Patents

Literature

107results about How to "The reaction conditions are not harsh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-silver antibacterial composite decorated by modified chitosan, preparing method and application

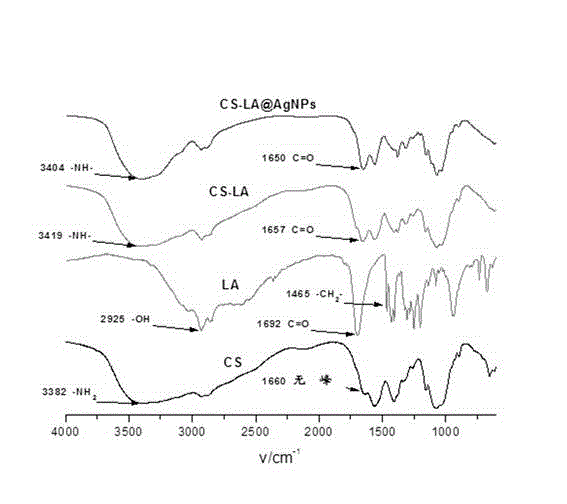

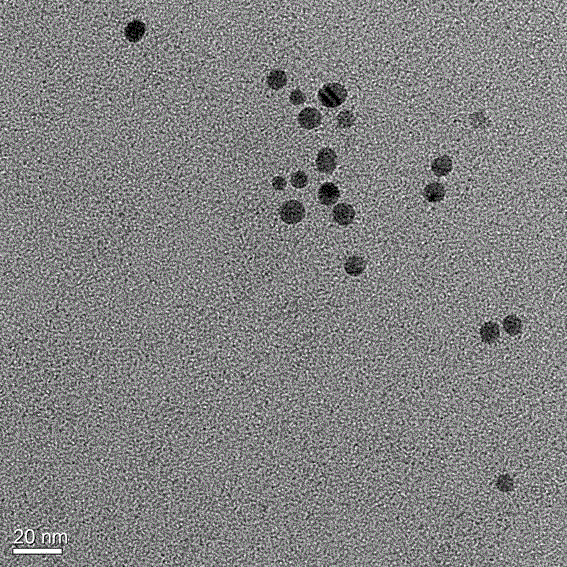

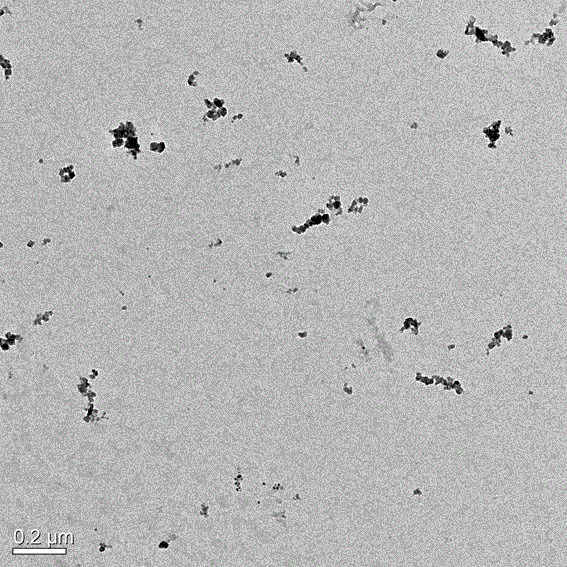

ActiveCN104128602AWide variety of sourcesLow priceMaterial nanotechnologyAntimicrobial actionCovalent modification

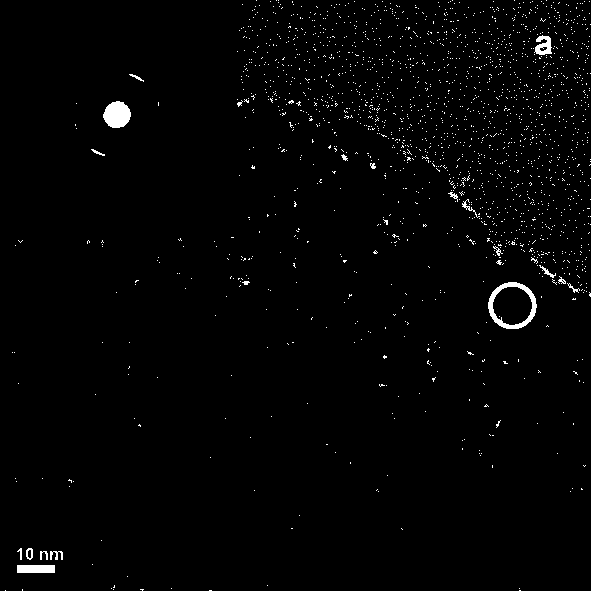

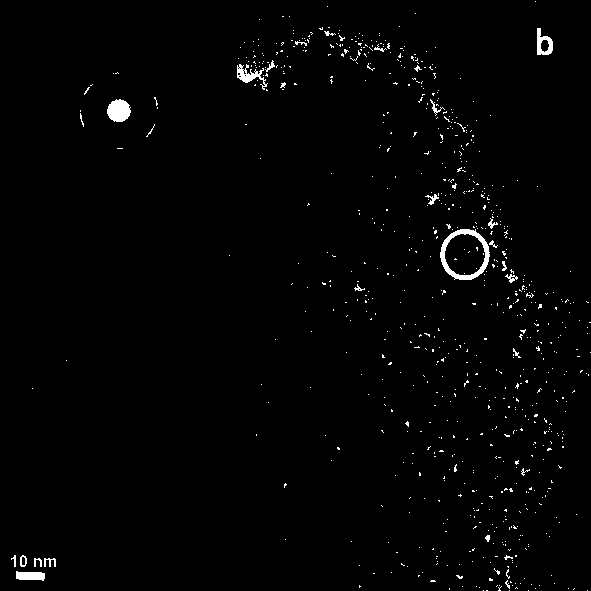

The invention discloses a nano-silver antibacterial composite modified by modified chitosan and a preparing method of the nano-silver antibacterial composite. According to the nano-silver antibacterial composite and the preparing method of the nano-silver antibacterial composite, the chitosan with the small molecule quantiy and good water solubility is selected and used as a raw material, chemical modification is conducted on the chitosan by using small molecules which are capable of having chelation with nano-silver particles, the modified chitosan is arranged on the surfaces of the nano-silver particles in a covalent modification mode, and the novel nano-silver antibacterial composite is prepared. The prepared nano-silver antibacterial composite modified by the modified chitosan has good water solubility and dispersibility and can be stably dispersed in a water solution in a long term without aggregation under the conditions of high salinity and wide pH. The prepared nano-silver antibacterial composite modified by the modified chitosan enables the antibacterial property of the chitosan and the antibacterial property of nano-silver to be in effective synergy, the antibacterial performance is good, and the nano-silver antibacterial composite can serve as a water coating agent to perform the surface antibacterial function on the surfaces of materials and can also permeate into fiber type materials to perform the deep internal antibacterial function.

Owner:SICHUAN UNIV

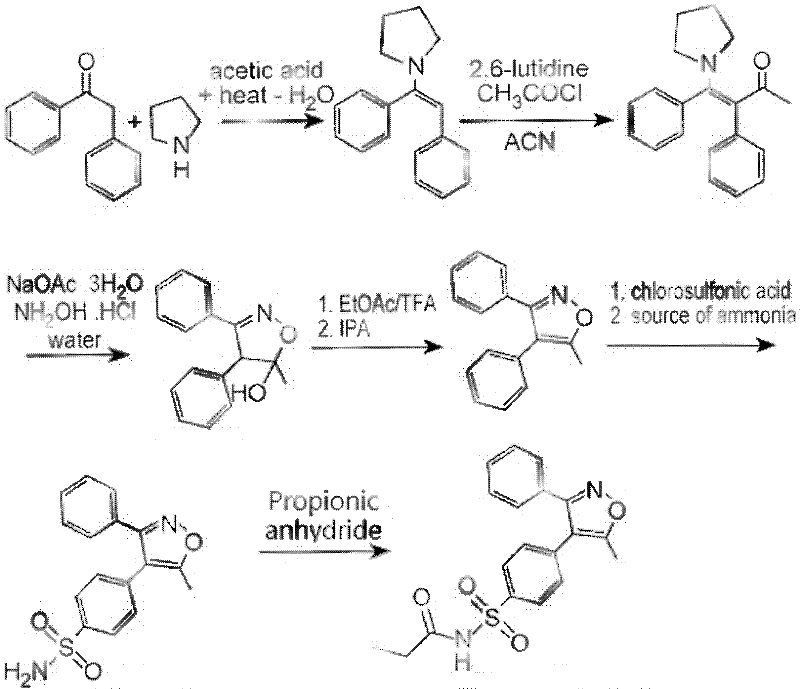

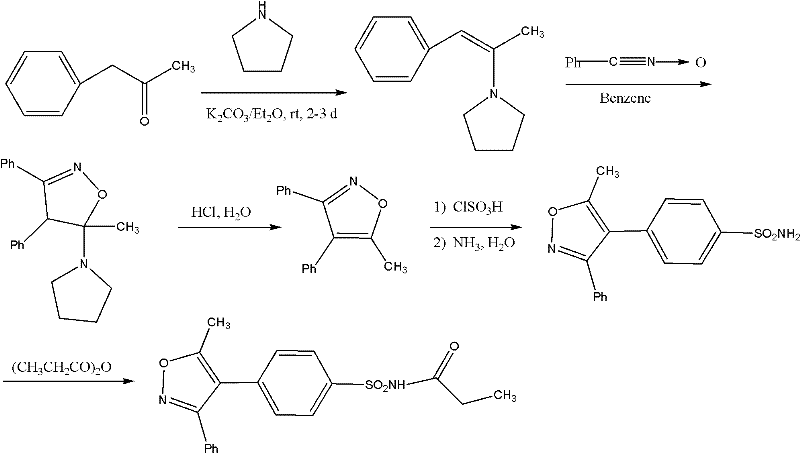

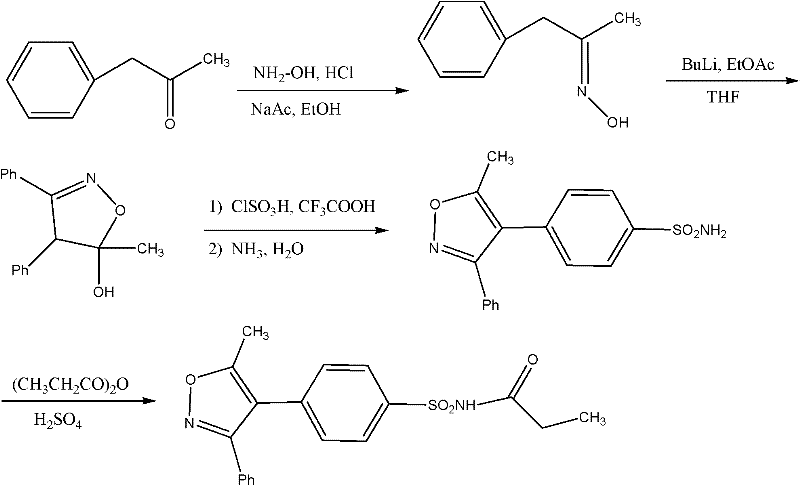

Method for preparing Parecoxib

InactiveCN102329277AThe reaction conditions are not harshRaw materials are easy to getOrganic chemistryPropionic anhydrideButanone

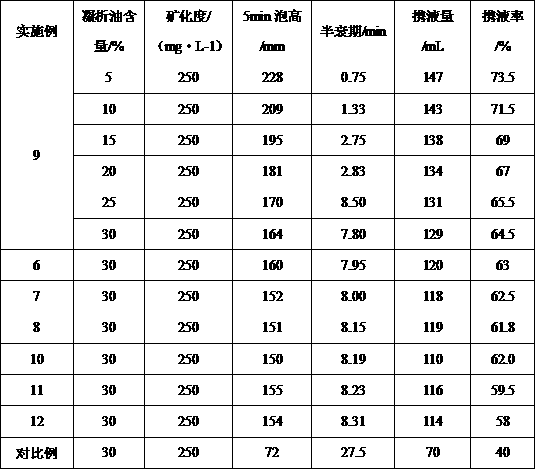

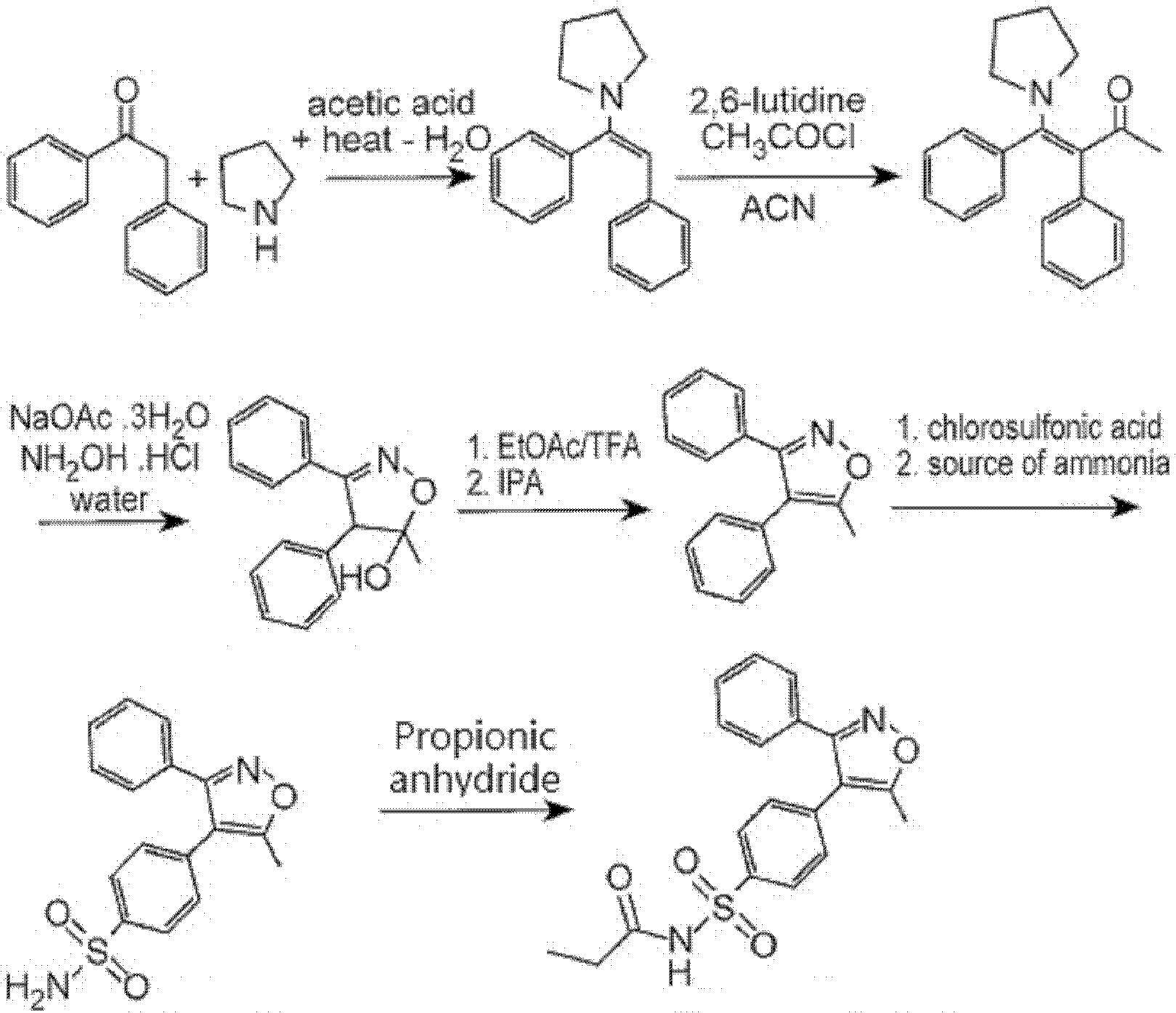

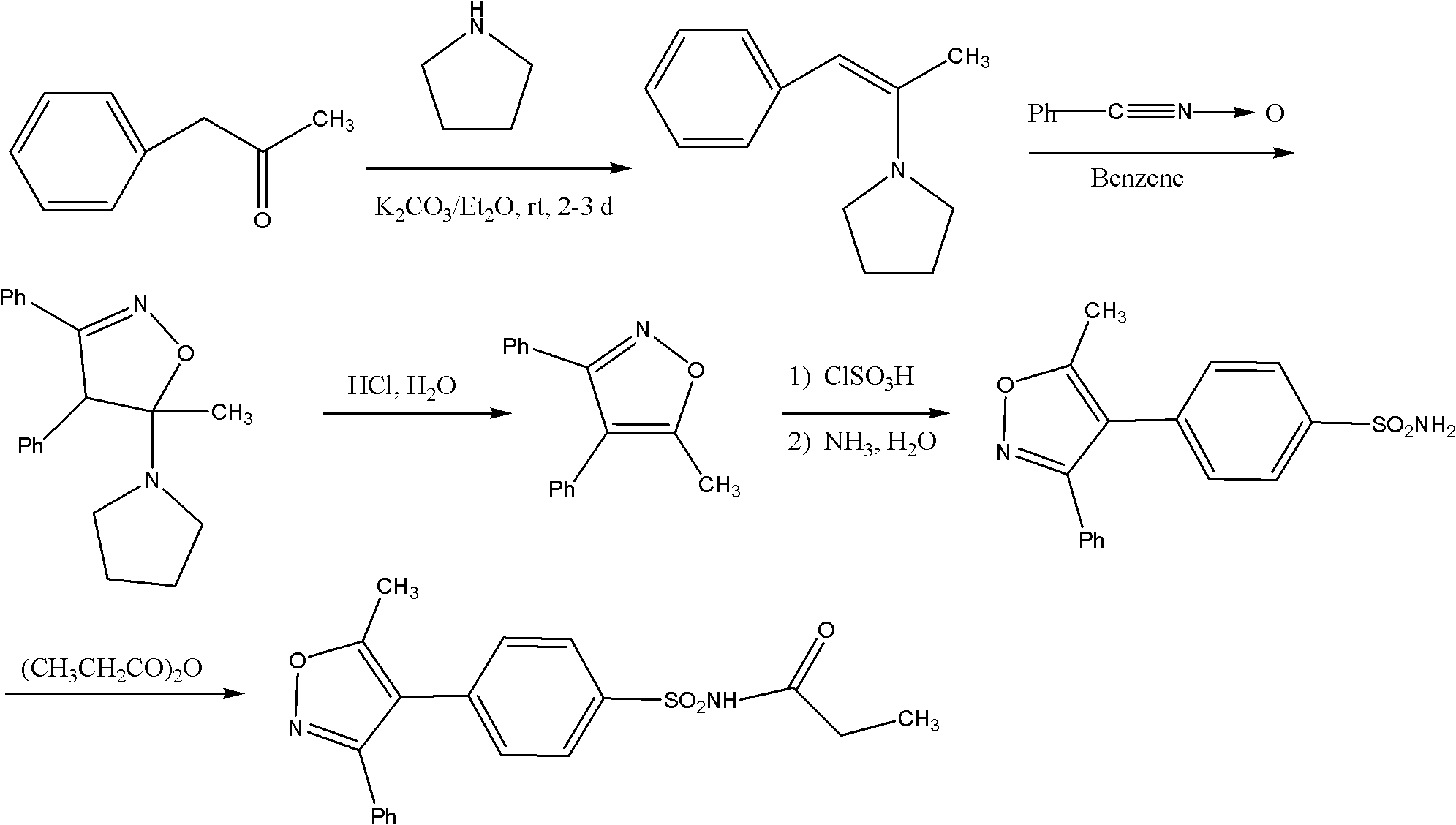

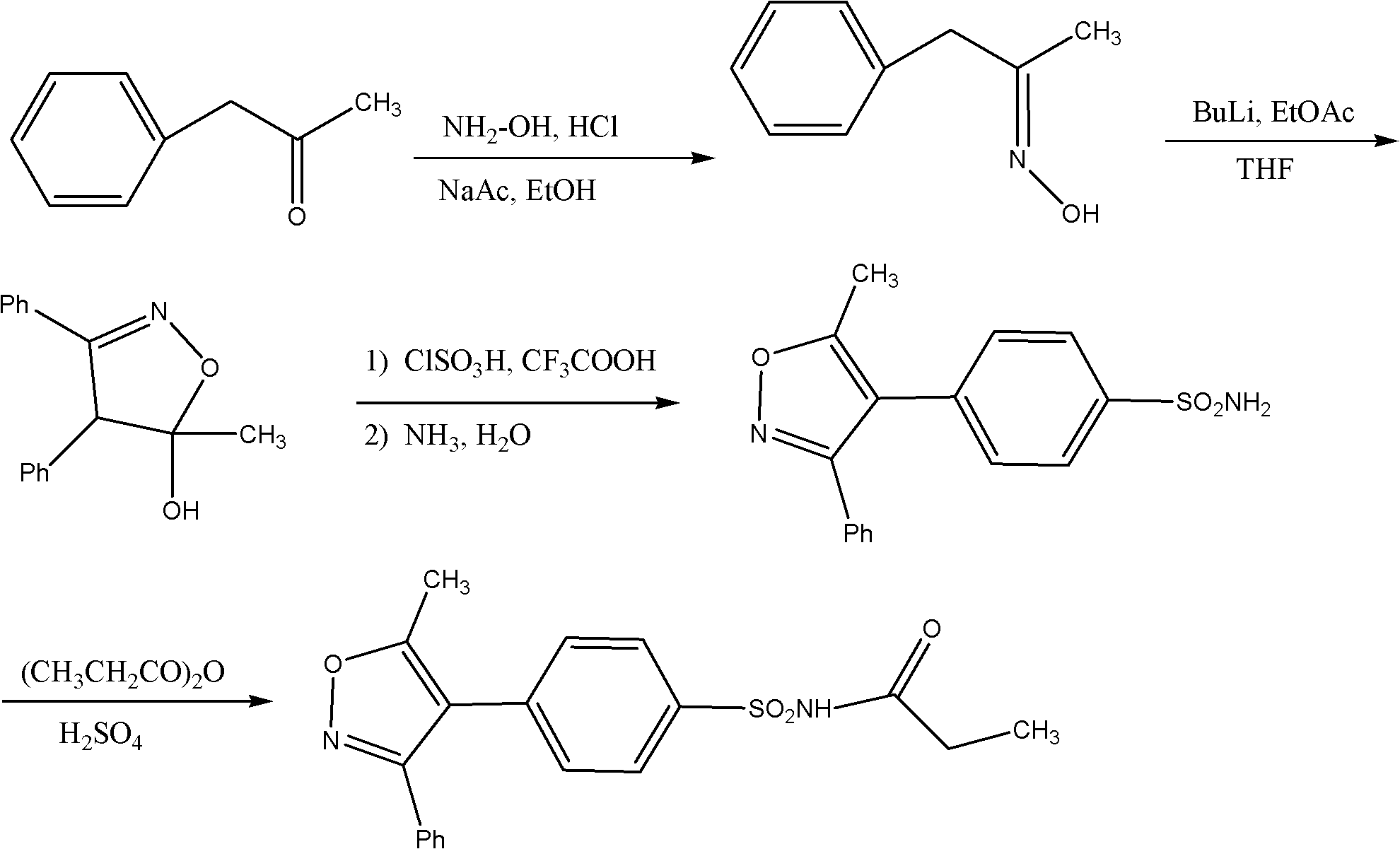

The invention discloses a method for preparing Parecoxib. The method for preparing the Parecoxib comprises the following steps of: performing sulfonation reaction on 1,2-diphenyl butanone serving as a raw material to obtain 1-phenyl-2-(4-sulfo phenyl)butanone; in the presence of alkali, performing condensation on the 1-phenyl-2-(4-sulfo phenyl)butanone and acetylchloride to prepare 1-phenyl-2-(4-sulfo phenyl)-2-acetyl butanone; performing cyclization on the 1-phenyl-2-(4-sulfo phenyl)-2-acetyl butanone and hydroxylamine hydrochloride to obtain 4-(5-methyl-3-phenyl-4-isoxazole)benzenesulfonic acid; performing chlorination and ammonolysis reaction to prepare Bextra; and reacting the Bextra with propionic anhydride to synthesize the Parecoxib. In the method, the raw materials are readily available and reaction conditions are not rigorous. The method is easy and convenient to operate and has certain industrialized value.

Owner:海南霞迪药业有限公司 +1

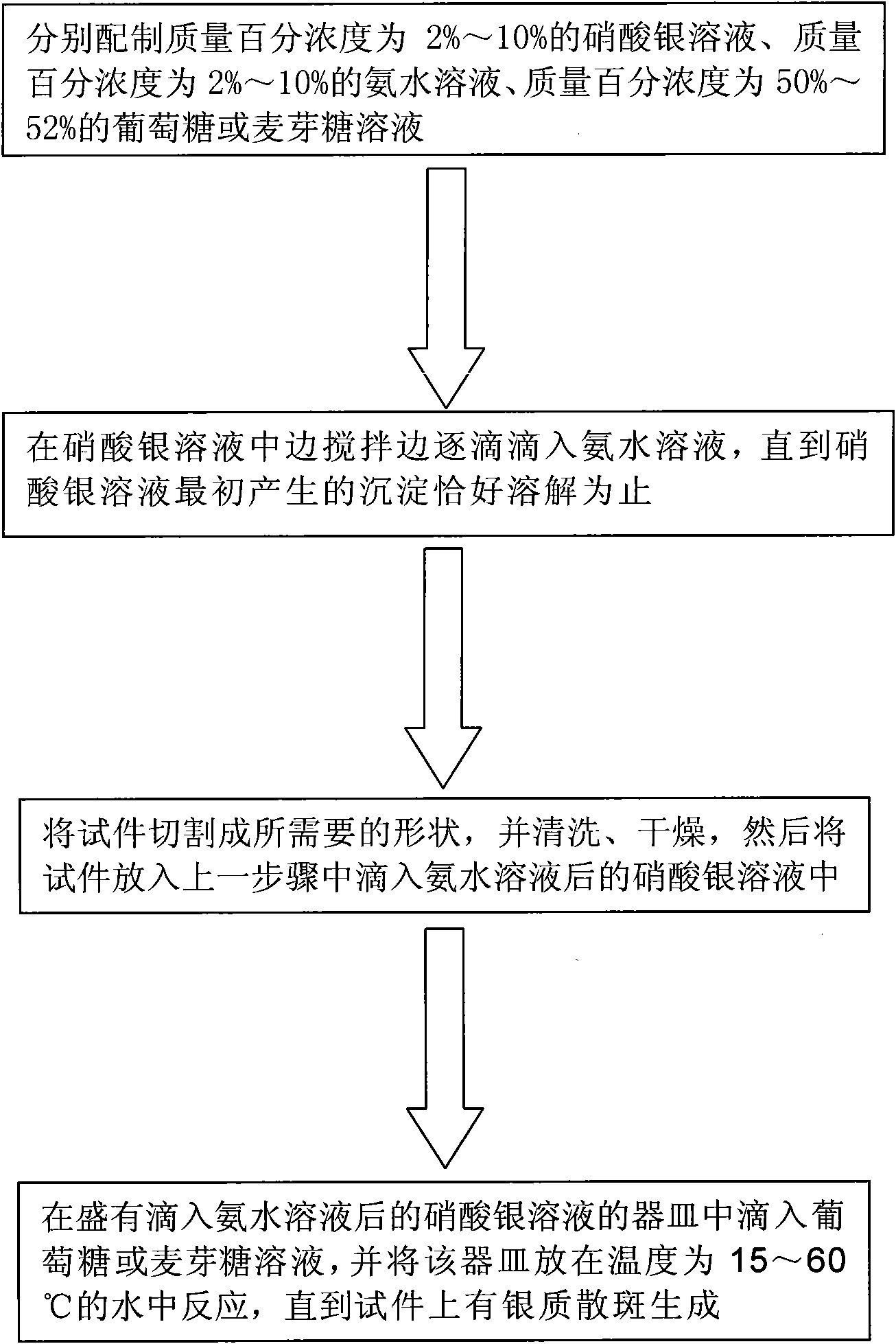

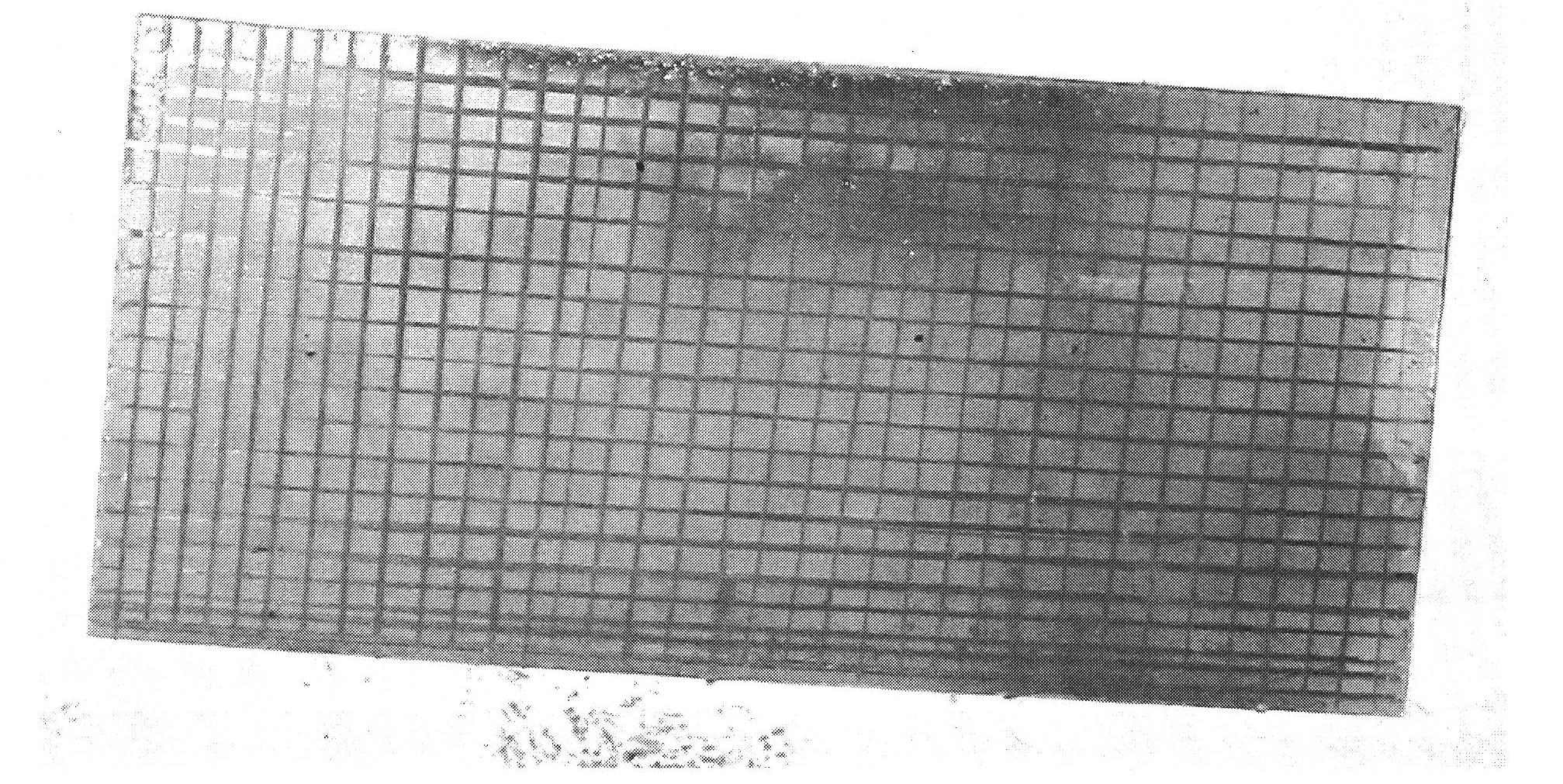

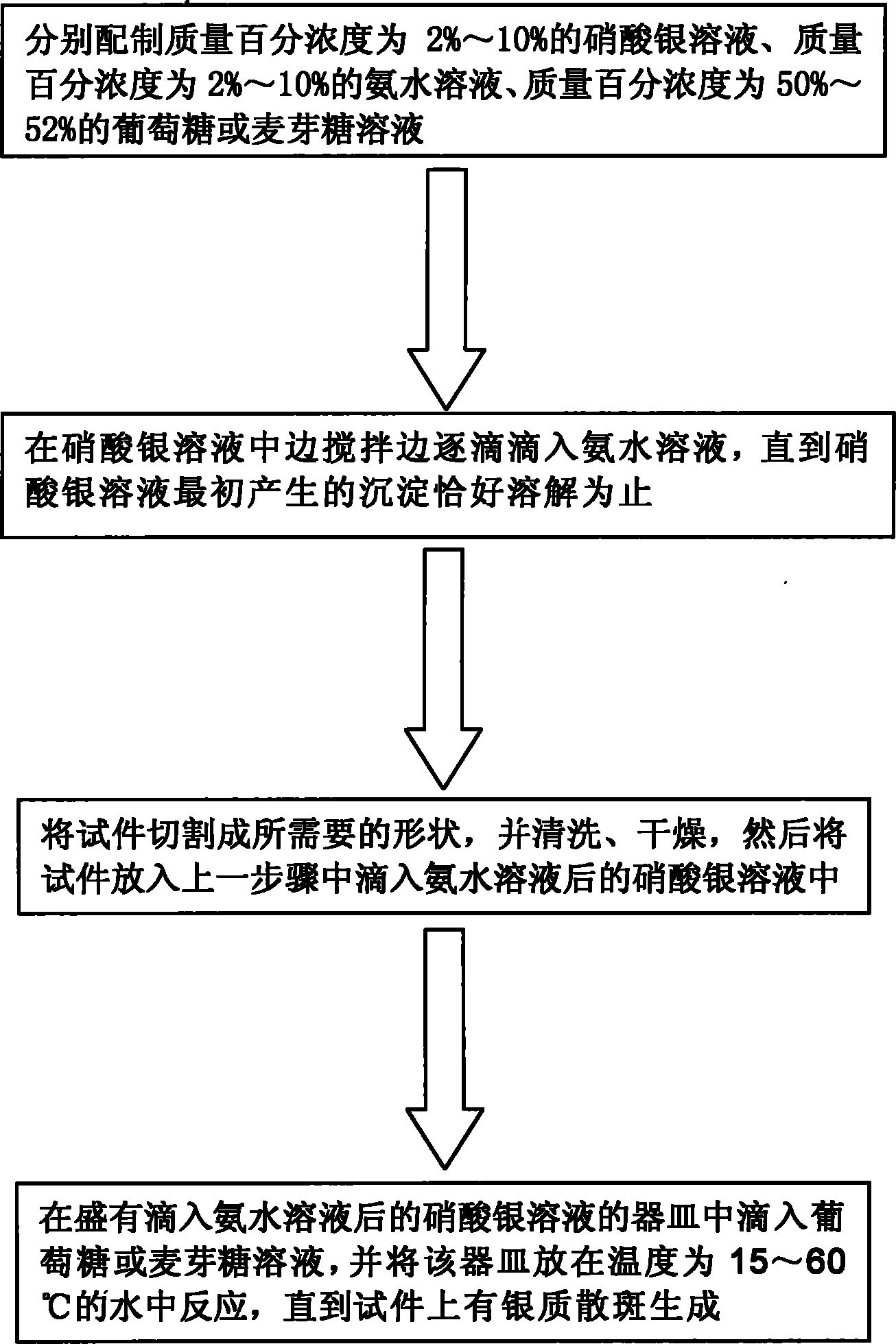

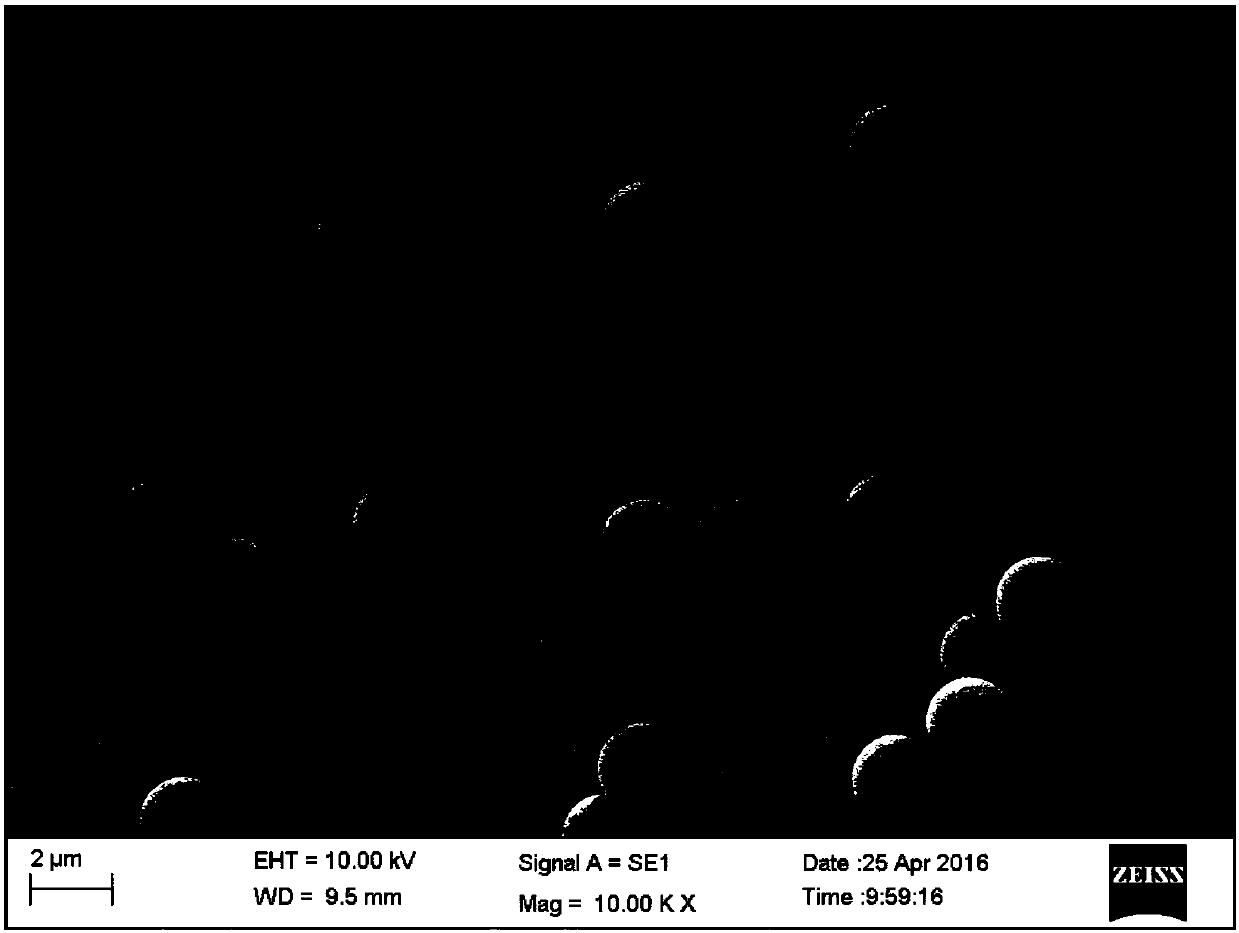

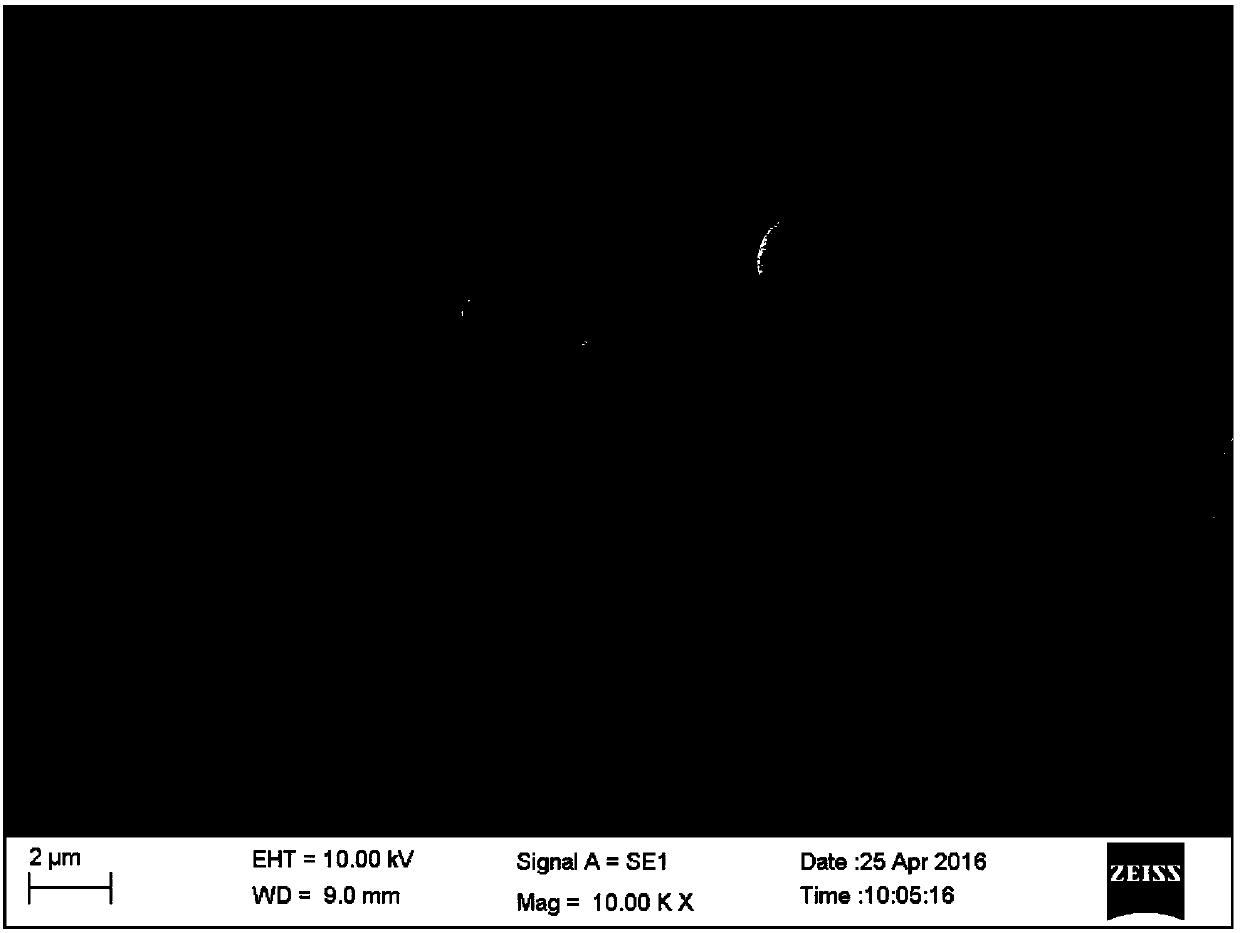

Manufacturing method of high-temperature speckle

The invention relates to a manufacturing method of high-temperature speckles, which belongs to the technical fields of optical device manufacture and photomechanics. The invention has the technical characteristic that high-temperature resistant speckles are manufactured on the surface of a material by utilizing a chemical reaction method. Silver speckles can be generated on the surface of the material put into solution which is prepared from silver nitrate powder, ammonia water, glucose powder and purified water according to a proper proportion in a certain temperature environment. The speckles can resist about 900 DEG C of temperature and can be matched with a digital image correlation method to finish the optical measurement of mechanical performance in multiple complicated loaded states, such as heat shock, fracture and the like of the material in a high-temperature environment. The invention has novel thought, simple and flexible operation and strong feasibility.

Owner:TSINGHUA UNIV

Method for synthesizing ethylene stearamide with octadecanoic acid

InactiveCN101665447AAvoid unresponsivePerfect conversionOrganic compound preparationCarboxylic acid amide separation/purificationEthylenediamineAntioxidant

The invention discloses a method for synthesizing ethylene stearamide with octadecanoic acid, comprising the following steps: octadecanoic acid, antioxidants and catalyst phosphoric acid are added ina boiling flask, nitrogen flows in at large flow rate, and then the octadecanoic acid is heated and melted down, when the temperature is 80-100 DEG C, ethene diamine is dropwise added for reaction for0.5-1 hour, and then high-temperature reaction is carried out for obtaining finished products. The method has the advantages that: 1. the process flow is simple and the reaction condition is not strict: the ethene diamine is added to lead the octadecanoic acid to be reacted completely at the temperature of 80-100 DEG C, and the conversion of the octadecanoic acid can be improved by heat insulation. 2. The reaction time is shortened: the method adopts dehydration at low temperature and then high-temperature reaction is carried out, so as to protect color well. 3. The product has good color andluster: as BHT antioxidants and the process conditions are adopted, the color and luster of the product are kept to be well.

Owner:RUGAO SHUANGMA CHEM

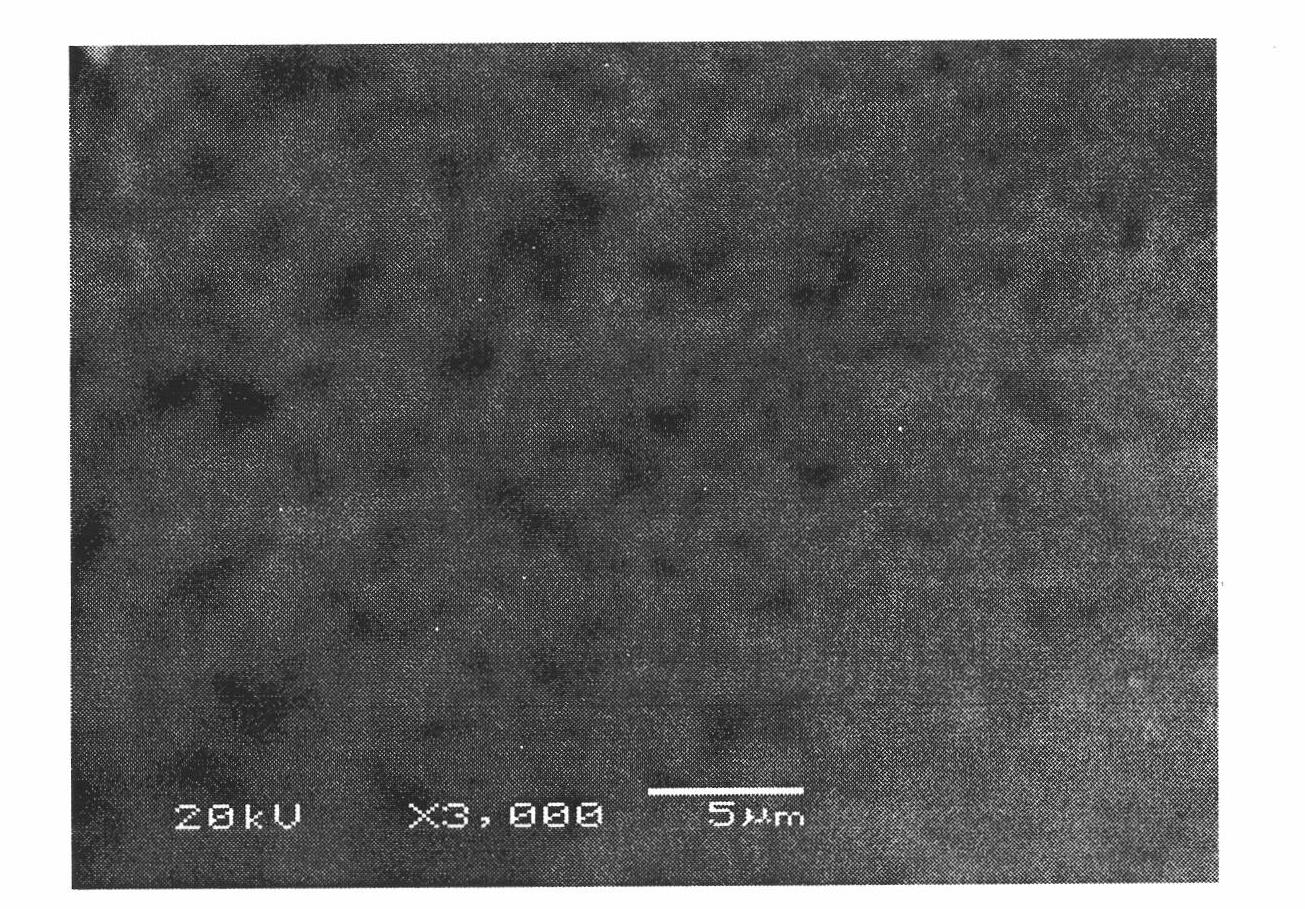

Method capable of realizing volume production and used for preparing micron order single-dispersibility polysiloxane microspheres

ActiveCN105949464AReduce typesThe reaction steps are simpleMicroballoon preparationMicrocapsule preparationPolymer scienceOrganic solvent

The invention discloses a method capable of realizing volume production and used for preparing micron order single-dispersibility polysiloxane microspheres. The method comprises the following steps of (1) preparing a basic catalyst solution; (2) adding trialkoxysilane monomers into the basic catalyst solution (1) to prepare a seed solution; (3) then adding trialkoxysilane monomers into the seed solution obtained in the step (2) to perform a polycondensation reaction; performing filtering, washing and drying to obtain a finished product. The operation can be performed under the conditions of normal temperature, normal pressure and no atmosphere protection; the synthesis steps are simple; the operation is easy; synthesis equipment does not have special requirements; the volume production can be easily realized. No organic solvents polluting the environment are used in the reaction process; no dispersing agents, swellers, stabilizing agents, emulgators or the like are used; the types of reaction polymerization raw materials are few; the product purity is high; the yield is high; the cost is low; the size of the particle diameter of the microspheres can be effectively regulated through controlling the concentration of an initial seed solution; the distribution of the particle diameter of the obtained microspheres is uniform; the high-degree monodispersity is shown; the surface is regular; the degree of sphericity is high.

Owner:贵州正业龙腾新材料开发有限公司

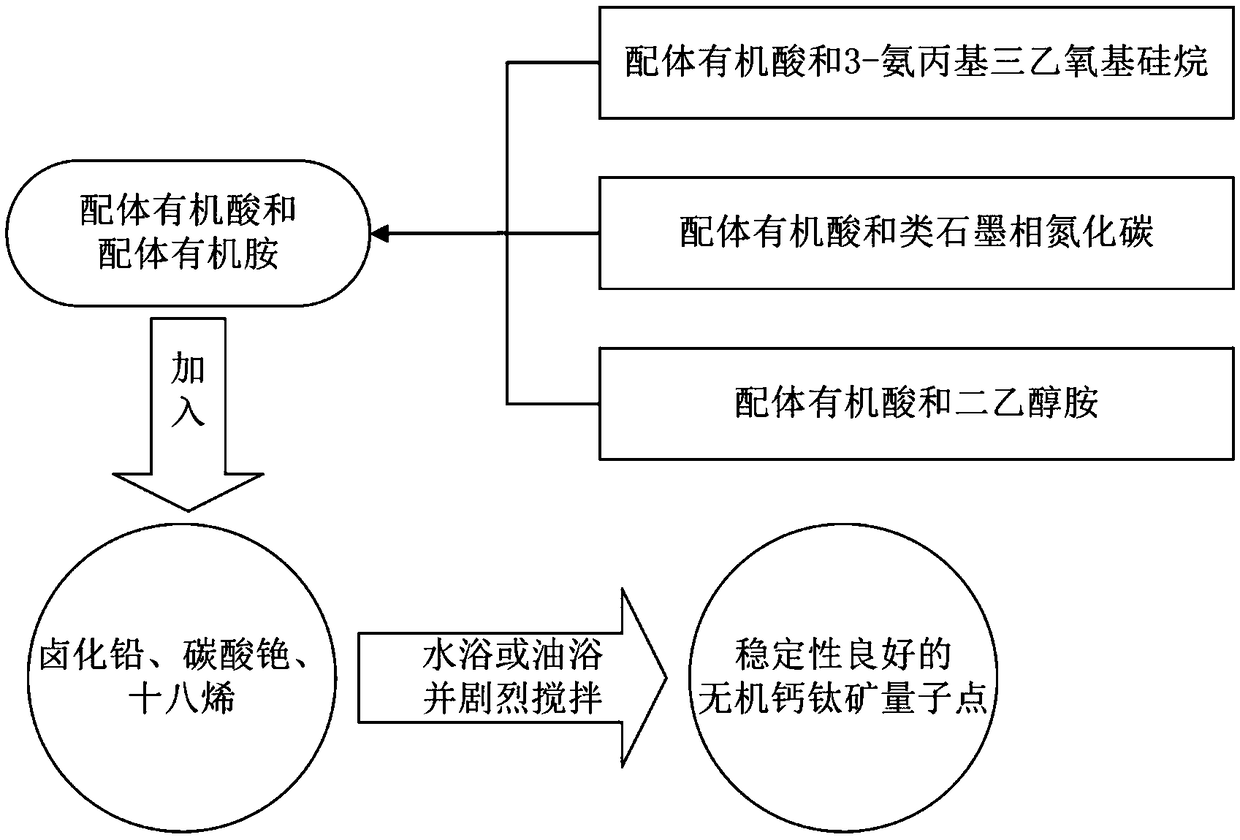

Ligand adjustment-based perovskite quantum dot stability increasing method

InactiveCN109370566AGood resistance to polar solventsImprove stabilityMaterial nanotechnologyNanoopticsWater bathsDissolution

The invention discloses a ligand adjustment-based perovskite quantum dot stability increasing method. The ligand adjustment-based perovskite quantum dot stability increasing method comprises the following steps of weighing out and placing lead halide and cesium carbonate at a certain ratio into a reaction container; at room temperature, adding in ligand organic acids and ligand organic amines; atroom temperature, mixing in a stable solvent of octadecene; performing water bath or oil bath reaction in the reaction container for a while, and intensely stirring the mixture inside the reaction container through a magnetic stirrer; washing reaction products with acetone to remove unreacted precursor and excessive ligands, performing centrifugal treatment, then adding in normal hexane of the same volume for oscillated dissolution and precipitation, then performing vacuum drying to obtain inorganic perovskite CsPbX3 quantum dot powder. The ligand adjustment-based perovskite quantum dot stability increasing method has the advantages of being simple in preparation method, low in preparation cost, simple in material and capable of easily satisfying reaction conditions, improves the anti-polarity solvent capacity and the thermal stability of inorganic perovskite CsPbX3 quantum dots.

Owner:SOUTH CHINA UNIV OF TECH

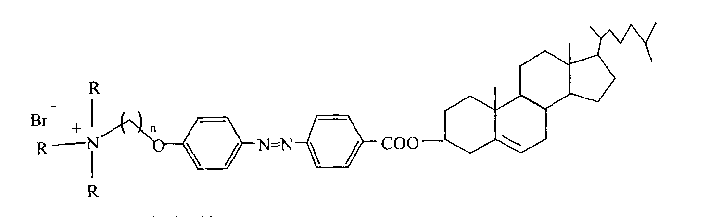

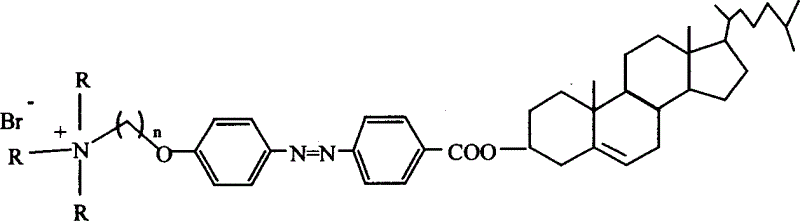

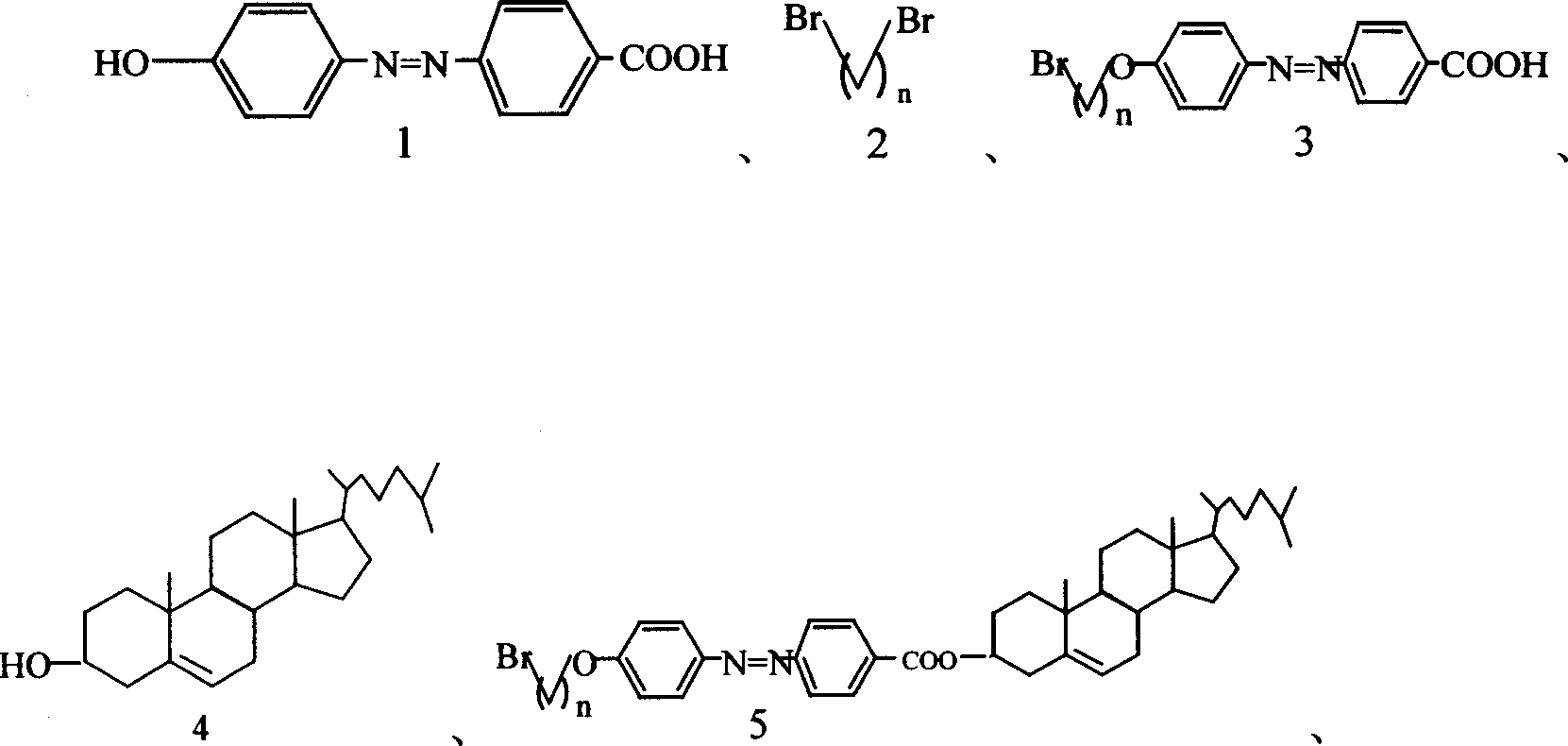

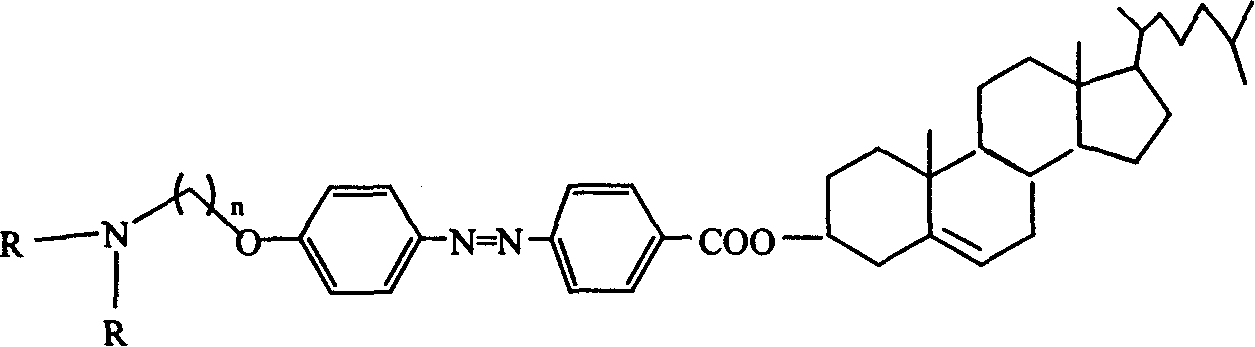

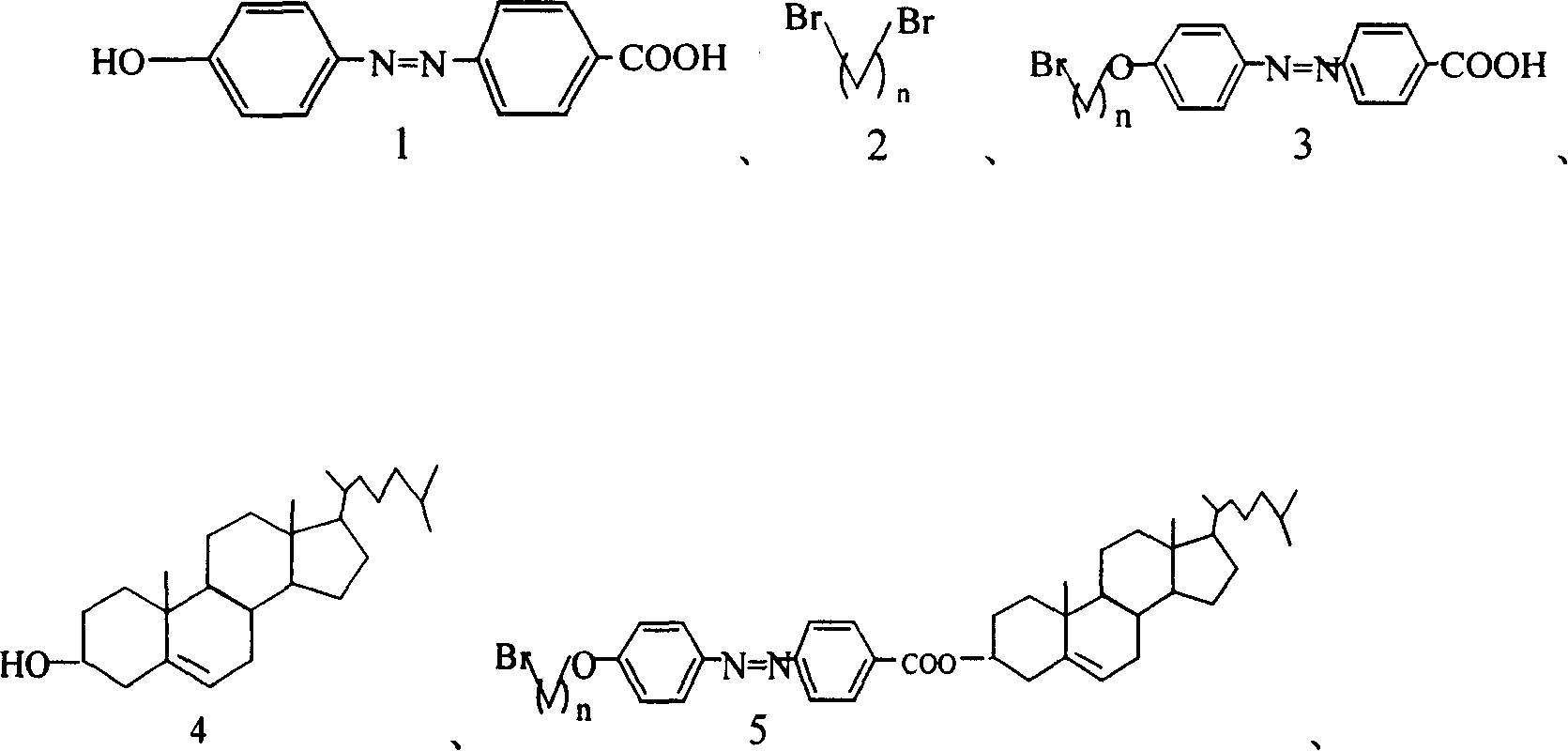

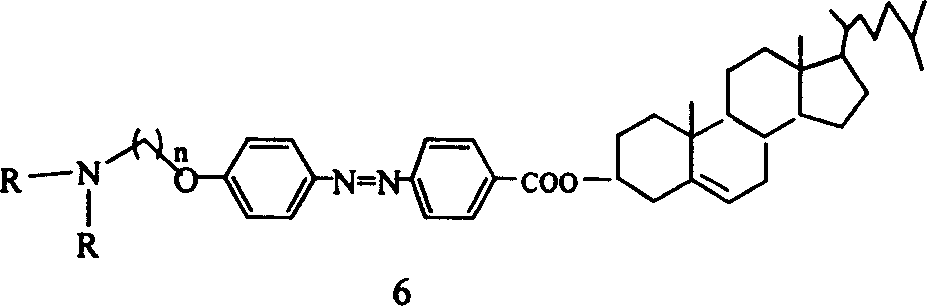

Cholesterin derivative containing azobenzol group and its synthesis and use

InactiveCN1526723AControl releaseThe reaction conditions are not harshSteroidsPharmaceutical non-active ingredientsControlled releaseDrug release

The present invention relates to one kind of cholesterin derivative containing aobenzol group and with novel structure, the synthesis of this kind of compounds and their use as light controlled release material in controlling the release of liposome coated medicine. The synthesis process is simple and suitable for industrial production.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Cholesterol derivative containing azobenzene group, and its synthesizing method and use

InactiveCN1850844AControl releaseThe reaction conditions are not harshSteroidsPharmaceutical non-active ingredientsCholesterol derivativeDrug release

The invention relates to a cholesterol ramification containing azobenzene group and the compounding method, and the application as light controlling releasing material. It has simple method, and is suitable for industrializing manufacturing.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

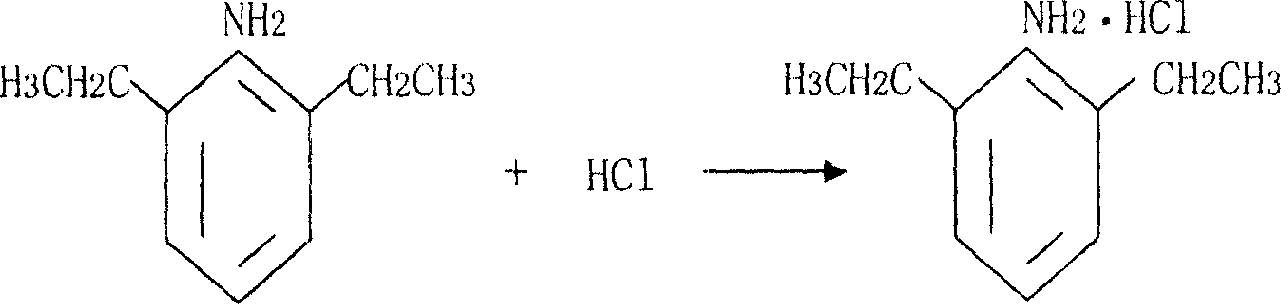

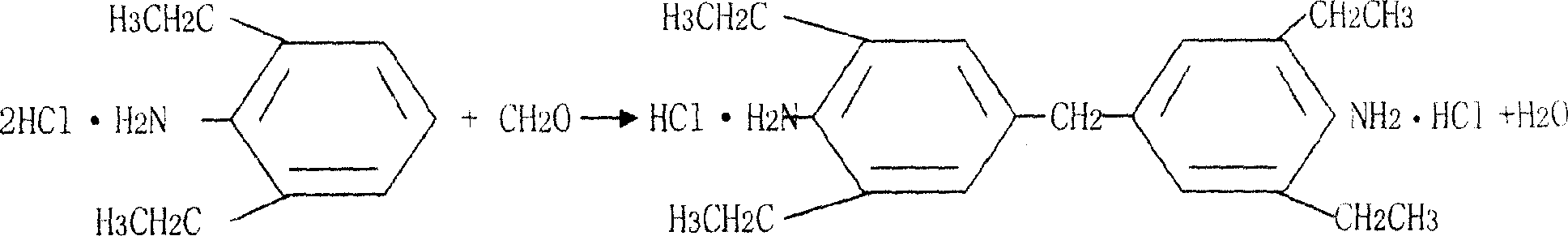

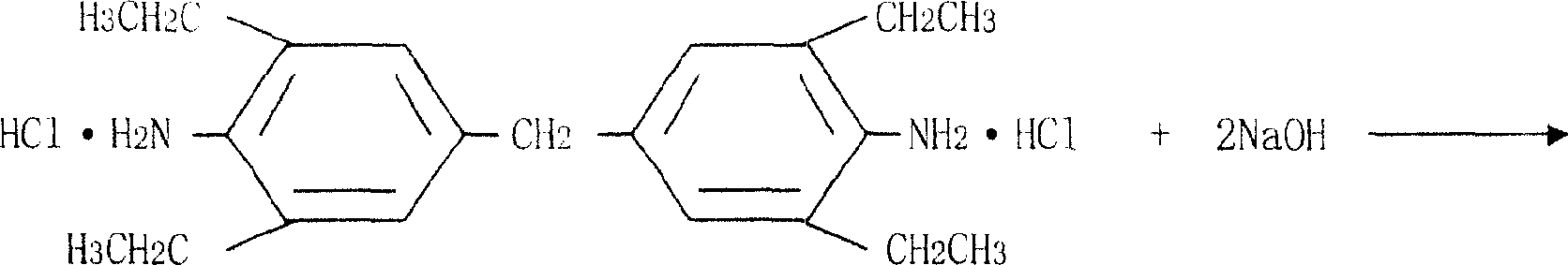

Prepn process of 4,4'-methylene-bis(2,6-diethyl aniline) (MDEA)

InactiveCN1706809AThe process is not complicatedThe reaction conditions are not harshOrganic chemistryChemistryToxicity

The preparation process of 4, 4'-methylene-bis-(2, 6-diethyl aniline) (MDEA) belongs to the field of polymer synthesis technology. Under the protection of inert gas, material 2, 6-diethyl aniline is dissolved in water and hydrochloric acid in certain amount is added to produce 2, 6-diethyl aniline hydrochloride. Then, water solution of formaldehyde in stoichiometric amount is dropped while heating to produce condensation; and through maintaining the temperature for finishing the reaction and neutralization with alkali, coarse MDEA product is separated. Through further decolorizing, dewatering, crystallizing and pelletizing, MDEA product is obtained. The preparation process is simple and has mild reaction condition, low production cost and high yield, and MDEA has less toxicity and may be used to replace MOCA as chain expander for PU material.

Owner:陆锦贤

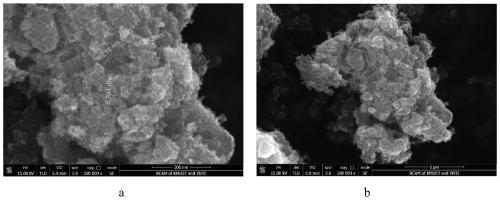

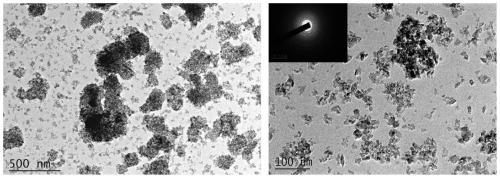

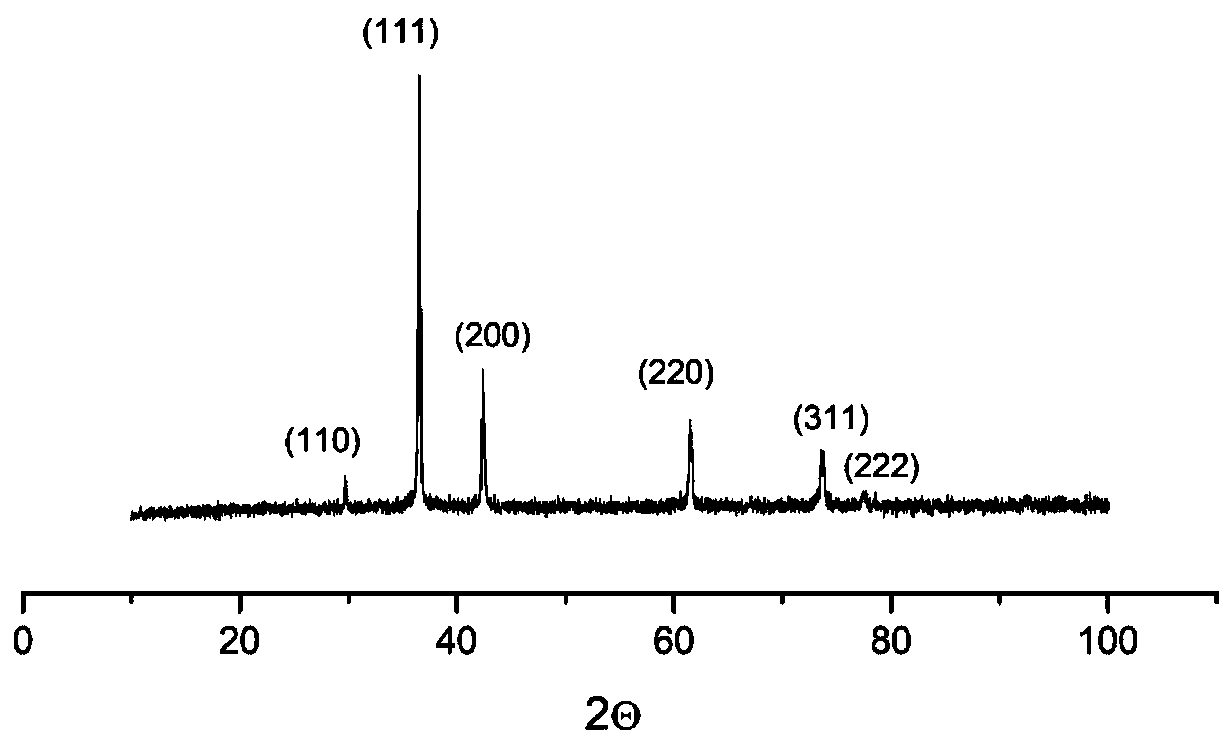

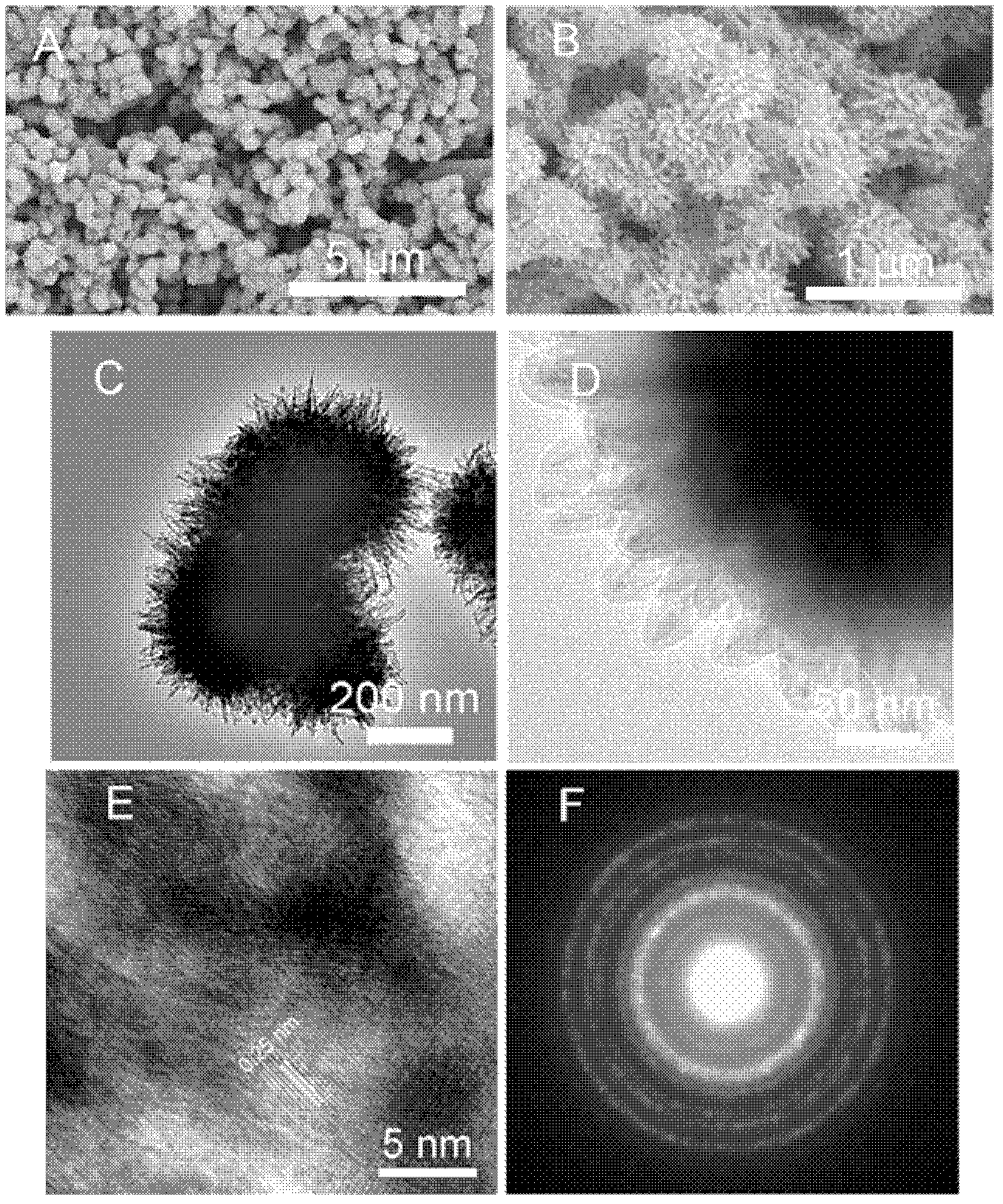

Preparation method of polycrystalline nano cuprous oxide particles

ActiveCN111285394AShort manufacturing timeImprove stabilityMaterial nanotechnologyCopper oxides/halidesMicrowave ovenPolyol

The invention discloses a preparation method of polycrystalline nano cuprous oxide particles, which comprises the following steps: adding a copper source into a 98% polyol solution, and completely dissolving the copper source to obtain a precursor solution; dissolving sodium citrate or glucose in deionized water to prepare a solution, slowly adding the prepared solution into the prepared precursorsolution, and fully stirring until the solutions are uniformly mixed; transferring the prepared mixed solution into a polytetrafluoroethylene reaction liner tube, and putting the polytetrafluoroethylene reaction liner tube into a variable-frequency microwave oven; and centrifugally filtering the reaction product, washing with absolute ethyl alcohol and deionized water, and finally putting the washed sample into a vacuum drying oven to obtain the nano cuprous oxide polycrystalline powder. The method is simple in process, easy and convenient to operate, short in reaction time, low in cost consumption and environmentally friendly in raw materials, and the prepared cuprous oxide nanoparticles are of a polycrystalline structure, narrow in particle size distribution and good in stability.

Owner:SOUTHWEST FORESTRY UNIVERSITY

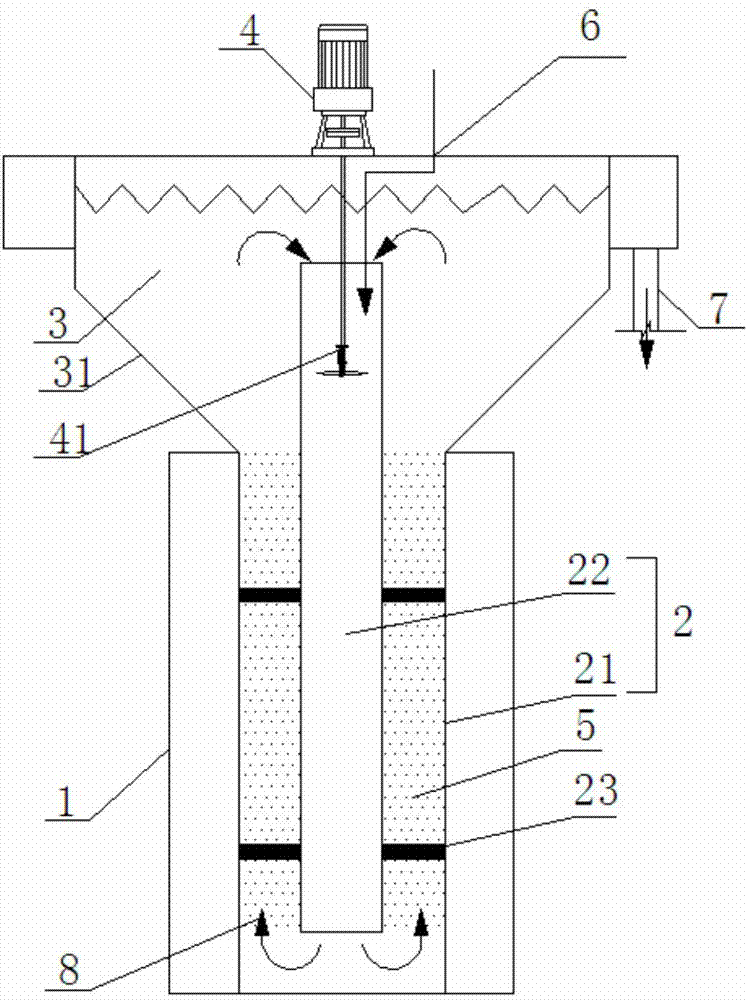

Microwave fluidization reaction device and method for processing benzol and derivatives of benzol

ActiveCN104707551AEasy to handleHigh removal rateWater/sewage treatment by irradiationWater contaminantsResonant cavityMicrowave

The invention relates to the technical field of water treatment, and particularly relates to a microwave fluidization reaction device and a method for processing benzol and derivatives of benzol. The microwave fluidization reaction device comprises a microwave resonant cavity, a fluidization reaction body, a solid-liquid separation system and a stirrer, wherein the fluidization reaction body is arranged inside the microwave resonant cavity; fluidization reaction carriers are arranged inside the fluidization reaction body; the solid-liquid separation system is connected with the fluidization reaction body; a water inlet and a water outlet are both formed in the solid-liquid separation system; a pushing paddle is arranged on the stirrer; one end of the pushing paddle penetrates through the solid-liquid separation system and stretches into the fluidization reaction body. As a microwave environment is provided through the microwave resonant cavity, the reaction carriers and a liquid sufficiently contact microwaves inside the fluidization reaction body, and moreover solid-liquid separation is effectively achieved through the solid-liquid separation system, the microwave fluidization reaction device is simple in overall operation and can be operated continuously.

Owner:BEIJING WANBANGDA ENVIRONMENTAL PROTECTION TECH

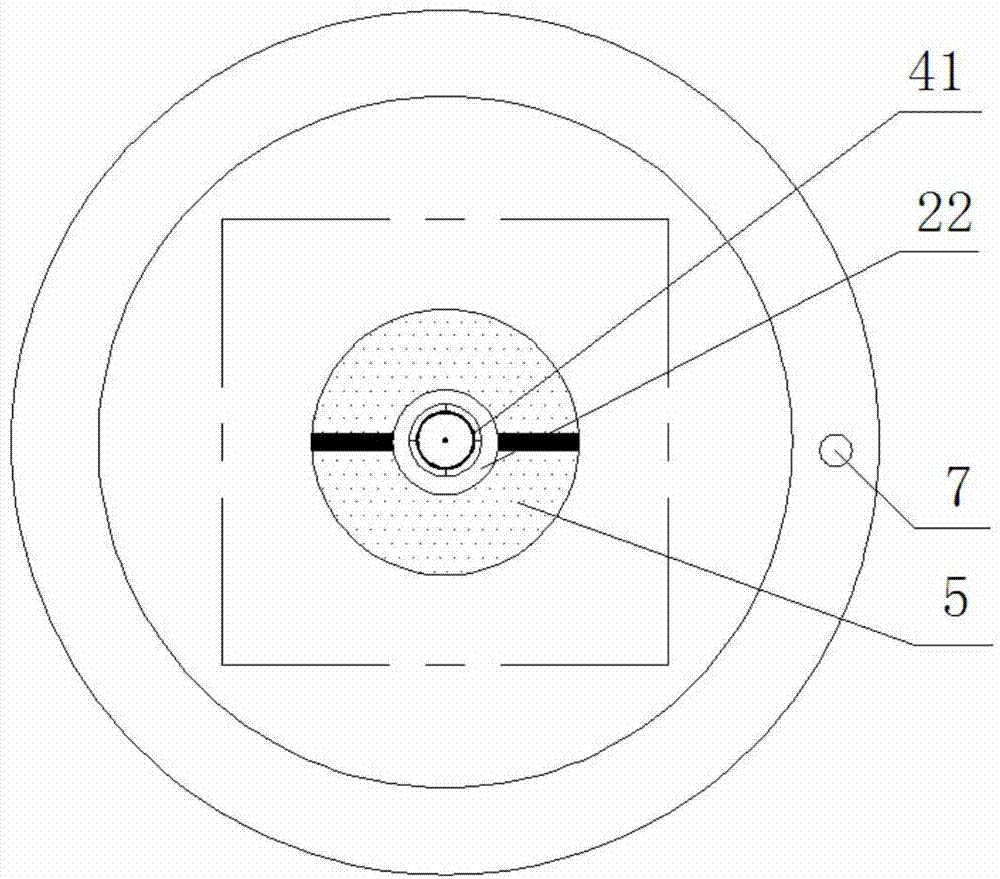

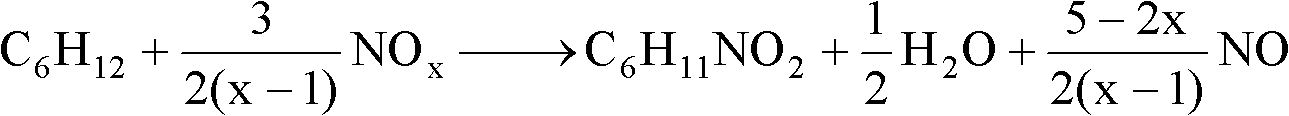

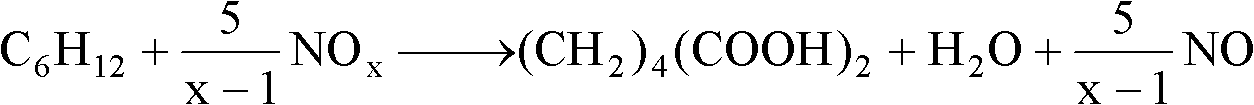

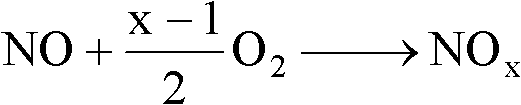

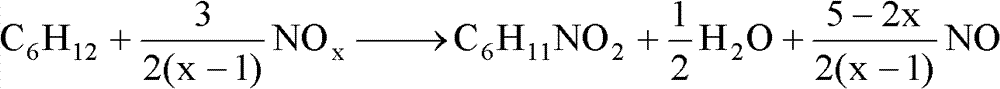

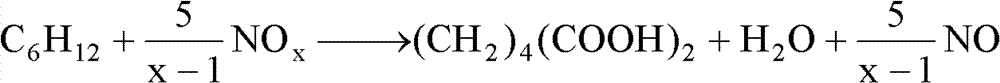

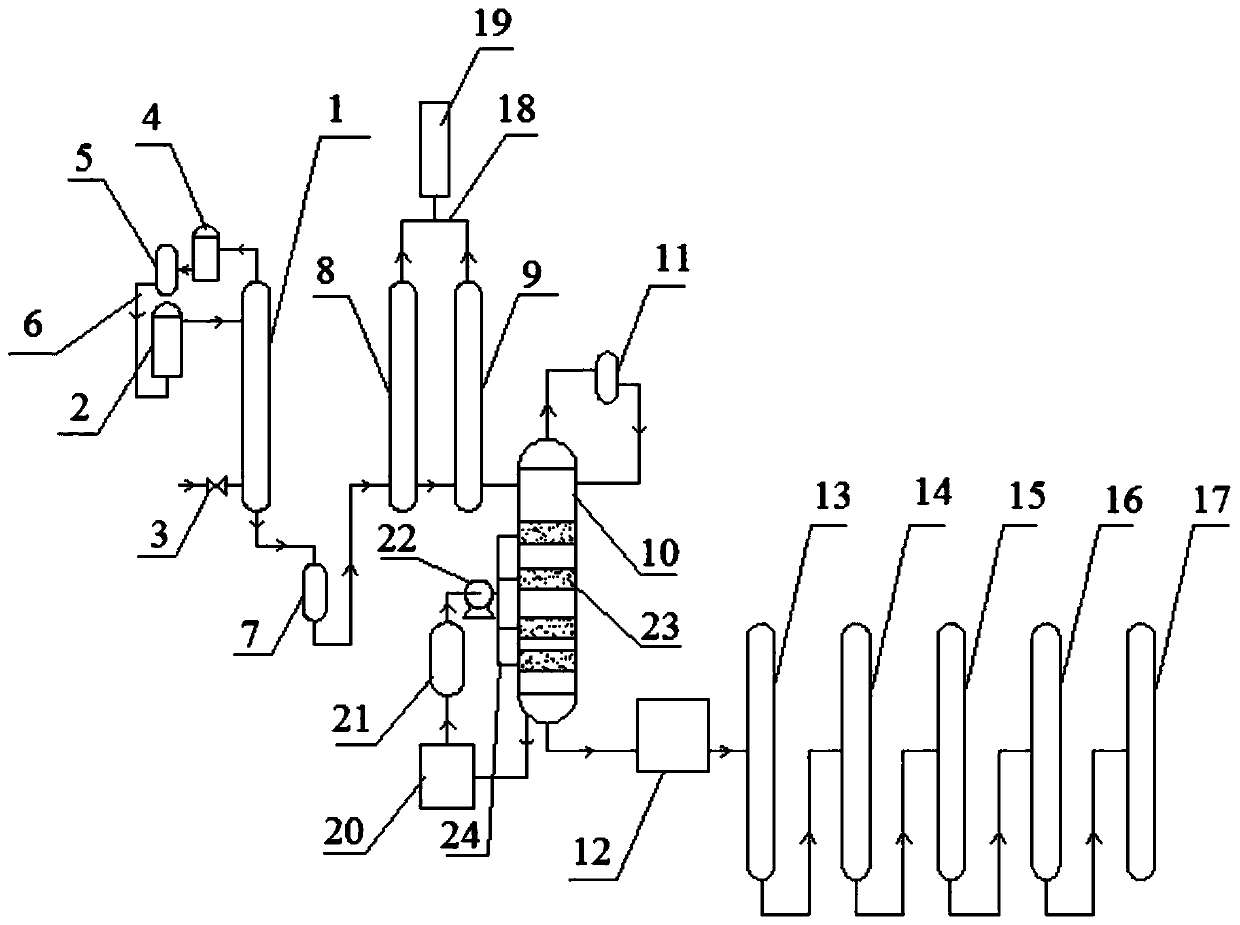

Method for high-selectivity co-production of nitrocyclohexane and adipic acid

InactiveCN101781217AHigh selectivityReduce generationOrganic compound preparationCarboxylic compound preparationGas phaseConcentration ratio

The invention relates to a method for the high-selectivity co-production of nitrocyclohexane and adipic acid, which adopts nitrogen oxide NOx as the nitrating and oxidizing agent, carrys out continuous gas-phase catalysis or non-catalytic nitration and oxidation reaction on cyclohexane. By effectively setting the conditions of the concentration ratio, the reaction temperature and the reaction time of the reactants and optimizing the reaction pressure as well as catalysts and assistants, the invention realizes the simultaneous high-selectivity co-production of the nitrocyclohexane and the adipic acid of different ratios, and the reduction product NO generated by the nitration and oxidation reaction can be recycled for cyclic utilization. The method of the invention has high resource efficiency, less waste generation, simple process flow and device and low production cost, and is an environment-friendly synthetic method.

Owner:XIANGTAN UNIV

Method for synthesizing 3-methyl-3-butene-1-ol

ActiveCN104387234AThe reaction conditions are not harshLower requirementOrganic compound preparationHydroxy compound preparationParaformaldehydeAluminium isopropoxide

The invention discloses a method for synthesizing 3-methyl-3-butene-1-ol. The method comprises the following steps of preparing a paraformaldehyde isopropanol solution, adding a catalyst, carrying out the reaction of the paraformaldehyde isopropanol solution with isobutene, and purifying a crude 3-methyl-3-butene-1-ol. The added catalyst can be aluminium isopropoxide, aluminium propoxide, aluminium ethylate, aluminium methoxide, basic aluminium chloride and aluminium hydroxide, and the addition amount of the catalyst is 0.1-1% of the mass of formaldehyde. The reaction condition of the method is not critical, and the catalysts containing acids, alkalis and halogens are not used. According to the method, the requirement on production equipment is not high, and the low-temperature low-pressure reaction condition has low requirement on the safety of industrial production, and the investment on equipment is low. The method has the advantages that the selectivity and the conversion rate are high, the reaction selectivity of formaldehyde is more than or equal to 95.6%, the conversion rate of formaldehyde is more than or equal to 96.7%, the purity of purified 3-methyl-3-buten-1-ol is more than 99.5%, and the content of water in 3-methyl-3-buten-1-ol is less than 0.1%.

Owner:SHANDONG NHU PHARMA

Cable material for new energy automobile and preparation method of cable material

InactiveCN109337273ASimple manufacturing methodThe reaction conditions are not harshNew energyWear resistant

The invention provides a preparation method of cable material for a new energy automobile. The preparation method comprises the following steps: (I) preparing 1-methallyl-2-(2-hydroxyl-5-methyl phenyl) benzothiazole, quaternary ammonium salt-15 and an acrylonitrile copolymer; (II) carrying out polycondensation on 4,4'-diamino stilbene-2,2'-disulfonic acid, 9-fluorenone-2,7-dicarboxylic acid; and (III) preparing the cable material for the new energy automobile. The invention also discloses the cable material for the new energy automobile prepared with the preparation method. The preparation method disclosed by the invention is simple and feasible, low in equipment dependency, unharsh in reaction condition, low in price and suitable for scaled production. The prepared cable material for thenew energy automobile has the characteristics of being low in manufacturing cost, oil-resistant, wear-resistant and flame-retardant, and has the advantages of being excellent in aging resistance, weather resistance and tear resistance, small in environmental influence, good in performance stability and long in service life.

Owner:师帅帅

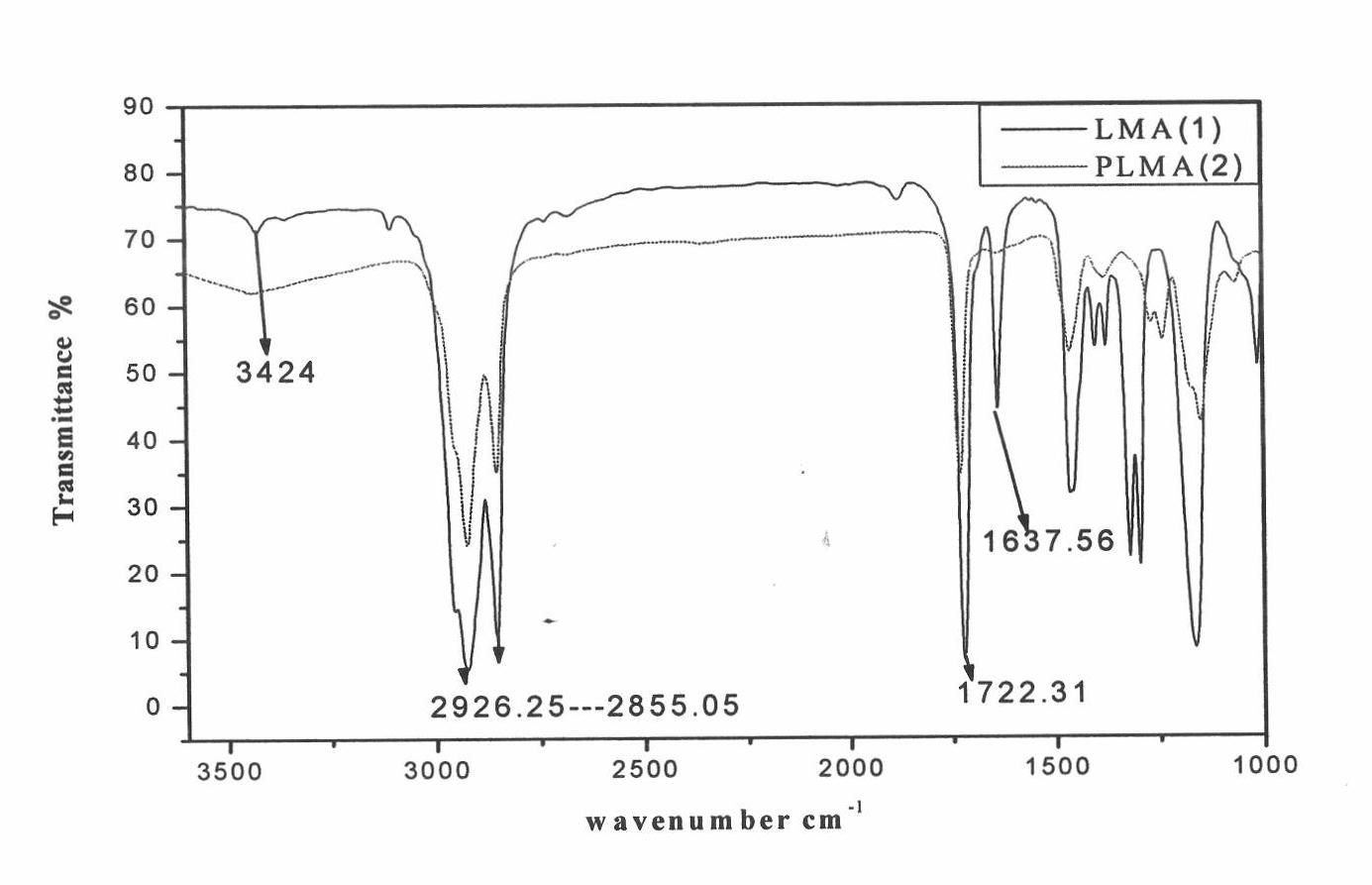

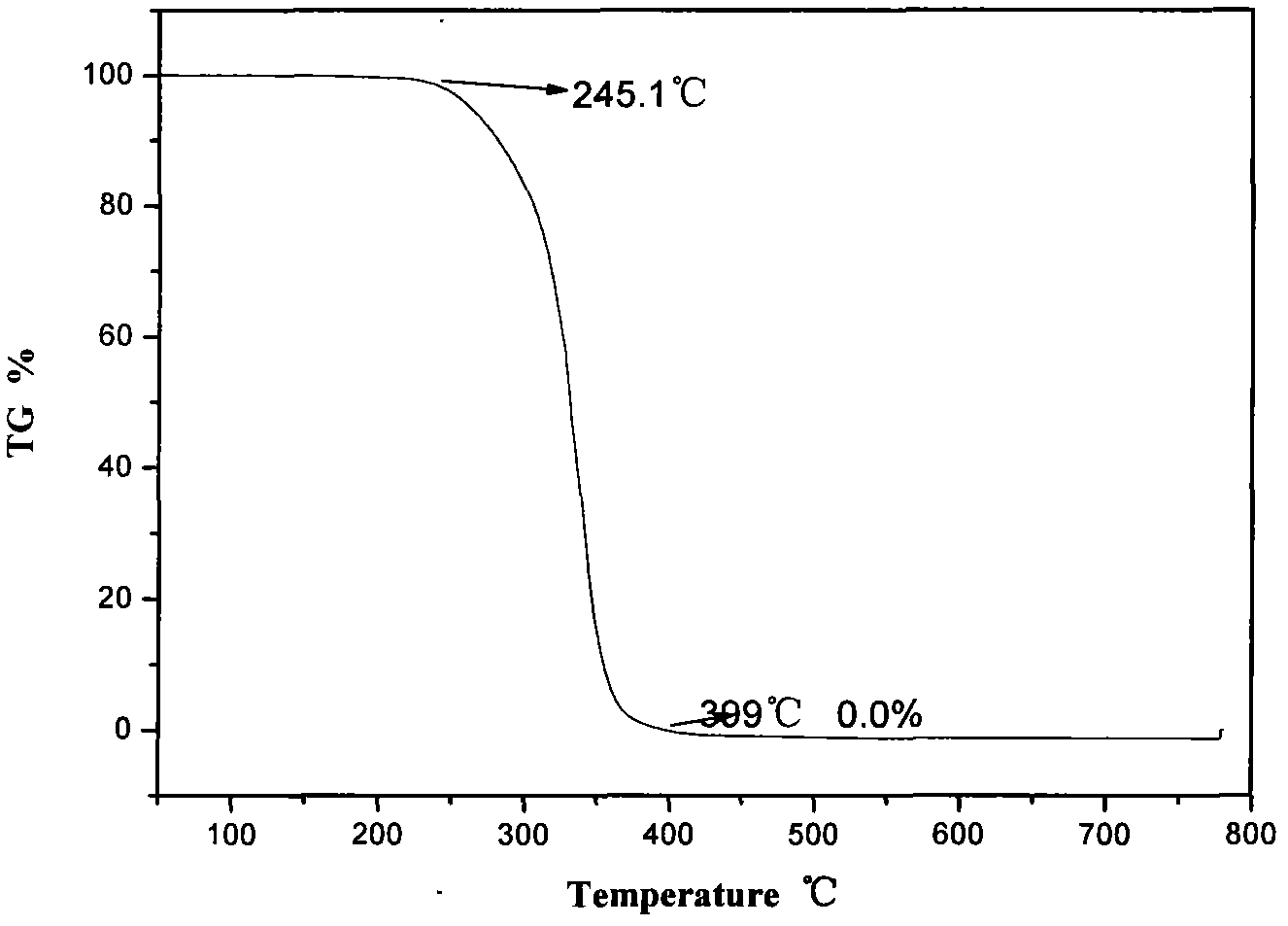

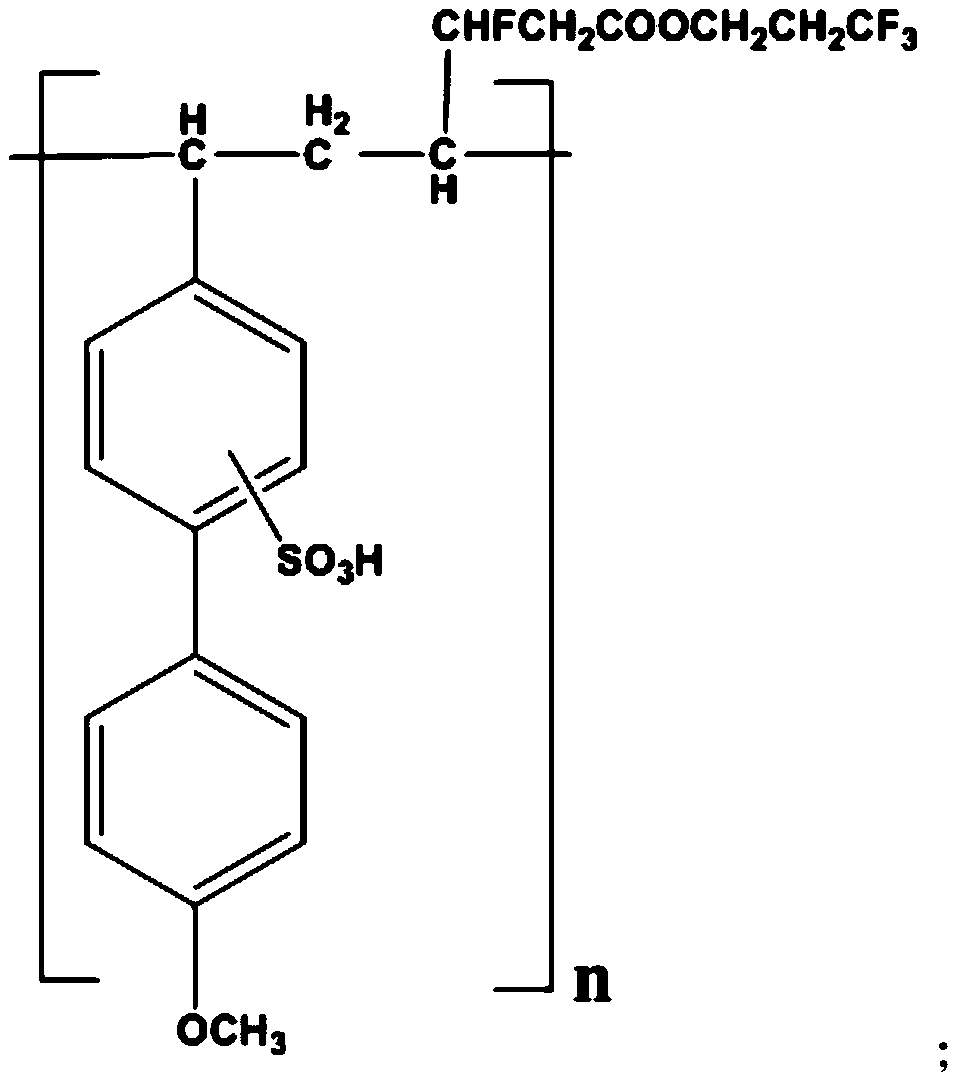

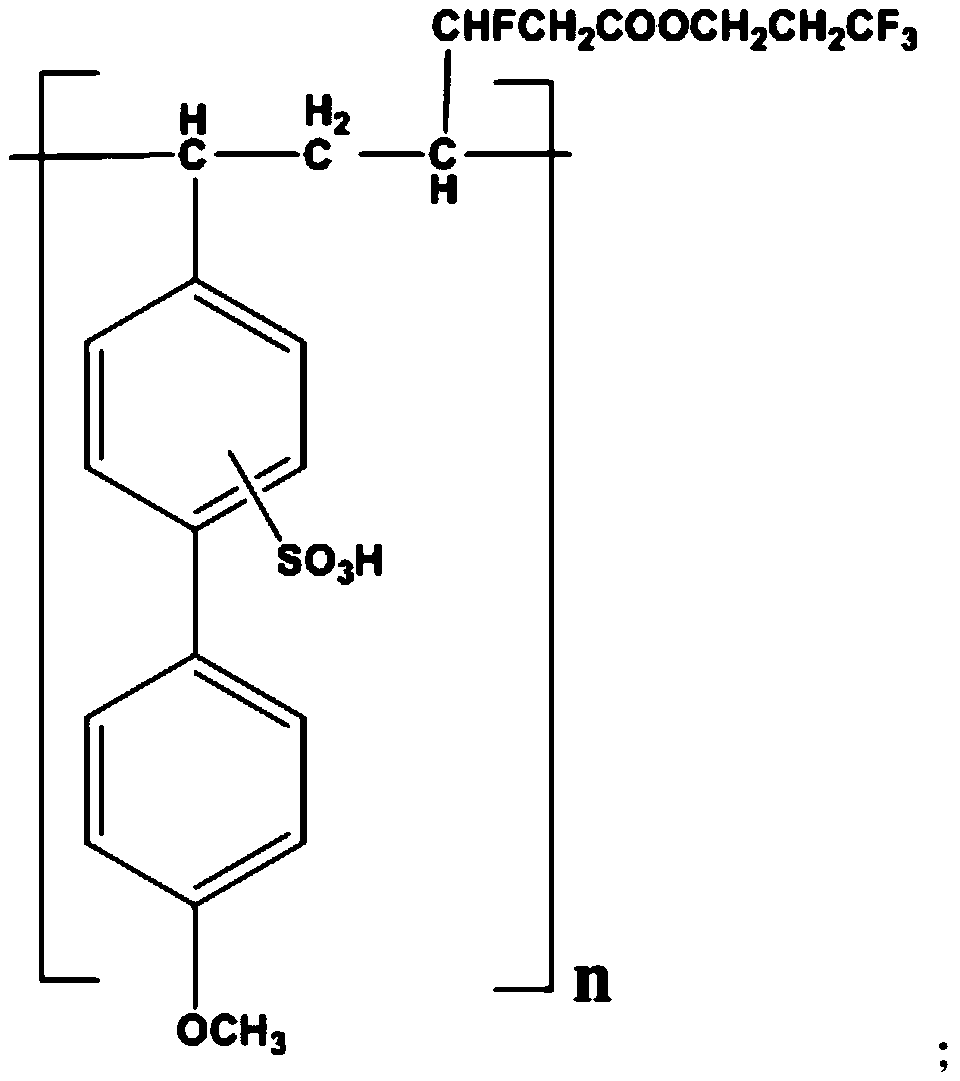

Porous high-oil-absorption resin and preparation method thereof

InactiveCN102504072AHigh oil absorption rateNo pollution in the processOther chemical processesWater/sewage treatment by sorptionCross-linkEmulsion polymerization

The invention relates to a porous high-oil-absorption resin and a preparation method thereof. The high-oil-absorption resin is prepared by radical-triggered composite emulsion polymerization of a monomer in the presence of a cross-linking agent, a trigger and an emulsifier and in a protective atmosphere of nitrogen. The high-oil-absorption resin in a small volume has high oil absorption rate and can absorb only oil but not water; after absorbing oil, the resin becomes a block and is easy to recover; with a density smaller than that of water, the resin can float on water and thus can well treat floating oil; and the resin has a certain application value in fields of petroleum, chemicals, environment protection and medicines.

Owner:NORTHWEST NORMAL UNIVERSITY

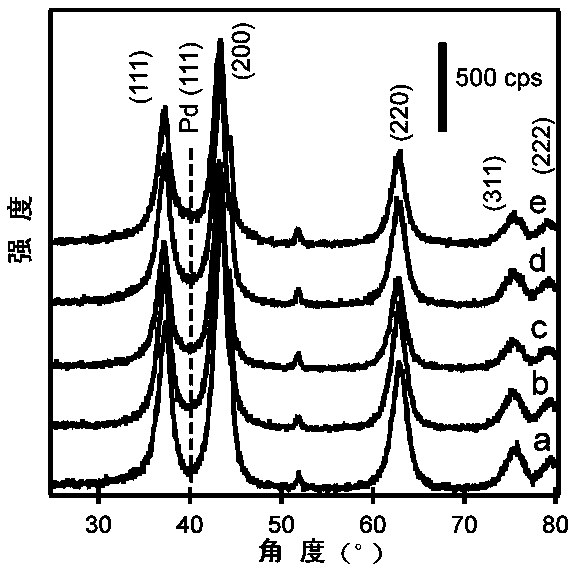

Preparation method for nickel oxide loaded palladium catalyst and application to room-temperature CO catalytic oxidation

InactiveCN104043460AEasy to prepareShort timeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPalladium catalyst

The invention provides a preparation method for a nickel oxide loaded palladium catalyst. The preparation method comprises the following steps: (1) preparing nickel nitrate solution; (2) preparing an oxalate solution; (3) dissolving the nickel nitrate solution and the oxalate solution to prepare a nickel oxalate solid suspension solution; (4) preparing nickel oxalate solid; (5) carrying out drying treatment; (6) preparing a nickel oxide carrier with a mesoporous structure; (7) preparing a solid suspension solution of nickel oxide impregnated palladium salt; (8) preparing a solid suspension solution of nickel oxide loaded palladium monomer; and (9) carrying out the drying treatment to obtain a target product, namely the nickel oxide loaded palladium catalyst. The nickel oxide loaded palladium catalyst prepared by the preparation method has little palladium, has a large specific surface, has good catalytic CO oxidative activity and stability at room temperature, and can be applied to room temperature carbon monoxide oxidization. The preparation method provided by the invention is simple, and little in consumed time of a synthesis process; reaction conditions are not rigorous and the requirements on equipment are not high; transition metal is used as a carrier so that the cost of a production process is low and the industrial production is easy to realize.

Owner:EAST CHINA UNIV OF SCI & TECH

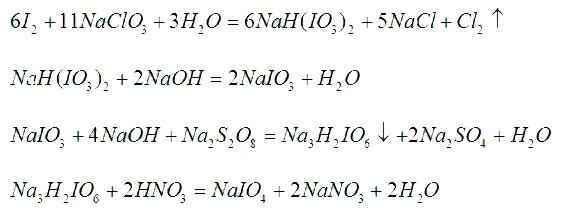

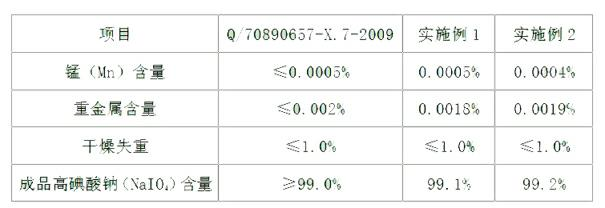

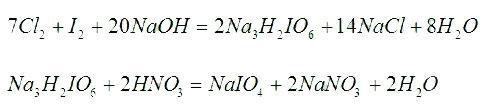

Method for producing sodium periodate

The invention discloses a method for producing sodium periodate. The method comprises the steps of preparation of trisodium dihydrogen periodate, preparation of sodium periodate, crystallization and separation, centrifugal dehydration and drying, wherein the preparation step of the trisodium dihydrogen periodate sequentially comprises the steps of preparation of sodium hydrogen iodate, preparation of sodium iodate and oxidation with sodium persulfate. The trisodium dihydrogen periodate is obtained by reacting sodium chlorate and iodine in an aqueous solution to produce the sodium hydrogen iodate, neutralizing the sodium hydrogen iodate by using sodium hydroxide to obtain the sodium iodate and oxidizing the sodium iodate in the sodium hydroxide solution by using the sodium persulfate, so that the method for preparing the trisodium dihydrogen periodate by using chlorine, iodine and sodium hydroxide in the prior art is abandoned, and the production method is stable in reaction, easy to control and high in production safety degree. Compared with a chlorine oxidation method, the method has the advantages of low consumption of raw materials, small amount of discharged waste liquor and environment friendliness.

Owner:自贡市金典化工有限公司

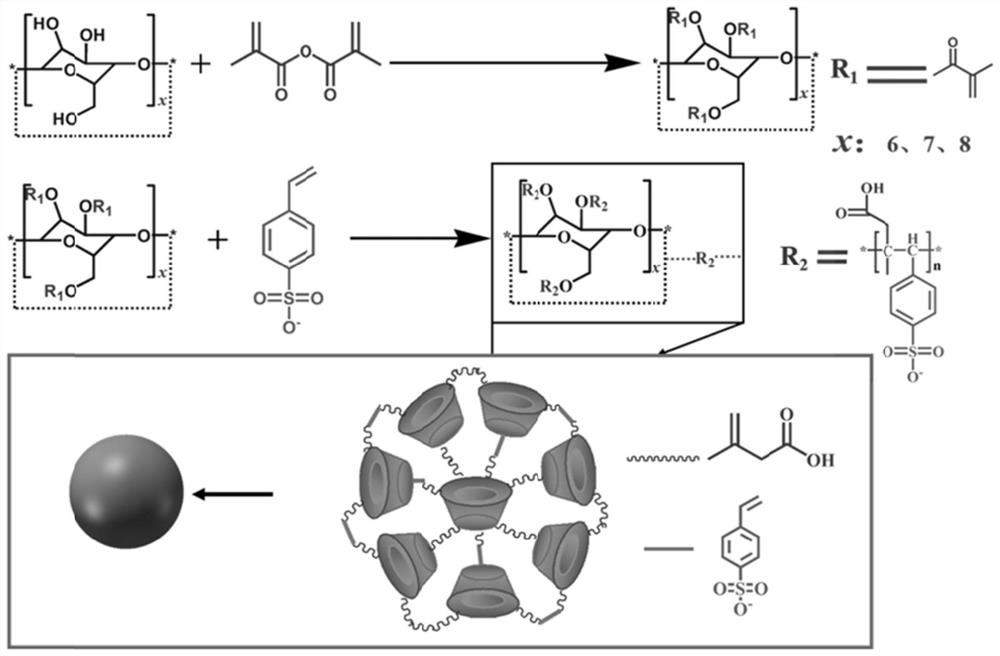

Cyclodextrin porous adsorption material as well as preparation method and application thereof

ActiveCN112934198AHas a multi-level pore structureLarge specific surface areaOther chemical processesEnergy based wastewater treatmentCyclodextrinAlkene

The invention relates to the technical field of functional porous materials, and provides a cyclodextrin porous adsorption material as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out a dehydration condensation reaction on cyclodextrin and acrylic anhydride, and then carrying out a cross-linking polymerization reaction with an olefin micromolecular monomer, so as to prepare the cyclodextrin porous adsorption material. The preparation method disclosed by the invention is simple in steps and relatively mild in reaction conditions; the obtained cyclodextrin porous adsorption material has a hierarchical pore structure, a relatively high specific surface area and various active binding sites, and can be used for efficiently removing pollutants in wastewater; and the cyclodextrin porous adsorption material can be simply recycled, and the cyclodextrin porous adsorption material can still keep a relatively high adsorption effect after 20 times of cyclic adsorption.

Owner:ZHEJIANG SCI-TECH UNIV

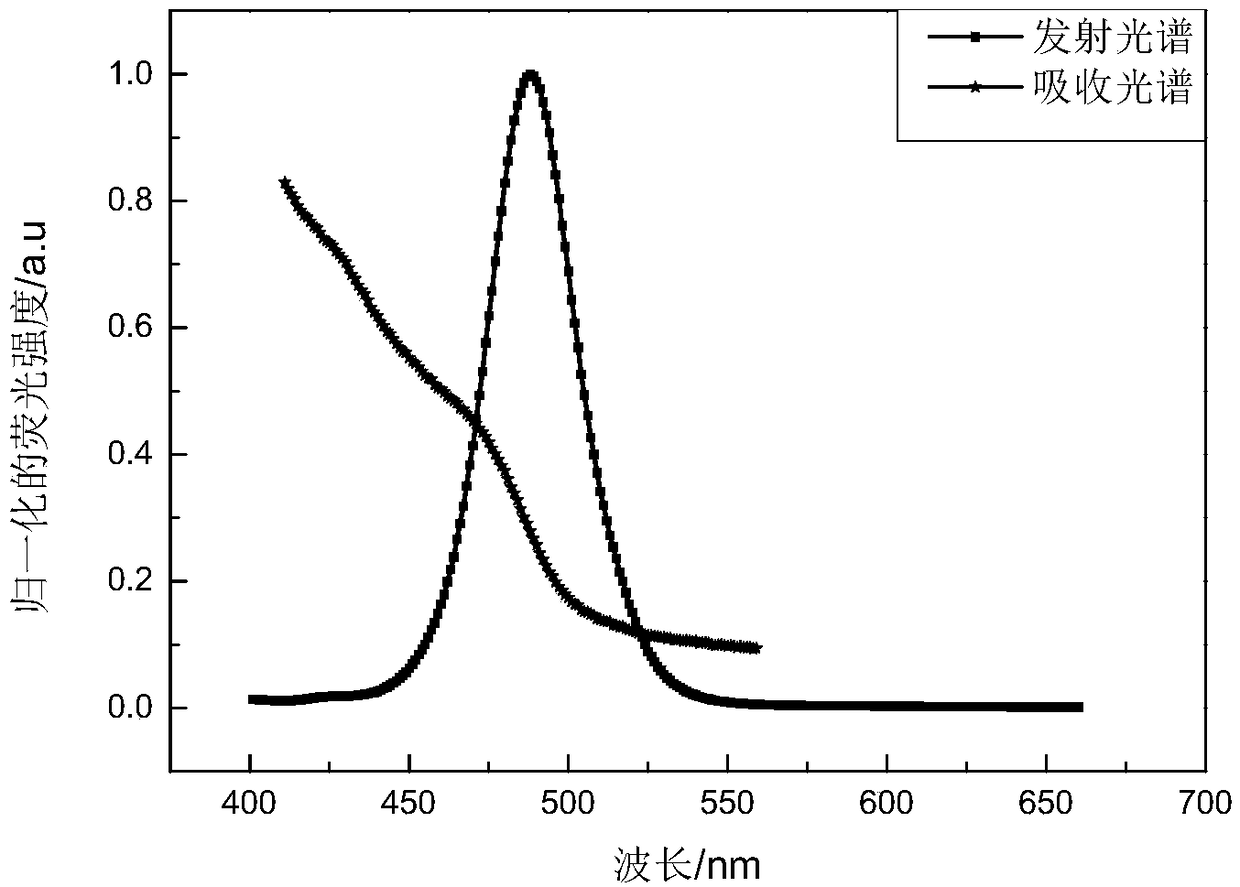

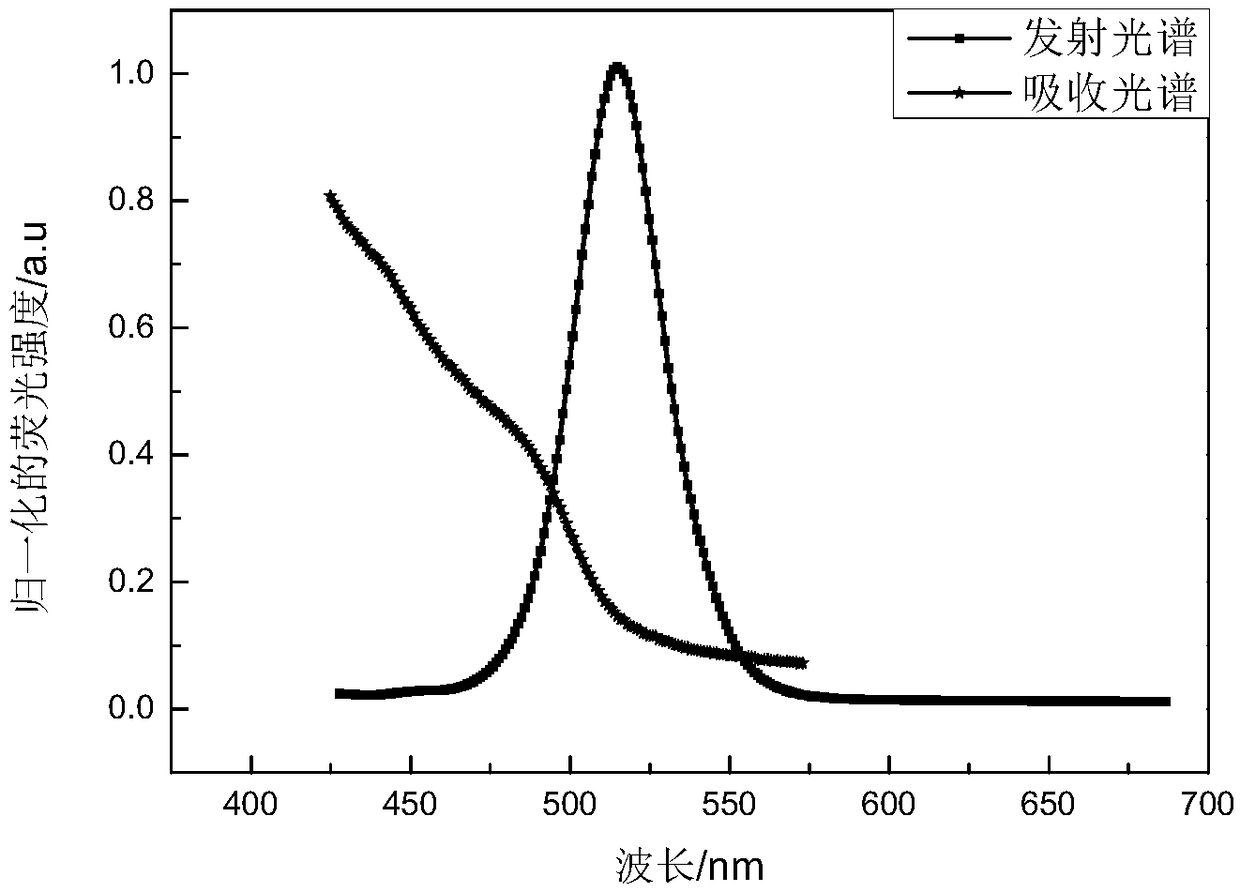

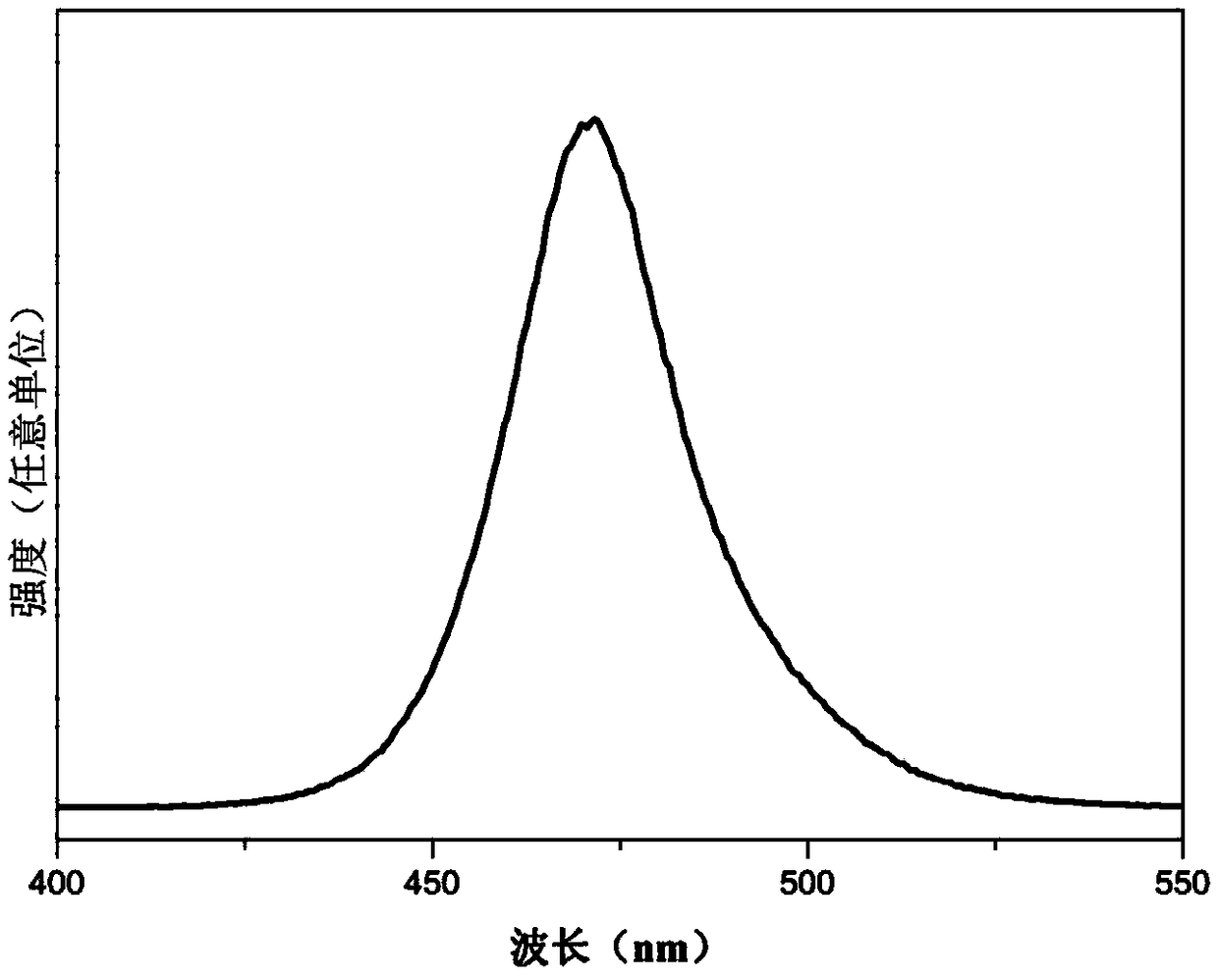

A preparation method of inorganic halogen perovskite fluorescent quantum dots through one-step synthesis and a product thereof

InactiveCN108774516AHigh fluorescence quantum efficiencyImprove stabilityMaterial nanotechnologyNanoopticsFluorescenceNitrogen gas

The invention relates to a preparation method of inorganic halogen perovskite fluorescent quantum dots through one-step synthesis. CsCO3, PbX2, octadecene, oleic acid and oleylamine are mixed, and directly heated and reacted under stirring to obtain the inorganic halogen perovskite fluorescent quantum dots CsPbX3, wherein the X is one of Cl, Br and I. The method is simple and convenient to operate, reaction conditions are not rigorous, and one-step synthesis of the three types of perovskite quantum dots can be achieved in air, nitrogen and vacuum conditions. Through comparison with fluorescence and absorption strength of standard fluorescence substances, the perovskite fluorescent quantum dots have the fluorescence quantum efficiency as high as 90%, and good stability. A container having avolume of 500 mL is utilized for reaction, and 10 grams or above of the quantum dots can be prepared in one time. The method is simple, feasible, and simple in reaction condition, and can be furtherscaled up, and the quantum dots can be prepared in a large scale in one time.

Owner:广东两山科技有限公司

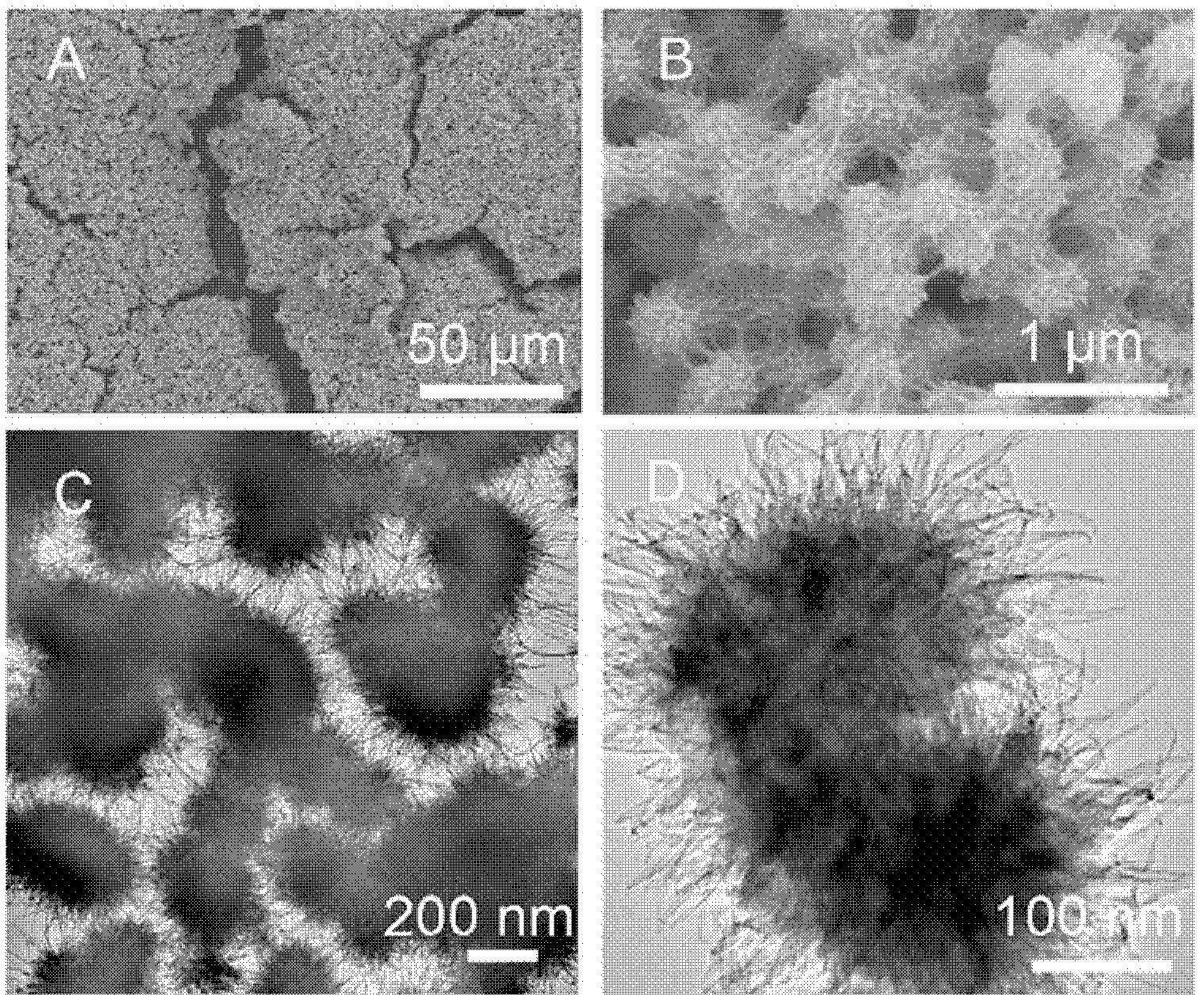

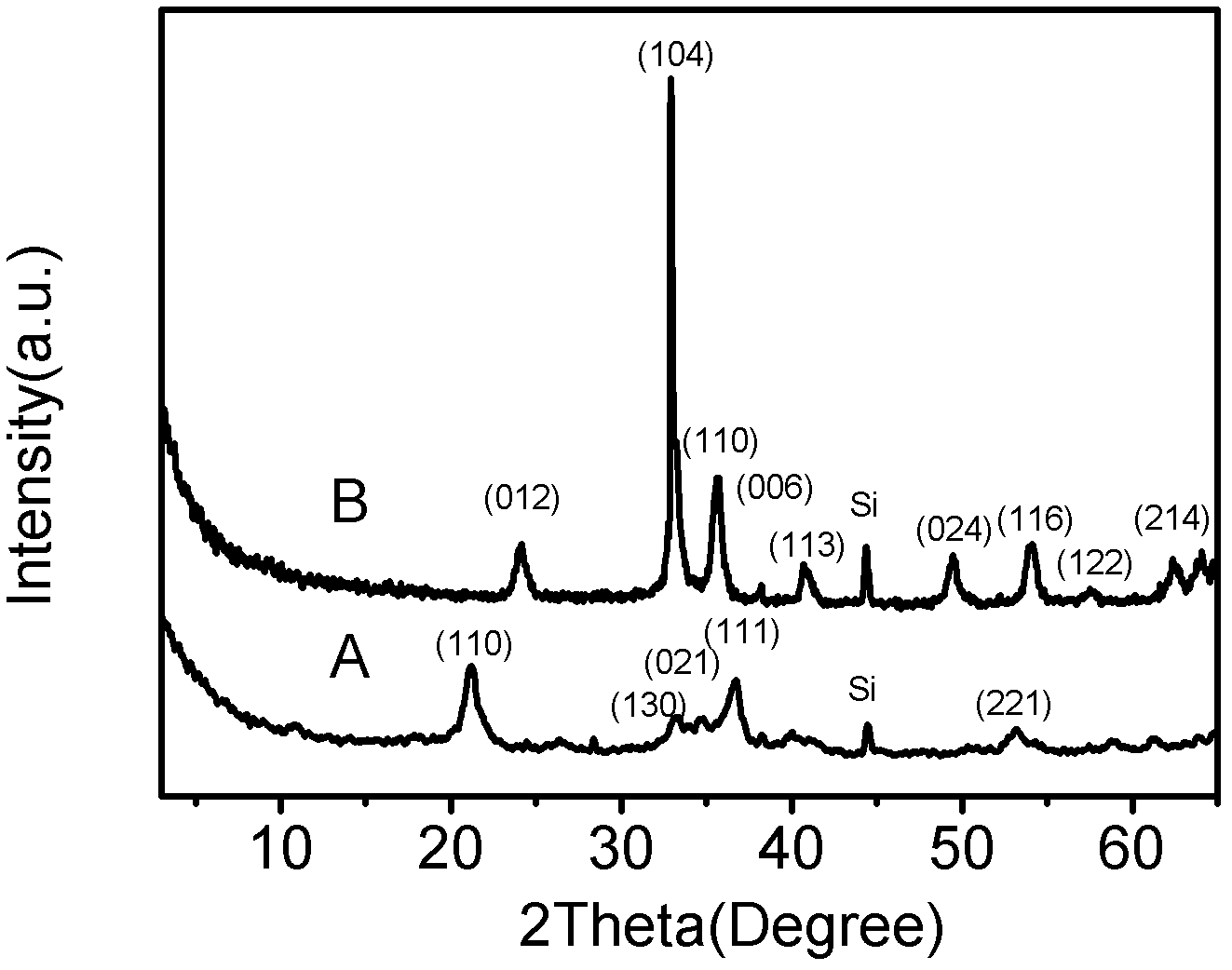

Ferrum oxyhydroxide and ferrum oxide hierarchical nanostructured material, preparation methods and applications thereof

InactiveCN103204547ALow priceReaction conditions are not harshNanotechnologyFerric oxidesFerrous saltsSolvent

The invention discloses a ferrum oxyhydroxide nano material and a ferrum oxide nano material, and preparation methods and applications thereof. The ferrum oxyhydroxide nano material and the ferrum oxide hierarchical nano material are respectively alpha-FeOOH and alpha-Fe2O3, and have a sea urchin-shaped self-assembly hierarchical nanostructure. The preparation methods comprise the steps of 1) mixing an alcoholic solvent saturated solution of sulphur with an aqueous solution of a ferrous salt and stirring to obtain a mixed colloidal particle turbid liquid of the sulphur and the ferrous salt; 2) subjecting the mixed colloidal particle turbid liquid to ultrasonic treatment to obtain a mixed colloidal particle dispersion liquid of the ferrum oxyhydroxide and the sulphur; 3) centrifuging the dispersion liquid, collecting precipitate, washing to remove the sulphur and drying, thus obtaining the ferrum oxyhydroxide nano material; and 4) calcining the ferrum oxyhydroxide nano material to obtain the ferrum oxide nano material. The ferrum oxyhydroxide nano material and the ferrum oxide nano material provided by the invention can be used in environmental treatment for removing organic pollutants from water.

Owner:INST OF CHEM CHINESE ACAD OF SCI

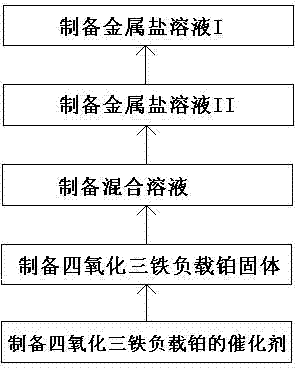

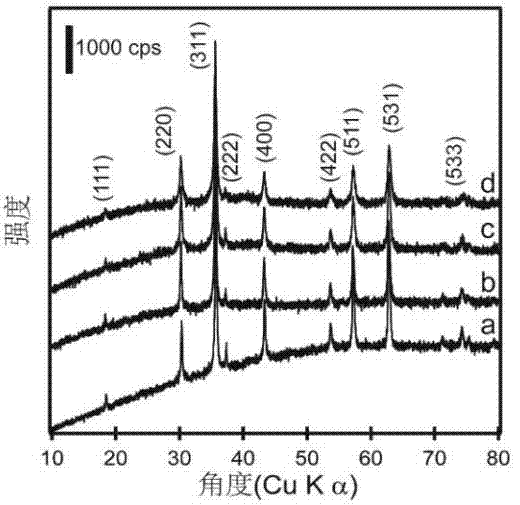

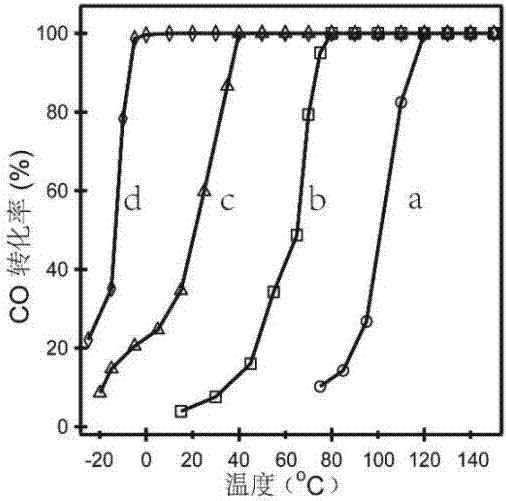

Preparation method and application of platinum-loaded ferriferrous oxide catalyst

InactiveCN104841455AThe preparation method is simple and straightforwardEasy to controlDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

The invention discloses a preparation method and application of a platinum-loaded ferriferrous oxide catalyst. The preparation method comprises the following steps: (1) preparing a metal salt solution I; (2) preparing a metal salt solution II; (3) preparing a mixed solution II; (4) preparing a platinum-loaded ferriferrous oxide solid; and (5) preparing the platinum-loaded ferriferrous oxide catalyst. According to the invention, the platinum-loaded ferriferrous oxide catalyst is prepared by using a coprecipitation method, and the preparation method has the advantages of simplicity, easy control, small time consumption in synthesis, low requirements on equipment, mild reaction conditions and good operationality; since transition metal is used as a carrier, production cost is reduced and industrial production can be easily realized; and the platinum-loaded ferriferrous oxide catalyst prepared in the invention has a small amount of platinum, a high specific surface and good CO oxidation catalytic activity and stability at room temperature and is applicable to CO oxidation at normal temperature.

Owner:EAST CHINA UNIV OF SCI & TECH

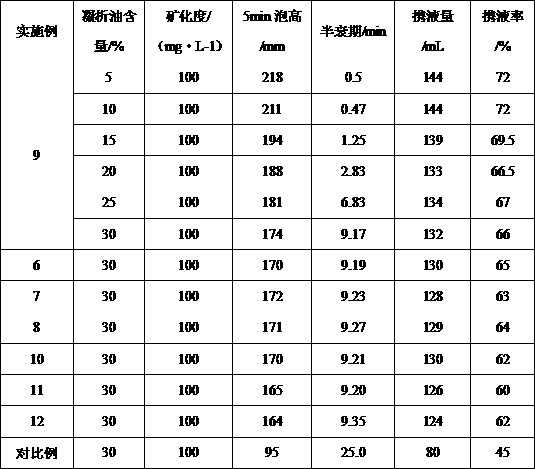

Condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and preparation method thereof

InactiveCN111139050AHigh fluid carrying capacityIncrease the lengthDrilling compositionChloroacetic acidsErucyl amide

The invention discloses a condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and a preparation method thereof. The condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent is composed of the following components in percentages by weight: 8%-22% of cocamidopropyl dimethyl tertiary amine, 3%-12% of oleamide propyl dimethyl tertiaryamine, 3%-15% of erucyl amide propyl dimethyl tertiary amine, 3%-18% of chloroacetic acid, 8%-22% of liquid caustic soda and 6%-20% of organic solution, with the balance being water. According to theinvention, through selection and specific proportion design of raw materials, the liquid carrying capacity of the foam scrubbing agent is still high under the condition of high condensate oil content;meanwhile, the liquid carrying capacity cannot be reduced along with increase of the condensate oil content; and the problem that a conventional foam scrubbing agent cannot simultaneously meet the requirements for high temperature resistance, salt resistance and condensate oil resistance is solved.

Owner:PETROCHINA CO LTD

Method for preparing Parecoxib

InactiveCN102329277BThe reaction conditions are not harshRaw materials are easy to getOrganic chemistryPropionic anhydrideHydroxylamine Hydrochloride

The invention discloses a method for preparing Parecoxib. The method for preparing the Parecoxib comprises the following steps of: performing sulfonation reaction on 1,2-diphenyl butanone serving as a raw material to obtain 1-phenyl-2-(4-sulfo phenyl)butanone; in the presence of alkali, performing condensation on the 1-phenyl-2-(4-sulfo phenyl)butanone and acetylchloride to prepare 1-phenyl-2-(4-sulfo phenyl)-2-acetyl butanone; performing cyclization on the 1-phenyl-2-(4-sulfo phenyl)-2-acetyl butanone and hydroxylamine hydrochloride to obtain 4-(5-methyl-3-phenyl-4-isoxazole)benzenesulfonic acid; performing chlorination and ammonolysis reaction to prepare Bextra; and reacting the Bextra with propionic anhydride to synthesize the Parecoxib. In the method, the raw materials are readily available and reaction conditions are not rigorous. The method is easy and convenient to operate and has certain industrialized value.

Owner:海南霞迪药业有限公司 +1

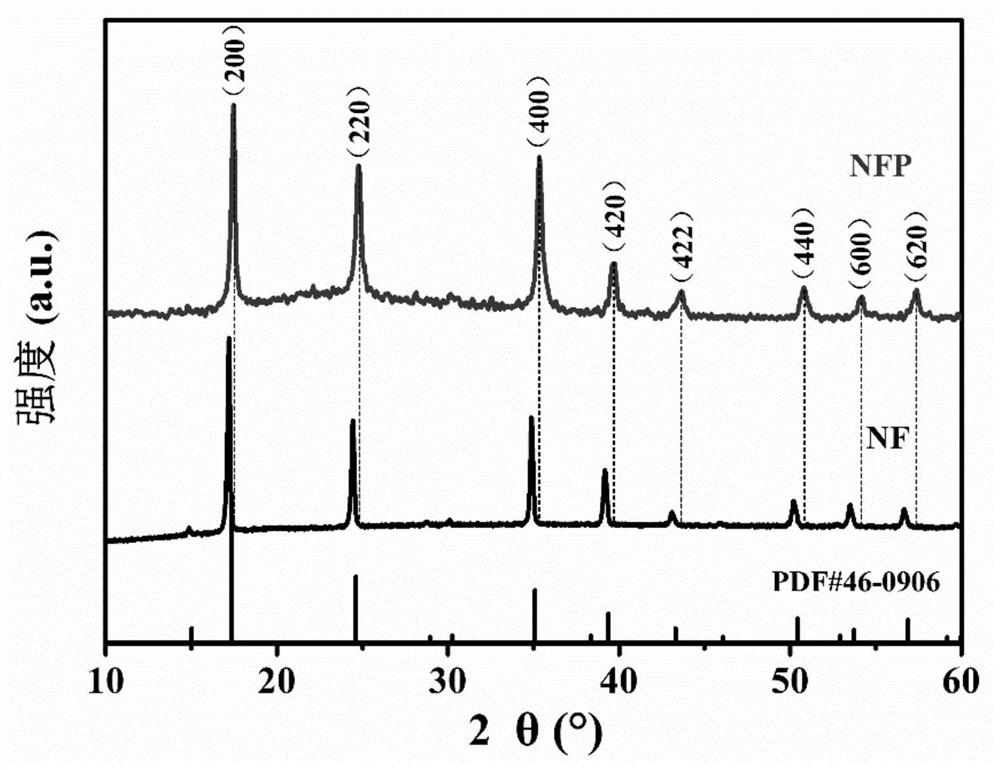

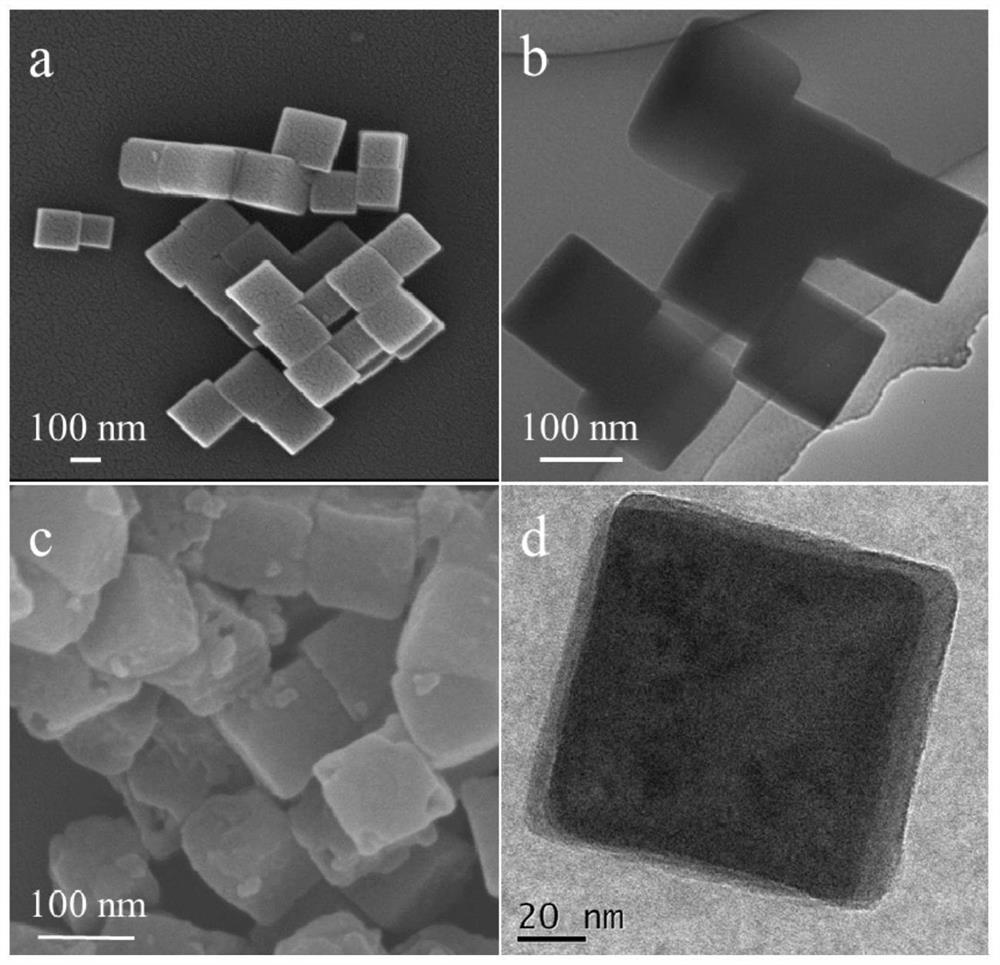

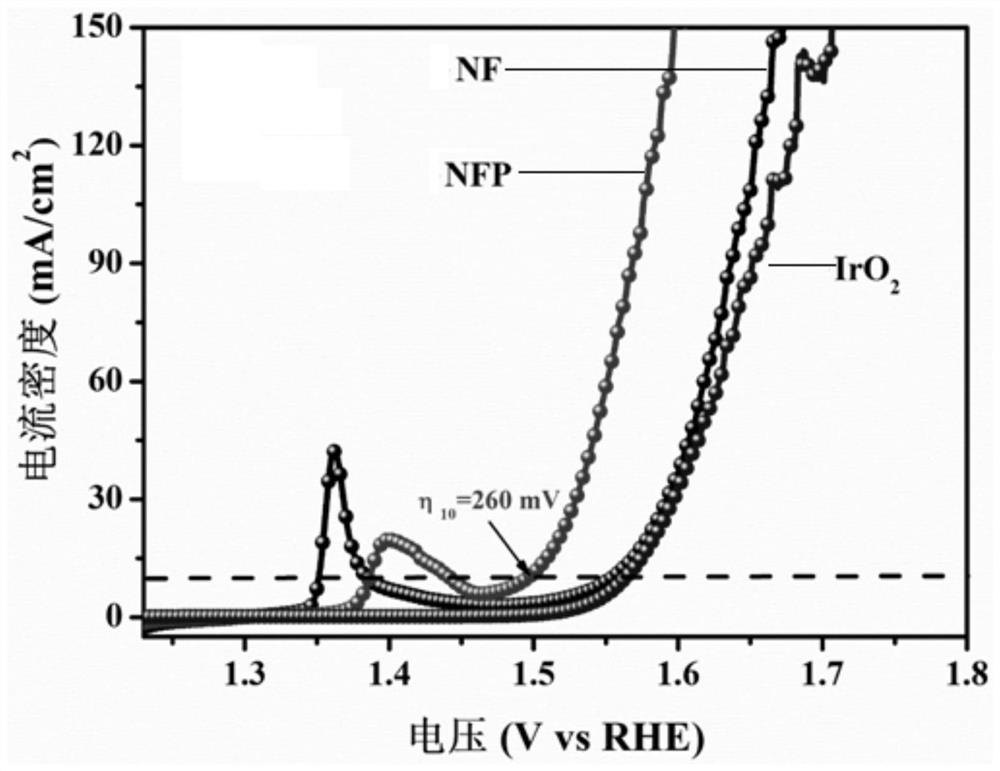

Nano-porous material anode catalyst and preparation method thereof

PendingCN111822054ASimple processThe reaction conditions are not harshOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesMaterials scienceNano porous

The invention discloses a nano-porous material anode catalyst and a preparation method thereof. The preparation method comprises the specific steps that (1) Ni (NO3) 2.6 H2O, TCD and K3 [Fe (CN) 6] serve as raw materials, and NiFe-PBA is synthesized in one step through a precipitation method; (2) dispersing the obtained NiFe-PBA in isopropanol to obtain a dispersion liquid, and mixing the dispersion liquid with an isopropanol solution containing PVP to obtain a mixed solution; and (3) carrying out solvothermal treatment on the obtained mixed solution, centrifuging, washing and drying to obtainthe nano-porous material anode catalyst. The preparation method disclosed by the invention is simple in overall process, not harsh in reaction condition and suitable for large-scale mass production preparation, and the prepared nano-porous material anode catalyst has large specific surface area and multiple catalytic active sites and has excellent electro-catalytic performance.

Owner:SHAANXI UNIV OF SCI & TECH

Method for high-selectivity co-production of nitrocyclohexane and adipic acid

InactiveCN101781217BHigh selectivityReduce generationOrganic compound preparationCarboxylic compound preparationGas phaseConcentration ratio

The invention relates to a method for the high-selectivity co-production of nitrocyclohexane and adipic acid, which adopts nitrogen oxide NOx as the nitrating and oxidizing agent, carrys out continuous gas-phase catalysis or non-catalytic nitration and oxidation reaction on cyclohexane. By effectively setting the conditions of the concentration ratio, the reaction temperature and the reaction time of the reactants and optimizing the reaction pressure as well as catalysts and assistants, the invention realizes the simultaneous high-selectivity co-production of the nitrocyclohexane and the adipic acid of different ratios, and the reduction product NO generated by the nitration and oxidation reaction can be recycled for cyclic utilization. The method of the invention has high resource efficiency, less waste generation, simple process flow and device and low production cost, and is an environment-friendly synthetic method.

Owner:XIANGTAN UNIV

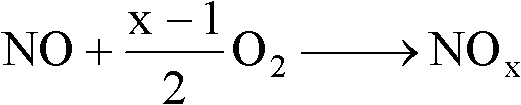

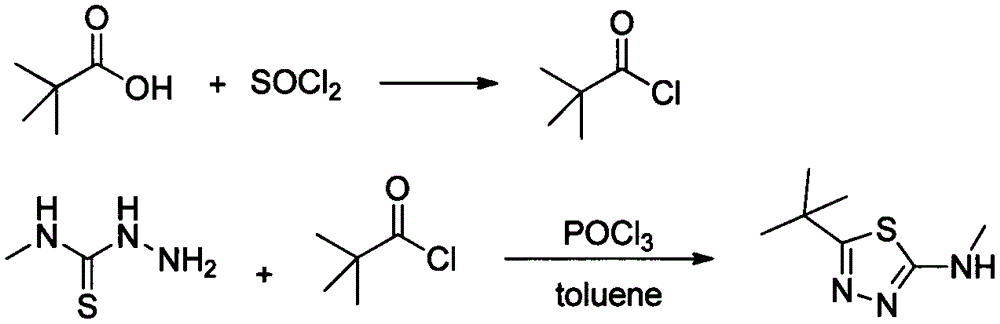

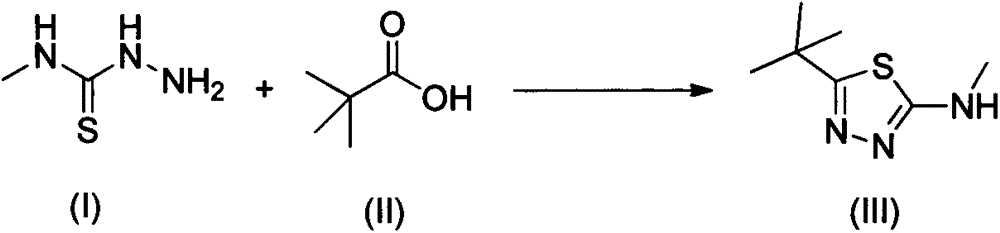

Preparation method of 2-methylamino-5-t-butyl-1,3,4-thiadiazole

ActiveCN105524017AEliminate separation and purificationThe reaction conditions are not harshOrganic chemistryPivalic acidThiourea

The invention provides a preparation method of 2-methylamino-5-t-butyl-1,3,4-thiadiazole. Pivalic acid directly used as a raw material reacts with methylthiosemicarbazide with solid phosgene or a phosgene dimer or phosgene as an acylation reagent and a cyclization reagent to synthesize 2-methylamino-5-t-butyl-1,3,4-thiadiazole. The preparation method allows highly pure 2-methylamino-5-t-butyl-1,3,4-thiadiazol to be prepared, has the advantages of very high yield, safe operation, very low production cost, solving of the defects of existing production technologies, environmental protection and no pollution.

Owner:JIANGSU HANLIAN BIOTECH CO LTD

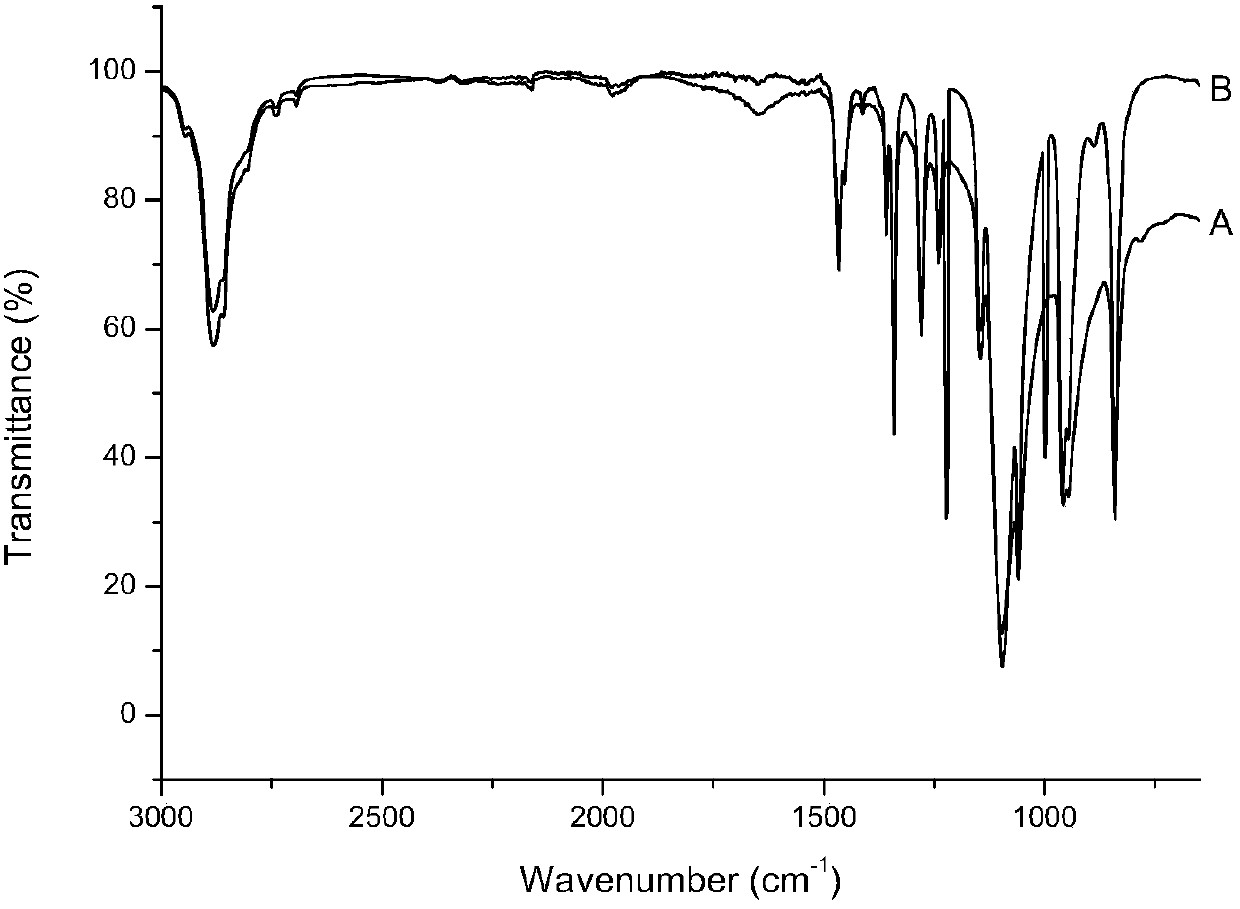

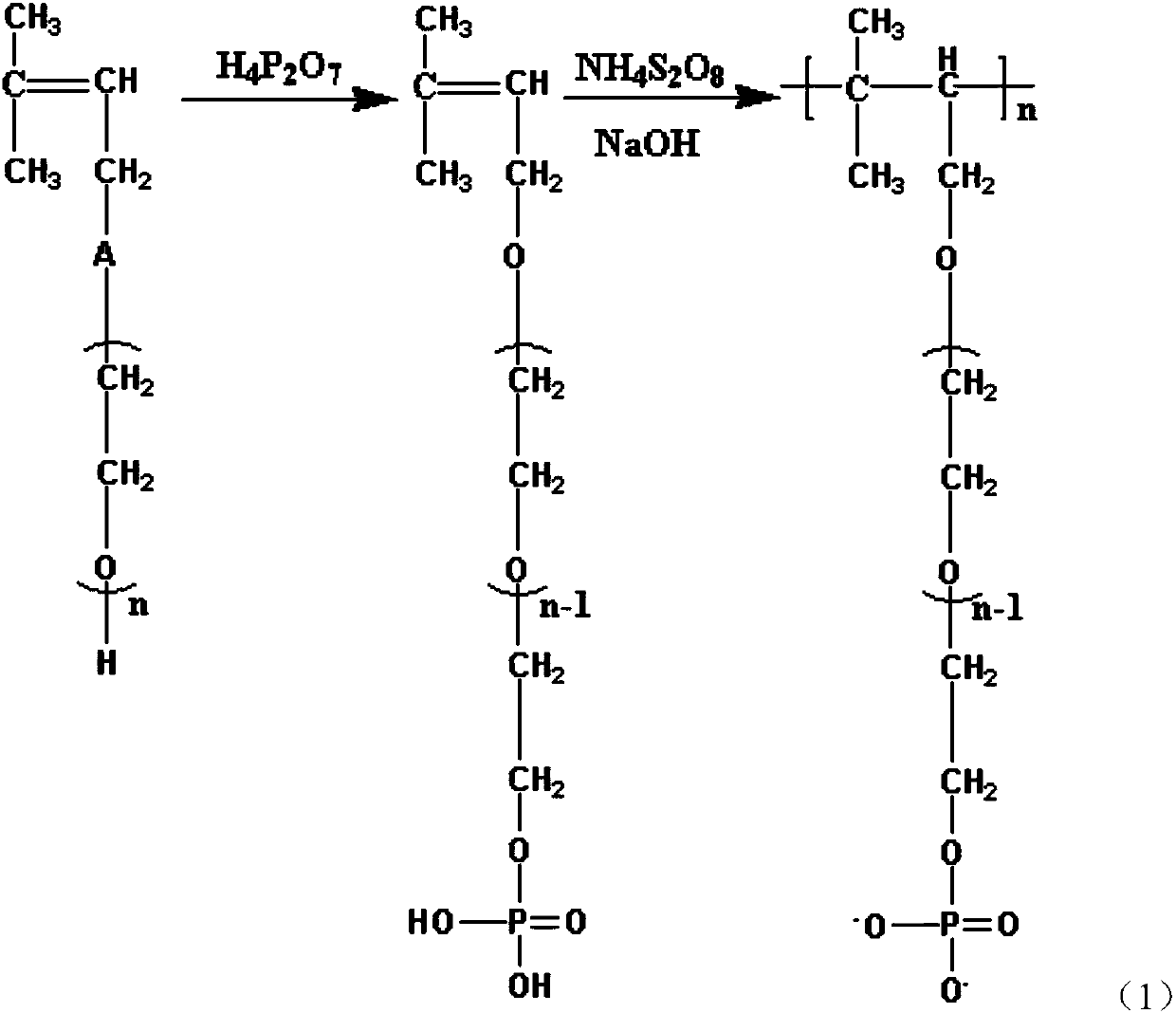

A kind of preparation method of polyphosphate ester superplasticizer

The invention discloses a preparation method for a polyphosphate water-reducing agent. The preparation method is characterized by comprising the following steps: subjecting isoamylenol polyoxyethylene ether and pyrophosphoric acid to a phosphate esterification reaction so as to obtain isoamylenol polyoxyethylene ether phosphate monomer; and then with ammonium persulfate as an initiator and mercaptopropionic acid as a conditioning agent, carrying out free radical homopolymerization in an aqueous solution so as to obtain the polyphosphate water-reducing agent. The preparation method is simple; a single, cheap and low-cost raw material is used in the method; and the obtained polyphosphate water-reducing agent is nonvolatile and basically nontoxic, and has good biodegradability, a water-reducing rate and slump loss resistance.

Owner:HEFEI UNIV OF TECH

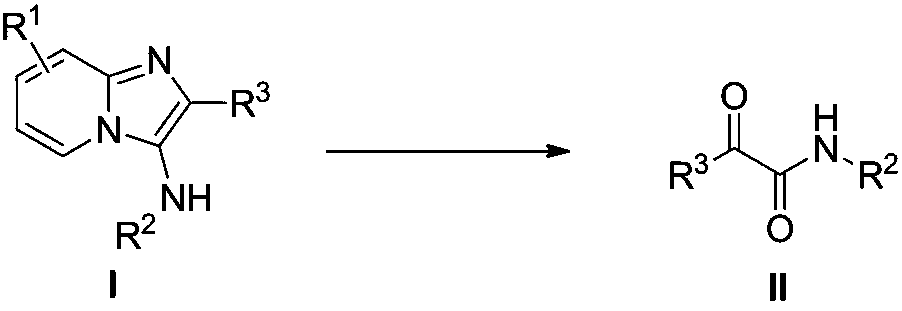

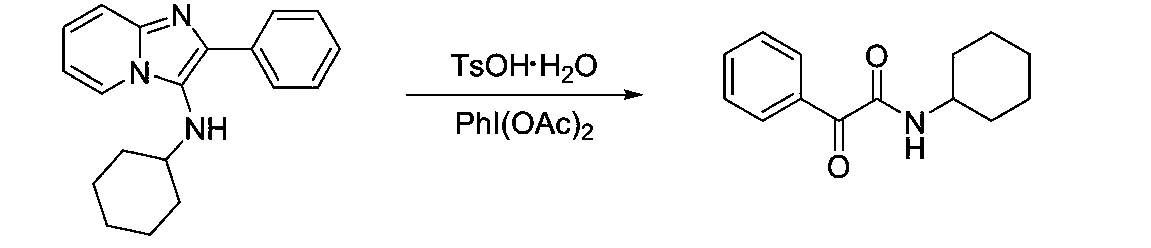

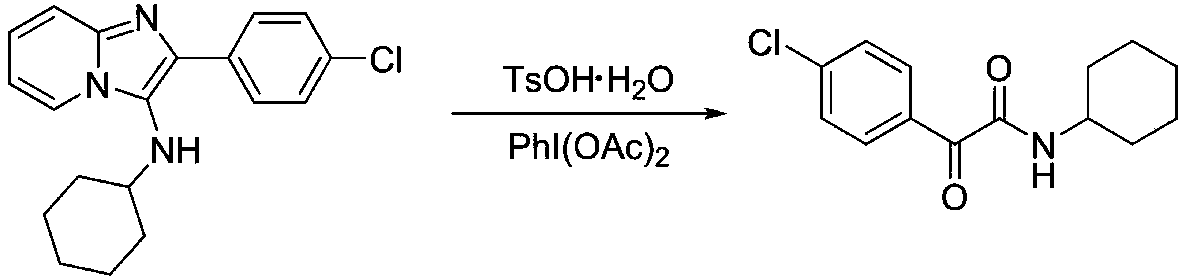

Preparation method of alpha-carbonyl amide derivatives

ActiveCN109096139AImprove economyAchieve recyclingOrganic compound preparationCarboxylic acid amides preparationAmine derivativesOxidizing agent

The invention discloses a preparation method of alpha-carbonyl amide derivatives. According to the method, pyridino-aminoimidazole compounds and water are subjected to ring-opening reaction under theaction of an oxidizing agent, meanwhile, oxygen atoms are inserted, and the alpha-carbonyl amide derivatives are prepared. The method is simple to operate, substrate universality is wide, metal catalysis is avoided in a reaction process, anhydrous and anaerobic conditions are not required, O atoms in the structure of the derivatives are derived from water, and by-products can be taken as pyridino-aminoimidazole raw materials for preparing the derivatives, thereby being recycled. The method further has the advantages of being high in yield and capable of being used for mass preparation of the alpha-carbonyl amide derivatives and preparation of part of the alpha-carbonyl amide derivatives which are relatively difficult to prepare with existing methods.

Owner:GUIZHOU UNIV

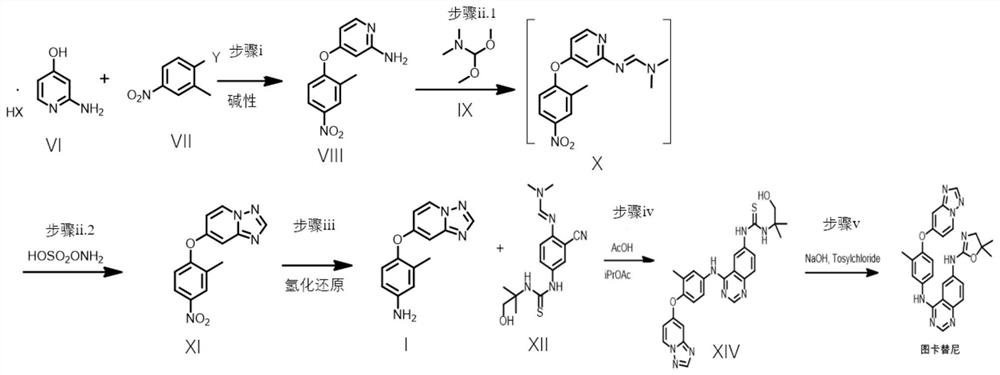

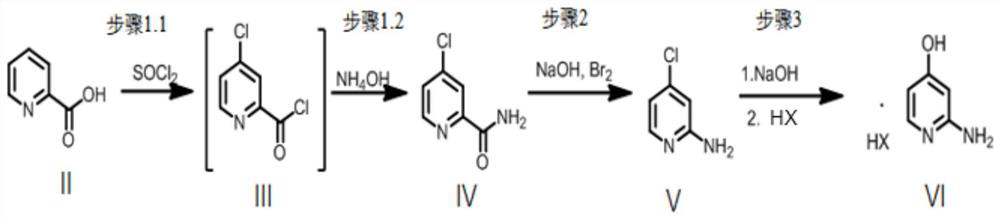

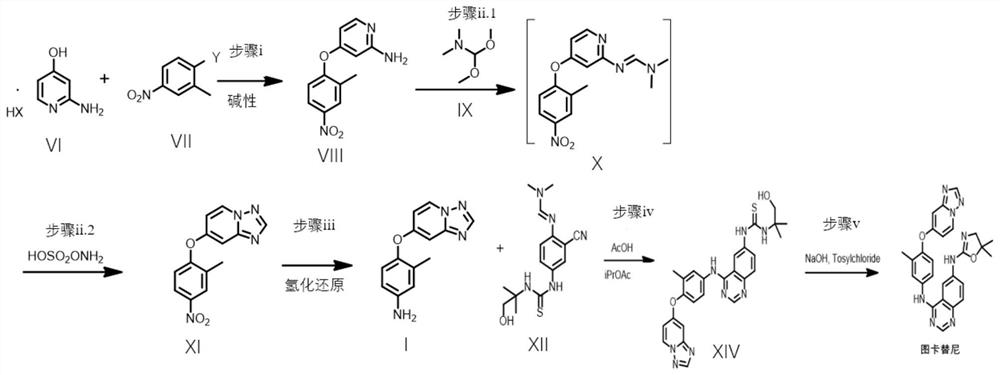

Synthesis method of Tucatinib and intermediate product thereof

PendingCN111825604AEasy accessReduce manufacturing costOrganic chemistryPtru catalystBiochemical engineering

The invention discloses a synthesis method of Tucatinib, and the method comprises the following step: carrying out substitution reaction on halate of a compound shown in a formula VI or free alkali thereof serving as a raw material and a compound shown in a formula VII under an alkaline condition to obtain a compound shown in a formula VIII. The raw materials used in the whole synthesis route areeasy to obtain, expensive catalysts are not needed, and the method is suitable for large-scale production and beneficial to industrial production of the Tucatinib.

Owner:宁波药腾医药科技有限公司

Manufacturing method of phenol and acetone

InactiveCN109776274ALower surface energyPlay a role of shielding protectionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic decompositionEvaporation

The invention discloses a manufacturing method for phenol and acetone, and relates to the technical field of chemical raw material synthesis. The manufacturing method comprises the steps that improvement is conducted on the basis of an existing method that phenol and acetone are synthesized through isopropyl benzene oxidation and selective acid catalytic decomposition, isopropyl benzene obtained after alkalization and pressurized air are subjected to a countercurrent contact reaction in an oxidation tower, falling film evaporation and two times of concentration are conducted, and then refinedcumene hydroperoxide is obtained; the refined cumene hydroperoxide is decomposed into the phenol and acetone in a moving bed reactor through catalysis of an acid resin catalyst, and then the refined phenol and acetone are obtained through water washing for deacidification, acetone roughing, acetone refining, coke cutting and secondary dealkylation. The manufacturing method has the good selectivityand yield of the phenol and acetone, the reaction conditions are not harsh and easy to control, the resin catalyst can be reused multiple times after collection and regeneration, and thus the production cost is lowered.

Owner:实友化工(扬州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com