Fluorine-containing aqueous polyurethane and preparation method and application thereof

A water-based polyurethane and polyurethane technology, applied in polyurea/polyurethane coatings, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as health pollution, increased danger, and flammability, so as to prolong the service life and solve the waste of resources , The effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

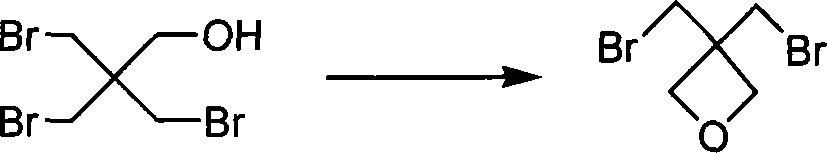

[0042] Add tribromoneopentyl alcohol (20.0 g, 61.5 mmol), NaOH (20 g), phase transfer catalyst TBAB (0.79 g, 2.46 mmol) and CH in a 250 mL three-necked flask equipped with a reflux condenser and a thermometer. 2 Cl 2 (100 mL), stirred evenly by magnetic force, then raised the temperature to 35°C for 12 hours, stopped the reaction, and cooled to room temperature. The layers were allowed to stand, the organic matter in the lower layer was removed, the aqueous layer was extracted with dichloromethane, the organic layers were combined, and dried over anhydrous magnesium sulfate. The organic solvent was removed under vacuum. Distilled under reduced pressure to obtain bromobutylene oxide as a colorless liquid (10.5 g, yield 70%).

[0043] The relevant data are as follows: 1 H NMR (300MHz, CDCl 3 )δ: 3.9(s, 4H), 4.4(s, 4H).

[0044] Under the protection of nitrogen, the compound bromobutylene oxide (10.0 g, 40.9 mmol) was added into a 100 mL three-necked flask equipped with a re...

Embodiment 2

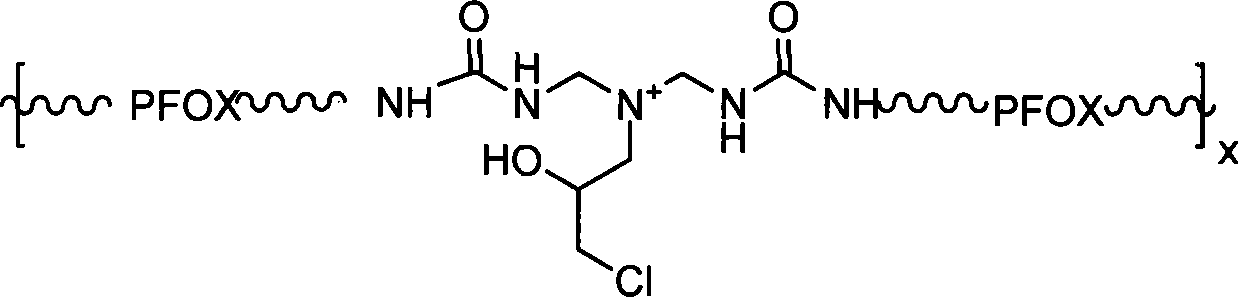

[0052] Under nitrogen protection, PFOX, IPDI ([IPDI] / [PFOX]=3.1 / 1, mol) and DBTDL ([DBTDL] / [monomers]=0.001 / 1, mol) were added to dry 500mL in a three-neck flask. Heating to 50°C for 3 hours, then adding the prepolymer to triethylenetetramine and epichlorohydrin ([triethylenetetramine] / [epichlorohydrin] / [prepolymer]=1:1.2 : 1, mol) in the acetone solution, heated to 50 ℃ after adding and continued to react for 3 hours. Finally, add acetic acid aqueous solution to control the degree of neutralization at 70%. After cooling to room temperature, residual acetone was removed in vacuo. The obtained polymer is a translucent liquid with blue fluorescence, and the molecular weight distribution is between 5,000 and 10,000.

[0053] The cationic water-based polyurethane obtained above is formulated into a solution, a crosslinking agent is added, and the padding-drying-baking process is used for finishing. The contact angle of the finished fabric to water reaches 142°, and the finished...

Embodiment 3

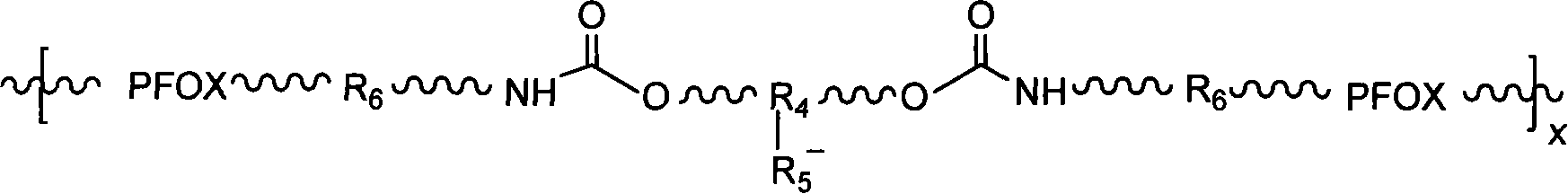

[0055] Under nitrogen protection, add PFOX, MDI (MDII] / [PFOX]=3.1 / 1, mol) and DBTDL ([DBTDL] / [monomers]=0.001 / 1, mol) to a dry 500mL three-port in the flask. Heating to 60°C for 4 hours, then adding the prepolymer to tetraethylenepentamine and epichlorohydrin ([triethylenetetramine] / [epichlorohydrin] / [prepolymer]=1:1.2 : 1, mol) in the acetone solution, heated to 70 ℃ after adding and continued to react for 5 hours. Finally, add acetic acid aqueous solution, and the degree of neutralization is controlled at 60%. After cooling to room temperature, residual acetone was removed in vacuo. The obtained polymer is a translucent liquid with blue fluorescence, and the molecular weight distribution is between 10,000 and 50,000.

[0056] The cationic water-based polyurethane obtained above is formulated into a solution, a crosslinking agent is added, and the padding-drying-baking process is used for finishing. The contact angle of the finished fabric to water reaches 145°, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com