Silane modified epoxidized soybean oil-polylactic acid polyurethane composition and preparation method thereof

A technology of epoxidized soybean oil and silane modification, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of poor biodegradability, poor storage stability, unfriendly environment, etc. Environmentally friendly, low-cost, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

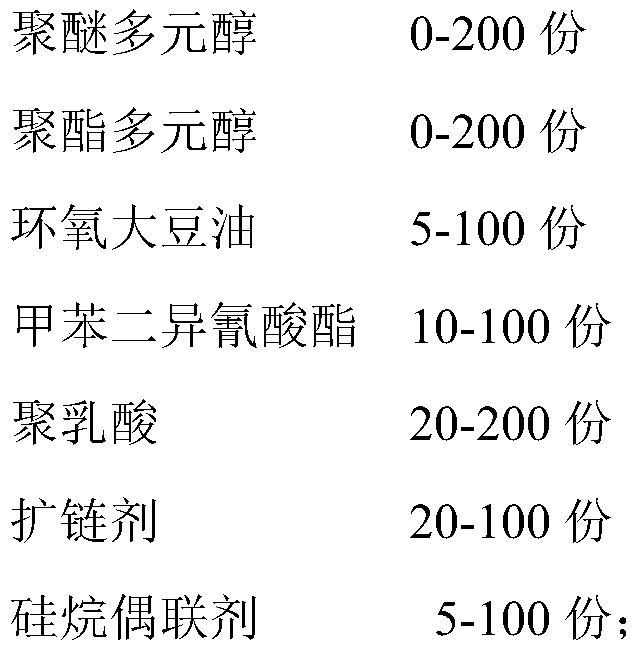

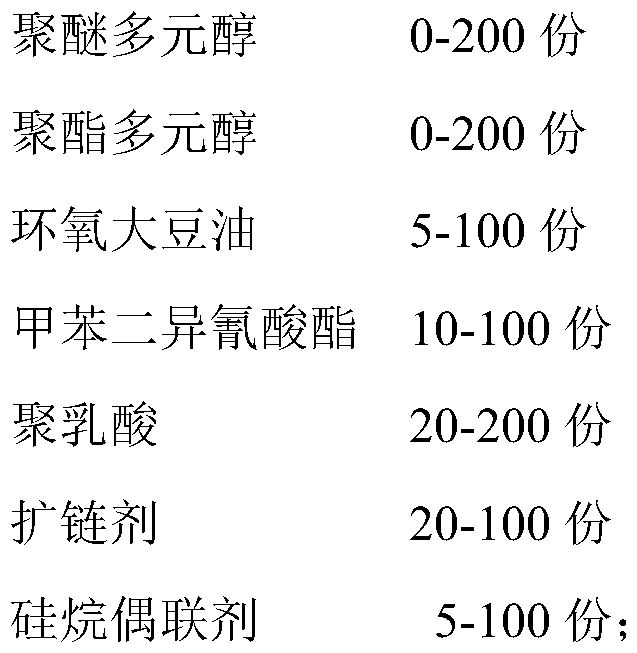

Method used

Image

Examples

Embodiment 1

[0022] Take 50 parts of polyether polyol DX-1 (functionality 2, molecular weight 1000), 50 parts of polyester polyol DX-2 (functionality 3, molecular weight 2000) and pour them into a three-necked flask, and raise the temperature to 110°C under nitrogen protection , dehydrated until the water content is less than 0.02%, drop in 5 parts of epoxy soybean oil, react at 110°C for 3 hours, drop in 38 parts of TDI, 25 parts of 1,4-butanediol, and add 20 mesh polylactic acid under the protection of nitrogen at 80°C 20 parts were stirred and reacted for 2 hours, heated up to 120°C, 10 parts of vinyltriethoxysilane was added dropwise, and reacted for 3 hours to obtain an adhesive product.

Embodiment 2

[0026] Take 150 parts of polyether polyol DX-1 (functionality 2, molecular weight 6000), 50 parts of polyester polyol DX-2 (functionality 3, molecular weight 8000), pour them into a three-necked flask, and raise the temperature to 150 under nitrogen protection. Dehydrate at ℃ until the water content is less than 0.02%, add 25 parts of epoxidized soybean oil dropwise, react at 120℃ for 4 hours, cool down to 90℃, add dropwise 30 parts of TDI, 55 parts of trimethylolpropane, and 50 parts of 80 mesh polylactic acid Stir the reaction for 3 hours, raise the temperature to 120° C., drop in 15 parts of vinyltrimethoxysilane and react for 5 hours to obtain an adhesive product.

Embodiment 3

[0030] Take 200 parts of polyether polyol DX-1 (functionality 4, molecular weight 10000), 100 parts of polyester polyol DX-2 (functionality 3, molecular weight 5000) and pour them into a three-necked flask, and raise the temperature to 130°C under nitrogen protection Dehydrate until the water content is less than 0.02%, add 10 parts of epoxidized soybean oil dropwise, react at 130°C for 5 hours, cool down to 100°C, drop in 42 parts of TDI, 25 parts of triethanolamine, add 100 parts of 100-mesh polylactic acid, and stir for reaction After 3 hours, the temperature was raised to 130° C., and 35 parts of vinyl tris(β-methoxyethoxy)silane was added dropwise to react for 8 hours to obtain an adhesive product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com