Preparation method of pore graded compound metal oxide

A composite metal and grading technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reduced specific surface area, small specific surface area, and limited scale production, etc., and achieve the effect of simple preparation process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

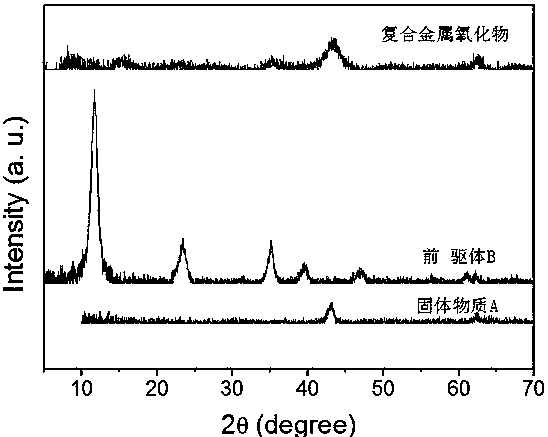

[0031] Step 1: Weigh 10 g of magnesium nitrate and add it to a beaker containing a mixed solution of 20 mL of glycerol and water, dissolve it, and process it at 400-600 °C for 3-8 hours to obtain solid substance A;

[0032] Step 2: Disperse 2 g of solid substance A into 20-50 mL of water, and add trivalent metal hydrochloride or nitrate to adjust the ratio of magnesium atoms to trivalent metal ions in the solution to 2 to 4;

[0033] Step 3: 20-80 o C, after standing and aging for 6 hours, the precipitate was filtered and dried to obtain precursor material B;

[0034] Step 4: Put the precursor material B at 300-800 o C roasting treatment to obtain hierarchical porous composite metal oxides.

Embodiment 2

[0036] This example is basically the same as Example 1, except that the trivalent metal hydrochloride or nitrate in step 2 is aluminum nitrate or aluminum chloride.

[0037] Magnesium aluminum hydrotalcite is easy to generate and its morphology is easier to control.

Embodiment 3

[0039] This embodiment is basically the same as Embodiment 2, the difference being step 3: 80 o C, after standing and aging for 6 hours, the precipitate was filtered and dried to obtain the precursor material B; step 4: the precursor material B was heated at 300 o C roasting treatment to obtain hierarchical porous composite metal oxides.

[0040] The prepared porous material has an adsorption capacity of 500 mg / g for Congo red; the specific surface area is greater than 120 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com