Cyclodextrin porous adsorption material as well as preparation method and application thereof

A porous adsorption material and cyclodextrin technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problem of small specific surface area, further improvement of adsorption effect, and few types of active functional group binding sites. etc. to achieve high specific surface area, low recycling cost and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

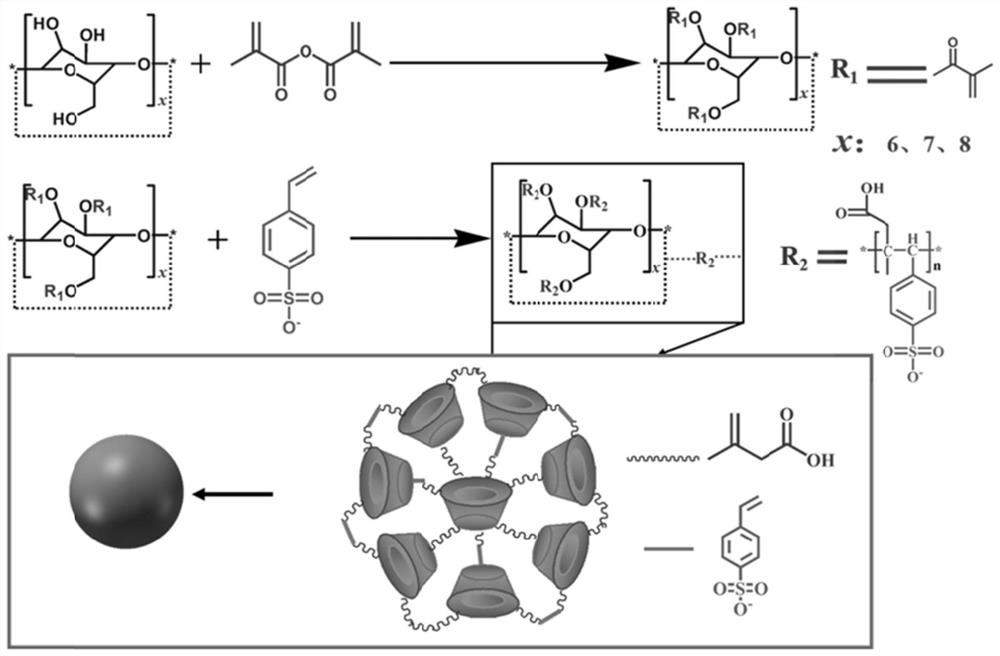

[0033] In this embodiment, the preparation method of cyclodextrin porous adsorption material comprises the following steps:

[0034] (1) Place 180ml of N,N-dimethylformamide (DMF) in a round-bottomed flask under ice bath, then add β-cyclodextrin (β-CD, 12g), acrylic anhydride (2.4g) Add triethylamine (2g) into a round bottom flask, and carry out dehydration condensation reaction after stirring. The reaction temperature is 0°C, the reaction time is 48h, the stirring speed is 500rpm, and the molar ratio of β-CD to acrylic anhydride is 1:2 , The molar ratio of β-CD and triethylamine added is 1:2.

[0035] (2) After the reaction of step (1) finishes, sodium p-styrene sulfonate (2g) and ammonium persulfate (2.2g) are added in the reaction solution, and the temperature of the reaction mixed solution is adjusted, and cross-linking polymerization occurs at a certain temperature The cyclodextrin cross-linked polymer was prepared by reaction, the reaction temperature was 80°C, the feed...

Embodiment 2

[0039] In this embodiment, the preparation method of cyclodextrin porous adsorption material comprises the following steps:

[0040] (1) 200ml of cyclohexane was placed in a round-bottomed flask under ice-cooling, and then β-cyclodextrin (β-CD, 12g), acrylic anhydride (2.4g) and triethylamine (2g) were added to In the round bottom flask, the dehydration condensation reaction is carried out by stirring, the reaction temperature is 0°C, the reaction time is 48h, the stirring speed is 1000rpm, the molar ratio of β-CD and acrylic anhydride is 1:2, β-CD and triethylamine are added The molar ratio of the amounts is 1:2.

[0041](2) After the reaction of step (1) finishes, sodium p-styrene sulfonate (2g) and ammonium persulfate (2.2g) are added in the reaction solution, and the temperature of the reaction mixed solution is adjusted, and cross-linking polymerization occurs at a certain temperature The cyclodextrin cross-linked polymer was prepared by reaction, the reaction temperatur...

Embodiment 3

[0045] In this embodiment, the preparation method of cyclodextrin porous adsorption material comprises the following steps:

[0046] (1) Place 200ml of N,N-dimethylformamide (DMF) in a round-bottomed flask under an ice bath, then add β-cyclodextrin (β-CD, 12g), acrylic anhydride (3.6g) Add triethylamine (2g) into a round bottom flask, and carry out dehydration condensation reaction after stirring. The reaction temperature is 0°C, the reaction time is 48h, the stirring speed is 800rpm, and the molar ratio of β-CD to acrylic anhydride is 1:3 , The molar ratio of β-CD and triethylamine added is 1:2.

[0047] (2) After the reaction of step (1) finishes, sodium p-styrene sulfonate (3g) and ammonium persulfate (2.2g) are added in the reaction solution, and the temperature of the reaction mixed solution is adjusted, and cross-linking polymerization occurs at a certain temperature The cyclodextrin crosslinked polymer was prepared by reaction, the reaction temperature was 80°C, the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com