Superfine environment-friendly thermal expansion microcapsule and preparation method thereof

A heat-expandable microcapsule, environmentally friendly technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problem that the particle size of heat-expandable microcapsules cannot be sub-micron, and achieve increased aesthetics, high monomer conversion rate, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

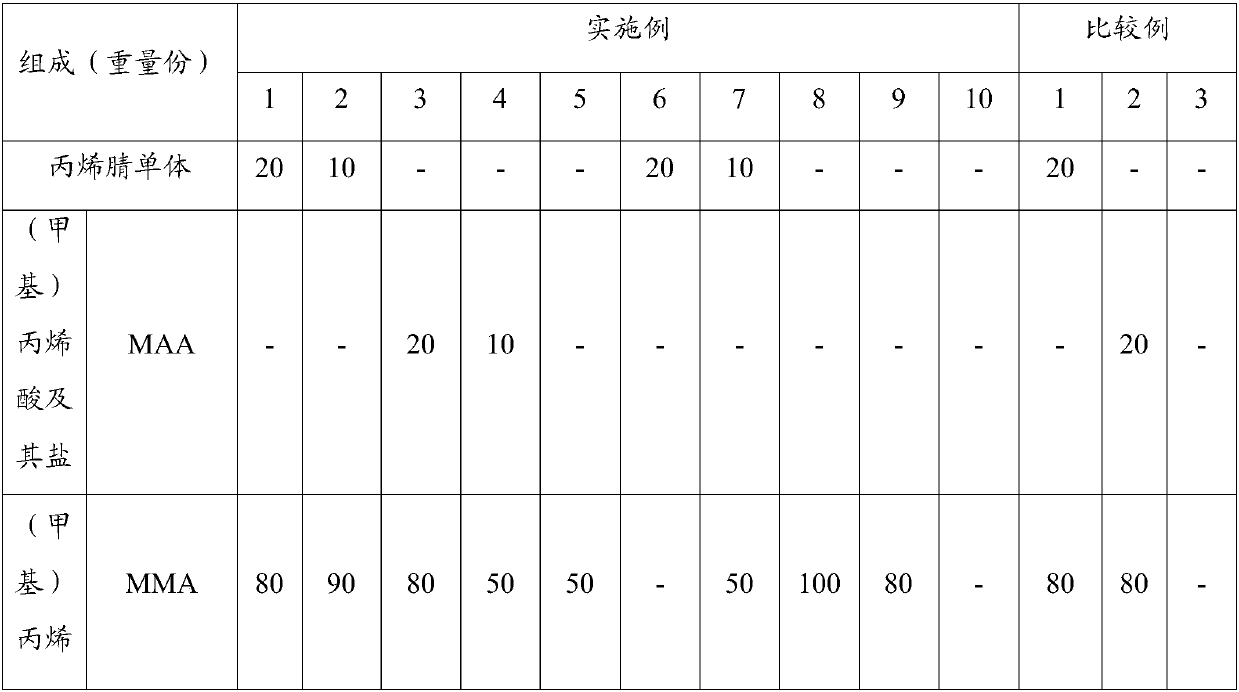

Embodiment 1

[0040] A preparation method of ultrafine environmental protection thermally expandable microcapsules, comprising the steps of:

[0041] (1) Preparation of water phase: 0.2 parts by weight of tween-20 and 0.5 parts by weight of Span-60, 5 parts by weight of polyvinylpyrrolidone, 60 parts by weight of sodium chloride, 0.2 parts by weight of sodium nitrite were added to 400 parts by weight in deionized water and dispersed to obtain a water phase composition;

[0042] (2) Preparation of oil phase: 10 parts by weight of isopentane, 30 parts by weight of isooctane, 20 parts by weight of acrylonitrile monomer, 80 parts by weight of methyl methacrylate, 1 part by weight of dilauroyl peroxide, 1 part by weight of Parts of trimethylolpropane trimethyl methacrylate are mixed uniformly to obtain an oil phase composition;

[0043](3) Preparation of dispersion: add the oil phase composition to the water phase composition, and at room temperature at a stirring speed of 15000r / min, emulsify ...

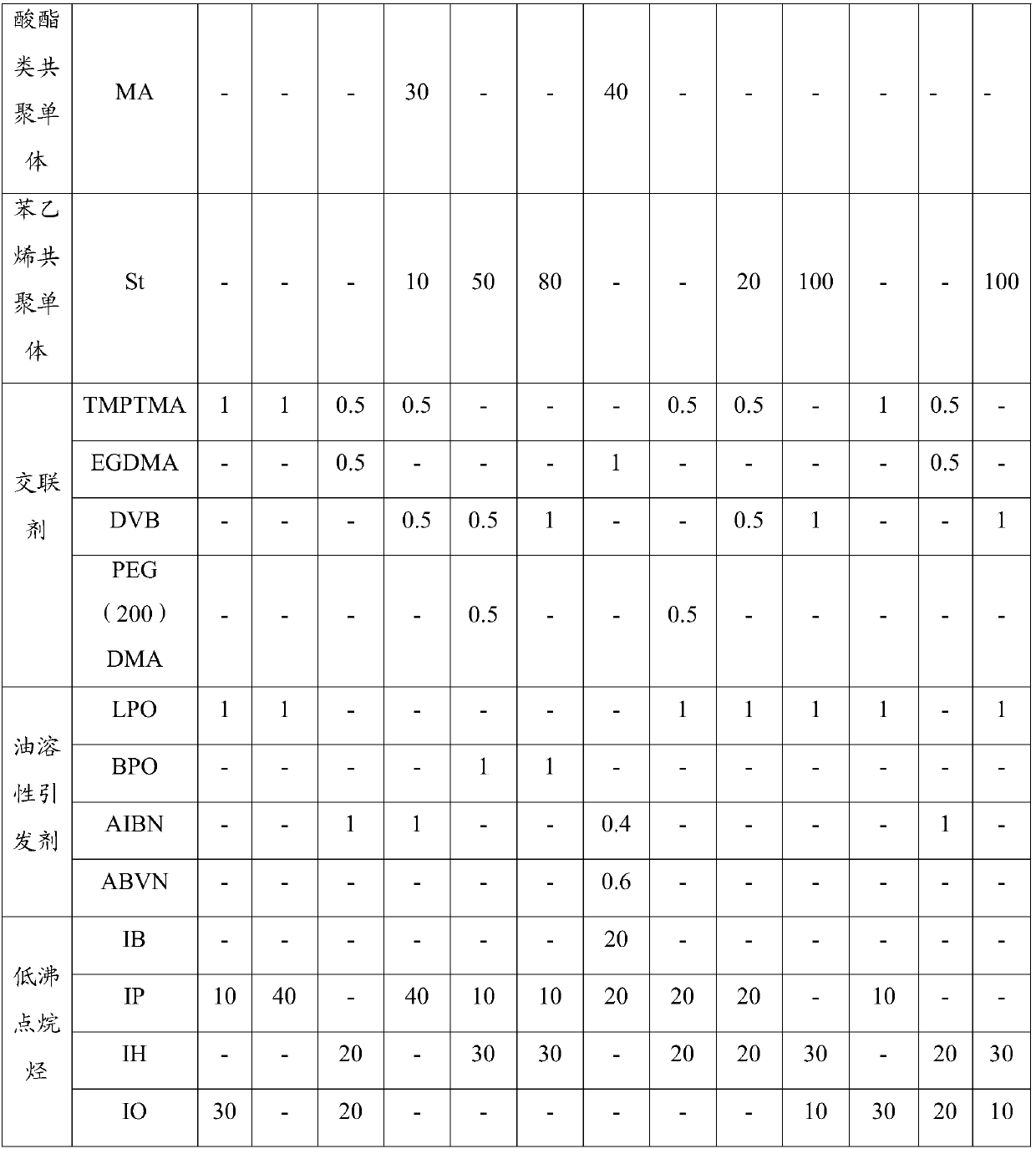

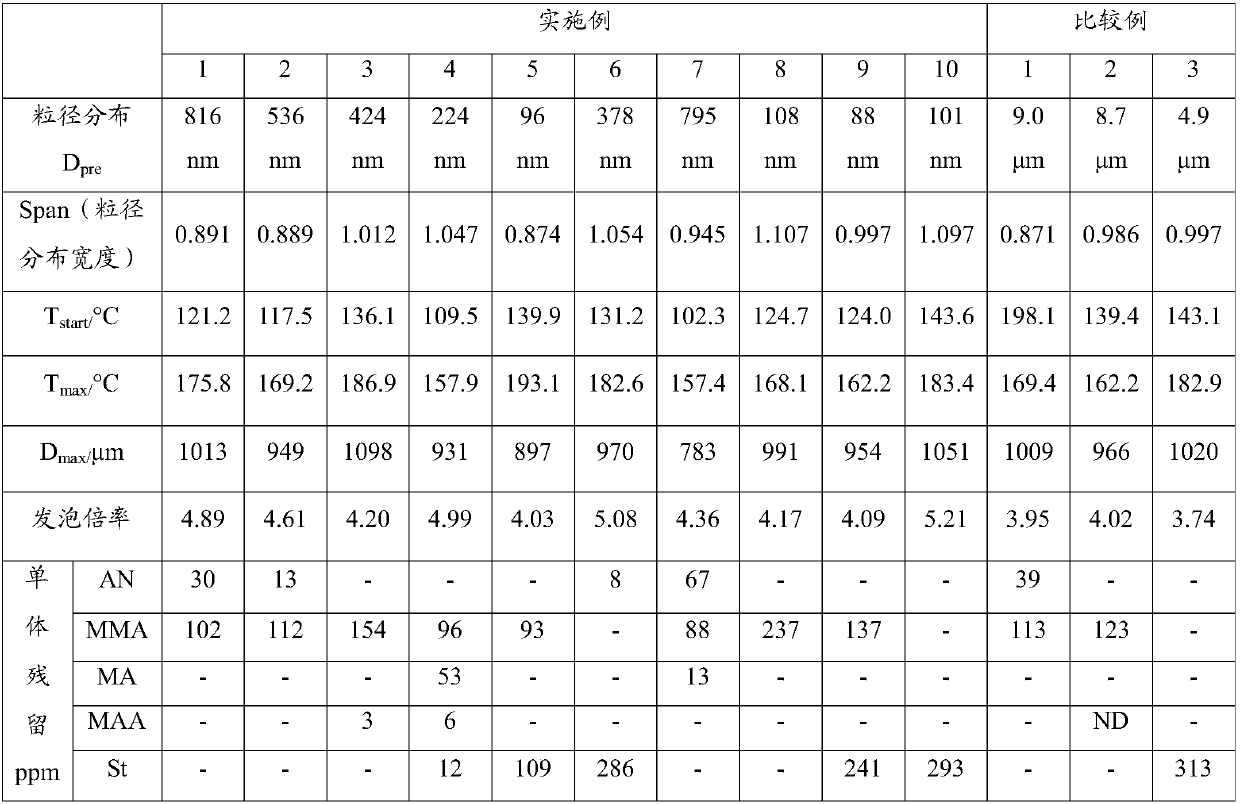

Embodiment 2~10

[0047] Except for changing the type and amount of each component in the oil phase composition, other conditions are the same as in Example 1, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com