Porous carbon material and preparation method thereof, lithium-sulfur battery modified diaphragm and preparation method thereof, and lithium-sulfur battery

A porous carbon material, lithium-sulfur battery technology, applied in lithium storage batteries, carbon preparation/purification, battery pack components, etc., can solve the problems of poor sulfur electrochemical activity, complex composite process, difficult size control, etc. The operation is simple and easy, the preparation method is simple, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] According to a first aspect of the present invention, a method for preparing a porous carbon material is provided, comprising the following steps:

[0053] (a) providing the mixed colloid formed by carbon source, templating agent and water;

[0054] Wherein, the carbon source is gelatin, and the template includes a transition metal salt template;

[0055] (b) coating the mixed colloid on the substrate, then drying to obtain a film;

[0056] (c) using CO 2 The laser performs laser direct writing processing on the thin film on the substrate, and separates the material obtained after the direct writing processing from the substrate, washes, separates and dries to obtain a porous carbon material.

[0057] Specifically, in step (a), the present invention uses a specific type of carbon source so that it can form a colloid after being mixed with a template agent and water, thereby facilitating film formation in the later stage, while ensuring the generation of porous carbon ...

Embodiment approach

[0082] As an optional embodiment of the present invention, the binder includes polyvinylidene fluoride or carboxymethyl cellulose.

[0083] As an optional embodiment of the present invention, the solvent includes 1-methyl-2-pyrrolidone or water.

[0084] As an optional embodiment of the present invention, the mass ratio of the porous carbon material to the binder is (2-4):1, preferably 3:1. Typical but non-limiting mass ratios of porous carbon material and binder are 2:1, 2.5:1, 3:1, 3.5:1 or 4:1.

[0085] The modified layer has good adhesion and flexibility by further limiting the binder, the type of solvent, and the relative amounts of the porous carbon material and the binder.

[0086] As an optional embodiment of the present invention, the drying is vacuum drying.

[0087] As an optional embodiment of the present invention, the vacuum drying temperature is 60-80° C., and the vacuum drying time is 12-24 hours. A typical but non-limiting temperature for vacuum drying is 6...

Embodiment 1

[0094] This embodiment provides a method for preparing a porous carbon material, comprising the following steps:

[0095] (a) Add 2 g of carbon source gelatin to 10 mL of deionized water, heat and stir at 65°C for 60 min to form a colloid, then add 4 g of template agent zinc nitrate hexahydrate and continue stirring for 5 h to obtain a mixed colloid;

[0096] The mixed colloid was coated on the copper foil (substrate) to form a thin film with a uniform thickness of 400 μm, and then the film was dried in an oven at 60°C.

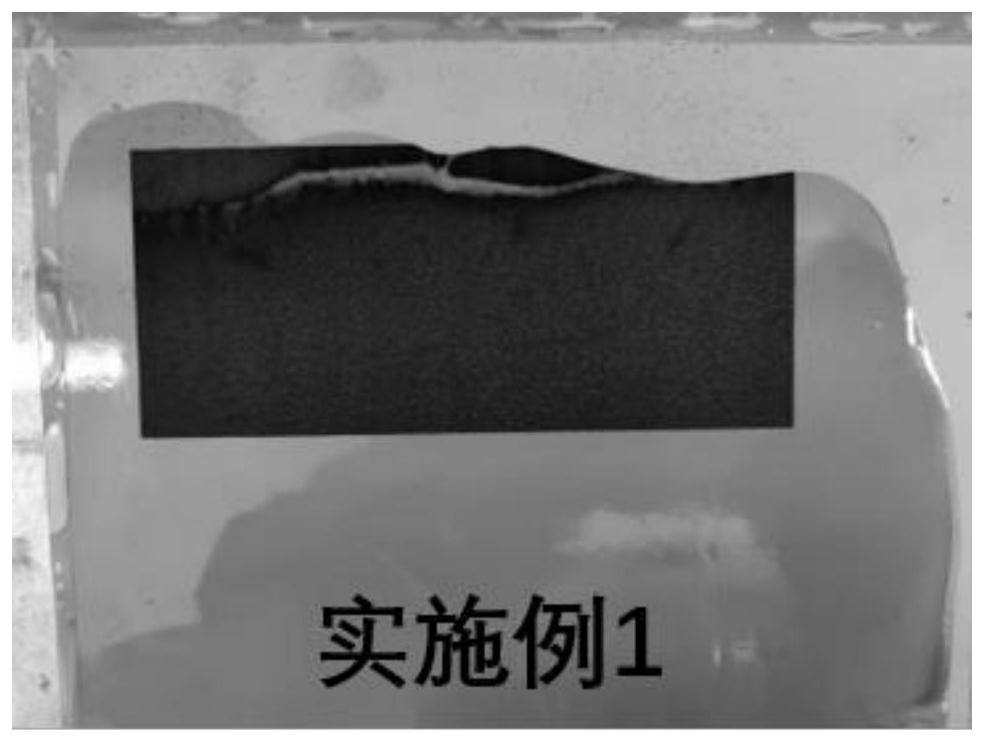

[0097] (b) Using 10.6μm wavelength CO 2 The laser performs direct writing processing on the thin film, the laser power is 3.6W, and the laser scanning speed is 343mm / s. The materials obtained after laser direct writing processing are as follows: figure 1 shown. The black powder on the surface of the material was scraped off and pickled in 2mol / L hydrochloric acid for 8 hours, and the pickling temperature was set at 60°C. After the pickling, it was washed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com