A kind of low permeability sustained-release coating material and preparation method thereof

A slow-release coating material and coating material technology, applied in the field of coating materials, can solve the problems of increased workload and unknown slow-control release performance of slow-control release materials, and achieve good film-forming properties, rich variety, The effect of low monomer residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A low-permeability slow-release coating material, which is mainly made of the following raw materials: methyl methacrylate 1kg, trimethylaminoethyl methacrylate chloride 0.5kg, butyl methacrylate 0.8kg, hypromellate Base cellulose 0.03kg, sodium dodecylbenzenesulfonate 0.02kg, Tween 60 0.05kg, ammonium persulfate 0.7kg, purified water 7.5kg.

[0053] Wherein, the specific steps of the method for preparing the above-mentioned slow-release coating material are as follows:

[0054] (1) Polymerizing the monomers methyl methacrylate, trimethylaminoethyl methacrylate chloride and butyl methacrylate at 40-60°C;

[0055] (2) Add hydroxypropyl methylcellulose, continue to polymerize at 65-80°C, and then cool to room temperature to obtain the finished product.

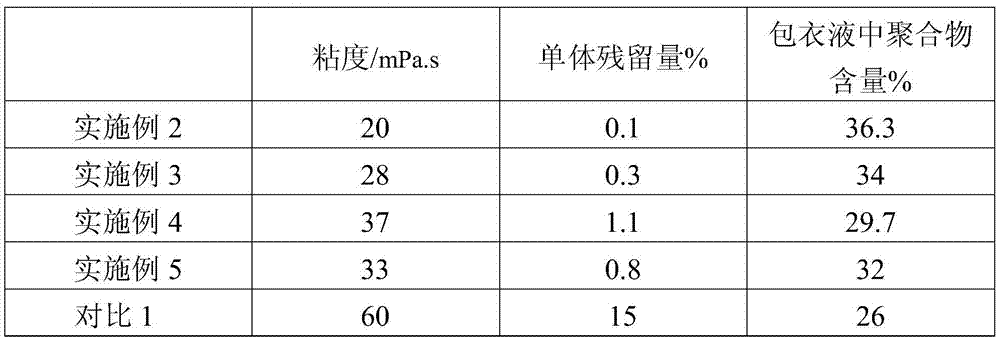

Embodiment 2

[0057] A low-permeability slow-release coating material, which is mainly made of the following raw materials: methyl methacrylate 1kg, trimethylaminoethyl methacrylate chloride 0.52kg, butyl methacrylate 1.1kg, ethyl cellulose Sodium dodecylbenzenesulfonate 0.03kg, sodium dodecylbenzenesulfonate 6.63g, Tween 20 1.33g, ammonium persulfate 0.036kg, purified water 8.745kg.

[0058] Wherein, the specific steps of the method for preparing the above-mentioned slow-release coating material are as follows:

[0059] (1) Mix monomer methyl methacrylate, trimethylaminoethyl methacrylate chloride, butyl methacrylate, sodium dodecylbenzenesulfonate, Tween 20, and purified water, heat up to 60°C, Under stirring, ammonium persulfate aqueous solution was added dropwise thereto, and the reaction was continued for 2 hours;

[0060] (2) Add ethyl cellulose, then raise the temperature to 65°C and react for 1 hour, then react at 80°C for 2 hours, and cool to room temperature after the reaction to...

Embodiment 3

[0062] A low-permeability sustained-release coating material, which is mainly made of the following raw materials: 1 kg of methyl methacrylate, 1 kg of trimethylaminoethyl methacrylate chloride, 1.5 kg of butyl methacrylate, and 0.05 kg of cellulose acetate kg, glyceryl stearate 0.0284kg, potassium persulfate 0.1065kg, purified water 17.75kg.

[0063] Wherein, the specific steps of the method for preparing the above-mentioned slow-release coating material are as follows:

[0064] (1) Mix the monomer methyl methacrylate, trimethylaminoethyl methacrylate, butyl methacrylate, glyceryl stearate, and purified water, raise the temperature to 60°C, and add dropwise to it under stirring Potassium persulfate aqueous solution continued to react for 2 hours;

[0065] (2) Add cellulose acetate, then raise the temperature to 65°C and react for 1 hour, then react at 80°C for 3 hours, and cool to room temperature after the reaction to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com