A kind of preparation method of polyphosphate ester superplasticizer

A technology of polyphosphate ester and water reducer, which is applied in the field of preparation of polyphosphate ester water reducer, can solve the problems of hindering the adsorption of water reducer and cement, the volatile environment of carboxylic acid, and the limitation of work performance, etc. Harsh, inexpensive, low-cost-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

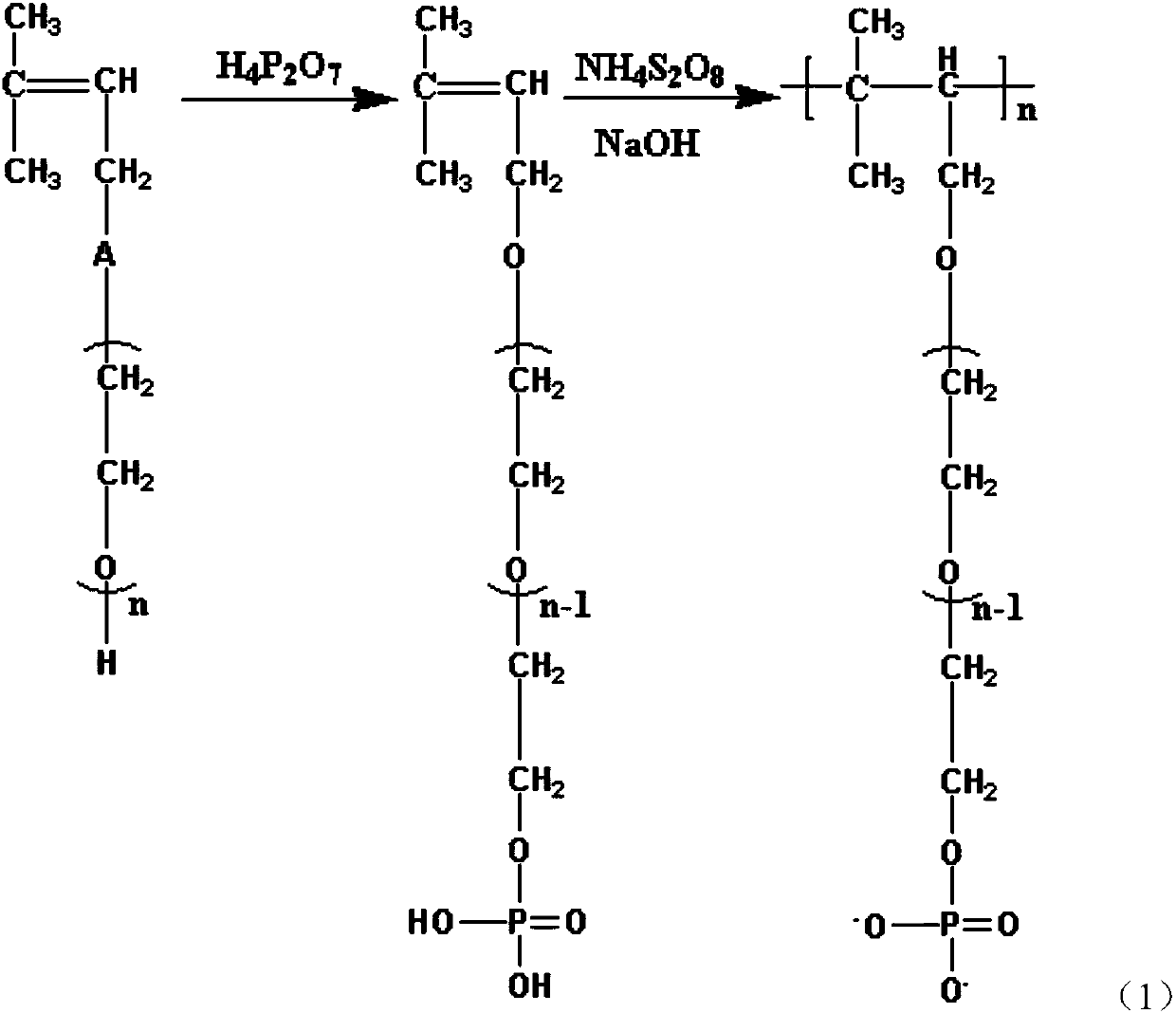

Method used

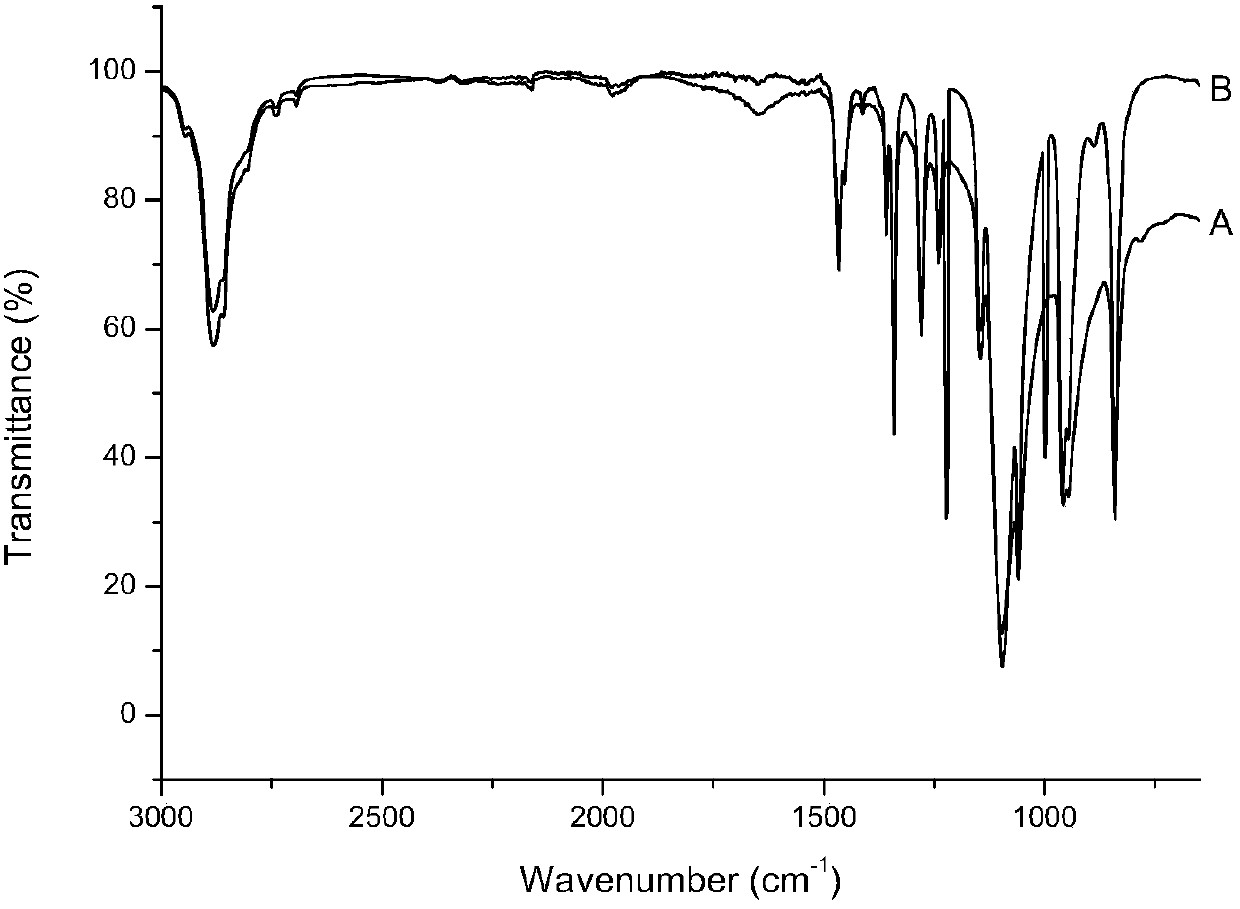

Image

Examples

Embodiment 1

[0018] In the preparation of the polyphosphate water reducer in this example: the molar ratio of isopentenol polyoxyethylene ether to pyrophosphoric acid is 1:1, the phosphating reaction temperature is 80°C, and the reaction time is 12h; the free radical homopolymerization temperature The temperature is 80°C, the mass of the initiator ammonium persulfate is 2% of the mass of the monomer, the mass of the regulator mercaptopropionic acid is 1% of the mass of the monomer, the dropping time is 2h, and the temperature is kept for 1h. The specific preparation process is:

[0019] Accurately weigh 24g of prenol polyoxyethylene ether (Mn=2400) and 1.98g of pyrophosphoric acid in a 100mL three-necked flask, fix them in an oil bath at 80°C, blow in nitrogen gas for 30min, and then react in a closed and constant temperature for 12h, and the reaction ends Then add 10g deionized water;

[0020] Weigh 0.48g of ammonium persulfate and 0.24g of mercaptopropionic acid and dissolve them in 10g...

Embodiment 2

[0026] In the preparation of the polyphosphate water reducer in this example: the molar ratio of isopentenol polyoxyethylene ether to pyrophosphoric acid is 1:1, the phosphating reaction temperature is 80°C, the reaction time is 12h, and the free radical polymerization temperature is 80°C, the mass of the initiator ammonium persulfate is 1% of the mass of the monomer, the mass of the regulator mercaptopropionic acid is 1% of the mass of the monomer, the dropping time is 2h, and the temperature is kept for 1h. The specific preparation process is:

[0027] Accurately weigh 24g of prenol polyoxyethylene ether (Mn=2400) and 1.98g of pyrophosphoric acid in a 100mL three-necked flask, fix them in an oil bath at 80°C, blow in nitrogen gas for 30min, and then react in a closed and constant temperature for 12h, and the reaction ends Then add 10g deionized water;

[0028] Weigh 0.24g of ammonium persulfate and 0.24g of mercaptopropionic acid and dissolve them in 10g of deionized water....

Embodiment 3

[0034] In the preparation of polyphosphate water reducer in this example: the molar ratio of isopentenol polyoxyethylene ether and pyrophosphoric acid is 1:1, the phosphating reaction temperature is 80°C, and the reaction time is 12h; the free radical polymerization temperature is 80°C, the mass of the initiator ammonium persulfate is 1% of the mass of the monomer, the mass of the regulator mercaptopropionic acid is 0.8% of the mass of the monomer, the dropping time is 2h, and the temperature is kept for 1h. The specific preparation process is:

[0035] Accurately weigh 24g of prenol polyoxyethylene ether (Mn=2400) and 1.98g of pyrophosphoric acid in a 100mL three-necked flask, fix them in an oil bath at 80°C, blow in nitrogen gas for 30min, and then react in a closed and constant temperature for 12h, and the reaction ends Then add 10g deionized water;

[0036] Weigh 0.24g of ammonium persulfate and 0.192g of mercaptopropionic acid and dissolve them in 10g of deionized water....

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com