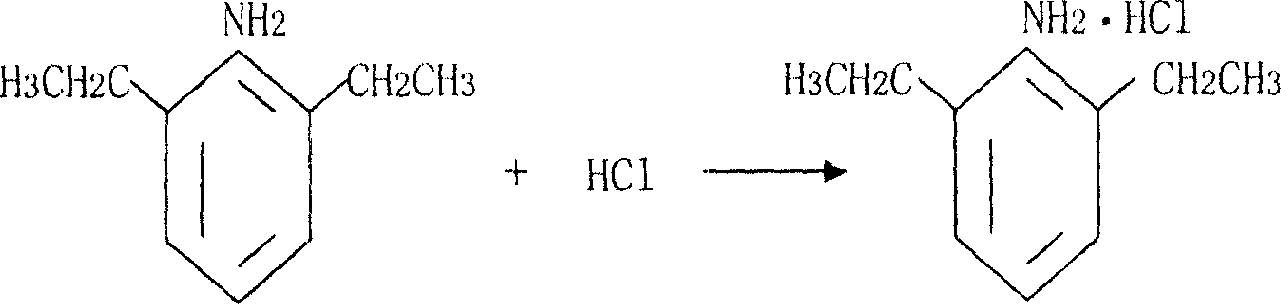

Prepn process of 4,4'-methylene-bis(2,6-diethyl aniline) (MDEA)

A technology of diethylaniline and methylene, which is applied in the field of polymer material synthesis, can solve problems such as no relevant reports, and achieve the effects of low preparation cost, high purity and yield, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

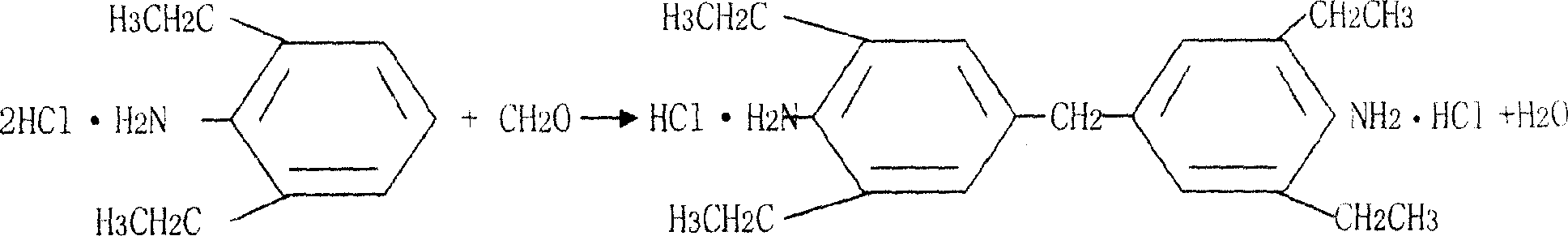

Method used

Image

Examples

Embodiment 1

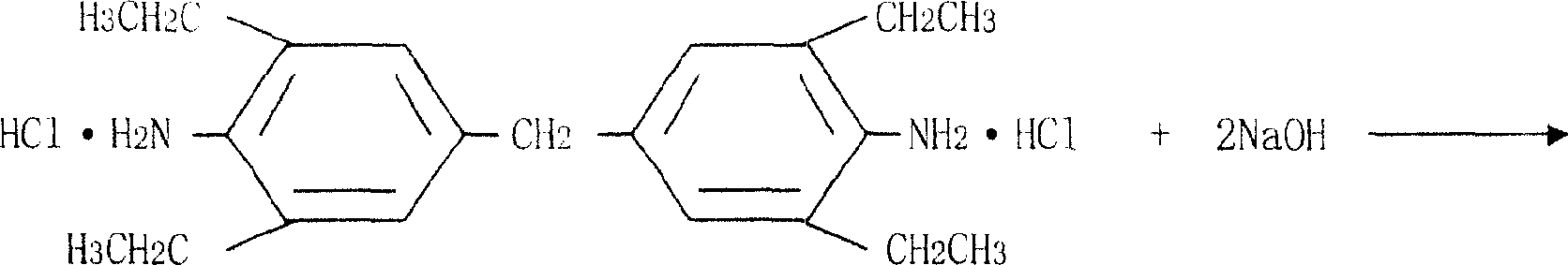

[0019] Put 400g of water (tap water or distilled water) in a 1000ml four-neck flask with stirring and nitrogen protection device, start stirring, and slowly add 150g of DEA (2,6-diethylaniline) weighed. Then, the weighed 133g hydrochloric acid (28%) was added in the flask with a separatory funnel, and the feed liquid was heated to 50°C. Add the weighed 52g formaldehyde solution (30%) dropwise in the flask to carry out the condensation reaction, drop it in about 60 minutes, and then keep warm for 1 hour. Reheat to 80°C for another 2 hours. After the reaction is completed, 30% NaOH solution is added to neutralize the feed liquid until the feed liquid pH=7.5-8. Stand still for 30 minutes, use a separatory funnel to separate the water layer, and wash the material twice with an appropriate amount of hot water, and get the crude MDEA after removing the water layer. The crude MDEA product is decolorized by activated carbon, dehydrated under reduced pressure, crystallized and granul...

Embodiment 2

[0028] Put 400g of water (tap water or distilled water) in a 1000ml four-neck flask with stirring and nitrogen protection device, start stirring, and slowly add 150g of DEA (2,6-diethylaniline) weighed. Then, the weighed 155g hydrochloric acid (28%) was added in the flask with a separatory funnel, and the feed liquid was heated to 60°C. Add the weighed 52g formaldehyde solution (37%) dropwise in the flask to carry out the condensation reaction, drop it in about 60 minutes, and then keep warm for 1 hour. Reheat to 90°C for another 2 hours. After the reaction is over, add 30% Na 2 CO 3 The solution neutralizes the feed liquid until the pH of the feed liquid is 8-9. Stand still for 30 minutes, use a separatory funnel to separate the water layer, and wash the material twice with an appropriate amount of hot water, and get the crude MDEA after removing the water layer. The crude product of MDEA is decolorized by ethanol recrystallization, filtered, dried and granulated to obtai...

Embodiment 3

[0030] Put 400g of water (tap water or distilled water) in a 1000ml four-neck flask with stirring and nitrogen protection device, start stirring, and slowly add 150g of DEA (2,6-diethylaniline) weighed. Then, add weighed 150g hydrochloric acid (33%) in the flask with a separatory funnel, and heat the feed liquid to 60°C. Add the weighed 65g formaldehyde solution (35%) dropwise in the flask to carry out the condensation reaction, drop it in about 60 minutes, and then keep warm for 1 hour. Reheat to 90°C for another 2 hours. After the reaction is completed, 30% NaOH solution is added to neutralize the feed liquid until the pH of the feed liquid is 9-10. Stand still for 30 minutes, use a separatory funnel to separate the water layer, and wash the material twice with an appropriate amount of hot water, and get the crude MDEA after removing the water layer. The crude MDEA is decolorized through ultrafiltration membrane filtration, dehydrated under reduced pressure, crystallized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com