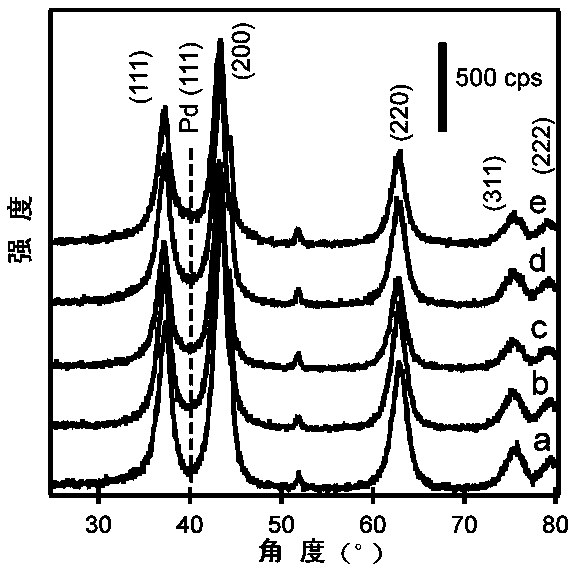

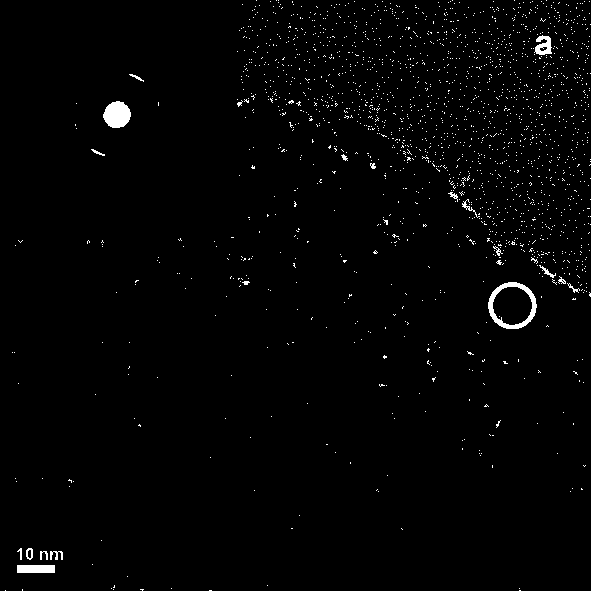

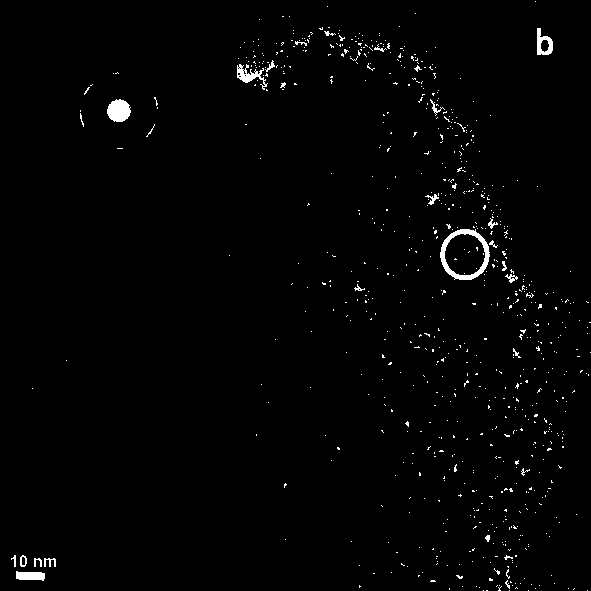

Preparation method for nickel oxide loaded palladium catalyst and application to room-temperature CO catalytic oxidation

A palladium catalyst, nickel oxide technology, applied in the directions of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve problems such as complicated preparation process, achieve simple preparation method, Strong operability and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of nickel oxide supported palladium catalyst, comprising the following steps:

[0054] (1) Add 29.1g nickel nitrate solid (analytical pure produced by Sinopharm Reagent Co., Ltd., mass purity ≥ 99%) in 100ml deionized water, stir at room temperature for 2 hours, and dissolve to obtain nickel nitrate solution.

[0055] (2) Add 13.4g of sodium oxalate (analytical pure produced by Sinopharm Reagent Co., Ltd., quality purity ≥99%) to 200ml of deionized water, and stir at 80°C for at least 2 hours to obtain an oxalate solution.

[0056] (3) Add the oxalate solution obtained in step (2) into the nickel nitrate solution obtained in step (1) until the nickel nitrate is completely precipitated, and continue stirring at 80°C for 15 minutes to obtain a nickel oxalate solid suspension.

[0057] (4) After cooling the nickel oxalate solid suspension obtained in step (3), perform suction filtration and separation, and then wash with deionized water to obtain nicke...

Embodiment 2

[0065] A preparation method of nickel oxide supported palladium catalyst, comprising the following steps:

[0066] The content of step (1) to step (6) is the same as that of embodiment 1.

[0067] (7) Weigh 0.5g of the nickel oxide carrier obtained in step (6) of Example 1, and use 10ml of chloropalladium acid with a concentration of 4.12g / L, 7.65g / L, 10.30g / L, and 13.83g / L respectively Sodium (Na 2 PdCl 4 ) solution for impregnation and stirring for 2 hours to obtain a nickel oxide solid suspension impregnated with sodium chloropalladate.

[0068] (8) Add hydrazine hydrate solutions with a volume of 50ml, 150ml, 250ml, and 350ml and a concentration of 10.2g / L to the nickel oxide impregnated with sodium chloropalladate obtained in step (7) slowly (at a speed of 1ml / min). In the solid suspension, stirring for 24 hours, the sodium chloropalladate was reduced to elemental palladium to obtain a solid suspension of palladium supported on nickel oxide.

[0069] (9) centrifuging ...

Embodiment 3

[0076] A preparation method of nickel oxide supported palladium catalyst, comprising the following steps:

[0077] In step (1) to step (6), the nickel salt is nickel chloride and its hydrate, and the oxalate is potassium oxalate;

[0078] Step (6): The single-phase nickel oxalate precursor solid obtained in step (5) is placed in a muffle furnace and heated from room temperature to 300°C at a heating rate of 20°C / min. The rest of the content is the same as in Example 1 .

[0079] The content of step (7) to step (9) is the same as that of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com