Manufacturing method of phenol and acetone

A manufacturing method and technology of acetone, applied in chemical instruments and methods, preparation of organic compounds, preparation of peroxygen compounds, etc., can solve the problems of demanding reaction equipment, increasing the yield of by-products, high reaction pressure, etc., and meet the reaction conditions Not harsh, lower production cost, lower surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

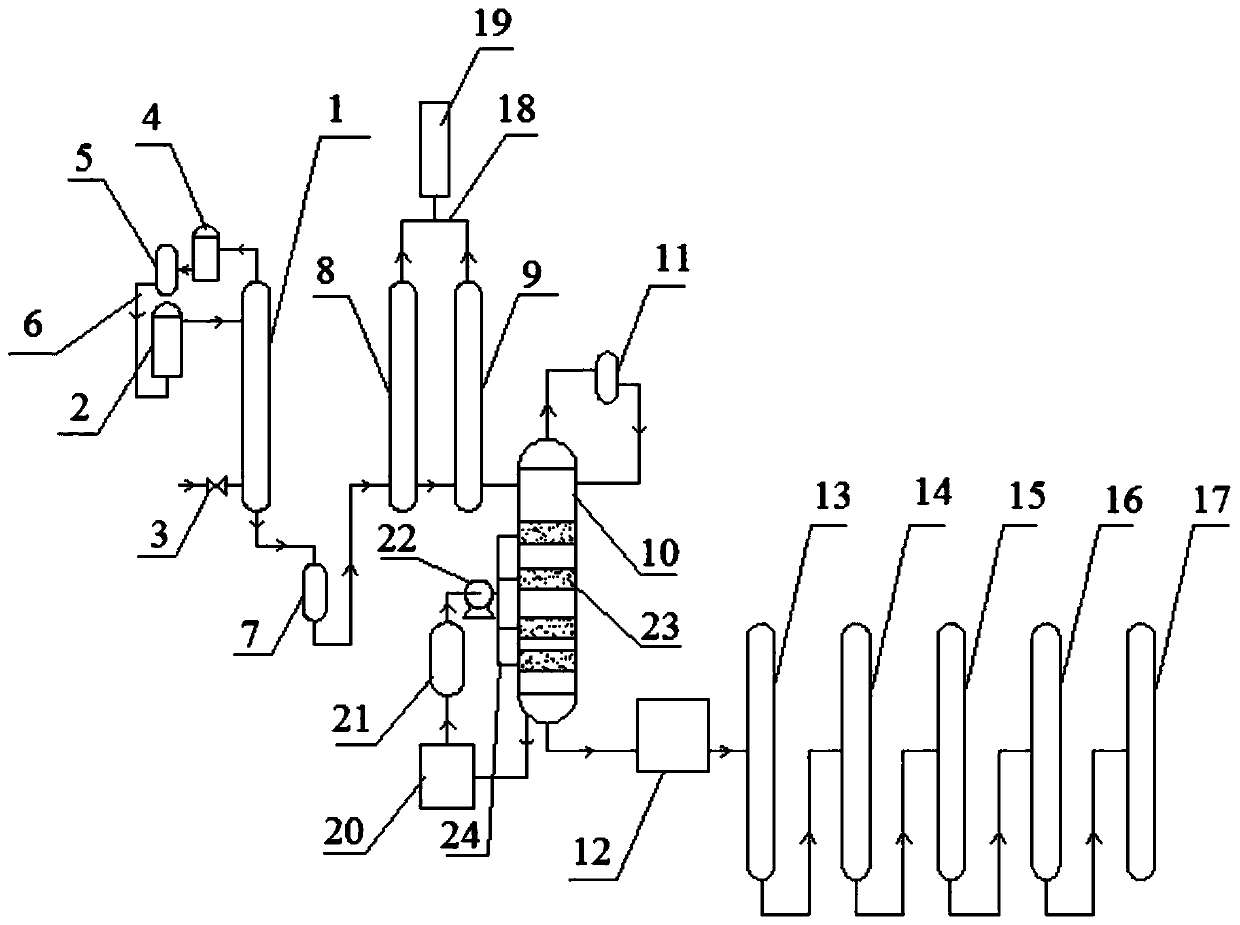

[0029] refer to figure 1 As shown, the present embodiment provides a kind of manufacture method of phenol and acetone, comprises the following steps:

[0030] S1. Oxidation of cumene: The air pressurized to 0.42MPa is passed through the pressure reducing valve 3 to the bottom of the oxidation tower 1, and the cumene with a pH value of 9.5 prepared by alkali, among the raw materials of cumene, ethylbenzene The content of butylbenzene is less than 0.03%, the content of butylbenzene is less than 0.01%, the content of phenol is less than 3ppm, the content of total sulfur is less than 2ppm, and the content of oxygen is less than 4ppm.

[0031] The cumene is discharged from the liquid storage tank 2, enters into the countercurrent contact with the air through the top of the oxidation tower 1, and reacts at 115°C; during the reaction process of the oxidation tower 1, a gas mixture containing a small amount of oxygen is discharged from the top, and passes through the first condenser 4 ...

Embodiment 2

[0039] refer to figure 1 As shown, the present embodiment provides a kind of manufacture method of phenol and acetone, comprises the following steps:

[0040] S1. Oxidation of cumene: The air pressurized to 0.45MPa is passed through the pressure reducing valve 3 to the bottom of the oxidation tower 1, and the cumene with a pH value of 9.5 prepared by alkali, among the raw materials of cumene, ethylbenzene The content of butylbenzene is less than 0.03%, the content of butylbenzene is less than 0.01%, the content of phenol is less than 3ppm, the content of total sulfur is less than 2ppm, and the content of oxygen is less than 4ppm.

[0041] The cumene is discharged from the liquid storage tank 2, enters into the countercurrent contact with the air through the top of the oxidation tower 1, and reacts at 110°C; during the reaction process of the oxidation tower 1, a gas mixture containing a small amount of oxygen is discharged from the top, and passes through the first condenser 4...

Embodiment 3

[0049] refer to figure 1 As shown, the present embodiment provides a kind of manufacture method of phenol and acetone, comprises the following steps:

[0050] S1. Oxidation of cumene: The air pressurized to 0.5MPa is passed through the pressure reducing valve 3 to the bottom of the oxidation tower 1, and the cumene with a pH value of 10 prepared by alkali, among the raw materials of cumene, ethylbenzene The content of butylbenzene is less than 0.03%, the content of butylbenzene is less than 0.01%, the content of phenol is less than 3ppm, the content of total sulfur is less than 2ppm, and the content of oxygen is less than 4ppm.

[0051] The cumene is discharged from the liquid storage tank 2, enters into the countercurrent contact with the air through the top of the oxidation tower 1, and reacts at 120°C; during the reaction process of the oxidation tower 1, a gas mixture containing a small amount of oxygen is discharged from the top, and passes through the first condenser 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com