Method for high-selectivity co-production of nitrocyclohexane and adipic acid

A nitrocyclohexane, high-selectivity technology, applied in chemical instruments and methods, nitro compound preparation, carboxylate preparation, etc., can solve the problem of low single-pass conversion rate and KA oil yield, slow progress, nitric acid consumption problems such as major problems, to achieve the effect of simplifying the process and equipment, simplifying the process, and generating less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

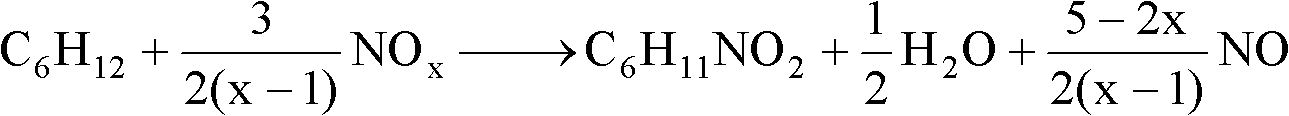

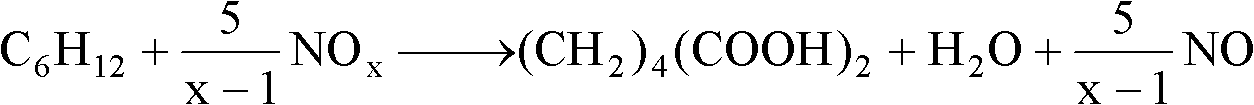

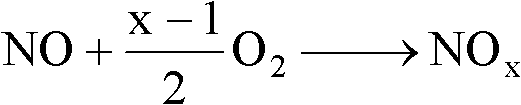

Method used

Image

Examples

Embodiment 1

[0022] Liquid cyclohexane is input by advection pump, and after being vaporized in the preheating section, according to cyclohexane: NO 2 =2:1 molar ratio with NO 2 Mixed into the tube reactor, the reaction is carried out at 300 ° C, the average residence time of the gas phase mixture is about 50 seconds, the reaction product from the reactor is condensed into the collection bottle through the condenser. The mixture in the collection bottle separated into two layers. After the upper layer was analyzed with the internal standard of gas chromatography, the conversion rate of cyclohexane was calculated by using material balance to be 15.5%, and the selectivity of nitrocyclohexane was 67.2%; Heavy, the selectivity of its adipic acid is 5.2%; the total selectivity of the two is 72.4%, and the selectivity of other by-products is 27.6%

Embodiment 2

[0024] The reaction steps are the same as in Example 1, except that the reaction temperature is 250°C. The conversion rate of cyclohexane is 12.6%, the selectivity of nitrocyclohexane is 78.1%, the selectivity of adipic acid is 21.8%, the total selectivity of the two is 99.9%, almost no other by-products are produced.

Embodiment 3

[0026] The reaction steps are the same as in Example 1, except that the reaction temperature is 200°C. The conversion rate of cyclohexane is 6.5%, the selectivity of nitrocyclohexane is 73.9%, the selectivity of adipic acid is 5.3%, the total selectivity of the two is 79.2%, and the selectivity of other by-products is 20.8% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com