Acrylate compound for coatings, preparation method of acrylate compound, and coating comprising acrylate compound and application of coating

A technology for acrylates and compounds, which is applied in the preparation of organic compounds, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of difficulty in large-scale production, harsh synthesis conditions, and few applications, and achieve good compatibility. , the conditions are easy to control, the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

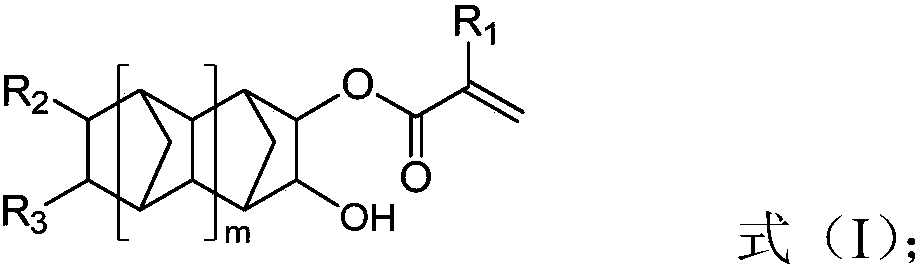

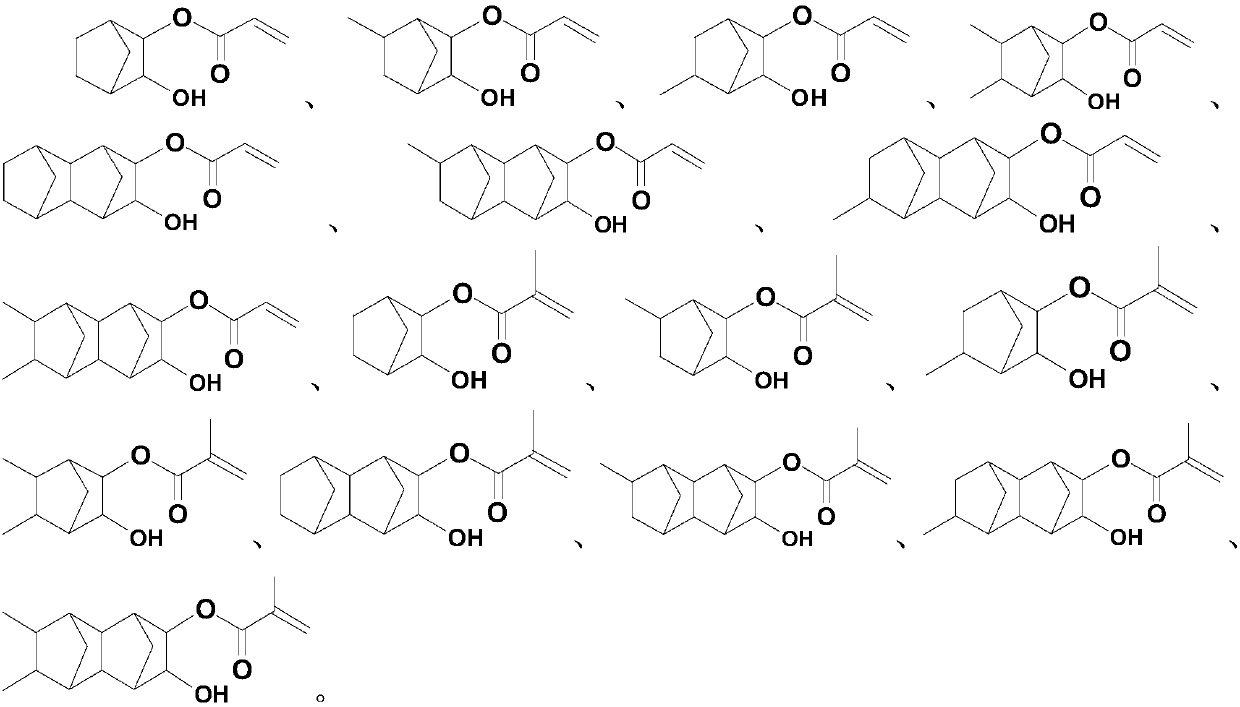

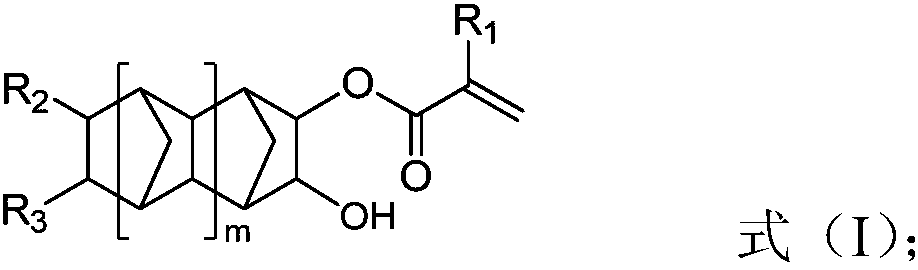

Method used

Image

Examples

Embodiment 1

[0082] A kind of acrylate compound 3-hydroxybicyclo[2.2.1]heptyl-2-acrylate for coating Its preparation method comprises the following steps:

[0083] (1) Bicyclo[2.2.1]-2-heptene The epoxidation reaction:

[0084]Drop into 50.0g (0.532mol) bicyclo[2.2.1]-2-heptene, 11.7g sodium carbonate and 200g chloroform in a four-necked glass flask equipped with constant pressure dropping funnel, thermometer and mechanical stirring, Place in an ice-water mixing bath, start stirring, mix evenly and keep the system temperature at 5-15°C, control the pH value of the system at 3.5-5.5, and put 234.2g of 18.3% peracetic acid (0.564mol) into the constant pressure dropping funnel The solution is slowly added dropwise to the reaction system, keeping the reaction temperature not exceeding 25°C, and the reaction is continued for 2 hours after the dropwise addition is completed;

[0085] After the reaction, the mixed solution was left to stand for stratification, the lower organic layer solutio...

Embodiment 2

[0095] A combination of acrylate compounds for coatings, which is isomer 3-hydroxy-6-methylbicyclo[2.2.1]heptyl-2-acrylate and 3-hydroxy-5-methylbicyclo[2.2.1]heptyl-2-acrylate Its preparation method comprises the following steps:

[0096] (1) 5-Methylbicyclo[2.2.1]-2-heptene The epoxidation reaction:

[0097] Put 54.0g (0.500mol) 5-methylbicyclo[2.2.1]-2-heptene, 5.50g sodium carbonate and 270g dichloromethane into a four-necked glass flask equipped with a constant pressure dropping funnel, a thermometer and mechanical stirring Methane, put it in an ice-water mixed bath, start stirring, mix evenly and keep the system temperature at 5-15°C, control the pH value of the system at 3.5-5.5, and put 241.5g of 20.5% peroxygen into the constant pressure dropping funnel Propionic acid (0.550mol) solution was slowly added dropwise to the reaction system, keeping the reaction temperature not exceeding 25°C, and the reaction was continued for 3 hours after the dropwise addition was...

Embodiment 3

[0107] A kind of acrylate compound 3-hydroxy-5,6-dimethylbicyclo[2.2.1]heptyl-2-acrylate for coating The preparation method comprises the following steps:

[0108] (1) 5,6-Dimethylbicyclo[2.2.1]-2-heptene The epoxidation reaction:

[0109] 122g (1.0mol) 5,6-dimethylbicyclo[2.2.1]-2-heptene, 6.33g potassium carbonate and 122g Dichloromethane, put it in an ice-water mixing bath, start stirring, mix evenly and keep the system temperature at 5-15°C, control the pH value of the system at 3.5-5.5, and put 633.3g of 12.0% dichloromethane into the constant pressure dropping funnel Slowly add peracetic acid (1.0mol) solution into the reaction system dropwise, keep the reaction temperature not exceeding 25°C, and continue the reaction for 5h after the dropwise addition is completed;

[0110] After the reaction, the mixed solution was left to stand for stratification, the lower organic layer solution was removed, washed with water to pH 6.5-7.0, filtered, and the solvent was distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com