A carbon-coated tungsten-doped metal phosphide and its preparation method

A metal phosphide and tungsten doping technology, which is applied in the preparation/purification of carbon, phosphide, phosphorus compounds, etc., can solve the problems of easy agglomeration and instability, and achieve the effect of small particle size and controllable structural units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Weigh 0.016g WCl 6 , 1.412g C 15 h 21 FeO 6 and 3g NaH 2 PO 2 Pour it into a ball mill jar, add 100ml of absolute ethanol, wherein the molar ratio of W element to Fe element is 0.1:1.

[0028] 2) Place the ball mill jar on a planetary ball mill, and mill for 5 hours at a revolution speed of 300r / min and an autorotation speed of 400r / min.

[0029] 3) Put the ball mill jar into an oven at 60°C to obtain uniformly mixed precursor powder.

[0030] 4) Perform high-temperature phosphating heat treatment on the precursor powder. The heat treatment process is: in N 2 In the atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, kept for 3 hours, and then naturally cooled to room temperature. After taking it out, you get W 0.1 - FeP / C nanoparticles.

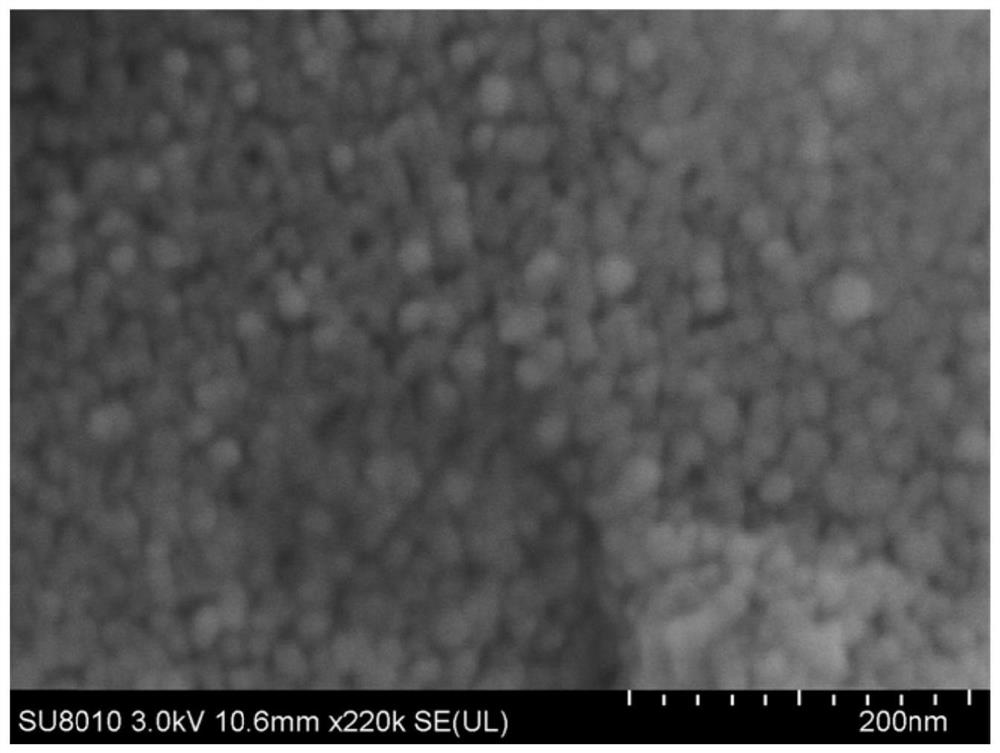

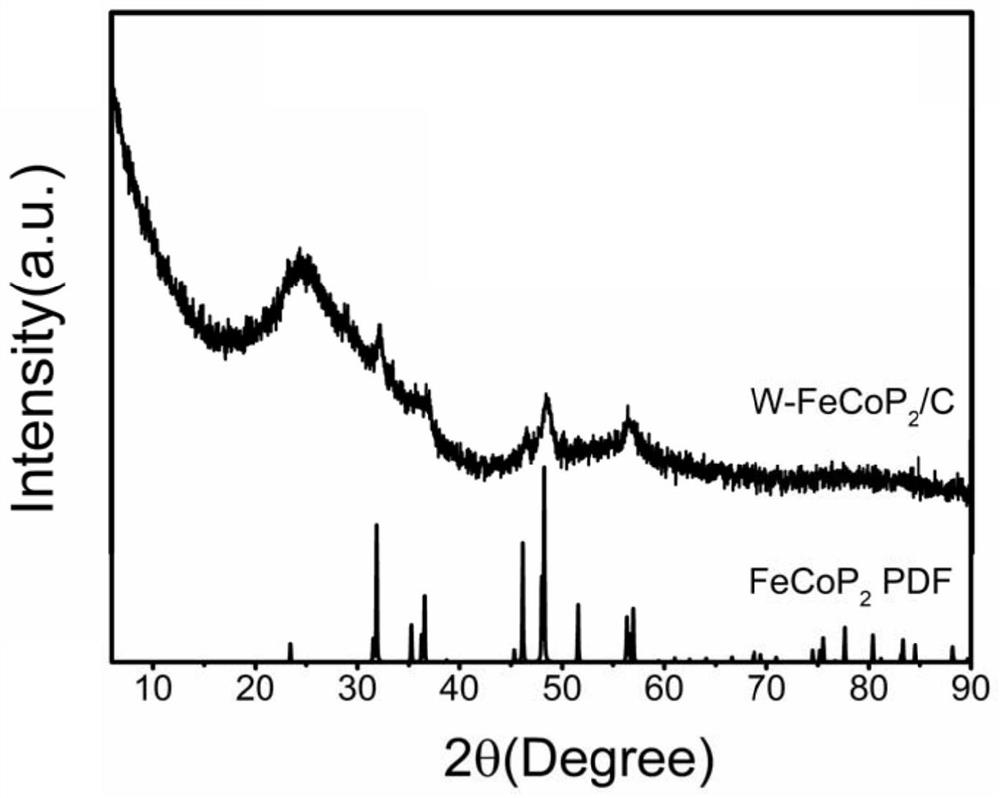

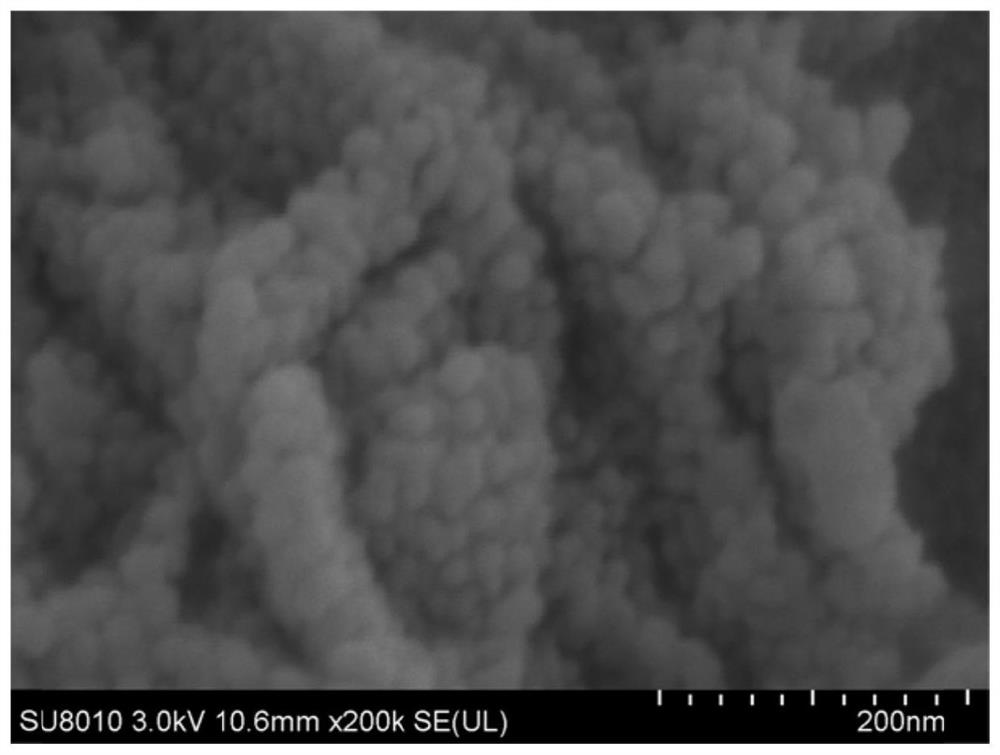

[0031] The phase of the carbon-coated tungsten-doped iron phosphide particles prepared in this example is FeP, image 3 It is a scanning electron microscope picture of the iron-cobalt phosphide nano-part...

Embodiment 2

[0033] 1) Weigh 0.008g WCl 6 , 1.412g C 15 h 21 FeO 6 and 3g NaH 2 PO 2 Pour it into a ball mill jar and add 100ml of absolute ethanol, wherein the molar ratio of W element to Fe element is 0.05:1.

[0034] 2) Place the ball mill jar on a planetary ball mill, and mill for 5 hours at a revolution speed of 300r / min and an autorotation speed of 400r / min.

[0035] 3) Put the ball mill jar into an oven at 60°C to obtain uniformly mixed precursor powder.

[0036] 4) Perform high-temperature phosphating heat treatment on the precursor powder. The heat treatment process is: in N 2 In the atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, kept for 3 hours, and then naturally cooled to room temperature. After taking it out, you get W 0.05 - FeP / C nanoparticles.

[0037] The phase of the carbon-coated tungsten-doped iron phosphide particles prepared in this example is FeP, and the size of the nanoparticles is about 17 nm.

Embodiment 3

[0039] 1) Weigh 0.024g WCl 6 , 1.412g C 15 h 21 FeO 6 and 3g NaH 2 PO 2Pour it into a ball mill jar, add 100ml of absolute ethanol, wherein the molar ratio of W element to Fe element is 0.15:1.

[0040] 2) Place the ball mill jar on a planetary ball mill, and perform ball milling for 6 hours at a revolution speed of 400r / min and an autorotation speed of 500r / min.

[0041] 3) Put the ball mill jar into an oven at 60°C to obtain uniformly mixed precursor powder.

[0042] 4) Perform high-temperature phosphating heat treatment on the precursor powder. The heat treatment process is: in N 2 In the atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, kept for 3 hours, and then naturally cooled to room temperature. After taking it out, you get W 0.15 - FeP / C nanoparticles.

[0043] The phase of the carbon-coated tungsten-doped iron phosphide particles prepared in this example is FeP, and the size of the nanoparticles is about 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com