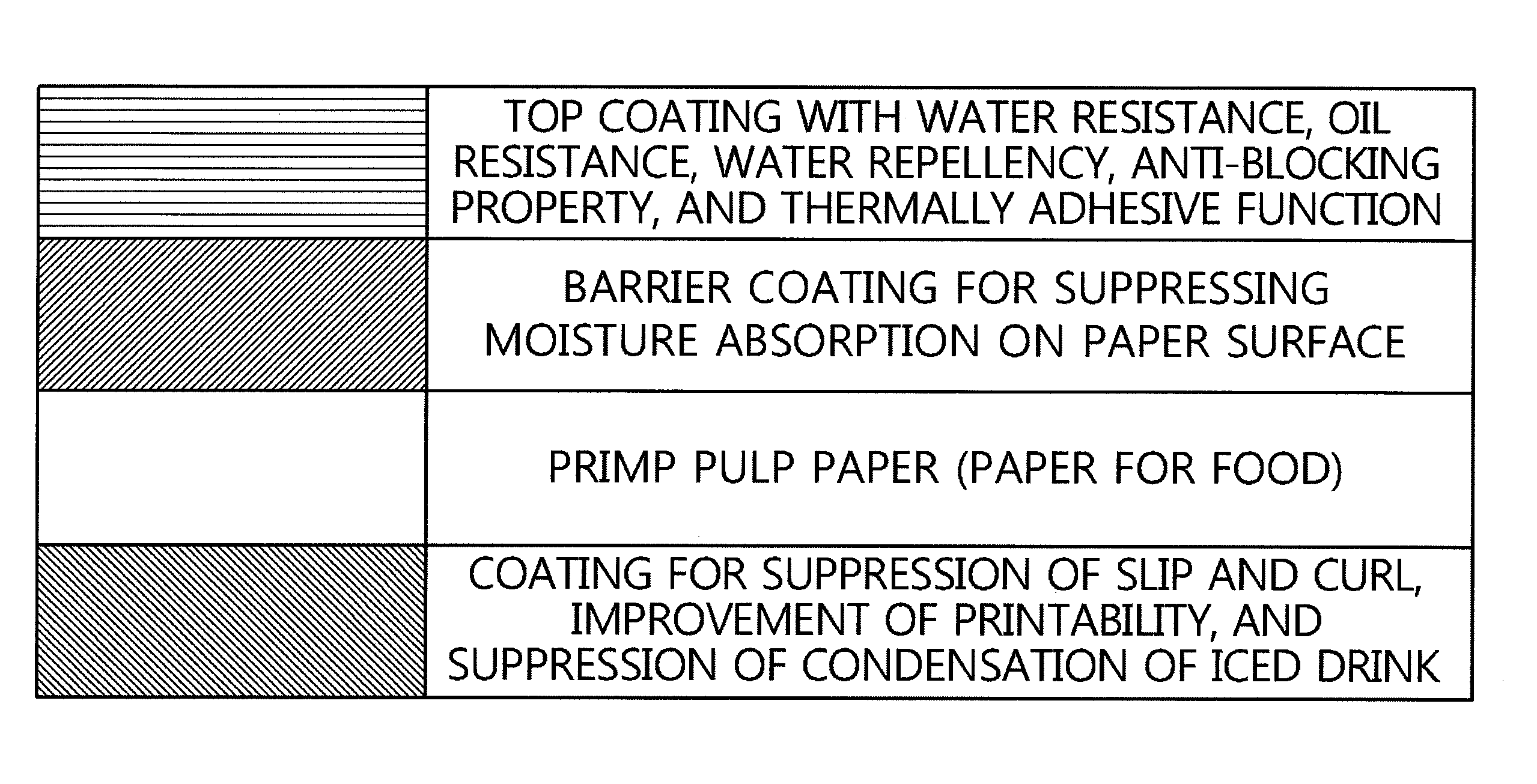

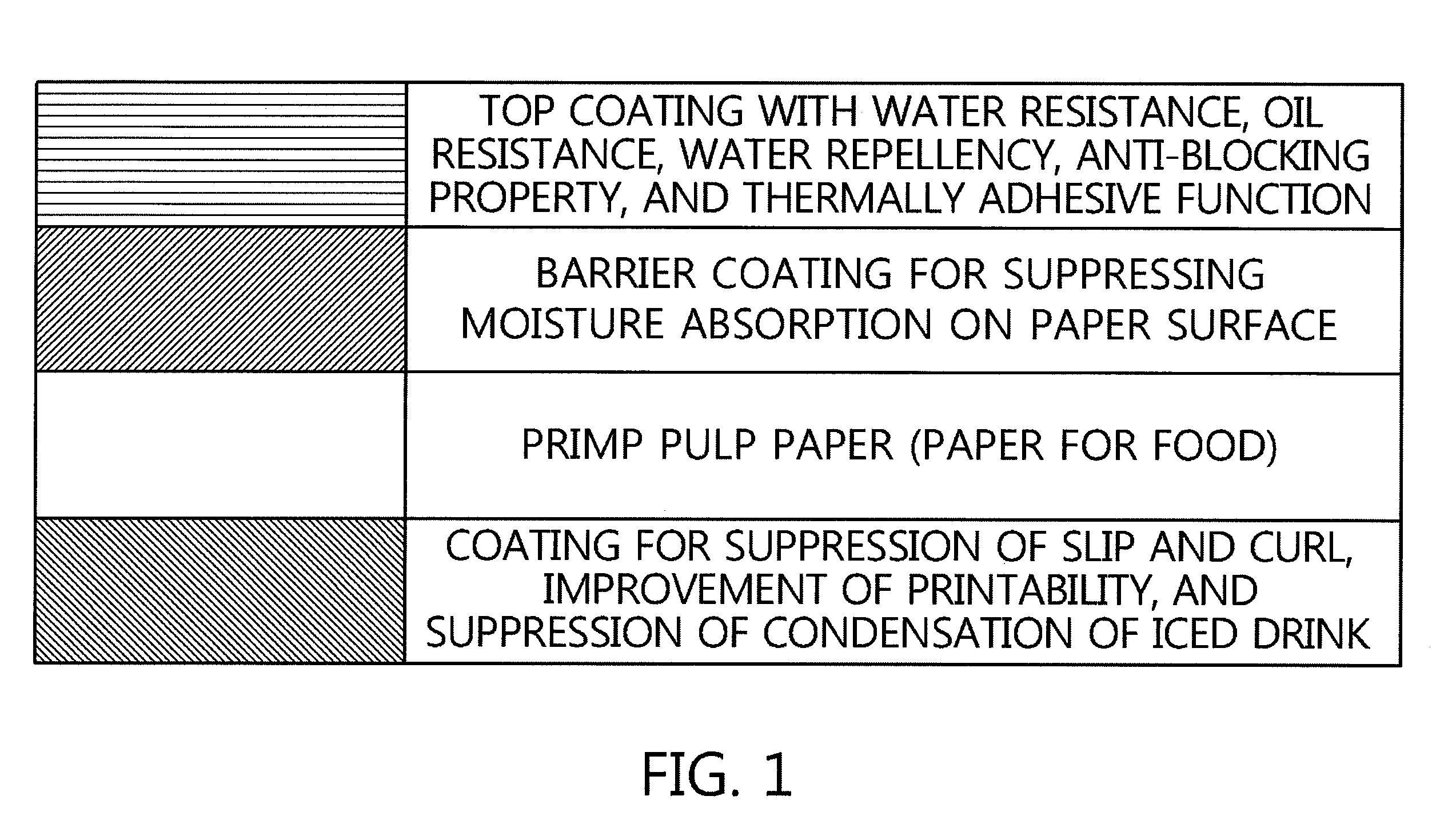

Method for preparing environmentally friendly paper coating agent by using water dispersible resin of ethylene-(METH)acrylic acid polymer, and use thereof

a technology of ethylene-methacrylic acid and paper coating agent, which is applied in the direction of synthetic resin layered products, rigid containers, packaging, etc., can solve the problems of difficult recycling, air pollution, and incineration of most conventional products, and achieves excellent dispersibility, reduced residue amount, and high uniformity of dispersed particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0094]240 g of NUCREL 2806 (acrylic acid content: 18 mass %, MFR=60 g / 10 minutes), 731.40 g of ion exchanged water, 4.00 g of DMEA, and 24.59 g of ammonia water were added to a 1500 ml autoclave, and then stirred at a temperature 100° C. at a stirring speed of 1200 rpm for 2 hours. Herein, a degree of neutralization of (DMEA+ammonia water) (a ratio of neutralization of an ethylene-acrylic acid-based copolymer with respect to a carboxylic group in terms of molar amount) was 75 mol %, and a mol % ratio of DMEA:ammonia water was 10:90. Then, the resultant product was cooled to 50° C. or less and then packaged, so that an aqueous dispersion was obtained. The obtained aqueous dispersion included solids of 24 mass % and had the viscosity of 7200 cps / 25° C.

example 3

[0095]230 g of NUCREL 2806 (acrylic acid content: 18 mass %, MFR=60 g / 10 minutes), 740.16 g of ion exchanged water, 11.51 g of DMEA, and 18.33 g of ammonia water were added to a 1500 ml autoclave, and then stirred at a temperature 100° C. at a stirring speed of 1200 rpm for 2 hours. Herein, a degree of neutralization of (DMEA+ammonia water) (a ratio of neutralization of an ethylene-acrylic acid-based copolymer with respect to a carboxylic group in terms of molar amount) was 75 mol %, and a mol % ratio of DMEA:ammonia water was 30:70. Then, the resultant product was cooled to 50° C. or less and then packaged, so that an aqueous dispersion was obtained. The obtained aqueous dispersion included solids of 23 mass % and had the viscosity of 10,000 cps / 25° C.

example 4

[0096]240 g of NUCREL 2806 (acrylic acid content: 18 mass %, MFR=60 g / 10 minutes), 735.06 g of ion exchanged water, 6.63 g of KOH, and 18.31 g of ammonia water were added to a 1500 ml autoclave, and then stirred at a temperature 100° C. at a stirring speed of 1200 rpm for 2 hours. Herein, a degree of neutralization of (KOH+ammonia water) (a ratio of neutralization of an ethylene-acrylic acid-based copolymer with respect to a carboxylic group in terms of molar amount) was 67 mol %, and a mol % ratio of KOH:ammonia water was 25:75. Then, the resultant product was cooled to 50° C. or less and then packaged, so that an aqueous dispersion was obtained. The obtained aqueous dispersion included solids of 24 mass % and had the viscosity of 1,850 cps / 25° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| mol % ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com