Nanoscale water-resisting oil-stain-resisting leather surface treatment agent and preparing method thereof

A surface treatment agent and nano-level technology, applied in the field of leather surface treatment agent and its preparation, can solve the problems affecting appearance aesthetics, use effect and service life, poor water and oil resistance, poor water and oil resistance, etc. , to fill leather folds and small cracks, good water and oil resistance, and maintain the mirror effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

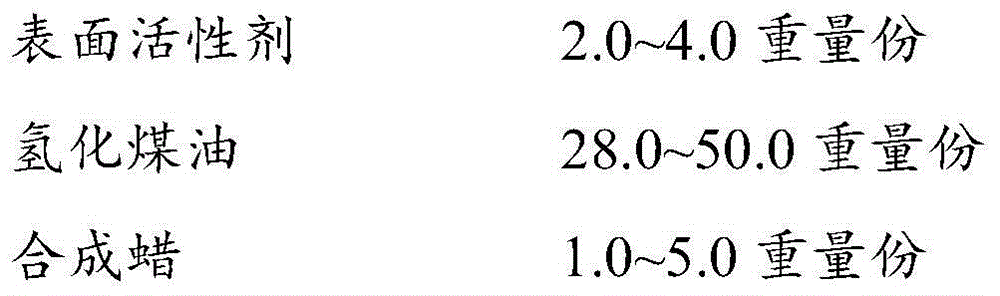

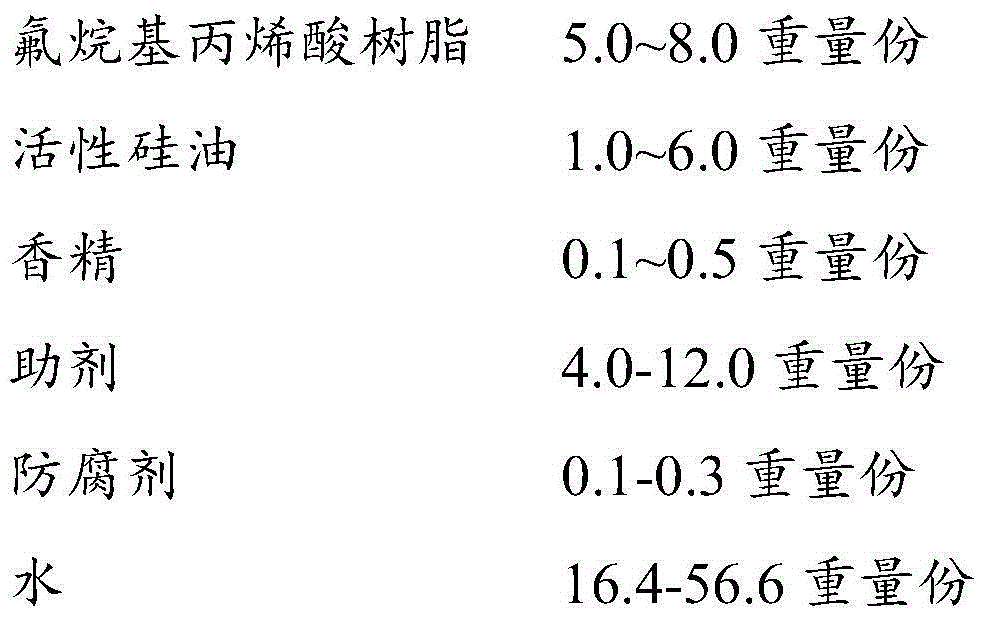

[0033] A nanoscale water and oil resistant leather surface treatment agent, the parts by weight of each component are as follows:

[0034]

[0035] Wherein the surfactant is a water-in-oil emulsifier.

[0036] The surfactant is lauryl polyoxyethylene ether-9 polydimethylsiloxane.

[0037] The synthetic wax is microcrystalline wax or S wax.

[0038] The auxiliary agent is propylene glycol or glycerin.

[0039] The following table is the component ratio table of embodiment 1-5:

[0040]

[0041]

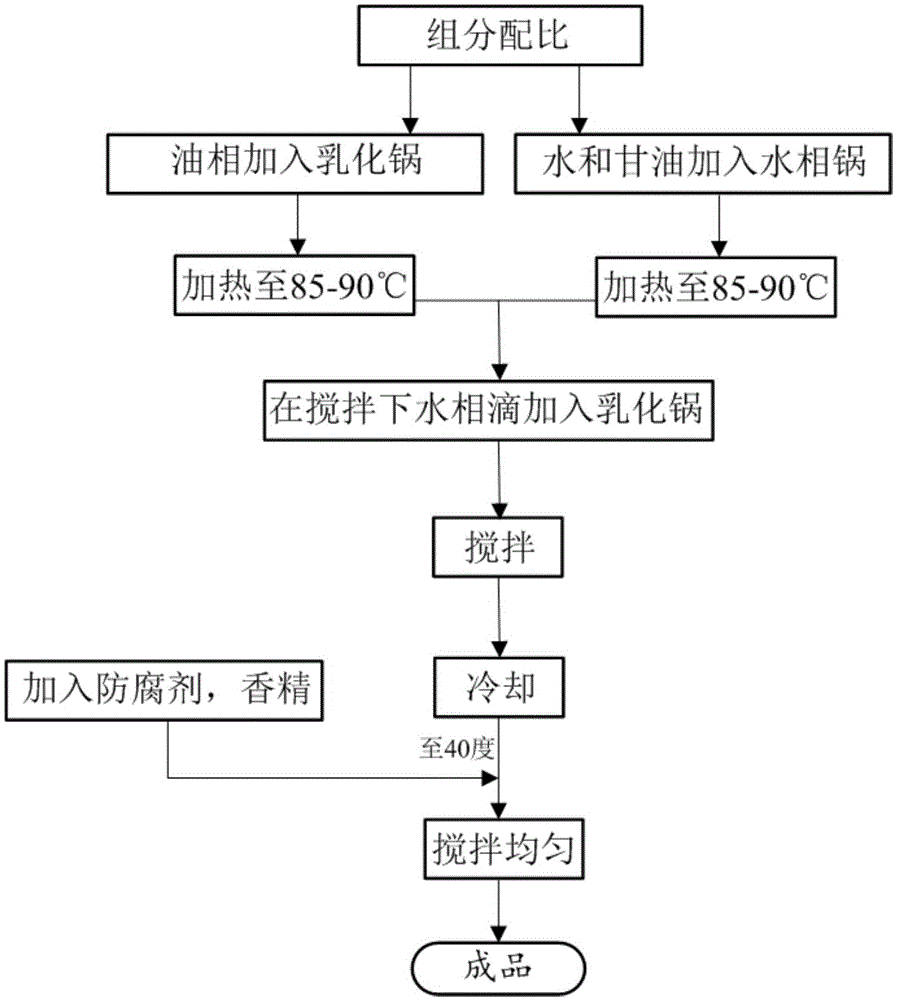

[0042] Such as figure 1 Shown, the preparation method of the nanoscale anti-water and oil-resistant leather surface treatment agent of above embodiment comprises the steps:

[0043] a. According to the ratio, add surfactant, hydrogenated kerosene, active silicone oil, syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com