Manufacturing method of high-temperature speckle

A production method and speckle technology, which is applied in the field of photomechanics and optical device manufacturing, can solve the problems of high temperature resistance, limited displacement information, pre-crack, etc., and achieve the effect of not harsh reaction conditions, simple operation, and easy generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

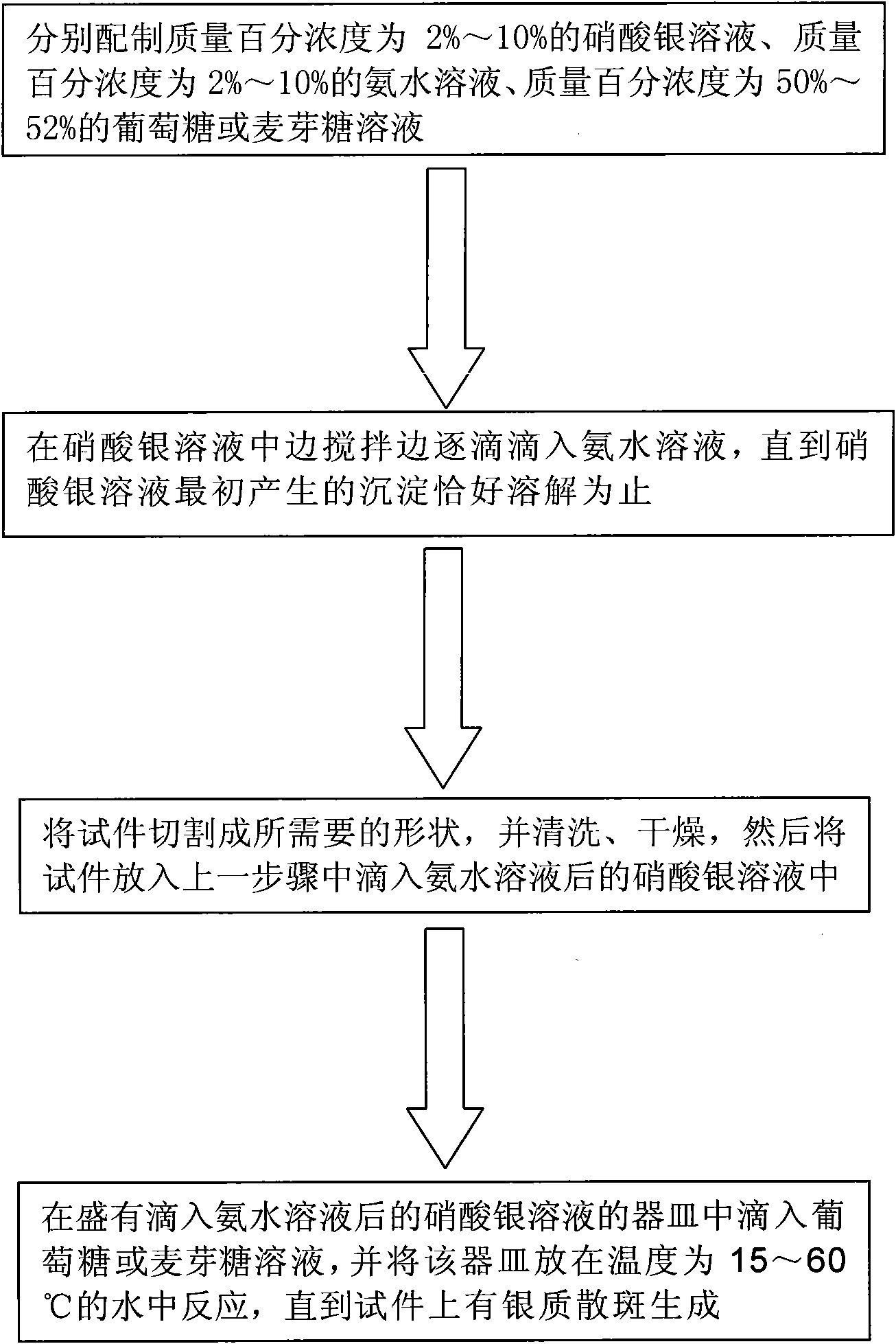

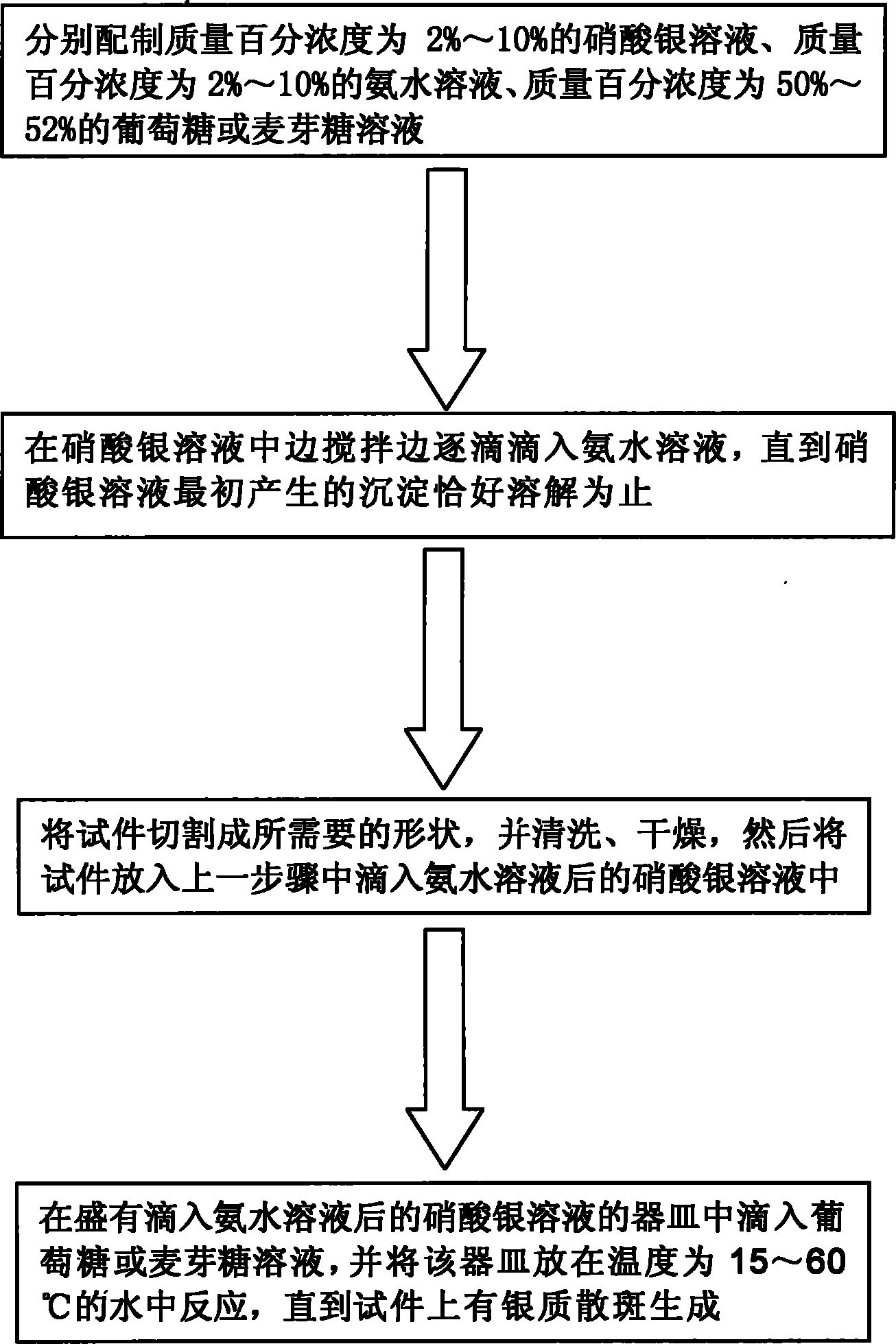

Method used

Image

Examples

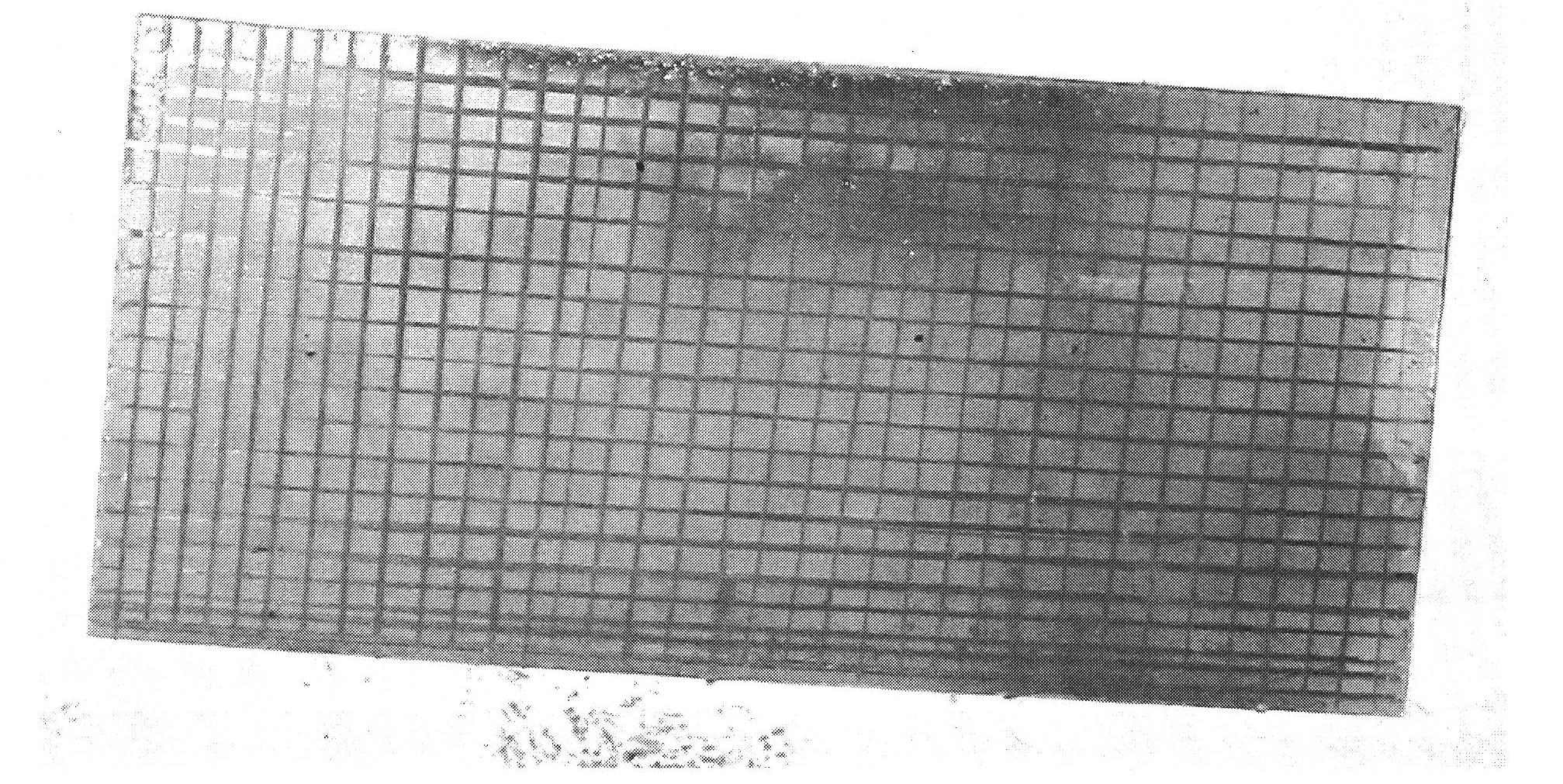

Embodiment 1

[0025] The material of the test piece is glass sheet, the size is 50mm×25mm×0.2mm. Clean and dry the glass slices; prepare 3 beakers, 3 glass rods, purified water, silver nitrate powder, concentrated ammonia water, and glucose powder; prepare 50 mL of 2% silver nitrate solution with purified water and silver nitrate powder, and use purified water Prepare a 2% ammonia solution with concentrated ammonia water, use pure water and glucose solution with a concentration of 50% glucose powder; add dilute ammonia water drop by drop to the silver nitrate solution while stirring, the silver nitrate solution will appear khaki-yellow precipitate, continue to drop Dilute ammonia water until the khaki precipitate just dissolves; at this time, put a glass piece in the silver nitrate solution after dripping ammonia water; prepare hot water at 60°C; put the beaker containing the silver nitrate solution in hot water to warm ; After warming for a period of time, drop 10mL of glucose solution int...

Embodiment 2

[0027] The material of the test piece is zirconium boride ceramics (ZrB2), and the size is 50mm×7.5mm×7.5mm. Clean and dry the zirconium boride ceramics; prepare 3 beakers, 3 glass rods, purified water, silver nitrate powder, concentrated ammonia water, and glucose powder to prepare 100mL of 10% silver nitrate solution with purified water and silver nitrate powder, and use pure Prepare 10% ammonia solution with water and concentrated ammonia water, use pure water and glucose solution with a glucose powder concentration of 52%; add dilute ammonia water drop by drop into the silver nitrate solution while stirring with a glass rod, the silver nitrate solution will produce at first Brown precipitate, continue to drop dilute ammonia water until the precipitate just dissolves; at this time, put zirconium boride into the silver nitrate solution after dripping ammonia water; prepare 40 ℃ hot water, put the beaker containing silver nitrate solution into the hot Warm the water; after wa...

Embodiment 3

[0028] Embodiment 3: The material of the test piece is an alumina ceramic sheet with a size of 75mm×25mm×2mm. Clean and dry the alumina ceramic sheet; prepare 3 beakers, 3 glass rods, purified water, silver nitrate powder, concentrated ammonia water, and glucose powder; prepare 50 mL of 10% silver nitrate solution with purified water and silver nitrate powder, and use Prepare a 10% ammonia solution with purified water and concentrated ammonia water, use pure water and glucose solution with a concentration of 52% glucose powder; stir while adding dilute ammonia water drop by drop into the silver nitrate solution, the silver nitrate solution will appear earthy brown precipitation, continue Add dilute ammonia water dropwise until the precipitate just dissolves; add 10mL of glucose solution into the silver nitrate solution; put alumina flakes into the silver nitrate solution after dripping ammonia water at this time; put the beaker containing silver nitrate in the In the air at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com