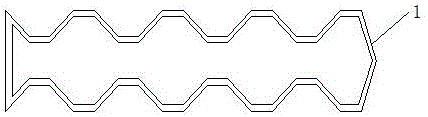

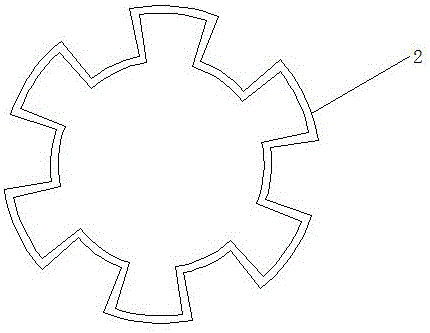

Trapezoidal efficient dust-removal inorganic film and manufacturing method thereof

An inorganic membrane and high-efficiency technology, which is applied in the field of dust removal inorganic membranes, can solve problems such as not being able to meet high-temperature discharge requirements, and achieve the effects of low manufacturing difficulty, high dust removal efficiency, and low surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Further, the present invention also provides a preparation method of the trapezoidal high-efficiency dust-removing inorganic membrane, the preparation method comprising the following steps:

[0023] (1) In terms of mass percentage, mix 50-85% of silicon carbide, 5-30% of alumina, 5-30% of kaolin, 2-20% of zirconia and 0.5-3% of cellulose, and grind to the particle size 10-40μm, to obtain mixed powder;

[0024] (2) Fully mix the above mixed powder with water accounting for 5-15% of the mass of the mixed powder to obtain a slurry;

[0025] (3) Coat the above-mentioned slurry on a trapezoidal mold, adopt isostatic pressing molding or plastic pressing molding, press molding, and after drying, fire at 1450-1550°C; wherein, the specific conditions for molding are: Pressure 1450~1650kgf / cm 2 , temperature 1000 ~ 1200 ℃, holding time 15 ~ 20min.

[0026] Wherein, in the preparation method of the above-mentioned trapezoidal high-efficiency dust-removing inorganic membrane, th...

Embodiment 1

[0030] The trapezoidal high-efficiency dust removal inorganic membrane is prepared according to the following steps:

[0031] (1) In terms of mass percentage, mix 55% silicon carbide (its particle size is 40μm, purity 97%), α-alumina 25%, kaolin 8%, zirconia 16% and cellulose 0.05%, mix well, Grinding to a particle size of 30 μm to obtain a mixed powder;

[0032] (2) Fully mix the above mixed powder with water accounting for 15% of the mass of the mixed powder to obtain a slurry;

[0033] (3) Coat the above slurry on a trapezoidal mold, use isostatic pressing to form, and after drying, repeat sintering at 1450°C for 3 times, each sintering for 12 hours; among them, the specific conditions for isostatic pressing For: pressure 1550kgf / cm 2 , temperature 1050 ° C, holding time 18min.

Embodiment 2

[0035] The trapezoidal high-efficiency dust removal inorganic membrane is prepared according to the following steps:

[0036] (1) In terms of mass percentage, mix 80% silicon carbide (its particle size is 60μm, purity 99%), α-alumina 10%, kaolin 25%, zirconia 8% and lignocellulose 0.1%, mix well , and grind to a particle size of 50 μm to obtain a mixed powder;

[0037] (2) Mix the above mixed powder with water accounting for 12% of the mass of the mixed powder under high-speed stirring conditions to obtain a slurry;

[0038] (3) Coat the above-mentioned slurry on the trapezoidal mold, adopt the method of plastic compression molding, press molding, after drying, repeat sintering at 1500°C for 3 times, and sinter for 12 hours each time, and fire it; among them, plastic compression molding The specific conditions are: pressure 1600kgf / cm 2 , the temperature is 1200°C, and the holding time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com