Process for producing material with equivalent heat-transfer performance of human body skin

A technology of human skin and equivalent materials, applied in the field of preparation of effective materials, can solve the problems of chitosan and polyurethane composite materials with single function, complex operation process, and narrow raw material range, and achieve simple preparation process, high biological activity, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

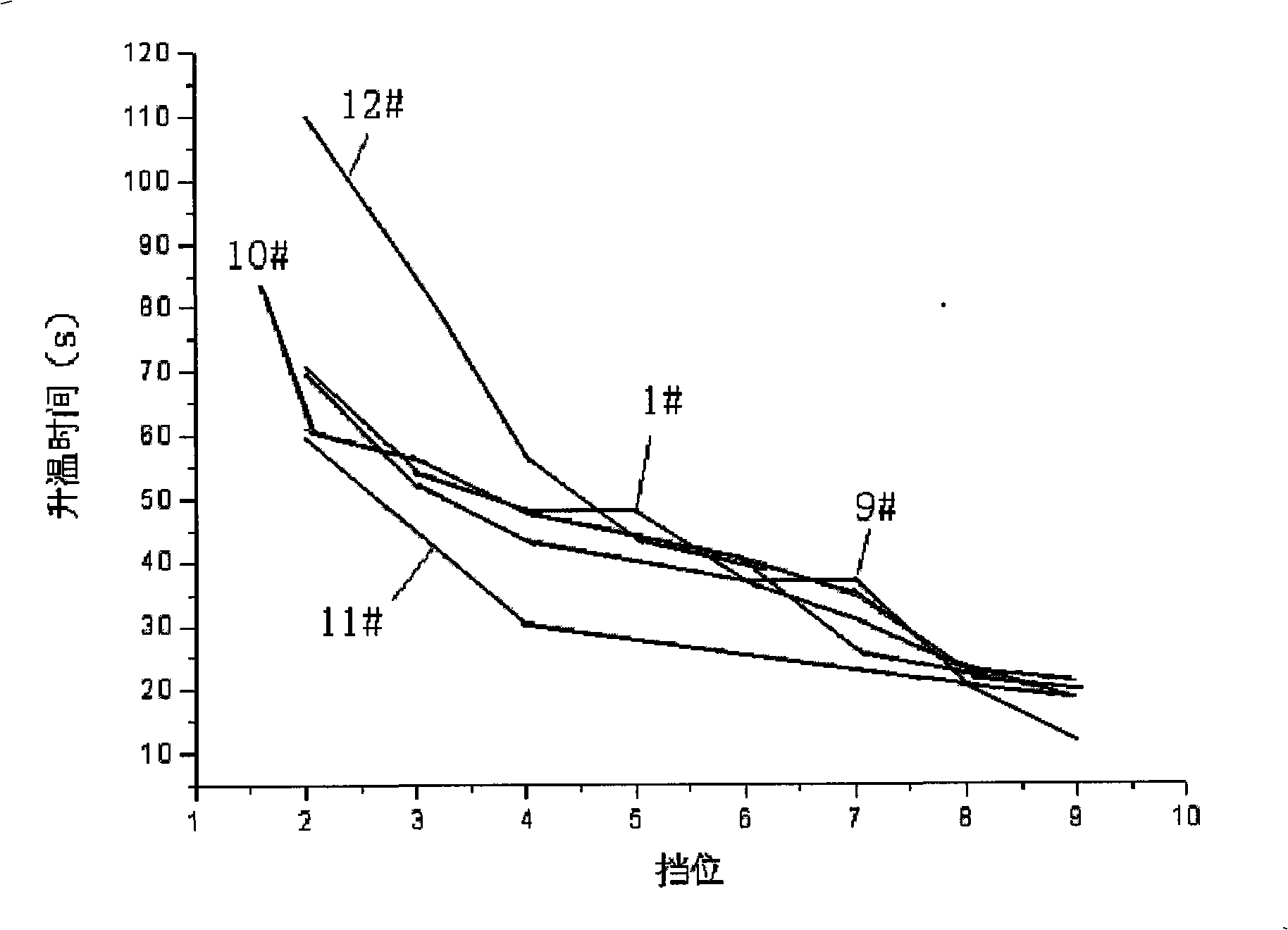

Embodiment 1

[0026] Add 9.063g terephthalylene diisocyanate (MDI) prepolymer (free isocyanate content (-NCO%) in the diisocyanate prepolymer is 20%) and 4.023g liquid polypropylene oxide successively in three-necked bottle, its Average molecular weight is 2000, at 80 ℃, high-speed stirring, constant temperature reaction 2.5 hours, obtain polyurethane pre-elastic polymer; Add 10g chitosan powder in this pre-polymer, amorphous form, degree of deacetylation ≥ 90.0%, pH ( 10g / L, 25℃) 7.0~8.0, viscosity 50~800mPa·s, heavy metal≤0.0015%, loss on drying≤10.0%, arsenic<0.00006%, residue on ignition≤1.5%, insoluble matter≤1.0%, high-speed strong stirring Dissolve it to obtain a viscous liquid without precipitation. After reacting at 80°C for 2 hours, cool the solution to 50°C, add 0.05g of triethylenetetramine for cross-linking, and add 0.23g of heat-sensitive material superconducting Carbon black and 0.4g of nano-hydrotalcite flame retardant were poured into a mold for solidification and defoaming...

Embodiment 2

[0029] 2.884g 4,4'-dicyclohexylmethane diisocyanate (H12MDI) prepolymer (free isocyanate content (-NCO%) in the diisocyanate prepolymer is 23%) and 7.779g liquid polycyclic Propylene oxide, the average molecular weight of which is 2000, was stirred at 80°C at high speed and reacted at a constant temperature for 2.5 hours to obtain a polyurethane prepolymer; 10 g of chitosan powder was added to the prepolymer, stirred at a high speed and vigorously to dissolve it to obtain a viscous , Liquid without precipitation; 90°C constant temperature cross-linking and curing reaction for 2 hours, the solution was cooled to 50°C, 0.5g of triethylenetetramine was added to the reaction system, and 0.325g of multi-armed carbon nanotubes were added as a thermosensitive material and 0.76g of nanometer hydrotalcite as a flame retardant, poured into a mold for solidification and defoaming for 24 hours, to obtain chitosan-based polyurethane elastomer human skin equivalent material. This sample is ...

Embodiment 3

[0032]Add 6.681g hexamethylene diisocyanate (HDI) prepolymer (free isocyanate content (-NCO%) in the diisocyanate prepolymer is 80%) and 3.717g polypropylene oxide successively in three-necked bottle, at 80 Stir at high speed at ℃ and react at constant temperature for 2.5 hours to obtain a polyurethane prepolymer; add 10 g of chitosan powder to the prepolymer, stir at a high speed and vigorously to dissolve it, and obtain a viscous liquid without precipitation; constant temperature at 60°C Cross-linking and curing reaction for 2 hours, lower the temperature of the solution to 50°C, add 0.23g of ethylenediamine to the reaction system, and at the same time add 0.2g of carbon fiber with a length of 2-6mm as a heat-sensitive material and 0.4g of nano-SiO 2 The flame retardant is poured into the mold for solidification and defoaming for 24 hours to obtain the equivalent material of chitosan-based polyurethane elastomer human skin. This sample is marked 11#.

[0033] Thermal perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com