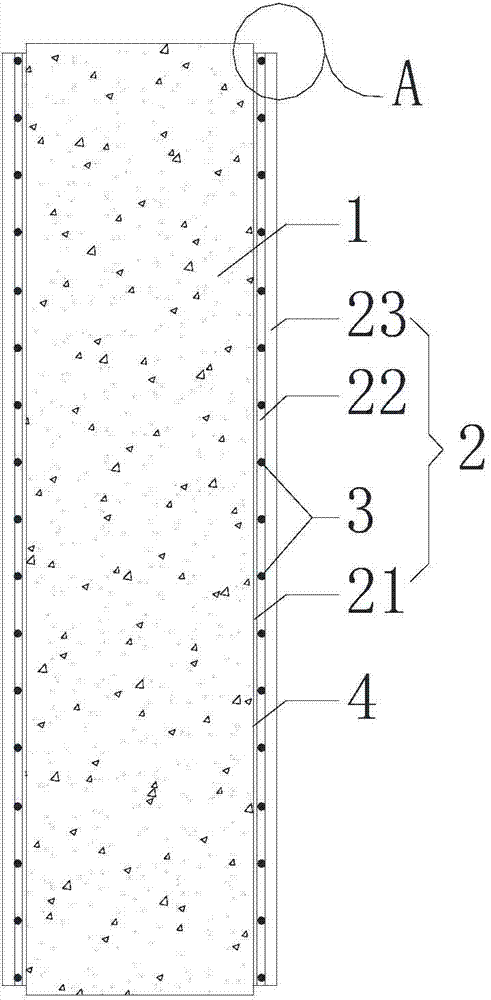

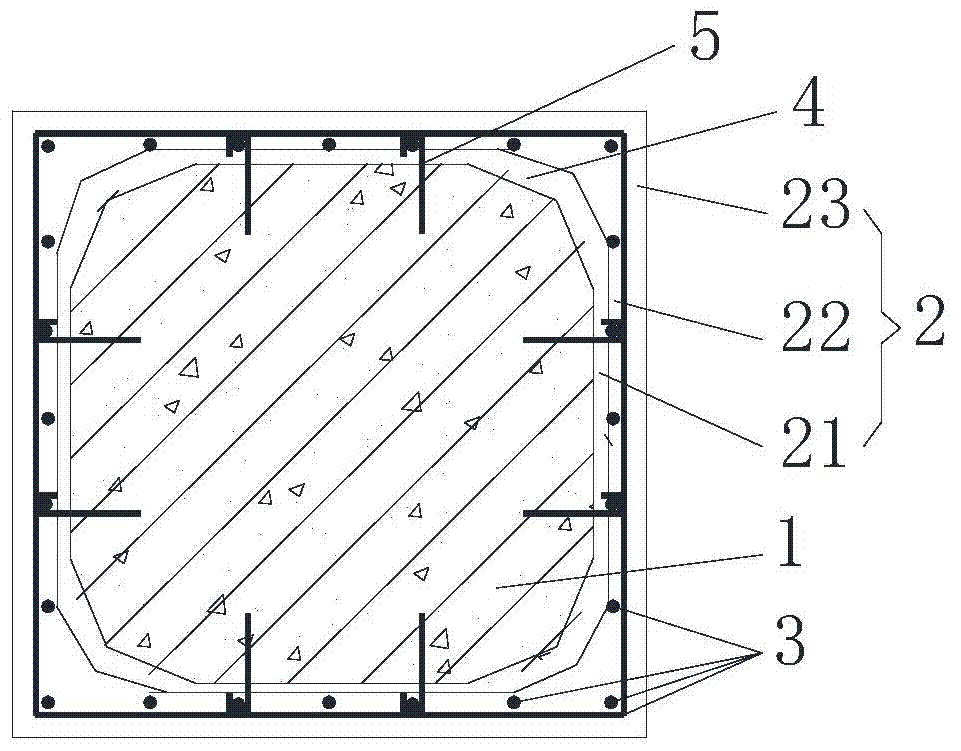

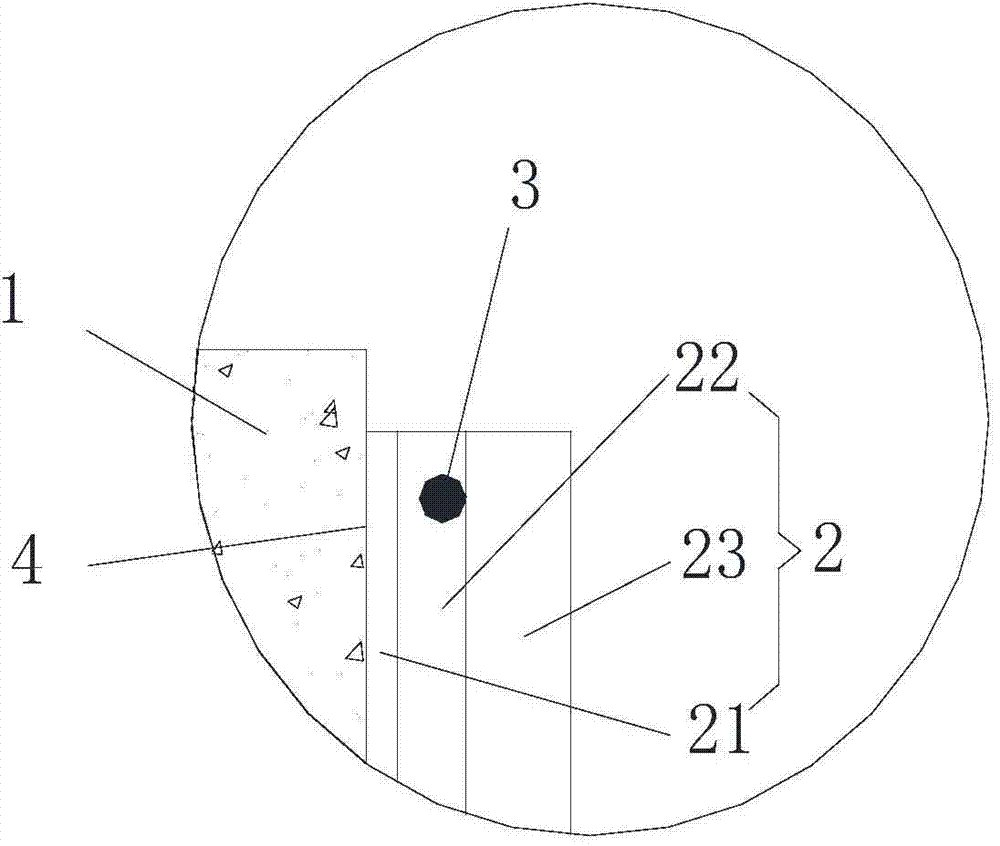

Reactive powder fiber concrete reinforced concrete column and reinforcement method

A technology of fiber concrete and active powder, which is applied in building maintenance, construction, building construction, etc. It can solve the problems of reinforcement cost, unsatisfactory construction efficiency, insufficient bearing capacity of concrete column members, and limited increase in bearing capacity, etc. problems, to achieve the effect of high reinforcement efficiency, light weight and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The original five-story frame structure office building of a certain unit, with a total construction area of 4200m2 2 , the foundation adopts an independent foundation under the column, the foundation depth is 2.2m, and the design strength grade of the concrete beam and column components of each floor is C35. . After the reinforcement calculation, it is determined that the concrete columns of each layer need to be reinforced.

[0031] Adopting the reinforcement method of the present invention to reinforce the above-mentioned concrete column can obtain the active powder fiber concrete reinforced concrete column, and the reinforcement method specifically includes the following steps:

[0032](1) Surface treatment of column components: First, clean the surface of the original concrete column to be strengthened, remove the plaster layer on the surface of the original concrete column component to be strengthened, and clean the degraded concrete such as spalling, looseness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com