Nano-porous material anode catalyst and preparation method thereof

A nanoporous, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of difficult to achieve catalytic effect, high OER overpotential, catalytic activity Problems such as fewer sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of nanoporous material anode catalyst of the present invention, concrete steps comprise:

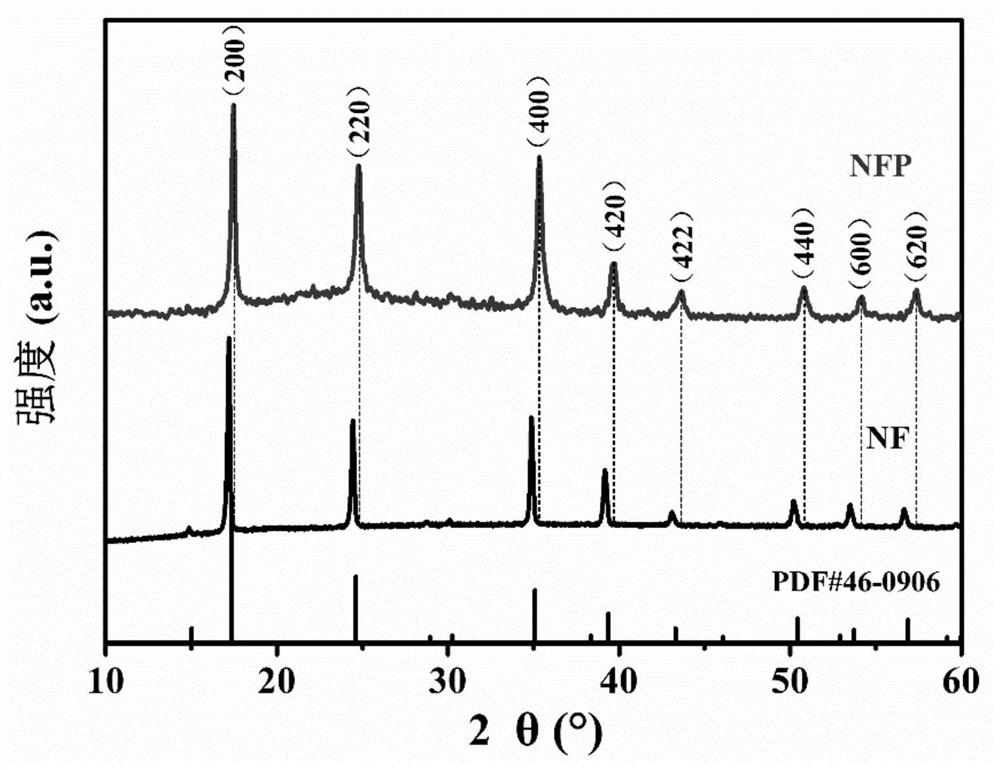

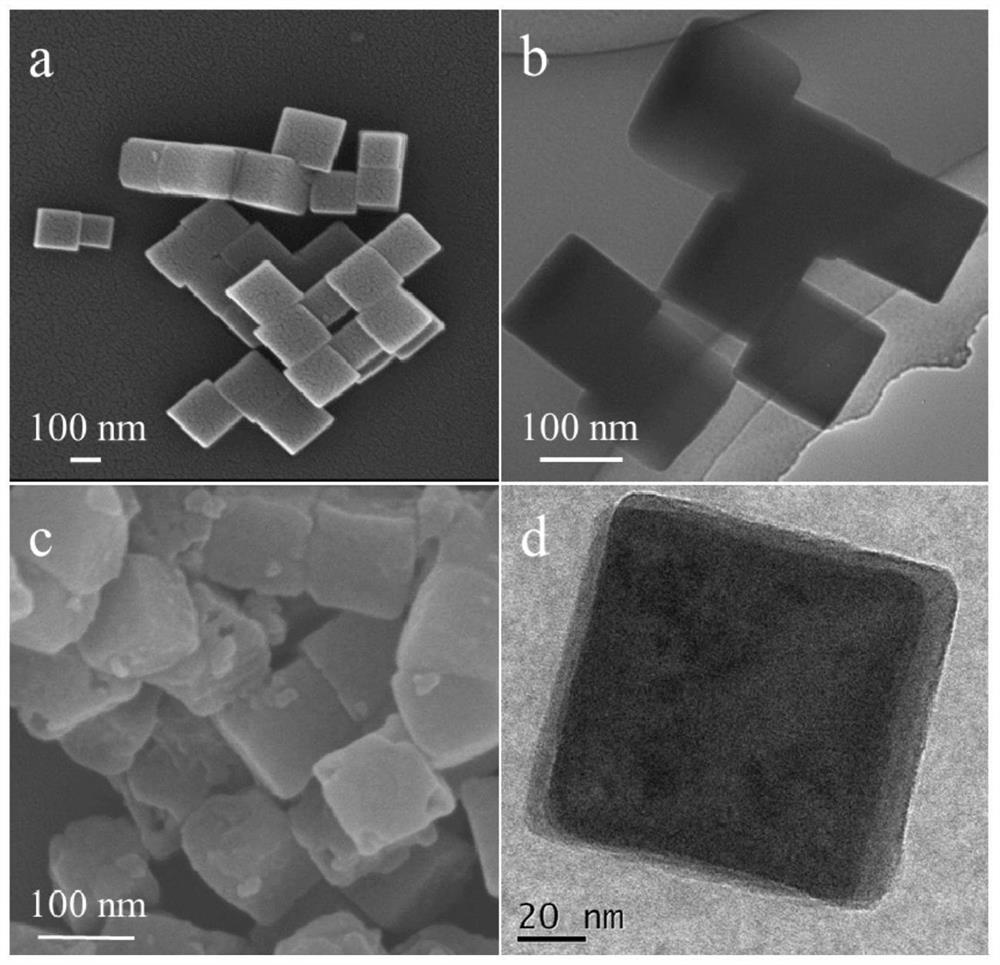

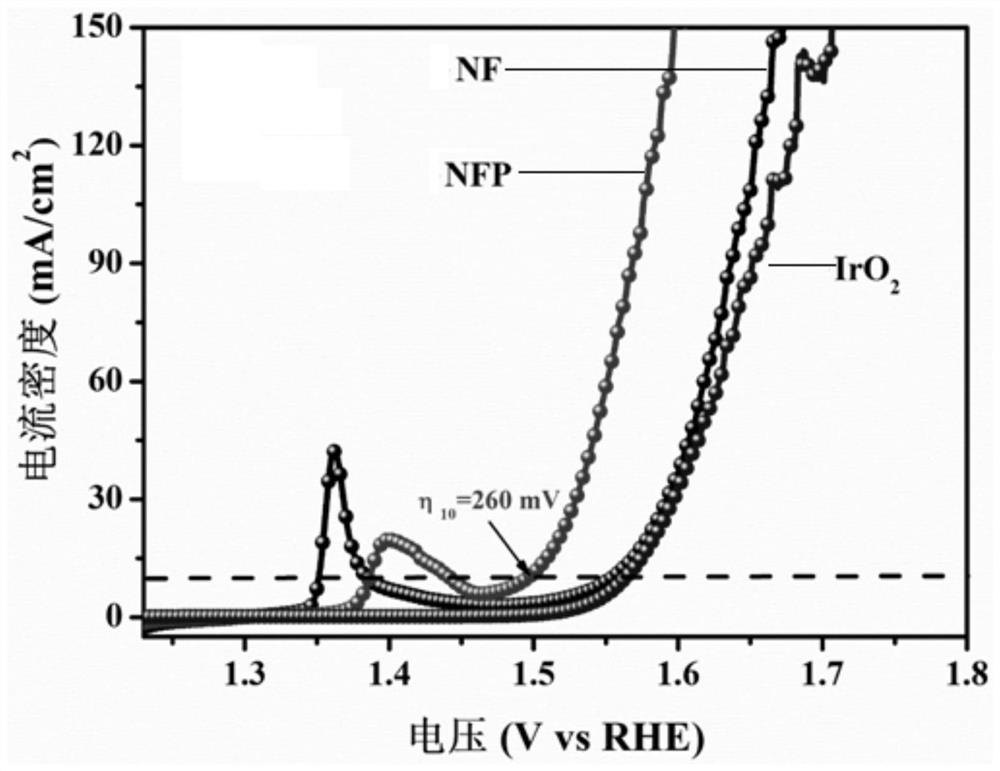

[0024] Step one: the Ni(NO of 0.6mmol 3 ) 2 ·6H 2 O and 0.9 mmol of TCD (sodium citrate dihydrate, the chemical formula is Na 3 C 6 h 5 o 7 2H 2 O) be dissolved in the deionized water of 20mL and form solution A, the K of 0.4mmol 3 [Fe(CN) 6 ] was dissolved in 20mL of deionized water to form solution B, then solution A was poured into solution B under vigorous stirring and continued to stir vigorously for 5min to obtain a mixture, the resulting mixture was left to stand for 20h and then centrifuged at 8000rpm / min, centrifuged After 10 minutes, the obtained precipitate was washed three times with deionized water and ethanol, and dried at 60°C for 24 hours to obtain the precursor NiFe-PBA, namely NF;

[0025] Step 2: Take 20 mg of the precursor NiFe-PBA obtained in Step 1 and disperse it in 20 mL of isopropanol to obtain a dispersion, and disperse it ...

Embodiment 2

[0032] The preparation method of nanoporous material anode catalyst of the present invention, concrete steps comprise:

[0033] Step one: the Ni(NO of 0.6mmol 3 ) 2 ·6H 2 O and 0.9 mmol of TCD (sodium citrate dihydrate, the chemical formula is Na 3 C 6 h 5 o 7 2H 2 O) be dissolved in the deionized water of 20mL and form solution A, the K of 0.4mmol 3 [Fe(CN) 6 ] was dissolved in 20mL of deionized water to form solution B, then solution A was poured into solution B under vigorous stirring and continued to stir vigorously for 5min to obtain a mixture, the resulting mixture was left to stand for 20h and then centrifuged at 8000rpm / min, centrifuged After 10 minutes, the obtained precipitate was washed three times with deionized water and ethanol, and dried at 60°C for 24 hours to obtain the precursor NiFe-PBA, namely NF;

[0034]Step 2: Take 20 mg of the precursor NiFe-PBA obtained in Step 1 and disperse it in 20 mL of isopropanol to obtain a dispersion, and disperse it u...

Embodiment 3

[0037] The preparation method of nanoporous material anode catalyst of the present invention, concrete steps comprise:

[0038] Step one: the Ni(NO of 0.6mmol 3 ) 2 ·6H 2 O and 0.9 mmol of TCD (sodium citrate dihydrate, the chemical formula is Na 3 C 6 h 5 o 7 2H 2 O) be dissolved in the deionized water of 20mL and form solution A, the K of 0.4mmol 3 [Fe(CN) 6 ] was dissolved in 20mL of deionized water to form solution B, then solution A was poured into solution B under vigorous stirring and continued to stir vigorously for 5min to obtain a mixture, the resulting mixture was left to stand for 20h and then centrifuged at 8000rpm / min, centrifuged After 10 minutes, the obtained precipitate was washed three times with deionized water and ethanol, and dried at 60°C for 24 hours to obtain the precursor NiFe-PBA, namely NF;

[0039] Step 2: Take 20 mg of the precursor NiFe-PBA obtained in Step 1 and disperse it in 20 mL of isopropanol to obtain a dispersion, and disperse it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com