Preparation method of polycrystalline nano cuprous oxide particles

A nano cuprous oxide and particle technology, applied in the field of nano materials, can solve the problems of affecting the purity of the final product, long reaction time, affecting the product, etc., and achieve the effects of shortening preparation time, short reaction time and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

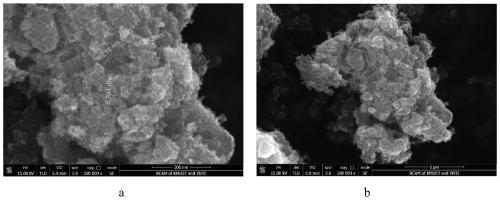

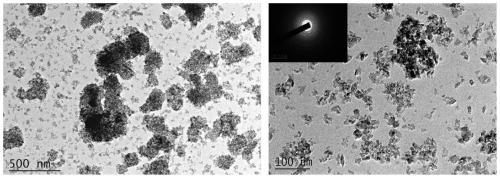

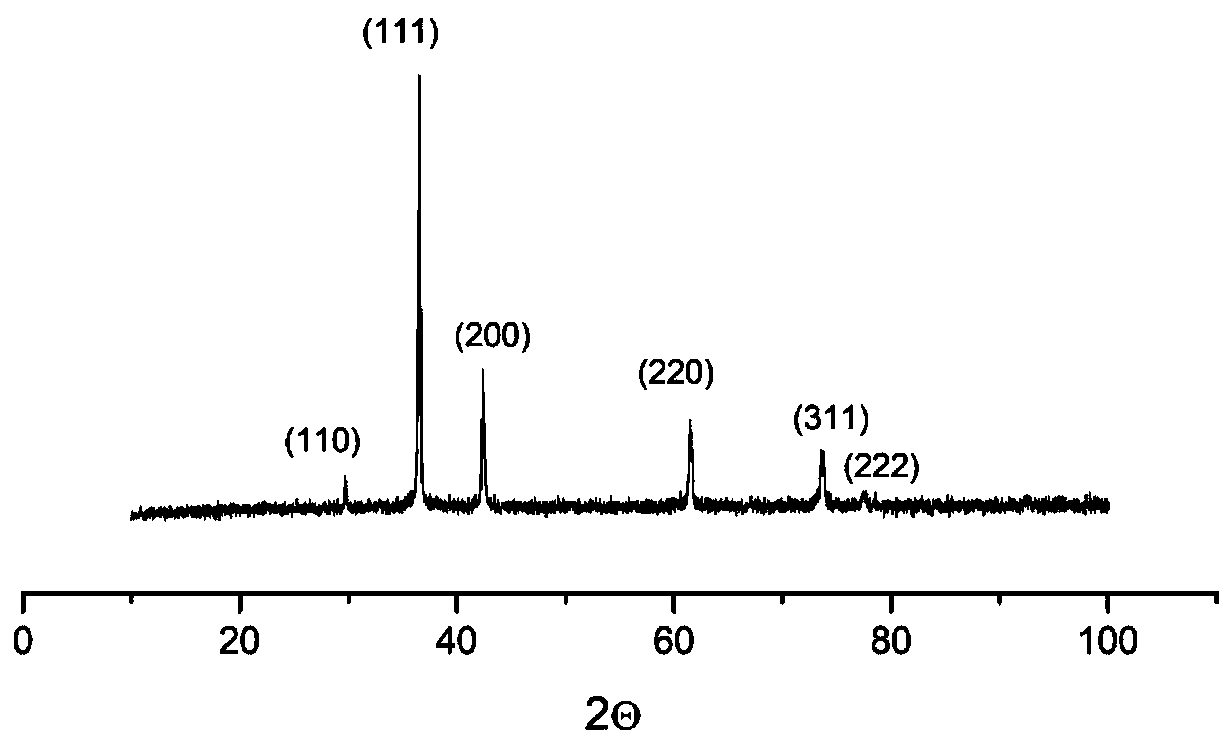

Embodiment 1

[0044] Take 60ml of 98% ethylene glycol and put it in a 300mL beaker, weigh 13.8mmol of copper acetate and add it to the ethylene glycol solution, and stir it magnetically for 30 minutes. After the copper acetate is completely dissolved, the ethylene glycol solution of copper acetate is obtained. Dissolve 18g of glucose in 100ml of deionized water to prepare a 0.18g / ml glucose solution. Take 5ml of glucose solution and slowly add it dropwise to the ethylene glycol solution of copper acetate, continue to stir until the solution is uniform, transfer the mixed solution to a polytetrafluoroethylene reaction liner, place it in an inverter microwave oven, set the power to 400W, and react for 10 minutes Afterwards the mixture turned dark red, indicating the formation of cuprous oxide. The reaction product was centrifugally filtered, washed 3-5 times with absolute ethanol and deionized water, and finally the washed sample was dried in a vacuum oven at 55°C for 3 hours to obtain nano-C...

Embodiment 2

[0046] Take 60ml of 98% ethylene glycol and put it in a 300mL beaker, weigh 10.8mmol of copper acetate and add it to the glycerol solution, and stir it magnetically for 30min. After the copper acetate is completely dissolved, a glycerol solution of copper acetate is obtained. Dissolve 16g of glucose in 100ml of deionized water to prepare a 0.16g / ml glucose solution. Take 5ml of glucose solution and slowly add it dropwise to the glycerol solution of copper acetate, continue to stir until the solution is uniform, transfer the mixed solution to a polytetrafluoroethylene reaction liner, place it in an inverter microwave oven, set the power to 500W, and react for 9 minutes Afterwards the mixture turned dark red, indicating the formation of cuprous oxide. The reaction product was centrifugally filtered, washed 3-5 times with absolute ethanol and deionized water, and finally the washed sample was dried in a vacuum oven at 58°C for 3 hours to obtain nano-Cu 2 O polycrystalline powder...

Embodiment 3

[0048] Take 60ml of 98% copper nitrate and put it in a 300mL beaker, weigh 7.41mmol of copper nitrate and add it to the triethanolamine solution, stir magnetically for 30min, and after the copper acetate is completely dissolved, a triethanolamine solution of copper nitrate is obtained. Dissolve 15g of glucose in 100ml of deionized water to prepare a 0.15g / ml glucose solution. Take 5ml of glucose solution and slowly add it dropwise to the triethanolamine solution of copper nitrate, continue to stir until the solution is uniform, then transfer the mixed solution to a polytetrafluoroethylene reaction liner, place it in an inverter microwave oven, set the power to 600W, and react for 8 minutes The mixture turned dark red, indicating the formation of cuprous oxide. The reaction product was centrifugally filtered, washed with absolute ethanol and deionized water for 3-5 times, and finally the washed sample was dried in a vacuum oven at 60°C for 3 hours to obtain nano-Cu 2 O polycry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com