Method for producing hollow short fibre by regenerating polyester

A technology of recycled polyester and staple fibers, applied in fiber processing, hollow filament manufacturing, fiber chemical characteristics, etc., can solve the problems of recycled polyester waste with many impurities, unable to spin high-grade staple fibers, etc. The effect of reducing production cost and increasing filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

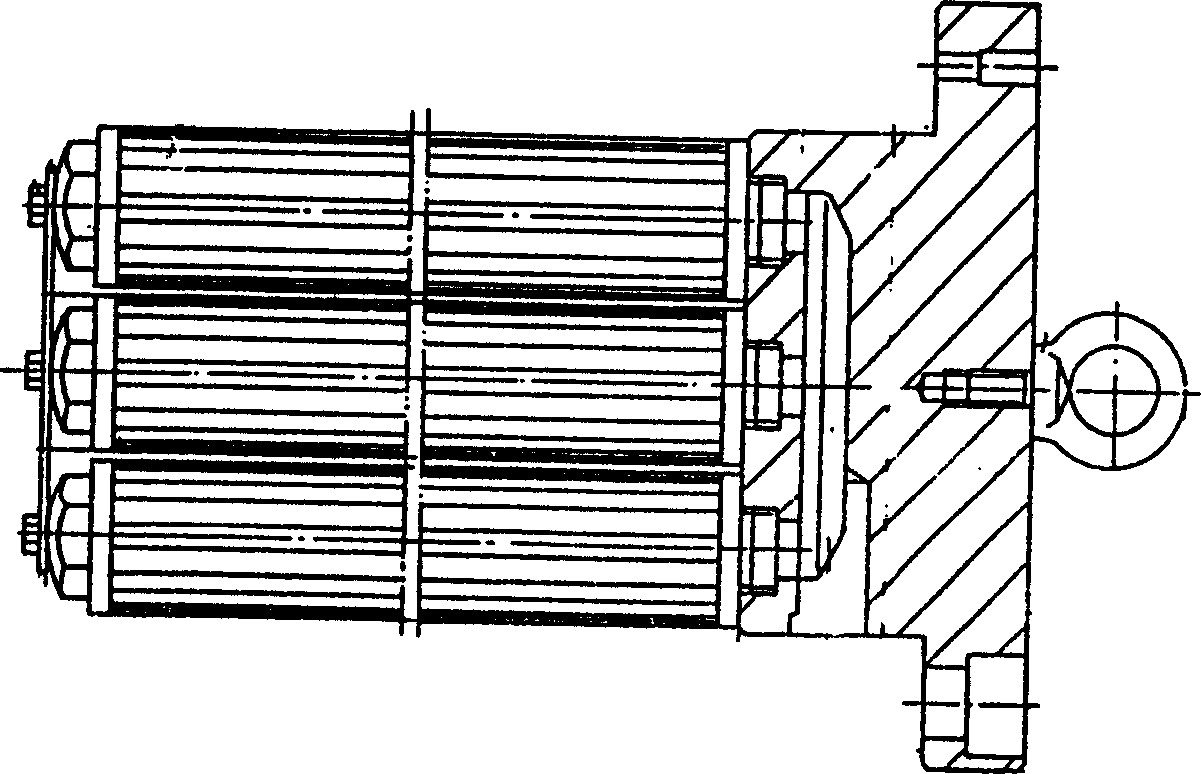

[0010] In the embodiment of the present invention, polyester (PET) waste and polyester scraps are first prepared through a series of raw material preparations such as selection, cleaning, and crushing, and then dried in a high-temperature vacuum. The drying temperature is 130--145°C. The temperature is 0.085-0.096Mpa, and the drying time is 8-10h. The polyester waste after high-temperature drying is melted at high temperature, and extruded by a screw, and then the extruded melt is passed through a special pre-filter. To filter impurities in polyester waste, the filter consists of 19 filter elements arranged side by side in a filter cartridge with a volume of 0.0708m2. The filter area of the filter cartridge is increased from the conventional 0.92m2 to 9.5m2, and the pre-filtration accuracy is also high. From the original 200 microns to less than 60 microns, the difference from the existing technology is that it is a super-large volume pre-filter. It is generally believed that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com