resin, thereby The ultrafine titanium dioxide treated with fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com