Fiber-hybrid high-ductility cement-based composite material and preparation method thereof

A composite material and cement-based technology, which is applied in the field of fiber-reinforced cement-based composite materials and cement-based composite materials, can solve the problems of increasing material production energy consumption, reducing material preparation efficiency, and time-consuming preparation process, so as to shorten preparation time, The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The weight ratio of cement, mineral admixture, fine aggregate, fiber, water and admixture is: 24.7%:32.9%:24.7%:1.17%:16.5%:0.19%. The mix ratio uses polypropylene fiber and glass fiber, and the weight ratio of the two fibers is: 63.6%:36.4%. Add the weighed cement, mineral admixture and fine aggregate into the mixer and dry mix for 2 minutes; dissolve the admixture in water, then slowly add them into the mixing bucket and stir for 5 minutes; sprinkle the fiber into the mixing bucket Inside, stir for another 7 minutes.

[0035] The mineral admixture is fly ash; the fine aggregate is mixed with quartz stone powder and river sand in a weight ratio of 1:1; the admixture is made of polycarboxylate high-performance water reducer And polyacrylic acid thickener composition.

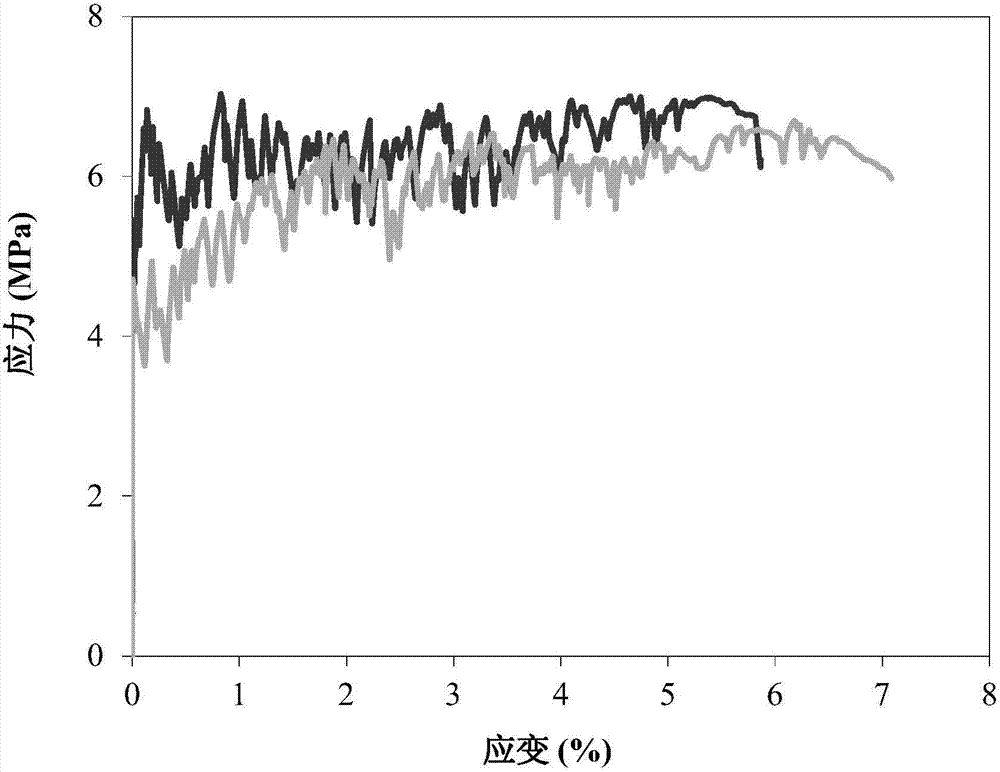

[0036] The material properties after 28 days are as follows: the tensile strength is 4.0MPa, the ultimate elongation is 3.2%, the flexural strength is 10.3MPa, and the compressive strength is 50.5MPa. ...

Embodiment 2

[0038]The weight ratio of cement, mineral admixture, fine aggregate, fiber, water and admixture is: 40.8%:24.5%:16.8%:1.29%:16.3%:0.37%. The mixing ratio uses polypropylene fiber, polyvinyl alcohol fiber and glass fiber, and the weight ratio of the three fibers is: 53.7%:25.8%:20.5%. Add the weighed cement, mineral admixture and fine aggregate into the mixer, and dry mix for 2 minutes; dissolve the admixture in water, then slowly add them into the mixing bucket, and stir for 6 minutes; sprinkle the fiber into the mixing bucket Inside, stir for another 10 minutes.

[0039] The mineral admixture is made by mixing fly ash and silica fume in a weight ratio of 8:1; the fine aggregate is quartz stone powder; the admixture is made of polycarboxylate high-performance water reducer And polyacrylic acid thickener composition.

[0040] The material properties after 28 days are as follows: the tensile strength is 6.3MPa, the ultimate elongation is 1.9%, the flexural strength is 17.9MPa,...

Embodiment 3

[0042] The weight ratio of cement, mineral admixture, fine aggregate, fiber, water and admixture is: 33.5%:31.3%:18.4%:1.4%:14.6%:0.8%. The mixing ratio uses polypropylene fiber and polyethylene fiber, and the weight ratio of the two fibers is: 48.4%:51.6%. Add the weighed cement, mineral admixture and fine aggregate into the mixer and dry mix for 3 minutes; dissolve the admixture in water, then slowly add them into the mixing bucket and stir for 8 minutes; sprinkle the fiber into the mixing bucket Inside, stir for another 8 minutes.

[0043] The mineral admixture is formed by mixing finely ground slag powder and silica fume in a weight ratio of 10:1; the fine aggregate is formed by mixing limestone powder and river sand in a weight ratio of 2:5; the The admixture described above is composed of polycarboxylate high-performance water reducer and polyacrylic acid thickener.

[0044] The properties of the material after 28 days are as follows: the tensile strength is 6.8MPa, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com