Method capable of realizing volume production and used for preparing micron order single-dispersibility polysiloxane microspheres

A technology of polyorganosiloxane and monodispersity, which is applied in the field of preparing micron-sized monodisperse polyorganosiloxane microspheres that are easy to mass-produce, and can solve the problem that is not conducive to mass production of micron-sized polyorganosiloxane microspheres. Problems such as complex selection and design of balls and equipment, harsh reaction conditions, etc., to achieve the effect of truly controllable particle size, mass production, and less harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step ①, add 400g of deionized water and 2g of KOH solid powder into the reactor equipped with a stirrer, the temperature is 15°C at room temperature, the stirring speed is 250rpm, the time is 15min, and the pH value is 10.65.

[0033] In step ②, add 8.8 g of methyltrimethoxysilane monomer solution to the basic catalyst solution in step ① to prepare a seed solution, the temperature is 15° C. at room temperature, the stirring speed is 300 rpm, and the time is 20 min.

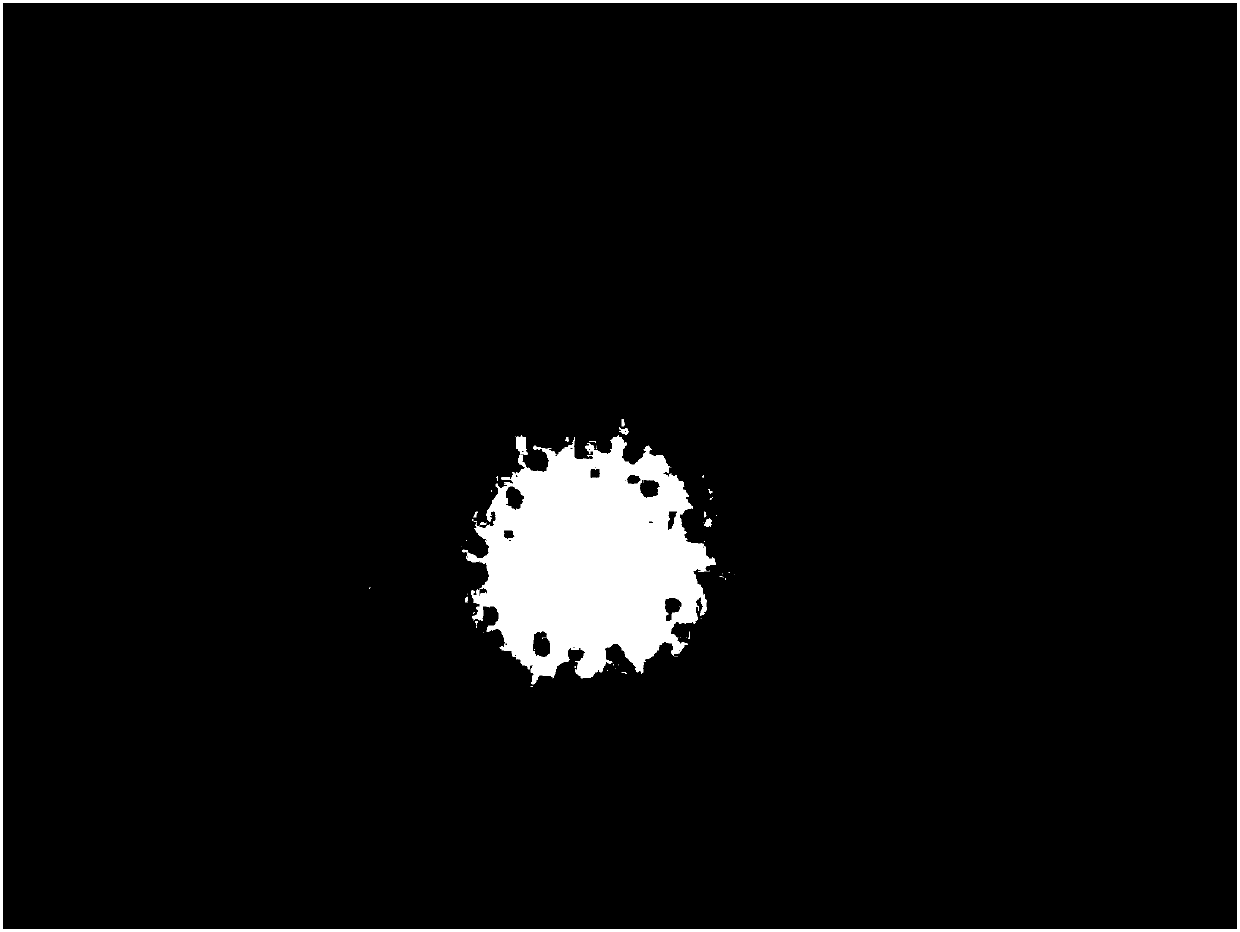

[0034] In step ③, add 56g of methyltrimethoxysilane monomer solution to the seed solution obtained in step ② to carry out polycondensation reaction. The temperature is 15°C at room temperature, the stirring speed is 250rpm, and the time is 30min. The obtained product is filtered and washed with deionized water , and dried at 150°C for 8h to obtain 29.45g of micron-sized monodisperse organosiloxane microspheres with an average particle size of 2.15μm, such as figure 2 shown.

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] Step ② Add 6 g of methyltrimethoxysilane monomer solution to prepare a seed solution. The temperature is 21° C. at room temperature, the stirring speed is 350 rpm, and the time is 20 minutes.

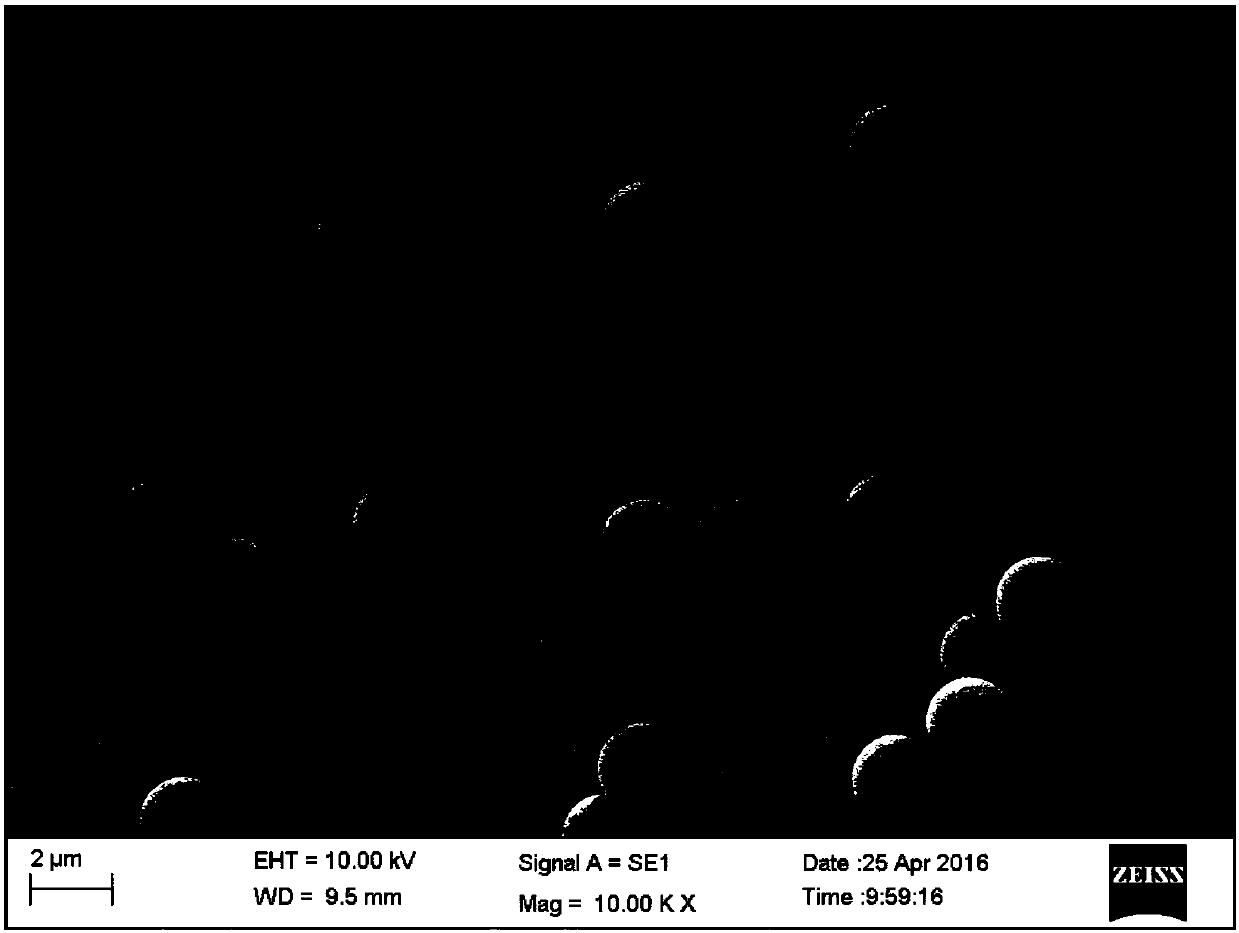

[0038] Step ③Add 75g of methyltrimethoxysilane monomer solution to carry out polycondensation reaction. The temperature is 21°C at room temperature, the stirring speed is 300rpm, and the time is 30min. The obtained product is filtered, washed with deionized water, and dried at 150°C for 8h to obtain micron single Dispersion grade silicone microspheres 36.8g, average particle size 2.5μm, such as image 3 shown.

Embodiment 3

[0040] Step ①, add 380g of deionized water and 4g of NaOH solid powder into the reactor equipped with a stirrer, the temperature is 22°C at room temperature, the stirring speed is 380rpm, the time is 18min, and the pH value is 12.55.

[0041] In step ②, add 9.4 g of phenyltrimethoxysilane monomer solution to the basic catalyst solution in step ① to prepare a seed solution. The temperature is 22° C. at room temperature, the stirring speed is 350 rpm, and the time is 25 minutes.

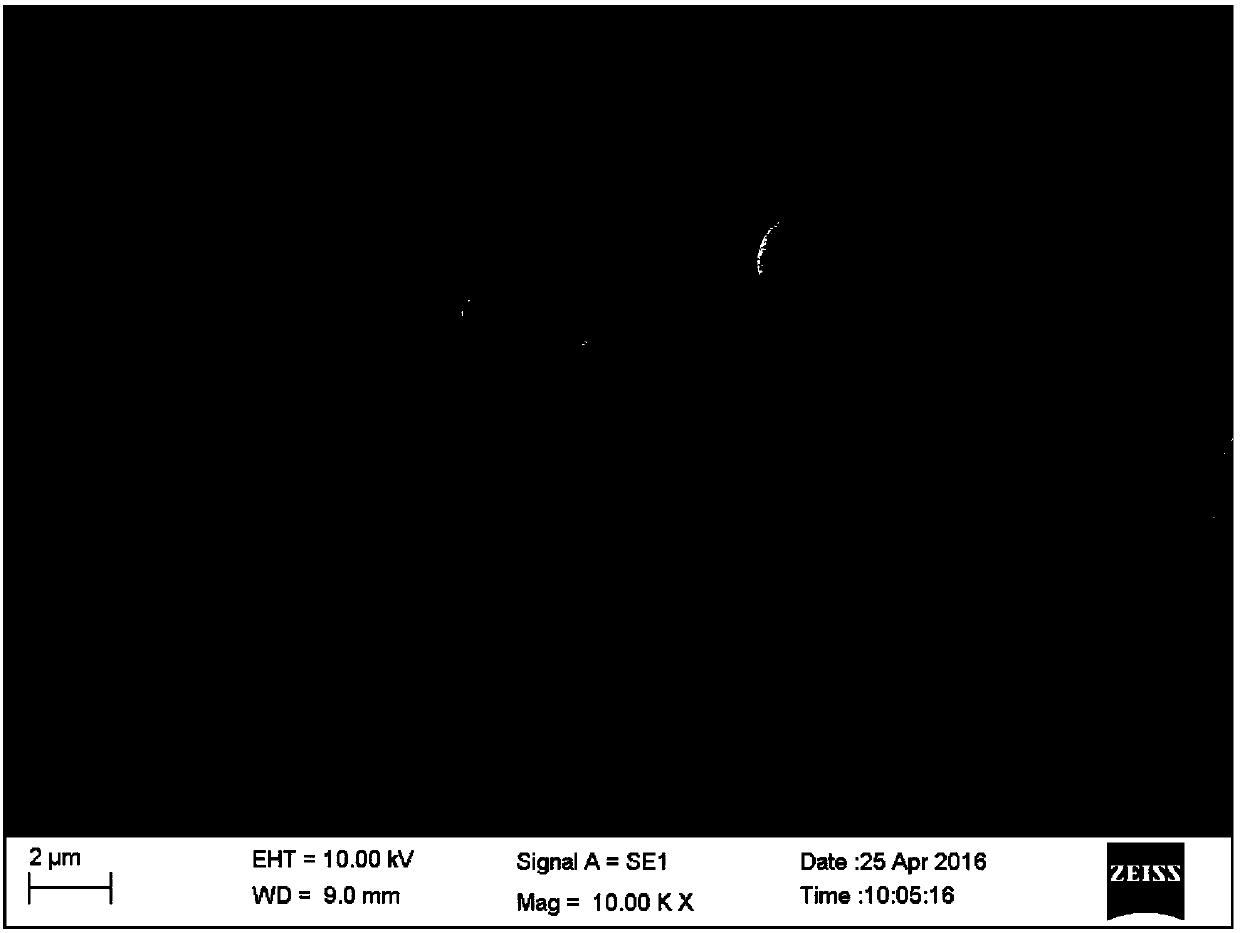

[0042] In step ③, add 48g of phenyltrimethoxysilane monomer solution to the seed solution obtained in step ② for polycondensation reaction. The temperature is 22°C at room temperature, the stirring speed is 300rpm, and the time is 40min. The obtained product is filtered and washed with deionized water , dried at 180°C for 6h to obtain 36.2g of micron-sized monodisperse organosiloxane microspheres with an average particle size of 1.67μm, as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com