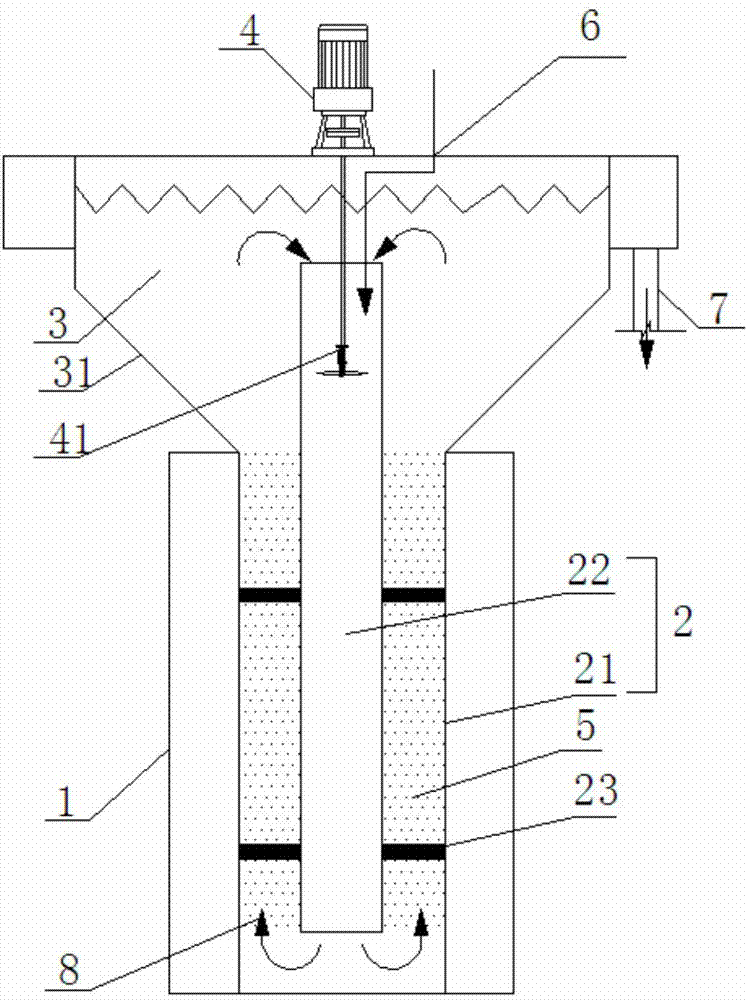

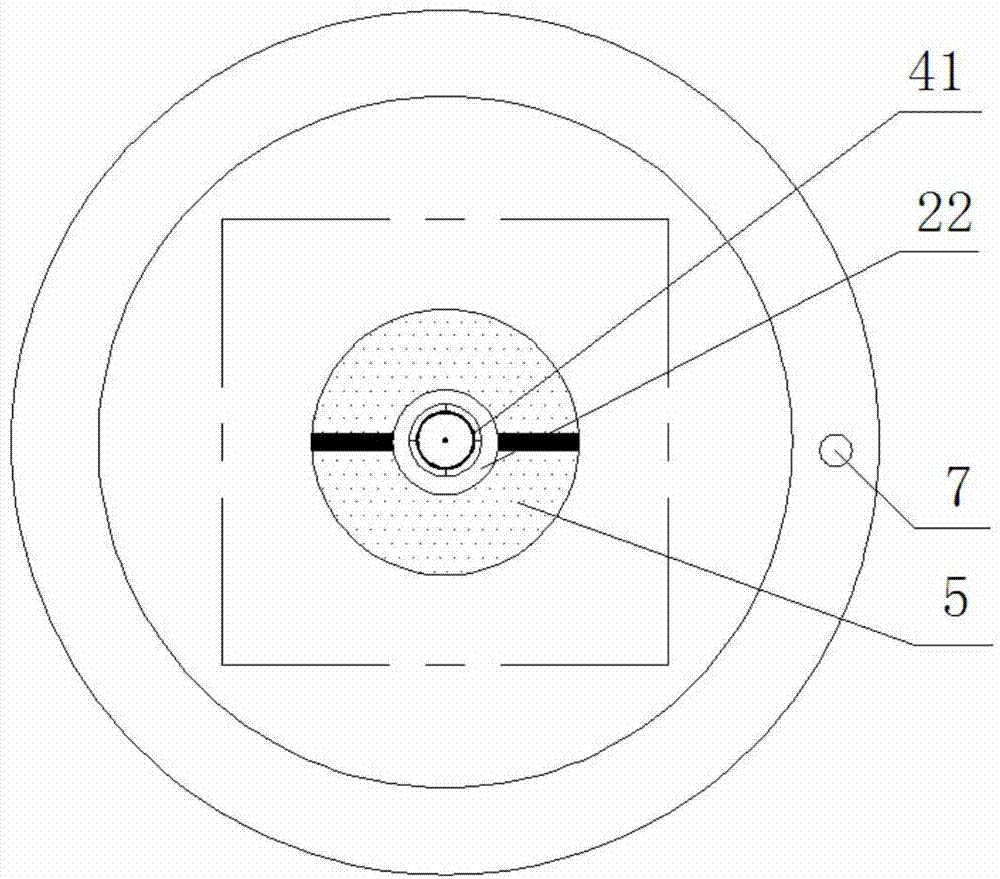

Microwave fluidization reaction device and method for processing benzol and derivatives of benzol

A technology of fluidized reaction and derivatives, which is applied in the field of microwave fluidized reaction devices, can solve the problems that no treatment methods for benzene and benzene derivatives have been proposed, and achieve the requirements of not harsh reaction conditions, simple overall operation, and high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The first embodiment is to use the microwave fluidization reaction device to treat fine chemical wastewater. The main pollutants in the wastewater are phenol, xylene, m-diphenol, o-toluene and other substances containing benzene rings. The treatment method is through the following process steps:

[0059] Adjust the pH of the sewage to 2, enter the microwave reaction fluidization device through the water inlet, add 500mg / l sodium hypochlorite and 25mg / l ferric chloride, the residence time in the microwave reaction fluidization device is 40min, and the effluent passes through the lime The milk was adjusted to pH8. The COD value of the raw water after treatment (English name is Chemical Oxygen Demand, Chinese name is Chemical Oxygen Demand) has dropped from 520mg / l to 60.3mg / l, the removal rate of phenol is 98%, the removal rate of xylene is 95%, m-di The removal rate of phenol reaches 94%, and the removal rate of o-toluene reaches 91%.

Embodiment 2

[0061] The second embodiment of this example is to use the microwave fluidization reaction device to treat the biochemical effluent of coking wastewater. The main pollutants in the wastewater are benzene ring substances such as 2,5-di-tert-butylphenol and dibutyl phthalate. The treatment method Through the following process steps:

[0062] Adjust the pH of the sewage to 1.8, enter the microwave reaction fluidization device through the water inlet, add 300mg / l hydrogen peroxide, the residence time in the microwave reaction fluidization device is 60min, and adjust the pH of the effluent to 7.5 through lime milk. After the treatment, the COD value of the raw water was reduced from 240 mg / l to 58 mg / l, the removal rate of 2,5-di-tert-butylphenol was 98%, and the removal rate of dibutyl phthalate was 83%.

Embodiment 3

[0064] The third example is to use the microwave fluidization reaction device to treat the biochemical effluent of landfill leachate. The main pollutants in the waste water are 2,4-bis(1,1-dimethylethyl)phenol, phenol, phenyl ketone, 2,5-dihydromethylaniline, 4-methoxy-3-methylphenol, N-butylbenzenesulfonamide and other substances, the treatment method goes through the following process steps:

[0065] Adjust the pH of the sewage to 1, enter the microwave reaction fluidization device through the water inlet, add 240mg / l hydrogen peroxide and 100mg / l potassium permanganate, the residence time in the microwave reaction fluidization device is 15min, and the effluent Adjust to pH9 by milk of lime. The COD value of raw water after treatment decreased from 890mg / l to 91mg / l, of which the removal rate of phenyl ketone was 93%, the removal rate of 2,5-dihydromethylaniline was 98%, and the removal rate of 4-methoxy-3- The removal rate of methylphenol is 91%, and the removal rate of N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com