Surface modified nano silicon dioxide and acrylic resin coating containing the same

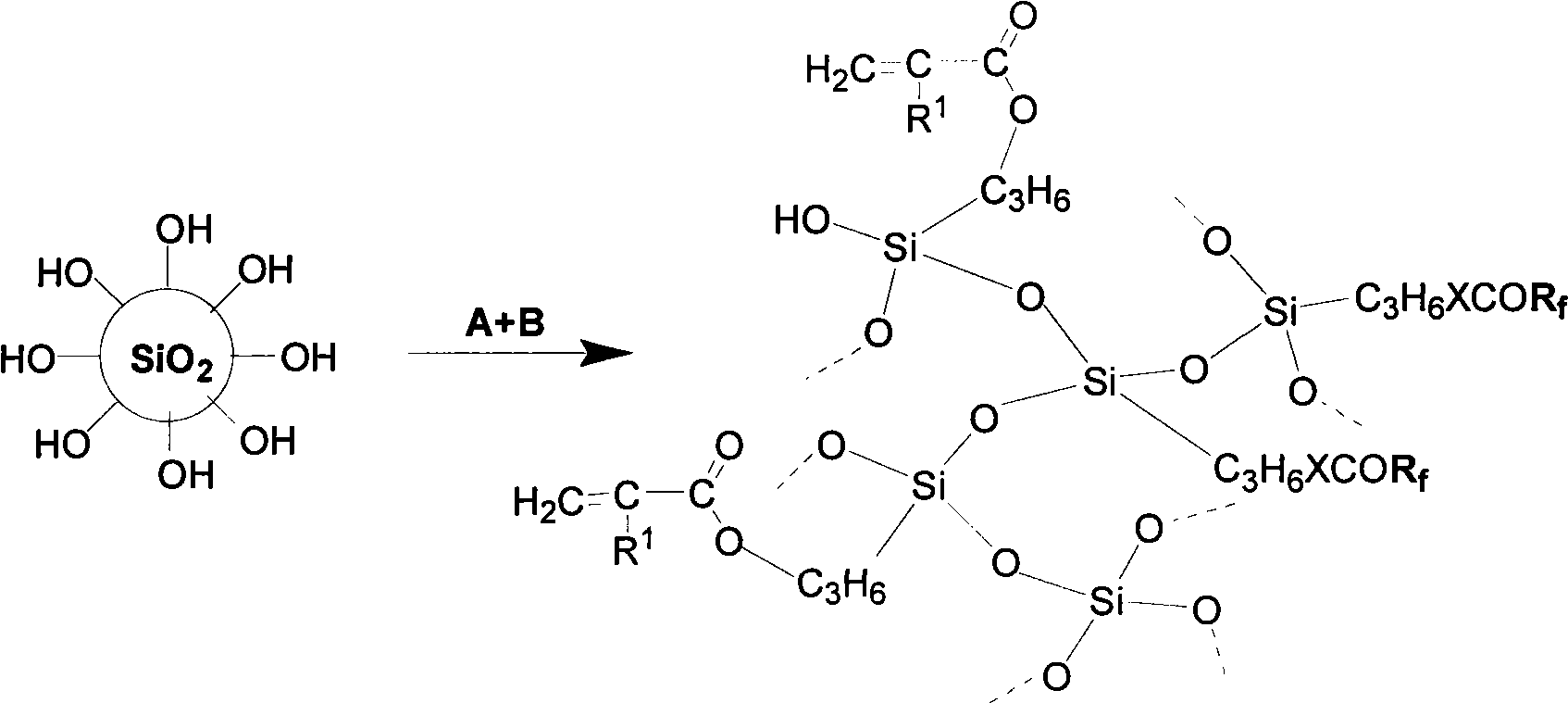

A technology for surface modification of nano and nano silica, which is applied in coatings, fibrous fillers, dyed low-molecular organic compounds, etc., can solve the problems that direct blending is difficult to achieve effectively, and cannot achieve synergistic effects, etc., to achieve a good surface Glossiness, excellent oil and water resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

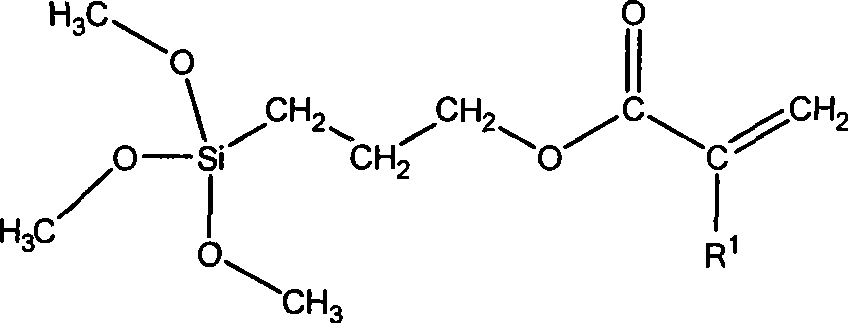

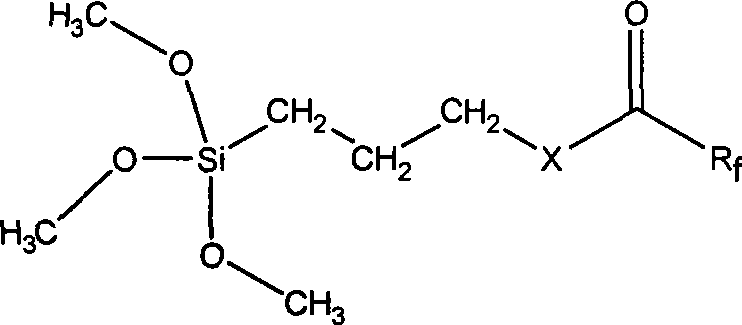

[0063] The 0.5 mole molecular formula is:

[0064]

[0065] Compound C (manufacturer: Zhejiang Juhua Group Co., Ltd.) and 0.5 mole of 3-mercaptopropyltrimethoxysilane (compound D) were mixed in a round bottom flask, diluted with a small amount of anhydrous ether, and reacted under slow reflux conditions After 2 hours, the solvent was evaporated to obtain the molecular formula:

[0066]

[0067] Compound B, the product is a colorless transparent liquid.

[0068] In parts by weight, 23 parts of silicon dioxide (manufacturer: Zhejiang Wanjing Material Co., Ltd.), 21 parts of isopropanol, 9 parts of water, 3-(methacryloyloxy ) 10 parts of propyltrimethoxysilane (compound A) and 4 parts of compound B obtained by the above steps were put into a three-neck flask, then added dilute hydrochloric acid solution to adjust pH=4~5, stirred at 75°C, and reacted for 3 hours After cooling, the acrylate functionalized and perfluoroalkoxy surface-modified nano-silica is obtained, and the...

Embodiment 2

[0072] Replace 3-mercaptopropyltrimethoxysilane (compound D) in Example 1 with 3-aminopropyltriethoxysilane (compound D), and other conditions are all the same as in Example 1, and the molecular formula obtained is:

[0073]

[0074] Compound B and the corresponding acrylate-functionalized and perfluoroalkoxy-surface-modified nanosilica.

[0075] The silicon-containing fluorine-containing acrylic resin coating was prepared according to the same method as in Example 1 and cured by light to form a silicon-containing fluorine-containing acrylic resin coating film.

Embodiment 3

[0077] With 3-aminopropyltrimethoxysilane (compound D) instead of 3-mercaptopropyltrimethoxysilane (compound D) in Example 1, other conditions are all the same as in Example 1, and the molecular formula obtained is:

[0078]

[0079] Compound B and the corresponding acrylate-functionalized and perfluoroalkoxy-surface-modified nanosilica.

[0080] The silicon-containing fluorine-containing acrylic resin coating was prepared according to the same method as in Example 1 and cured by light to form a silicon-containing fluorine-containing acrylic resin coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com