Fan impeller of air conditioner and manufacturing technology thereof

An air-conditioning fan and impeller technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low connection strength, easy damage, complex process, etc., to improve production efficiency, enhance connection strength, and uncomplicated process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

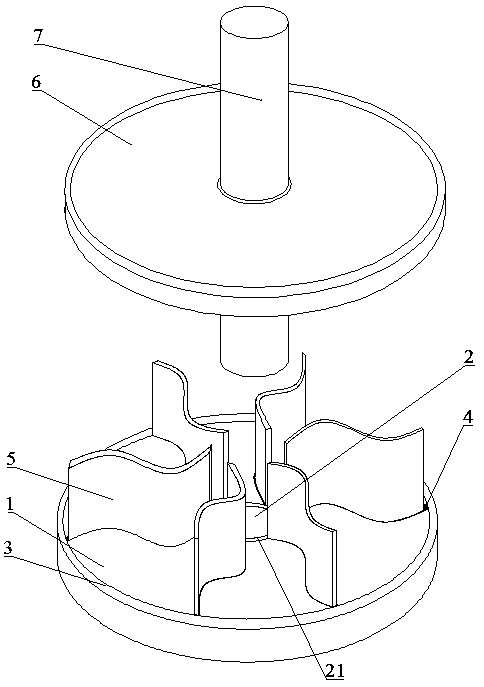

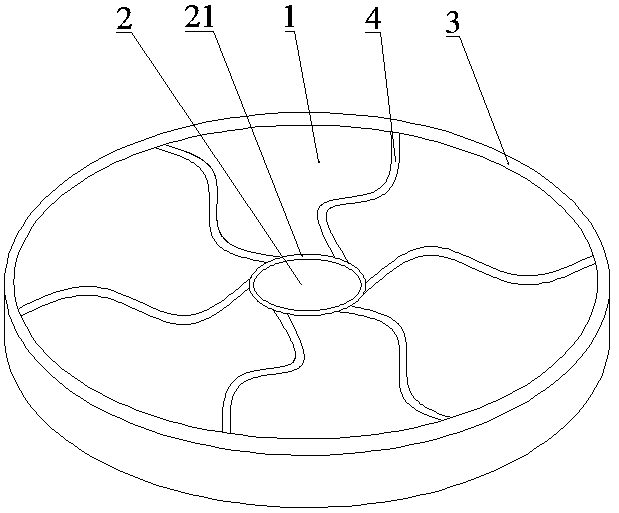

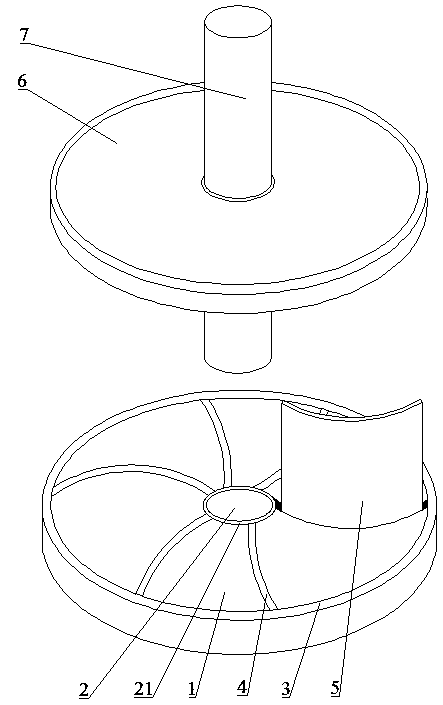

[0032] Such as figure 1 , image 3 As shown, the air conditioner fan impeller provided by the present invention includes: a fixed chassis 1, a shaft hole 2 arranged at the center of the fixed chassis 1, an outer flange 3 arranged at the edge of the fixed chassis 1, and several strips arranged on the upper surface of the fixed chassis 1. The mounting groove 4, several blades 5 engaged in the mounting groove 4, the upper cover 6 arranged symmetrically with the fixed chassis 1; the edge of the central axis hole 2 is provided with an inner flange 21; to the inner flange 21, and the other end is connected to the outer flange 3; the mounting grooves 4 are circularly arranged on the upper surface of the fixed chassis 1; the thickness of the blades 5 is smaller than the width of the mounting grooves 4; the blades 5 and the installation groove 4 are provided with metal injected and cooled by casting; the upper cover is connected with the fixed chassis 1 through the rotating shaft 7 be...

Embodiment 2

[0037] On the basis of Embodiment 1, the shape of the blade 5 preferably adopted in this embodiment is a C-shaped blade, and the C-shaped blade is relative to the generally used straight blade. A vortex airflow can be formed, so that the airflow can be transported at high speed and efficiently, and the connection method between the blade and the fixed chassis described in the present invention can be suitable for the installation of the C-shaped blade.

Embodiment 3

[0039] On the basis of embodiment 1, the material of blade 5 described in the present invention is titanium alloy, and titanium alloy metal is the relatively light metal of relative mass, and in the working operation of impeller, has reduced the load of impeller, has improved mechanical efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com