Patents

Literature

35results about How to "High polymer content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer delivery in well treatment applications

InactiveUS8044000B2Reduce solubilityLow viscosityTransportation and packagingFluid removalActive polymerEmulsion

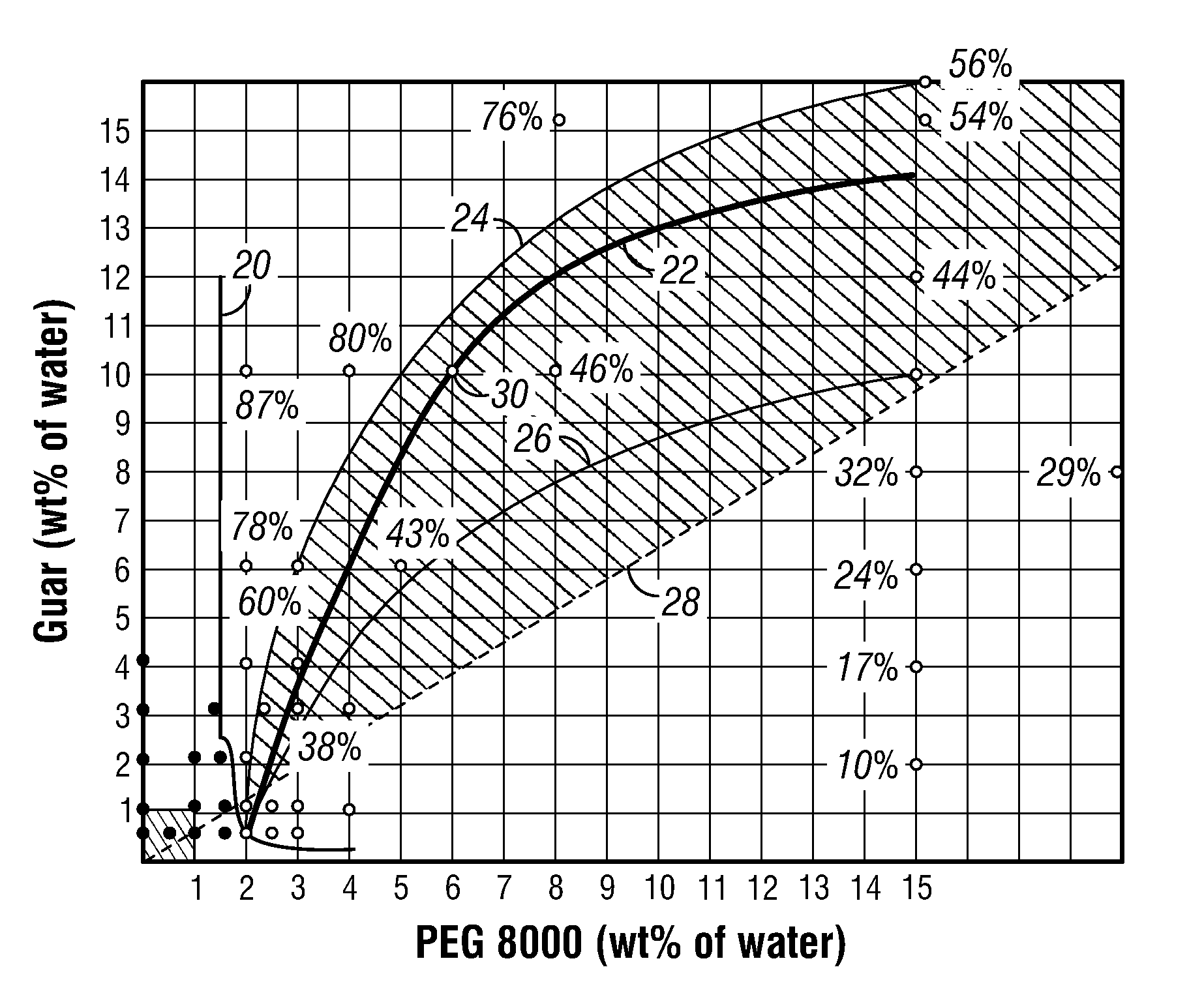

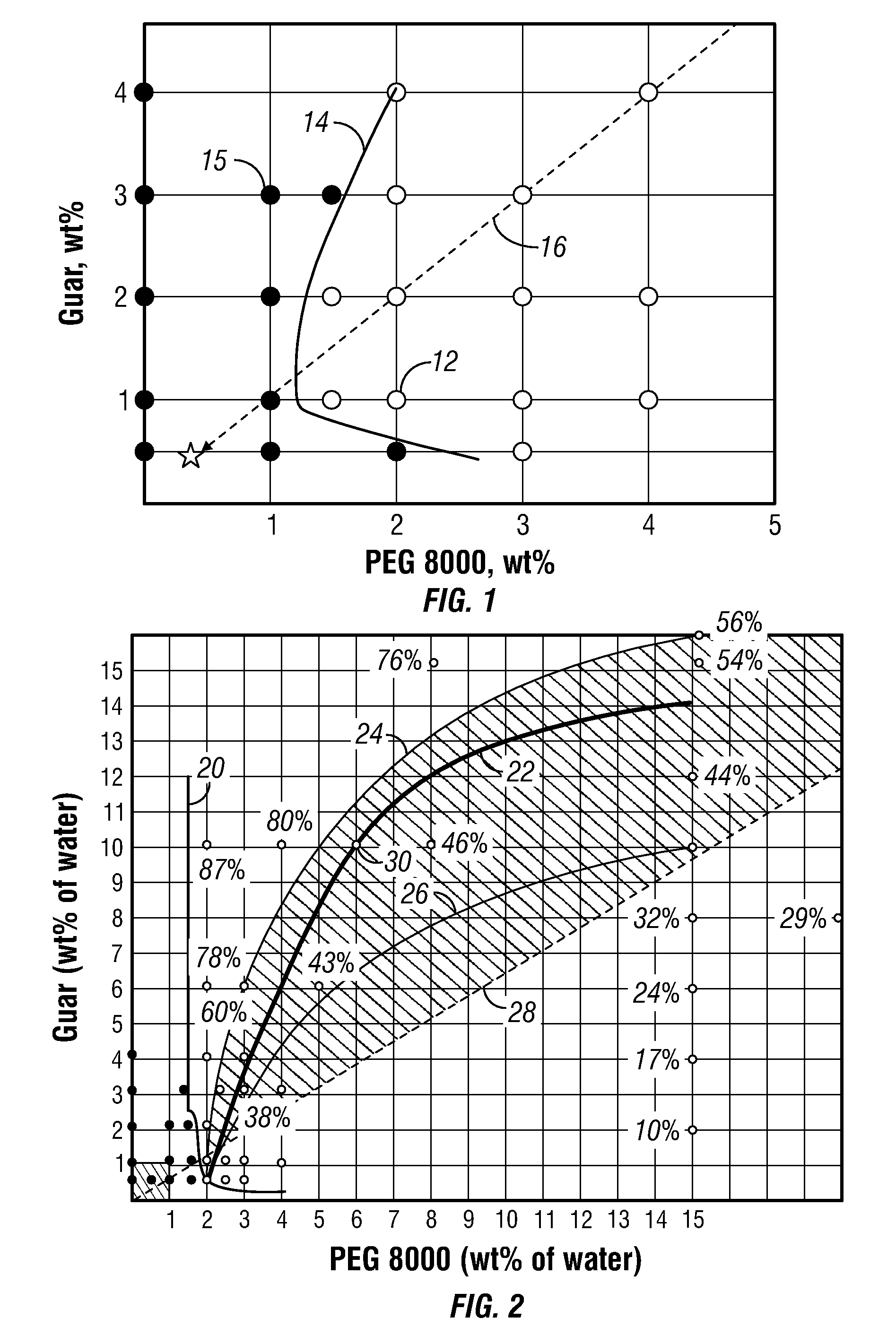

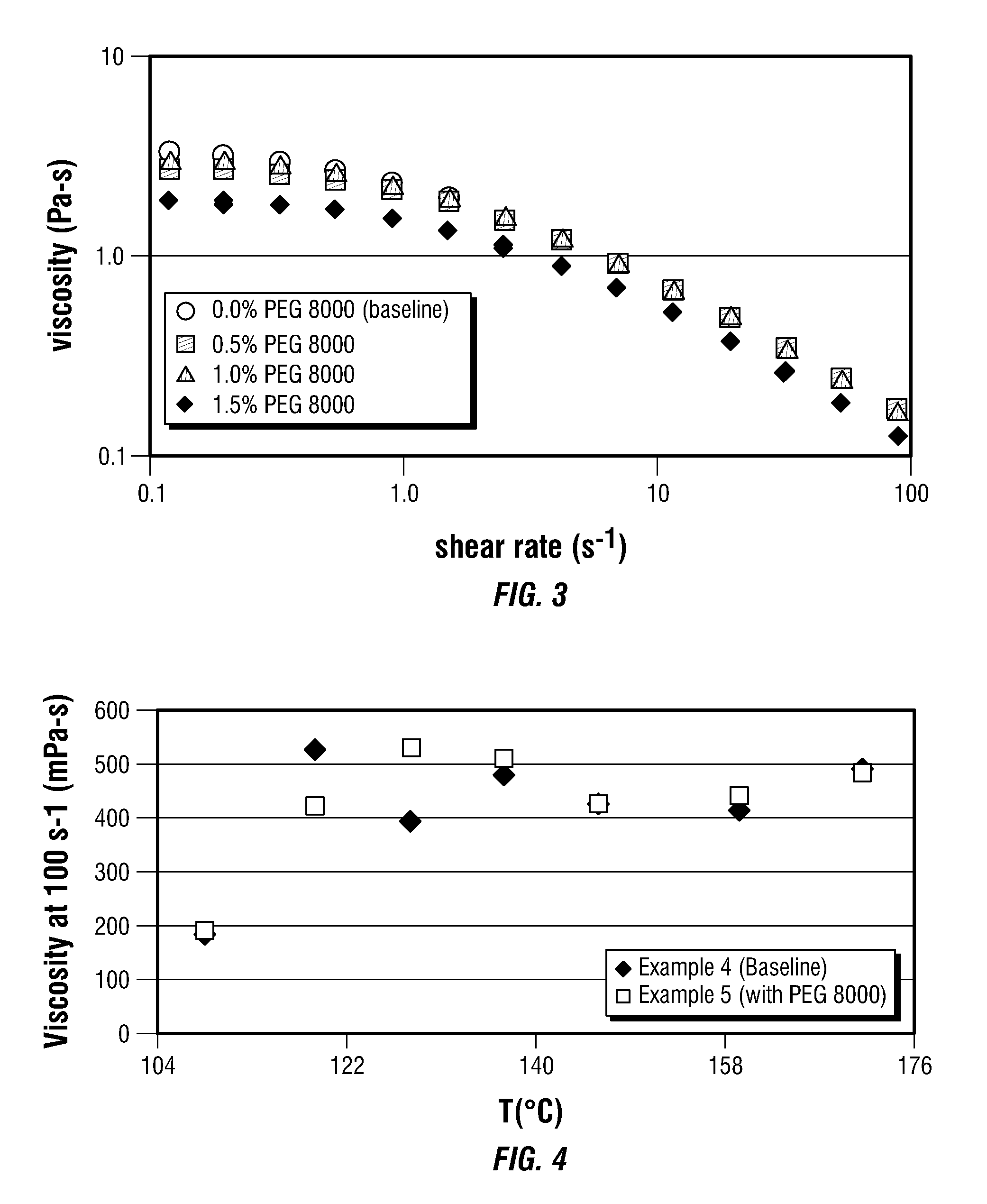

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

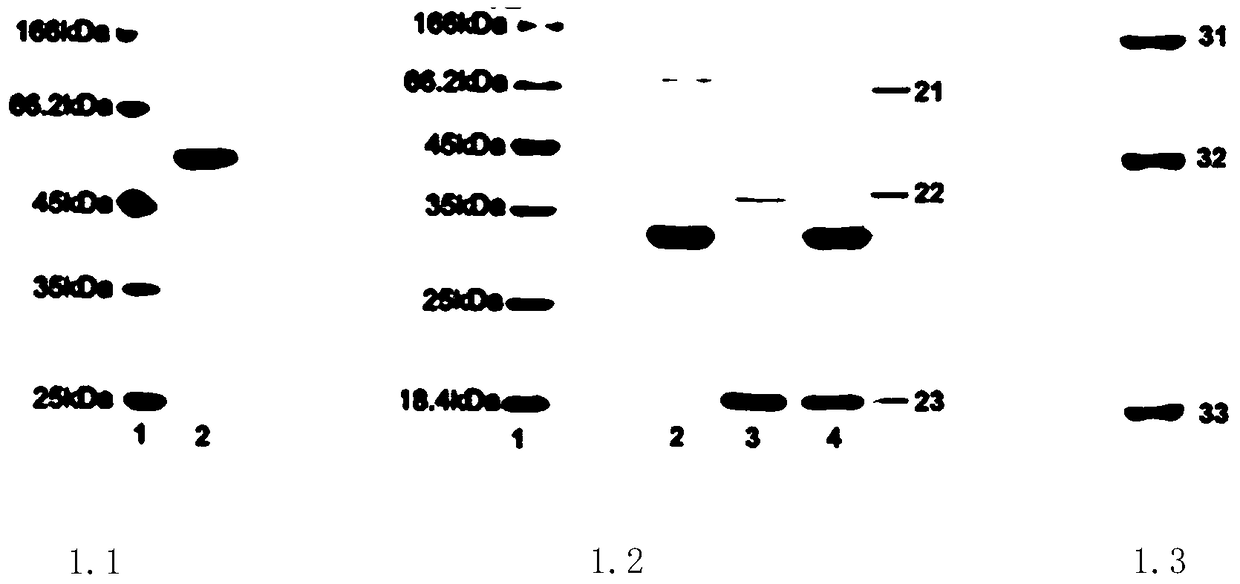

Process for preparing human serum albumin

ActiveCN103394076ANon-deterministicHigh yieldPeptide/protein ingredientsSerum albuminUltrafiltrationFiltration

The invention discloses a process for preparing human serum albumin. According to the process, a low-temperature ethanol separation method is adopted, and the human serum albumin is prepared from human plasma. The process comprises the steps of dissolving plasma; preparing an ingredient I; preparing an ingredient II and an ingredient III; preparing an ingredient IV; preparing an ingredient V; refining the ingredient V; carrying out ultrafiltration; diluting; carrying out pasteurization; sterilizing and packaging albumen; incubating products; and packaging finished products. The process has the advantages that solid-liquid separation is carried out by adopting a pressure filtration technology, so that the albumin yield which is higher than 29 g / L plasma is increased remarkably, the purity is higher than 98%, and the stability of the products is improved remarkably; Zetaplus deep filter-core filtration is combined with the prolongation of pasteurization time, so that the PKA (Protein Kinase A) level of the products is effectively controlled to be lower than 20IU / ml, and the risks of excessive heat source and virus infection in the products are reduced; and during the process, sodium chloride solutions of two gradient concentrations are used for carrying out ultrafiltration, so that not only can the ethanol residual quantity of the products be controlled to be lower than 0.025%, but also the aluminum residual quantity can be effectively minimized to be lower than 50 micrograms / L.

Owner:华润博雅生物制药集团股份有限公司

Asphalt binder for porous pavements

ActiveUS20090182074A1High polymer contentWorkable viscosityIn situ pavingsBituminous coatingsPolymer sciencePorous pavement

An asphalt binder is provided, comprising 85 to 97.5 parts by weight of a bitumen and 16 to 2.5 parts by weigh of a polymer composition, wherein the polymer composition comprises:(i) from 2 to 8, preferably from 3 to 6 parts by weight of a styrenic block copolymer having at least two blocks of monovinylaromatic hydrocarbon (A) and at least one block of a conjugated diene (B), wherein the block copolymer composition has a vinyl content of at least 25% by weight, preferably from 25 to 40% by weight, based on the total diene content;(ii) from 0 to 5, preferably from 1 to 3 parts by weight of a styrenic diblock copolymer having one block of monovinylaromatic hydrocarbon (A) and one block of a conjugated diene (B); and(iii) from 0.5 to 3, preferably from 1 to 2.5 parts by weight of an ethylene-vinyl acetate copolymer,wherein the weight ratio of (i)+(ii):(iii) is from 2:1 to 6:1, preferably from 3:1 to 4:1. In addition, an asphalt mix is provided comprising 2 to 8 parts by weight of the asphalt binder of the present invention and 98 to 92 parts by weight of gap-graded aggregate or open-graded aggregate material.Furthermore, a porous pavement is claimed, produced from the open or gap-graded mixes, by compacting the asphalt mix mentioned above.

Owner:KRATON POLYMERS US LLC

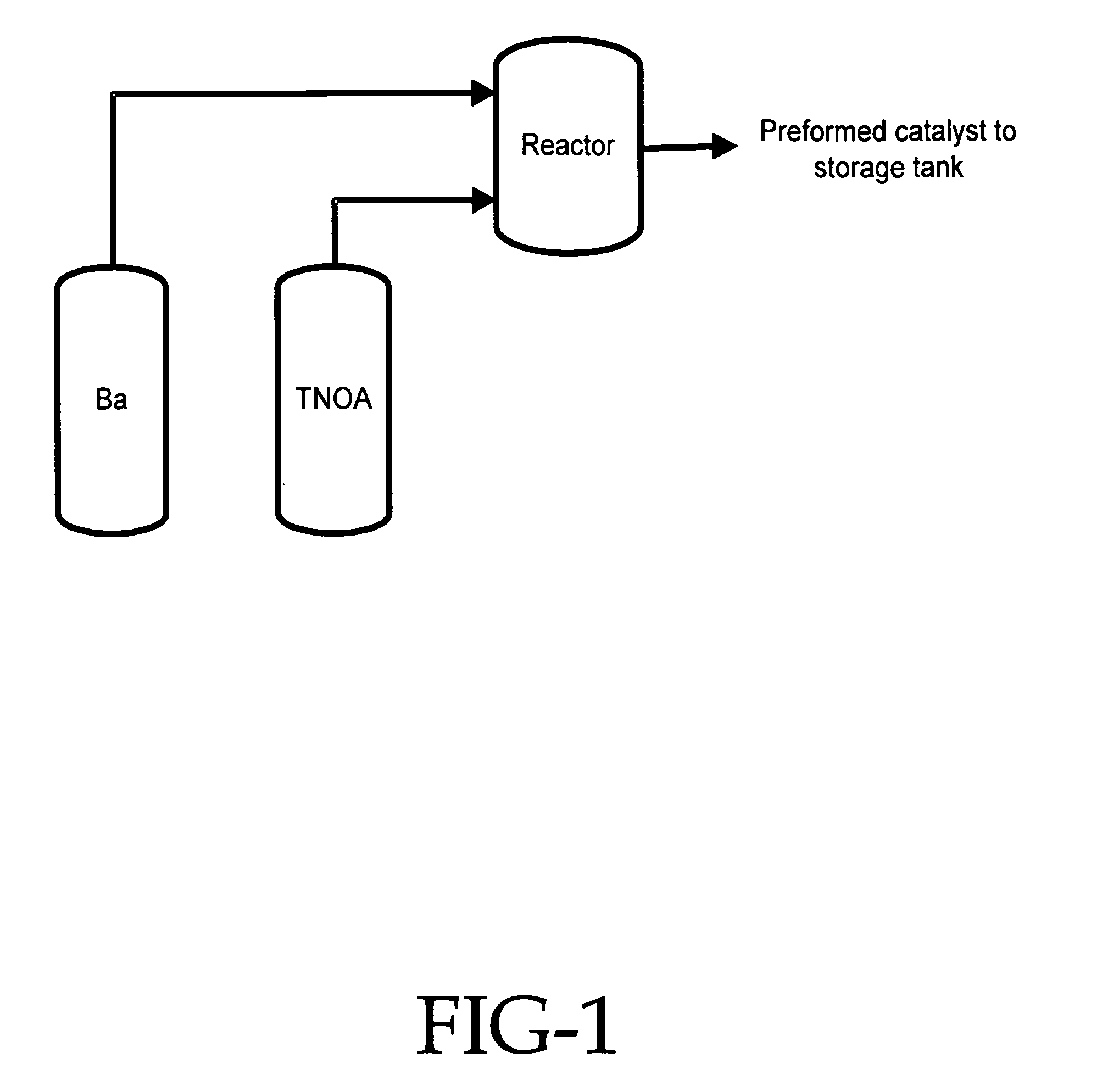

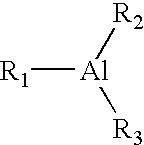

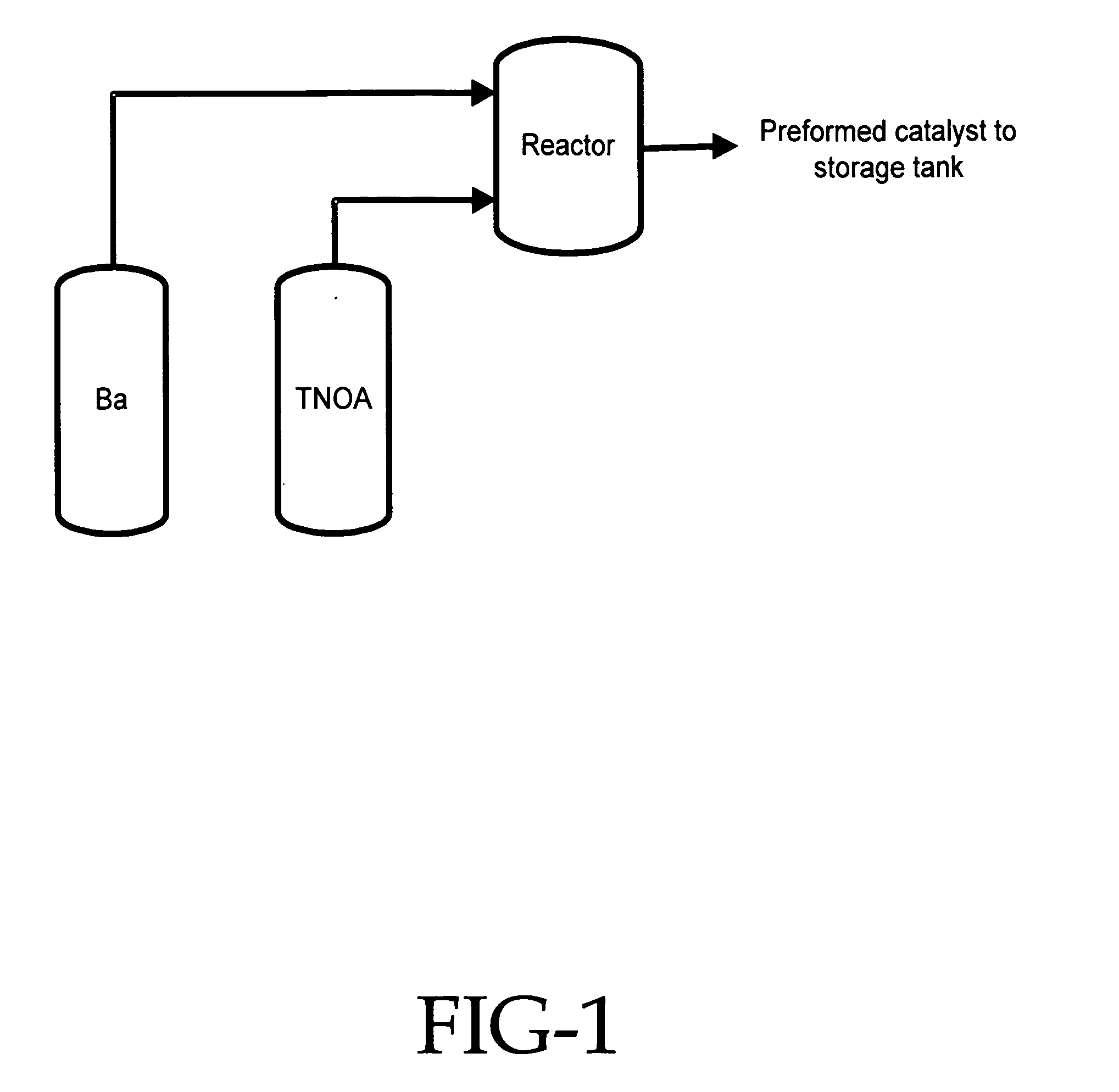

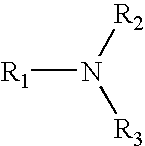

Catalyst for synthesizing high trans polymers

InactiveUS7189792B2High polymer contentInexpensive and safe materialOrganic-compounds/hydrides/coordination-complexes catalystsPhosphateEthylene Homopolymers

The process and catalyst of this invention can be utilized to synthesize homo and copolymers of conjugated diene monomers and vinyl aromatic monomers having high trans contents of greater than 60% with low melting points. These homo and copolymers of conjugated diene monomers and vinyl aromatic monomers can be utilized in tire tread and sidewall rubbers that exhibit outstanding wear and tear characteristics in the tread and excellent flexing properties in the sidewall. The rubber polymers of this invention are made utilizing an improved catalyst system. This catalyst system is comprised of (a) organo aluminum compounds, (b) organo lithium compounds, (c) a barium compound selected from barium salts of (i) di(ethylene glycol) ethyl ether, (ii) di(ethylene glycol) propyl ether, (iii) di(ethylene glycol) hexyl ether, (iv) di(N,N-dimethyl amino glycol) ethyl ether, (v) menthol and thymol in the presence of polar modifier consisting of water, alcohols, amines, thiols, phosphates and phosphites. The trans polymers and copolymers of this invention made with the above catalyst system typically have a glass transition temperature ranging from −97° C. to −40° C., a melt temperature ranging from −30° C. to +30° C., and a number average molecular weight from 20,000 to 250,000. The inclusion of such polar modifiers in the barium catalyst system results in a high styrene content in copolymerization, a high trans content, and high molecular weight. Copolymers of conjugated diolefin monomers and vinyl aromatic monomers made with the catalyst system of this invention also have a tapered macrostructure.

Owner:THE GOODYEAR TIRE & RUBBER CO

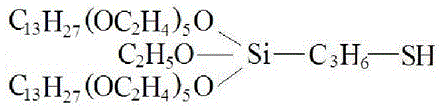

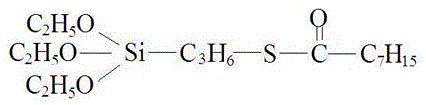

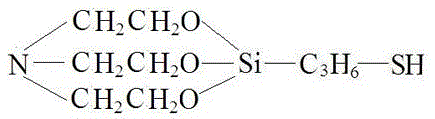

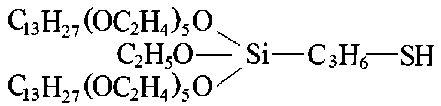

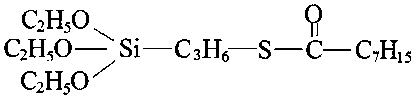

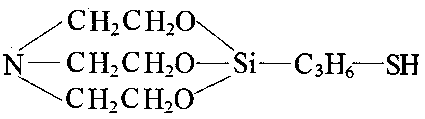

Method for preparing mercaptosilane coupling agent by using channel reactor

ActiveCN105601661AGuarantee continuous and stable operationIncrease in sizeGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

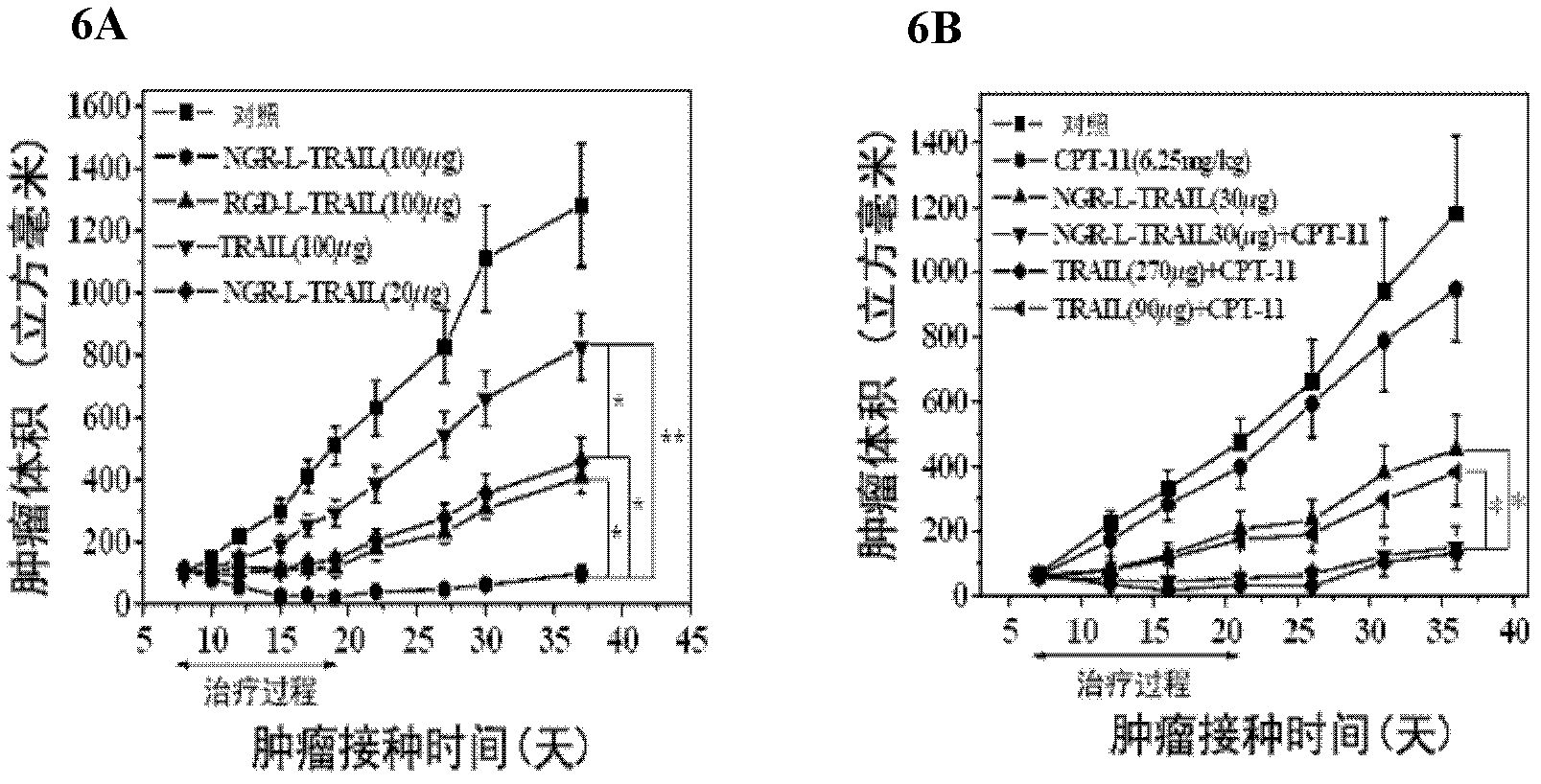

Tumor necrosis factor related apoptosis ligand fusion protein, and method of preparation and use thereof

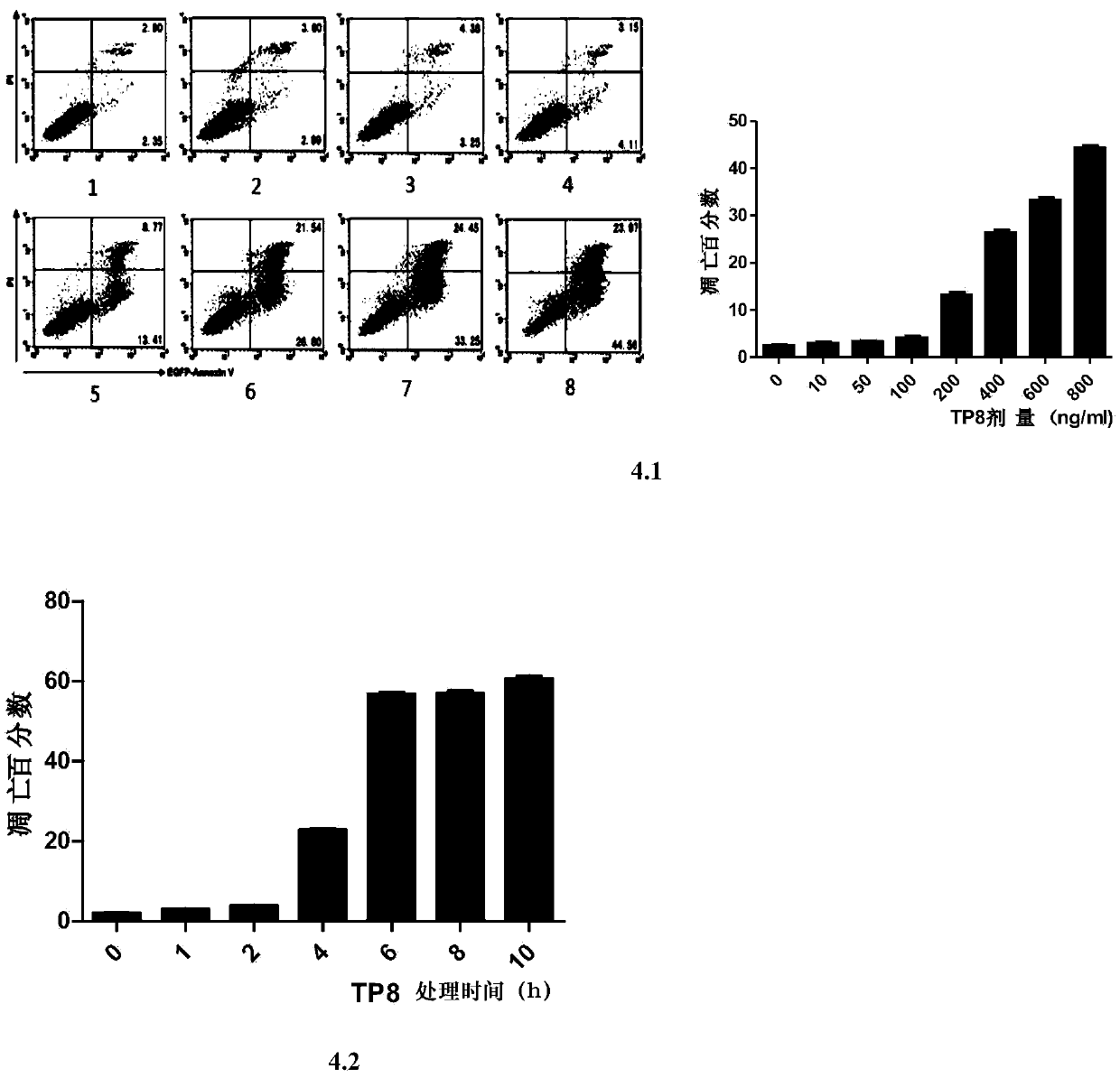

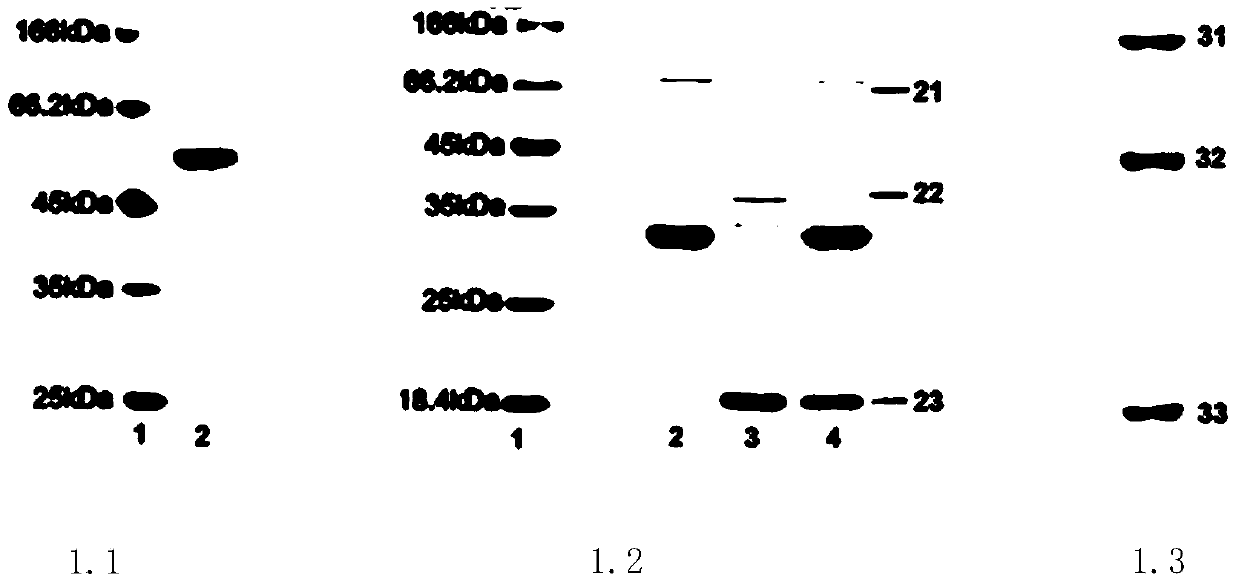

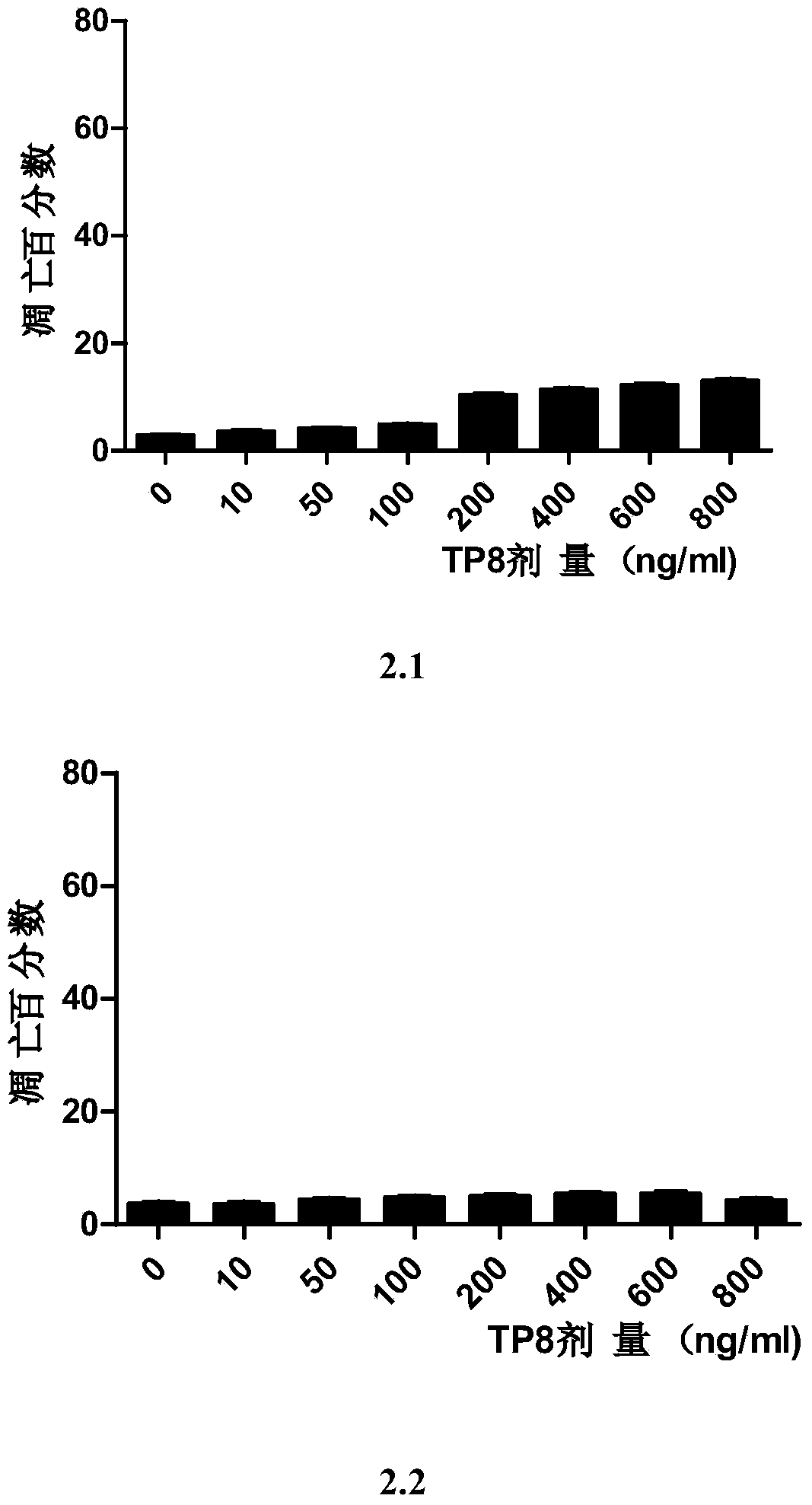

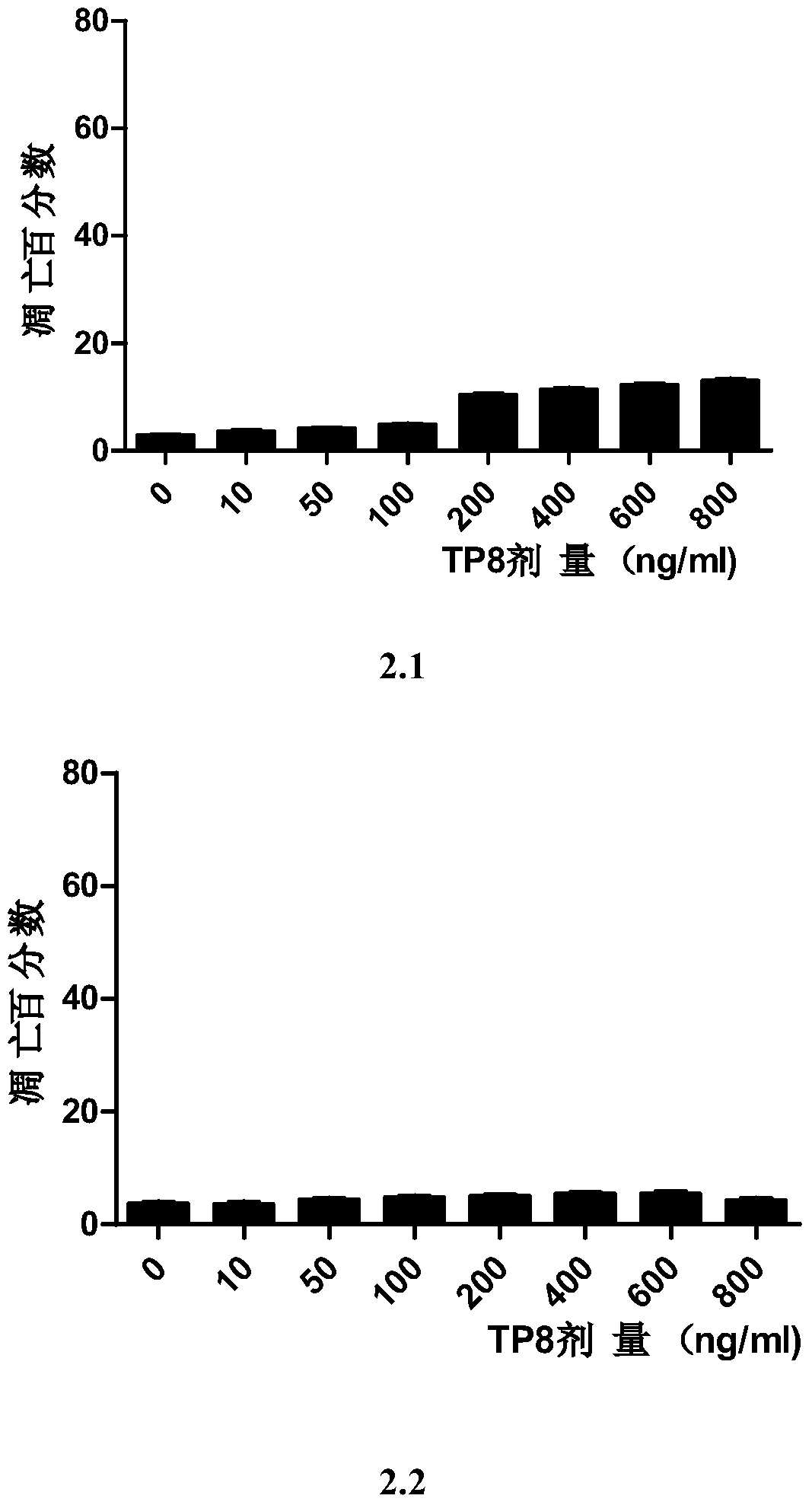

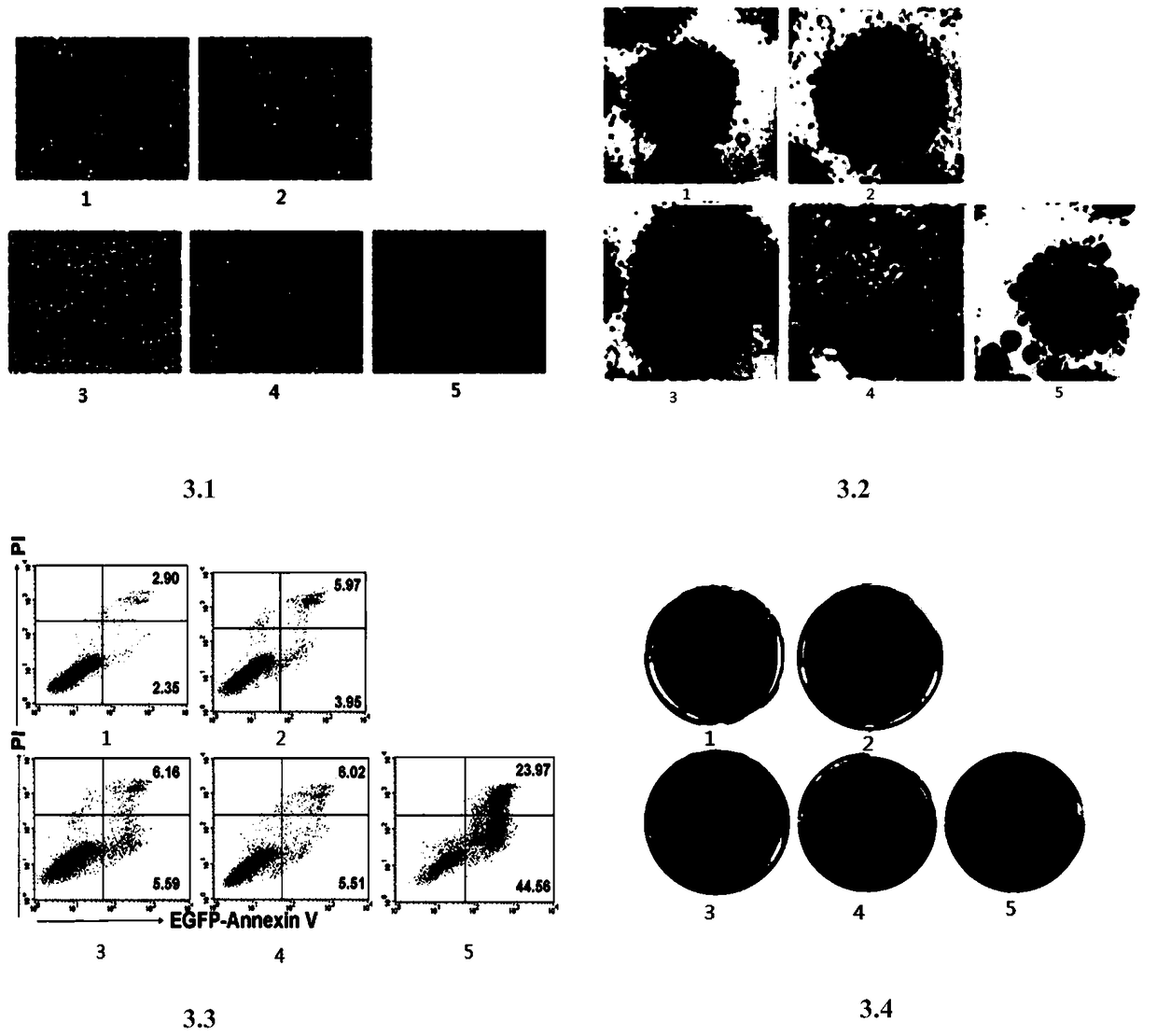

ActiveCN104177500AExtended half-lifeGood pharmacokinetic propertiesBacteriaPeptide/protein ingredientsPeptideTreatment effect

The invention belongs to the biotechnical field, and concretely relates to a tumor necrosis factor family cell apoptosis protein fusion protein, and a preparation method and a use thereof. The fusion protein is composed of annexin, a connecting peptide and a tumor necrosis factor family cell apoptosis protein, and coding gene of the fusion protein is constructed through cloning. The tumor necrosis factor family cell apoptosis protein fusion protein has a substantial enhanced cell apoptosis induction effect, can induce the apoptosis of tumor cells insensitive to the cell apoptosis, and can reduce the protein administration dosage needed by the obtaining of the treatment effect.

Owner:JIANGSU TARGET BIOMEDICINE RES INST

Method for preparing food-grade xylooligosaccharide

InactiveCN101880298AImprove efficiencySimple and safe operationSugar derivativesOligosaccharidesPolyolFood grade

The invention relates to a method for preparing food-grade xylooligosaccharide, which comprises the following steps of: putting xylose, edible acid and polyol into a reaction kettle in a weight ratio, mixing the mixture uniformly to perform polymerization, controlling the temperature to be between 140 and 260 DEG C, reacting the mixture for 0.25 to 4 hours under the vacuum degree of 0 to 1 to form a polymer, and cooling and crushing the polymer to obtain the food-grade xylooligosaccharide. The polymer content of the xylooligosaccharide obtained by the method is up to over 93 percent, the reducing sugar content is less than 1 percent, and the average molecular weight is between 500 and 900; and the xylooligosaccharide is of milk white, has good mouthfeel and can fully meet the application in food processing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

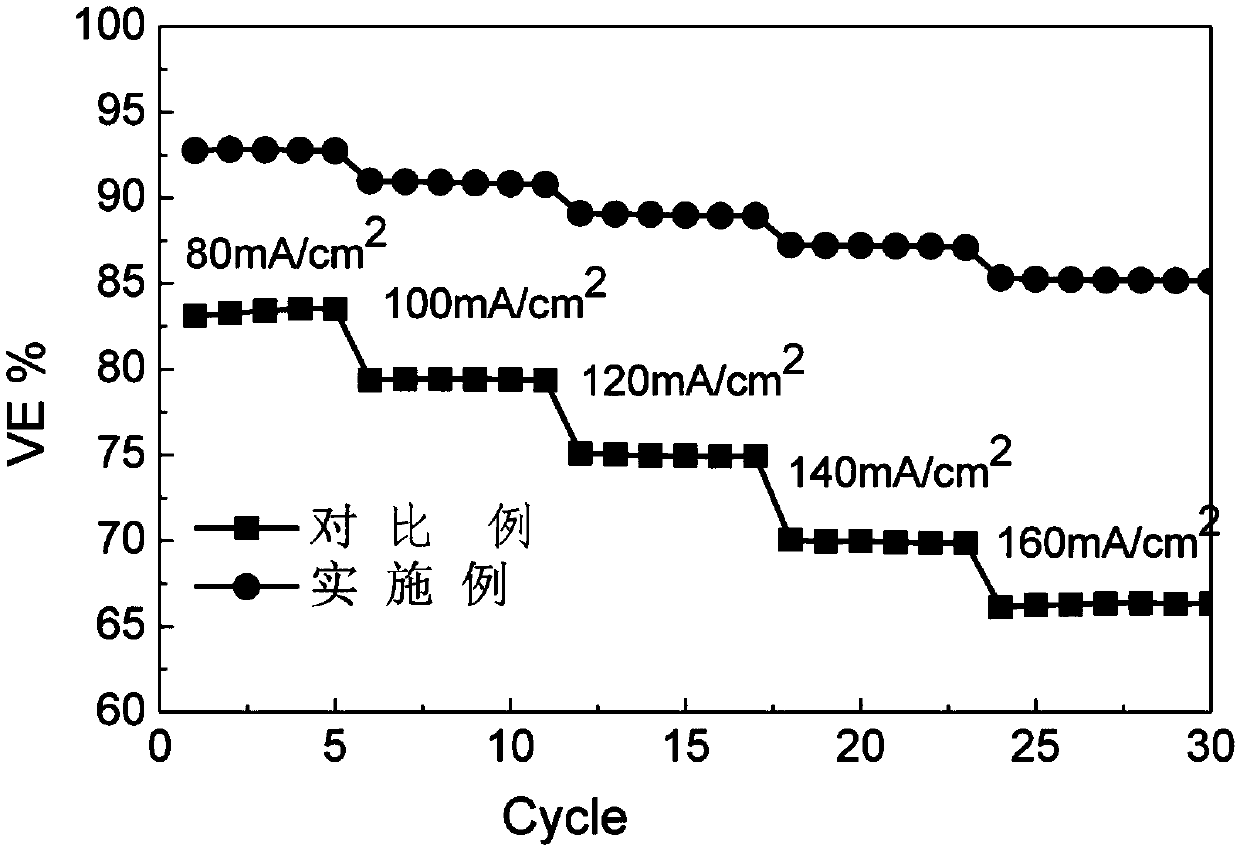

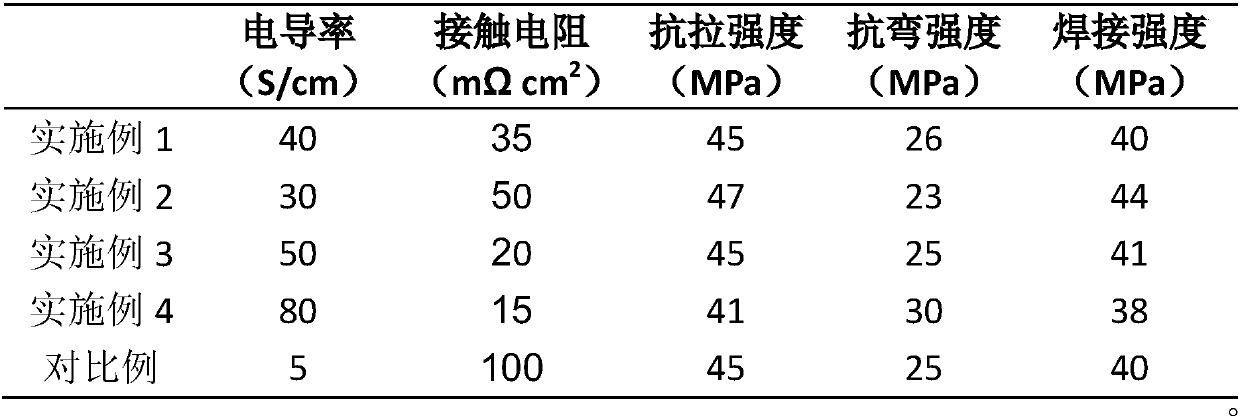

Weldable bipolar plate for flow battery and preparation and application thereof

InactiveCN111261891AReduce contentEasy to assembleMaterial nanotechnologyRegenerative fuel cellsElectrical batteryWeld strength

The invention relates to a weldable bipolar plate for a flow battery and preparation and application thereof. The weldable bipolar plate comprises a main body layer consisting of high-density polyethylene, carbon nanotubes, a coupling agent and a lubricant, and the areas, in contact with the electrode, in the middle parts of the upper and lower surfaces of the main body layer are provided with high-conductivity coatings. The area, in contact with the electrode material, on the bipolar plate has relatively high conductivity and low contact resistance, so that the ohmic polarization of the battery is reduced, and the voltage efficiency of the battery is improved; and the contact area with the electrode frame has relatively high polymer content, so that enough high welding strength can be ensured during welding, and the sealing reliability of a galvanic pile is ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

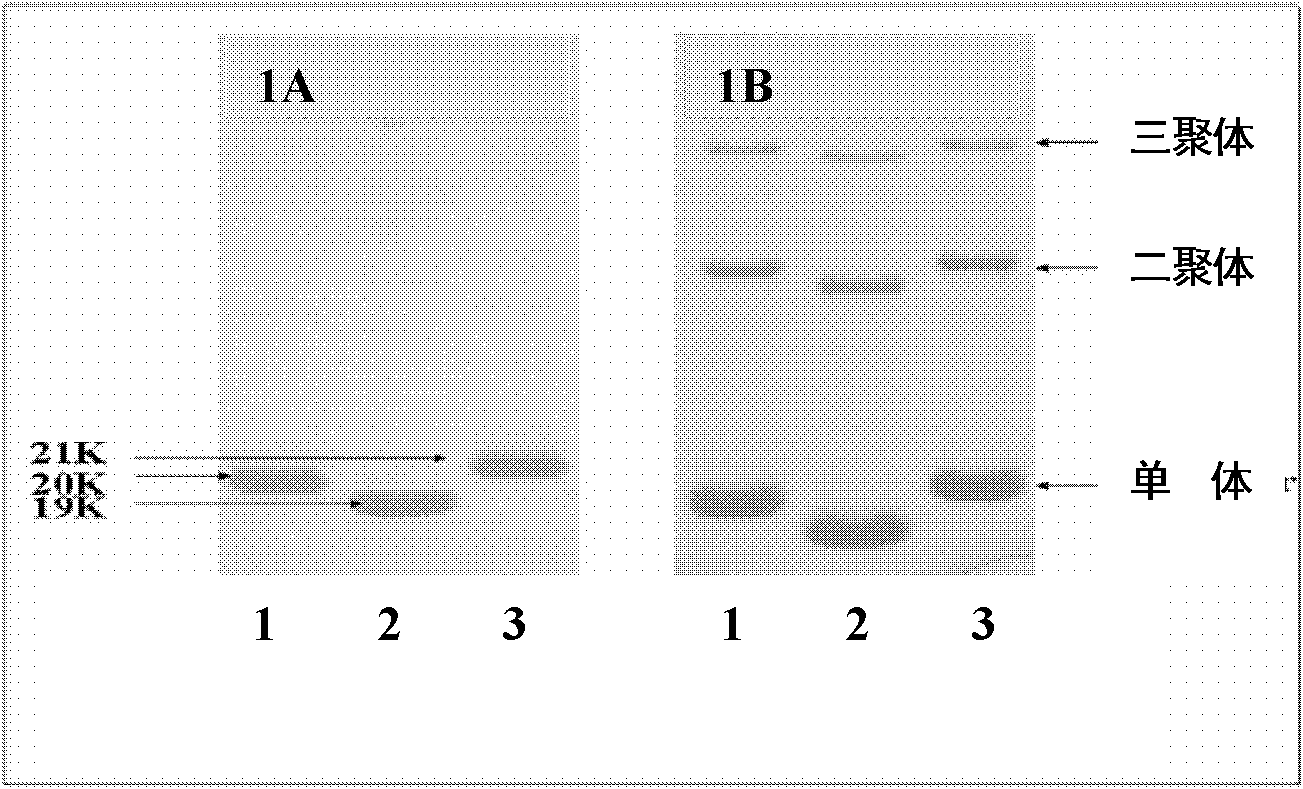

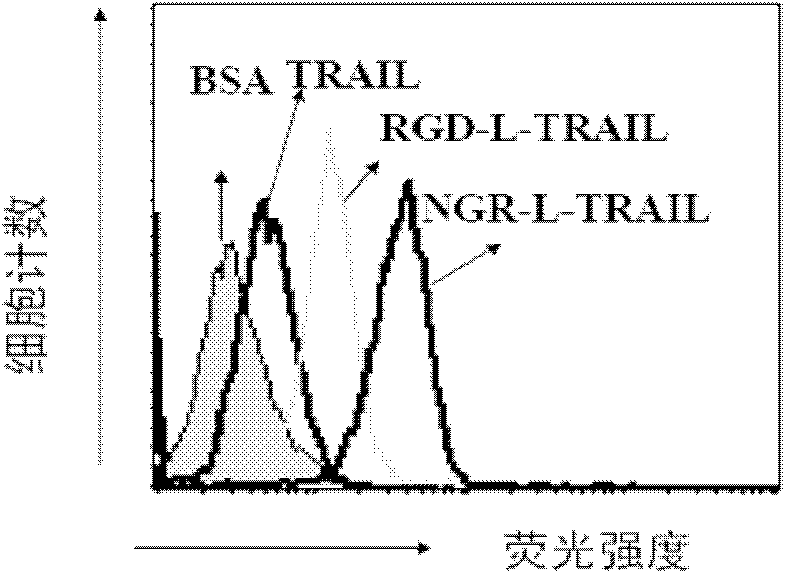

Tumor targeting tumor necrosis factor related apoptosis ligand variant and application thereof

InactiveCN102863537AImprove targetingAchieve targeted deliveryPeptide/protein ingredientsAntibody mimetics/scaffoldsTumor targetSide effect

The invention belongs to the technical field of biological genetic engineering and particularly discloses design, a preparation method and pharmaceutical application of a tumor targeting tumor necrosis factor related apoptosis ligand variant. The tumor targeting tumor necrosis factor related apoptosis ligand variant is fusion protein composed by ligand, connecting peptide and tumor necrosis factor related apoptosis ligand of CD13 and is produced through cloning and constructing of coding genes of the variant, soluble recombination expression and simple separation and purification in a genetic engineering method. The variant generated by the preparation method of the tumor targeting tumor necrosis factor related apoptosis ligand variant has good tumor tissue targeting property, remarkably enhances antitumous effect, can reduce protein administration dosage required for obtaining therapeutic effect, improves bioavailability, lowers treatment cost, and eliminates potential toxic and side effect of the tumor necrosis factor related apoptosis ligand. Simultaneously, the manufacturing method of the tumor targeting tumor necrosis factor related apoptosis ligand variant provides an expression method for producing soluble high-polymer form content and a simple separation and purification process.

Owner:JIANGSU TARGET BIOMEDICINE RES INST +1

Catalyst for synthesizing high trans polymers

InactiveUS20060149010A1Improve the level ofModerates polymerization temperatureOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePhosphite salt

The process and catalyst of this invention can be utilized to synthesize homo and copolymers of conjugated diene monomers and vinyl aromatic monomers having high trans contents of greater than 60% with low melting points. These homo and copolymers of conjugated diene monomers and vinyl aromatic monomers can be utilized in tire tread and sidewall rubbers that exhibit outstanding wear and tear characteristics in the tread and excellent flexing properties in the sidewall. The rubber polymers of this invention are made utilizing an improved catalyst system. This catalyst system is comprised of (a) organo aluminum compounds, (b) organo lithium compounds, (c) a barium compound selected from barium salts of (i) di(ethylene glycol) ethyl ether, (ii) di(ethylene glycol) propyl ether, (iii) di(ethylene glycol) hexyl ether, (iv) di(N,N-dimethyl amino glycol) ethyl ether, (v) menthol and thymol in the presence of polar modifier consisting of water, alcohols, amines, thiols, phosphates and phosphites. The trans polymers and copolymers of this invention made with the above catalyst system typically have a glass transition temperature ranging from −97° C. to −40° C., a melt temperature ranging from −30° C. to +30° C., and a number average molecular weight from 20,000 to 250,000. The inclusion of such polar modifiers in the barium catalyst system results in a high styrene content in copolymerization, a high trans content, and high molecular weight. Copolymers of conjugated diolefin monomers and vinyl aromatic monomers made with the catalyst system of this invention also have a tapered macrostructure.

Owner:THE GOODYEAR TIRE & RUBBER CO

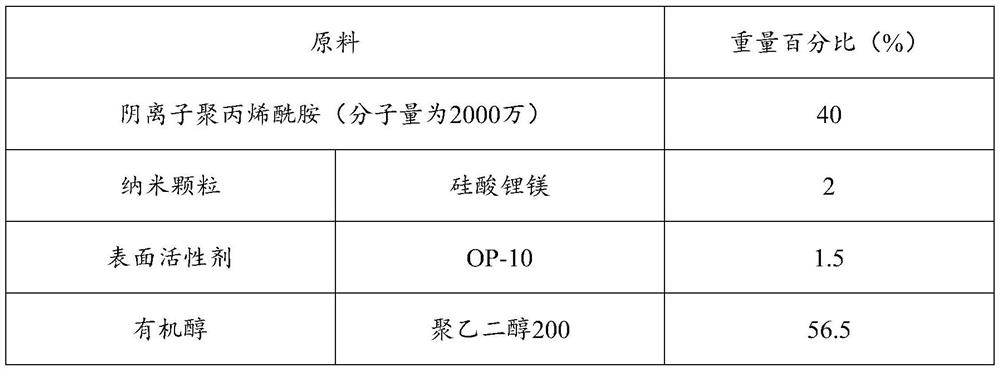

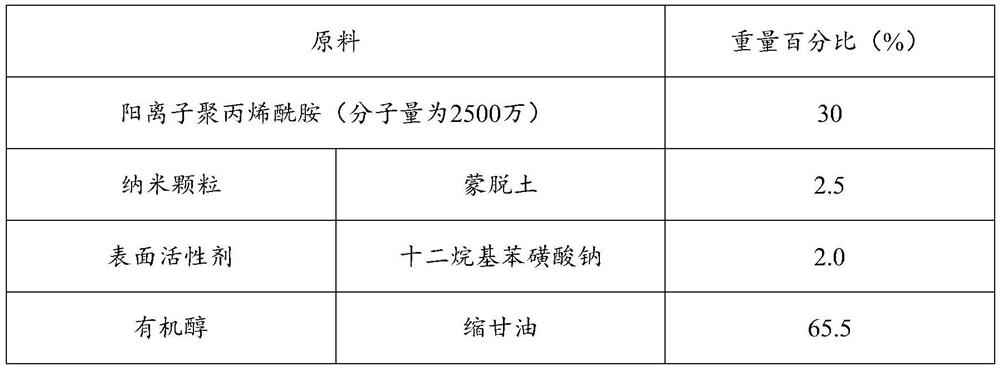

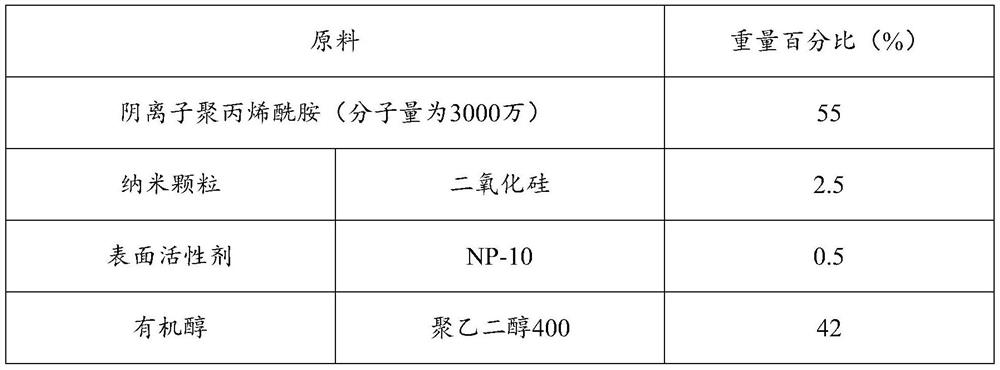

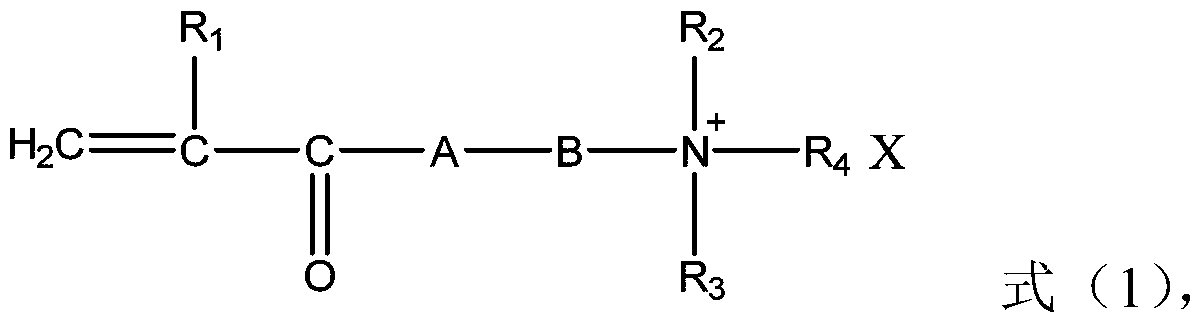

Alcohol-soluble slickwater system for fracturing as well as preparation method and application of alcohol-soluble slickwater system

ActiveCN112375557AImprove thixotropyImprove suspension abilityGeneral water supply conservationDrilling compositionAcid fracturingAlcohol

The invention discloses an alcohol-soluble slickwater system for fracturing as well as a preparation method and application of the alcohol-soluble slickwater system, and relates to the technical fieldof acid fracturing agents. The slickwater system is composed of the following components in percentage by weight: 20.0-60.0% of a polyacrylamide polymer, 0.5-4.0% of nano particles, 0.1-3% of a surfactant, and the balance of organic alcohol.

Owner:四川川庆井下科技有限公司

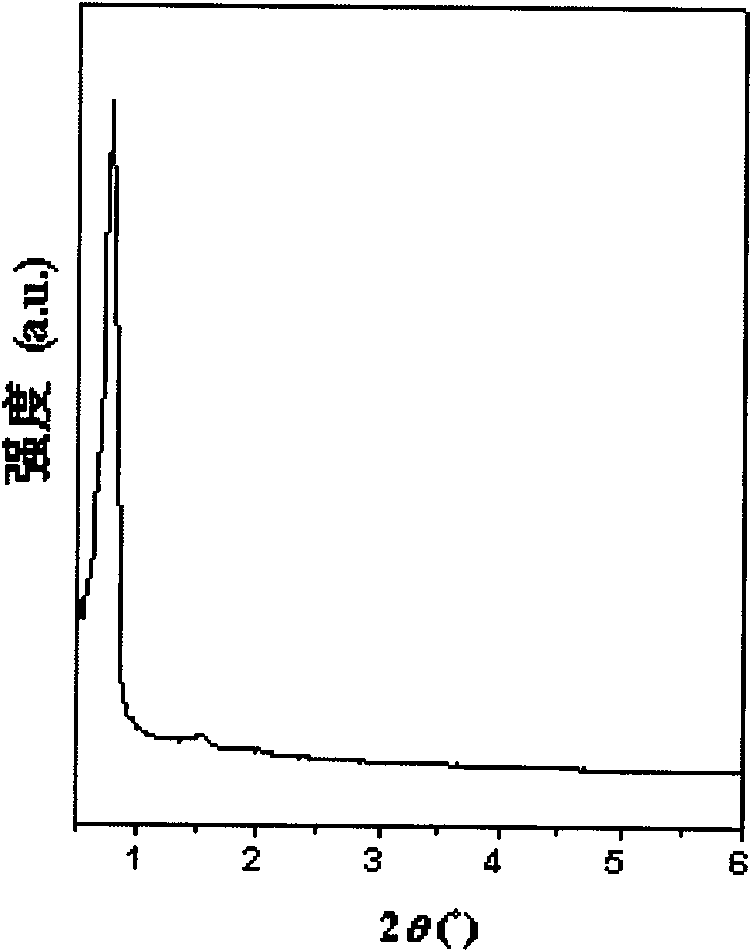

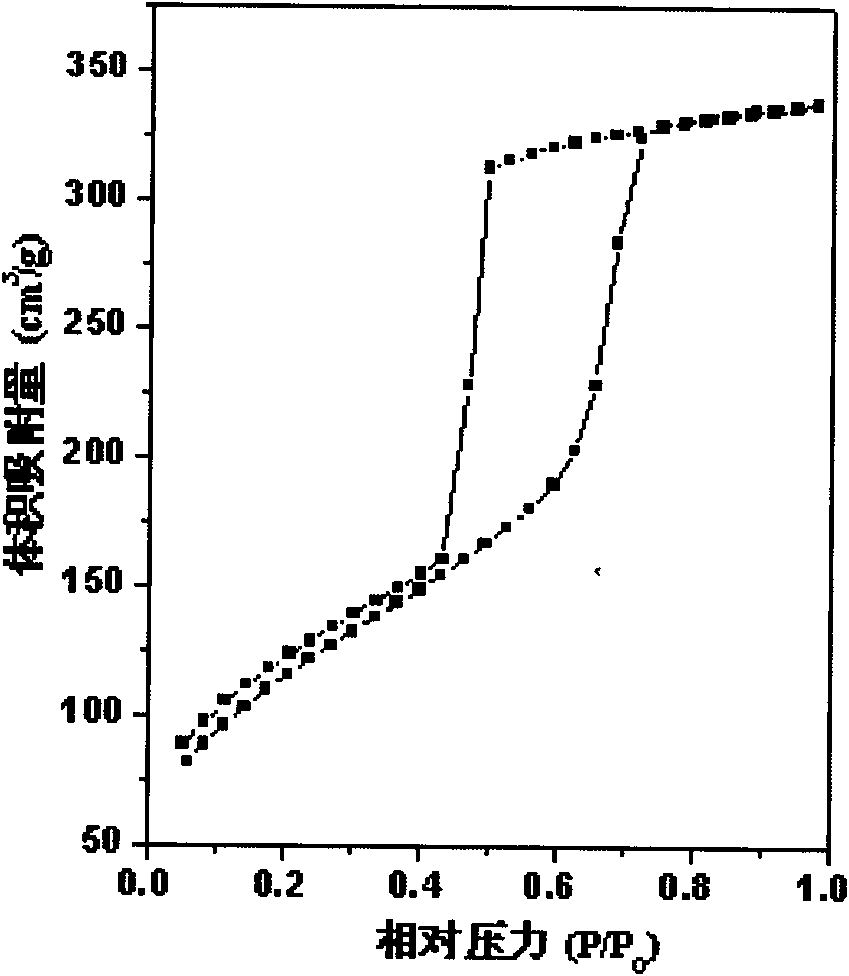

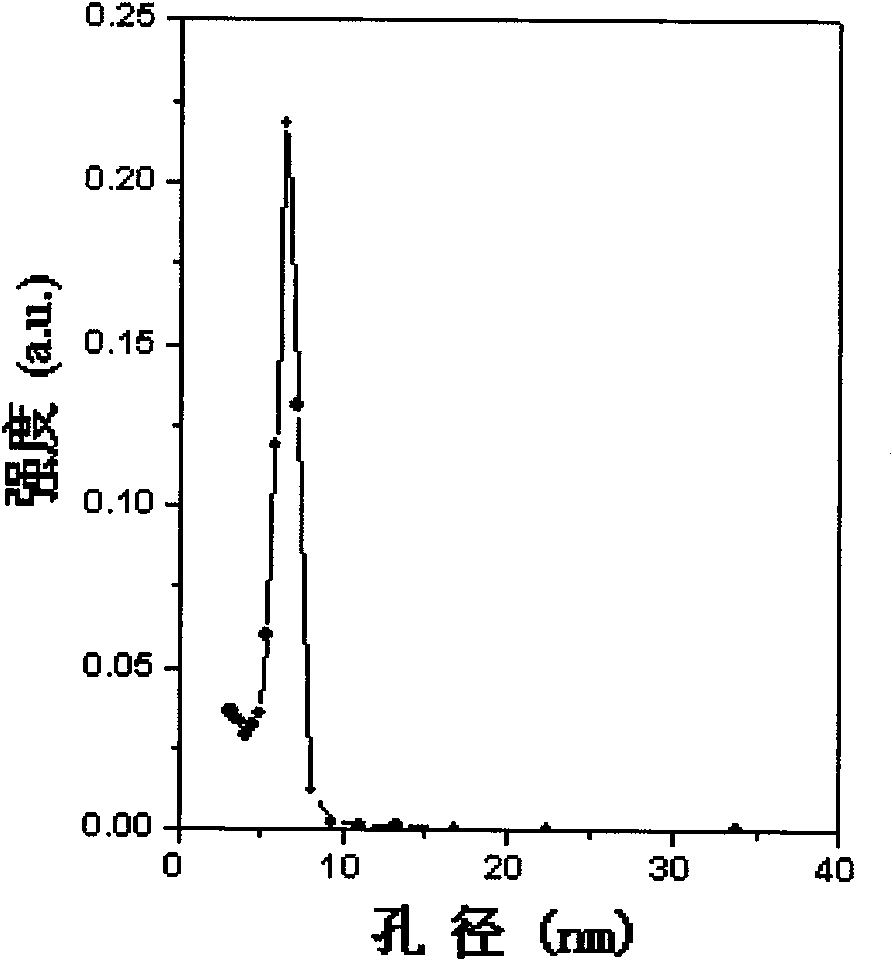

Mesoporous polymer-titanium silicon oxide nano composite material and preparation method thereof

The invention discloses a mesoporous polymer-titanium silicon oxide nano composite material which has two-dimensional hexagonal structure, the space group of p6mm, the pore diameter of 5.0-9.0nm, thepore volume of 0.4-1.0cm<3> / g and the specific surface area of 300-800m<2> / g; polymer and titanium silicon oxide are evenly distributed on a mesoporous framework, and titanium atoms are mainly bondedon a silicon oxide framework in a form of quadridentate; and the polymer is phenolic resin, furan resin or urea resin. The composite material utilizes sol-gel technology to introduce a polymer source,a silicon source and a titanium source into a self-assembly reaction system of surface active agent under the condition of organic solvent, and is prepared by synergistic assembly function, polymerization cross-linking and solvent volatilization self-assembly technology. The preparation method of the nano composite material has the advantages of simple operation, wide sources of raw materials, low requirements for equipment, low preparation cost, being suitable for industrialized production and the like.

Owner:SHANGHAI NORMAL UNIVERSITY +1

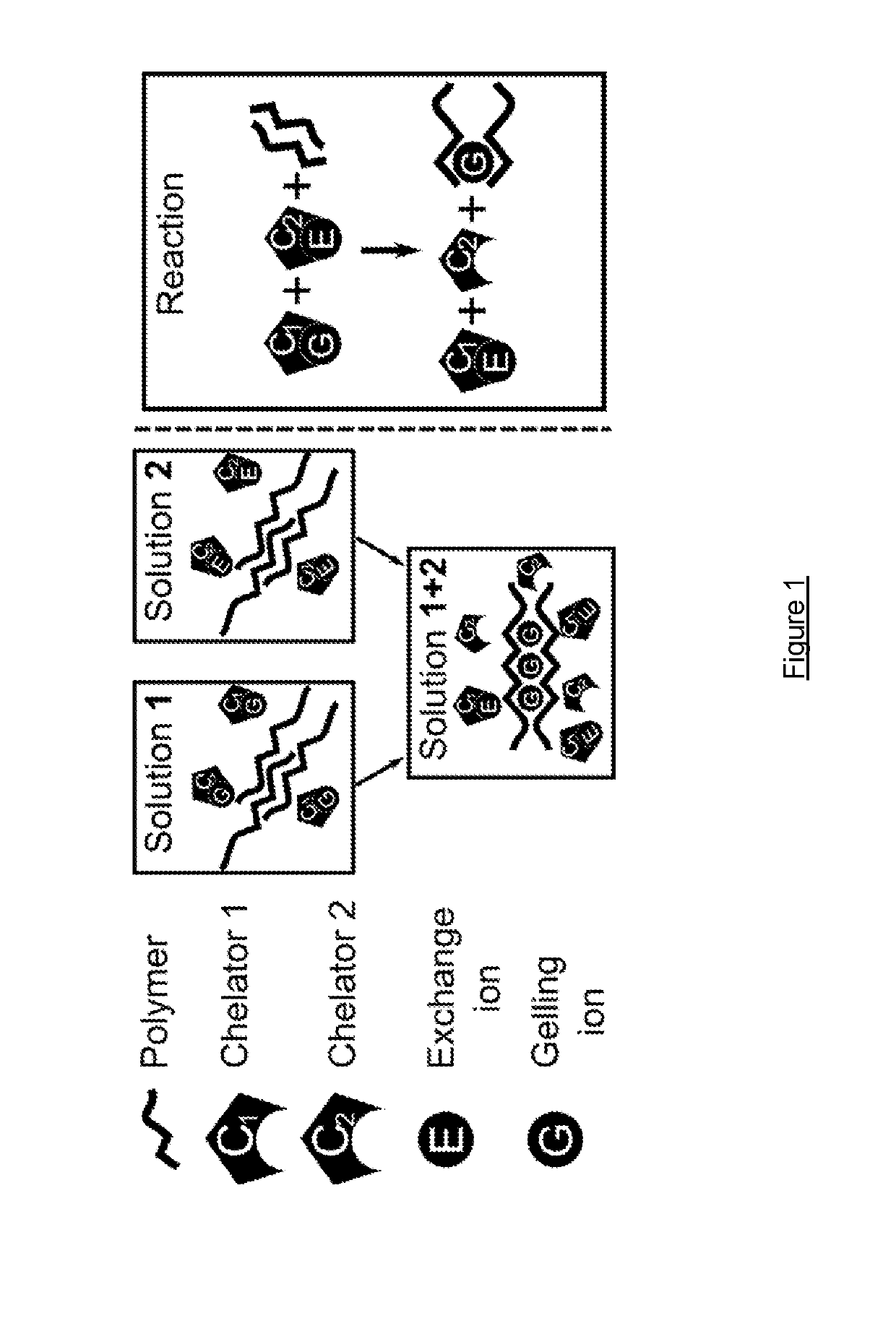

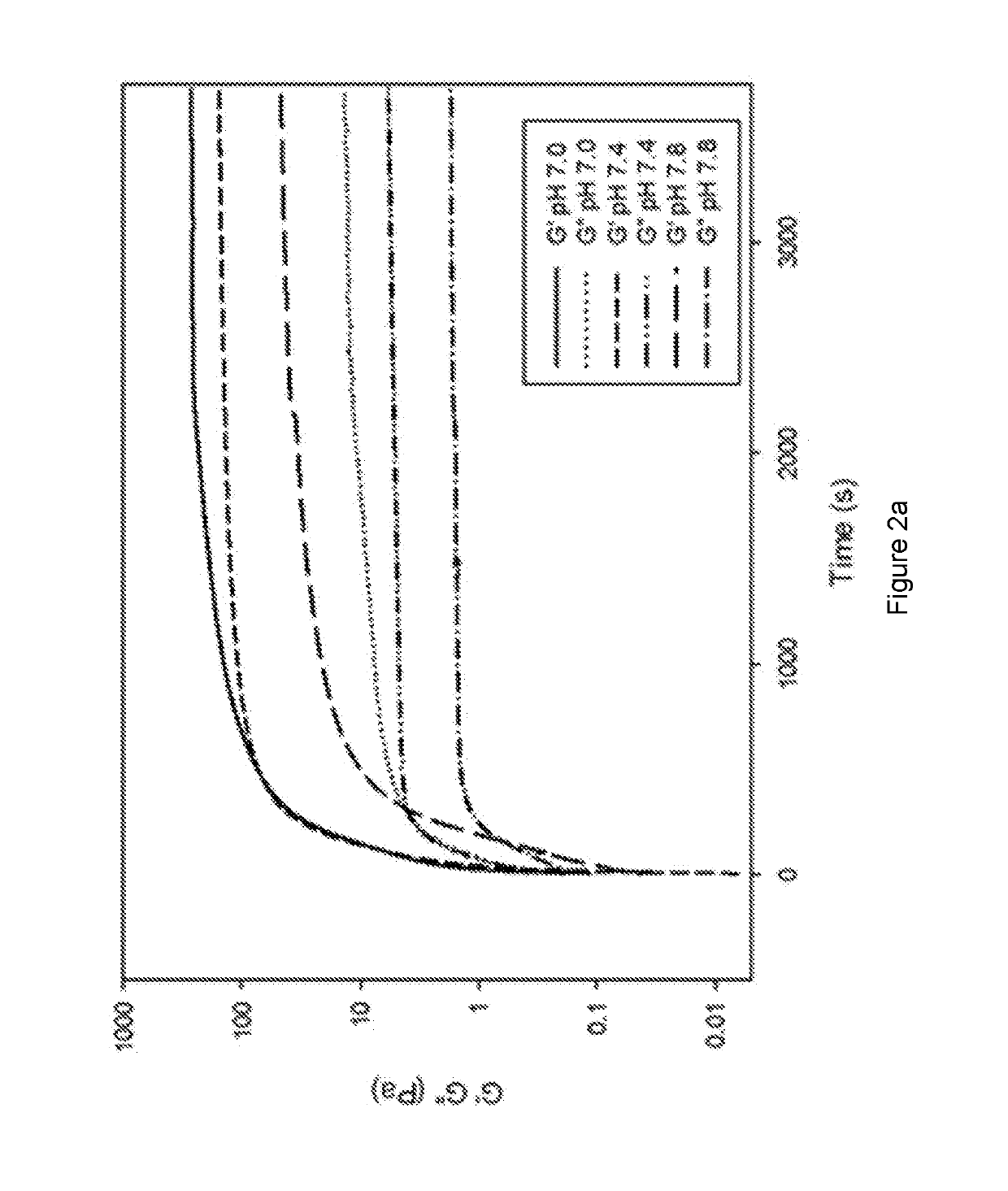

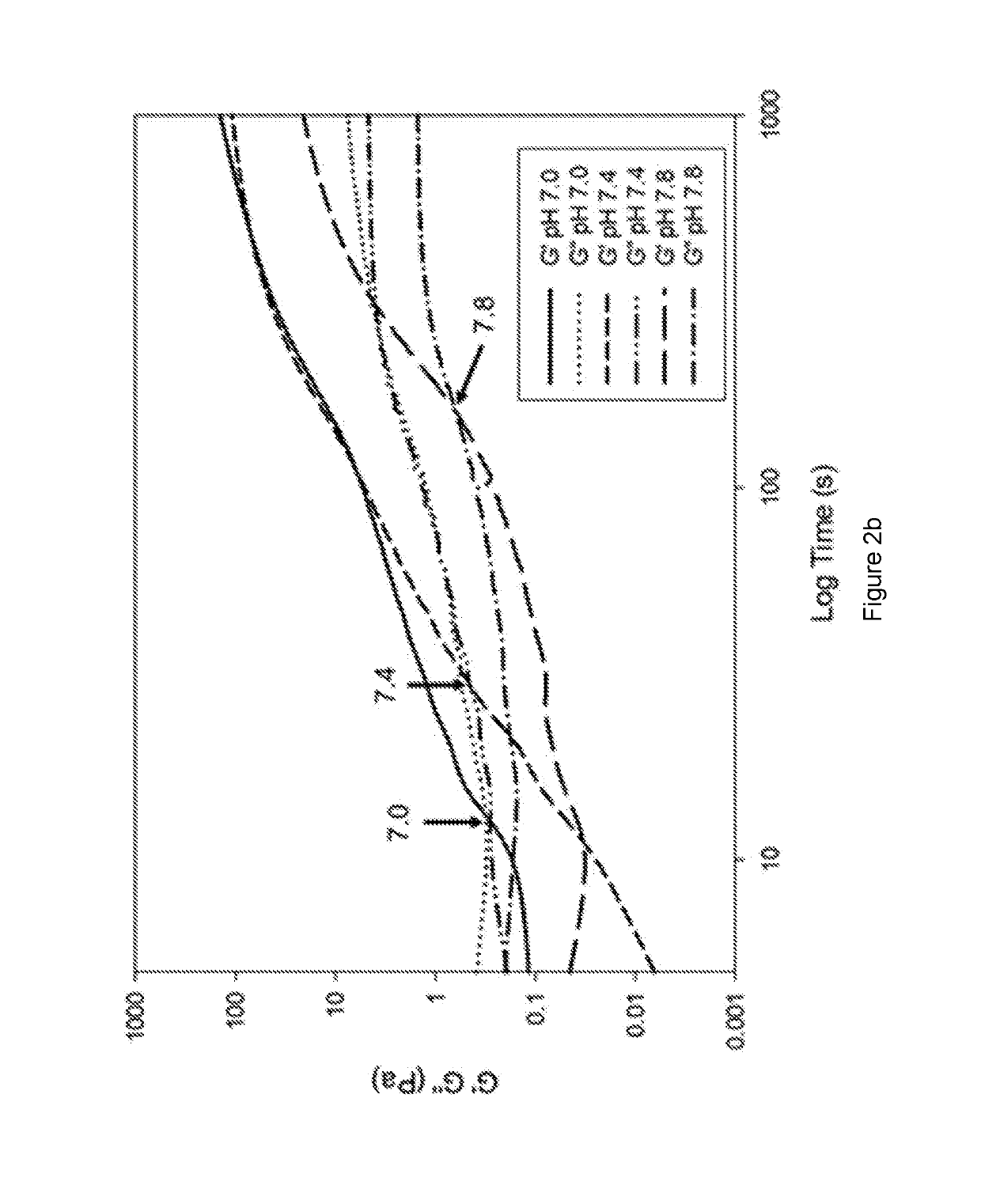

Methods of forming ionically cross-linked gels

ActiveUS20190284349A1Increase productionHigh polymer contentMetabolism disorderOintment deliveryCross-linkCrosslinked polymers

The present invention relates to the formation of gels. In particular, the present invention is directed to a method of forming a cross-linked polymer hydrogel using competitive ligand exchange.

Owner:NORDOVO BIOSCI AS

Method for purifying Fc fusion protein

InactiveCN110172102AHigh polymer contentAntibody mimetics/scaffoldsPeptide preparation methodsIon exchangeChemistry

The invention discloses a method for purifying Fc fusion protein. The method is characterized by comprising the following steps: (1) capturing GLP-1-Fc fusion protein by using Mabselect SuRe LX; (2) further removing degradation fragments by using Capto Q ImpRes ion exchange chromatography; (3) removing a large quantity of aggregates with CHT I type filler. The method disclosed by the invention iscapable of removing the degradation and aggregates in interest protein.

Owner:北京军科华仞生物工程技术研究有限公司

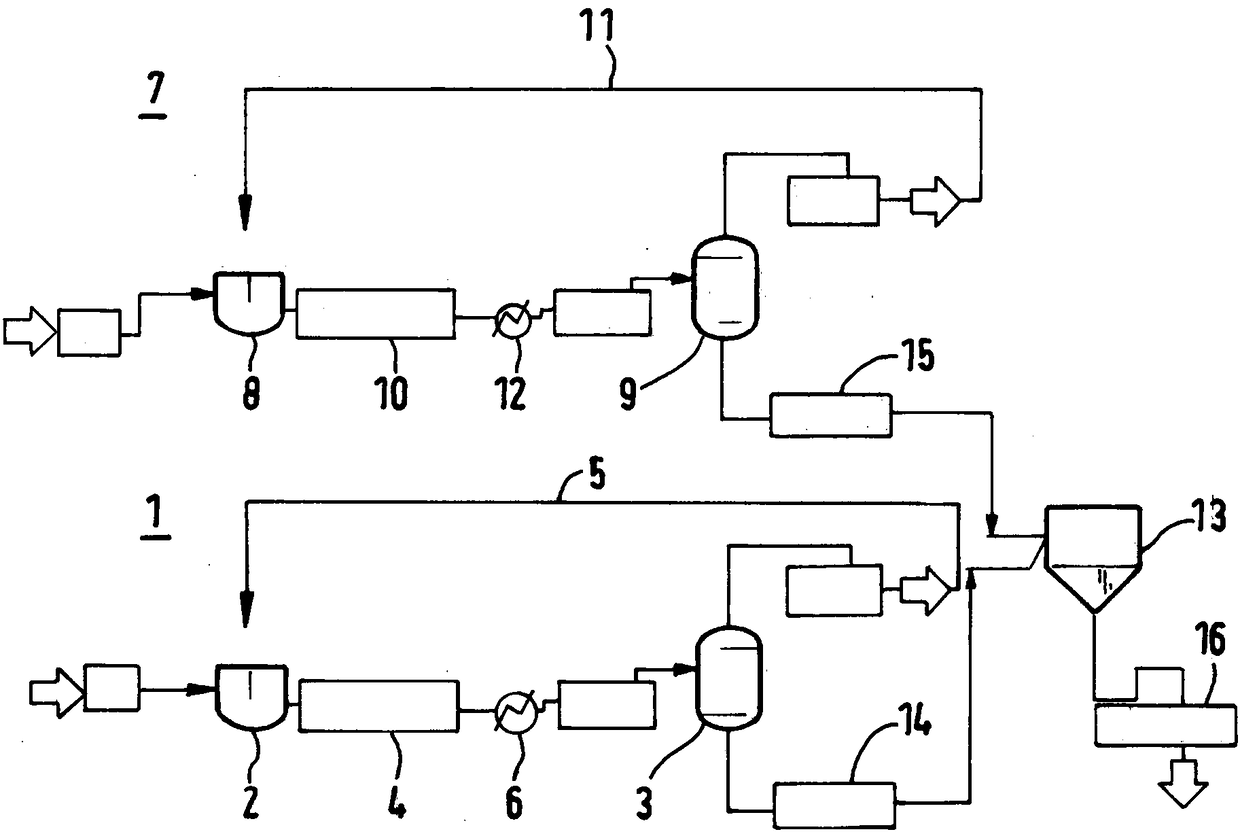

In-line blending process

ActiveCN108473601AHigh polymer contentChemical recyclingEvaporator regulation/controlEngineeringSolvent

An in-line blending process for polymers comprising: (a) providing two or more reactor-low pressure separator units (1, 7) in parallel configuration, each reactor-low pressure separator unit comprising one reactor (2, 8) fluidly connected to one low pressure separator (3, 9) downstream and further a recycling line (5, 11) connecting the low pressure separator (3, 9) back to the corresponding reactor (2, 8); (b) polymerizing olefin monomers having two or more carbon atoms in each of the reactors (2, 8) in solution polymerisation; (c) forming an unreduced reactor effluents stream including a homogenous fluid phase polymer-monomer-solvent mixture in each of the reactors (2, 8), (d) passing the unreduced reactor effluents streams from each of the reactors (2, 8) through the corresponding low pressure separators (3, 9), whereby the temperature and pressure of the low pressure separators (3, 9) is adjusted such that a liquid phase and a vapour phase are obtained, whereby yielding a polymer-enriched liquid phase and a polymer-lean vapour phase, and (e) separating the polymer-lean vapour phase from the polymer-enriched liquid phase in each of the low-pressure separators (3, 9) to form separated polymer-lean vapour streams and separated polymer-enriched liquid streams; (f) combining the polymer-enriched liquid streams from step (e) in a further low-pressure separator and / or a mixer (13)to produce a combined polymer-enriched liquid stream (16); (g) reintroducing the polymer-lean vapour streams from step (e) via recycling lines (5, 11) into the corresponding reactors (2, 8).

Owner:BOREALIS AG

Asphalt binder for porous pavements

ActiveUS7745518B2High polymer contentWorkable viscosityIn situ pavingsBuilding insulationsPolymer scienceRoad surface

An asphalt binder is provided, comprising 85 to 97.5 parts by weight of a bitumen and 16 to 2.5 parts by weigh of a polymer composition, wherein the polymer composition comprises:(i) from 2 to 8, preferably from 3 to 6 parts by weight of a styrenic block copolymer having at least two blocks of monovinylaromatic hydrocarbon (A) and at least one block of a conjugated diene (B), wherein the block copolymer composition has a vinyl content of at least 25% by weight, preferably from 25 to 40% by weight, based on the total diene content;(ii) from 0 to 5, preferably from 1 to 3 parts by weight of a styrenic diblock copolymer having one block of monovinylaromatic hydrocarbon (A) and one block of a conjugated diene (B); and(iii) from 0.5 to 3, preferably from 1 to 2.5 parts by weight of an ethylene-vinyl acetate copolymer,wherein the weight ratio of (i)+(ii):(iii) is from 2:1 to 6:1, preferably from 3:1 to 4:1. In addition, an asphalt mix is provided comprising 2 to 8 parts by weight of the asphalt binder of the present invention and 98 to 92 parts by weight of gap-graded aggregate or open-graded aggregate material.Furthermore, a porous pavement is claimed, produced from the open or gap-graded mixes, by compacting the asphalt mix mentioned above.

Owner:KRATON POLYMERS US LLC

Method for preparing mercaptosilane coupling agent by channel reaction device

ActiveCN105601661BIncrease in sizeGreat operating flexibilityGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

Method for making heterophasic polymer compositions

ActiveUS20180237625A1Improve impact resistanceHigh polymer contentPlastic recyclingFree-radical reactionPolymer composition

A method for producing a polymer composition comprises the steps of providing a compatibilizing agent, providing a heterophasic polymer composition, providing a second polymer composition comprising recycled polymer; mixing the compatibilizing agent, the heterophasic polymer composition, and the second polymer composition, and generating free radicals in the heterophasic polymer composition and the second polymer composition. At least a portion of the compatibilizing agent is believed to react with the free radicals generated in the heterophasic polymer composition and the second polymer composition.

Owner:MILLIKEN & CO

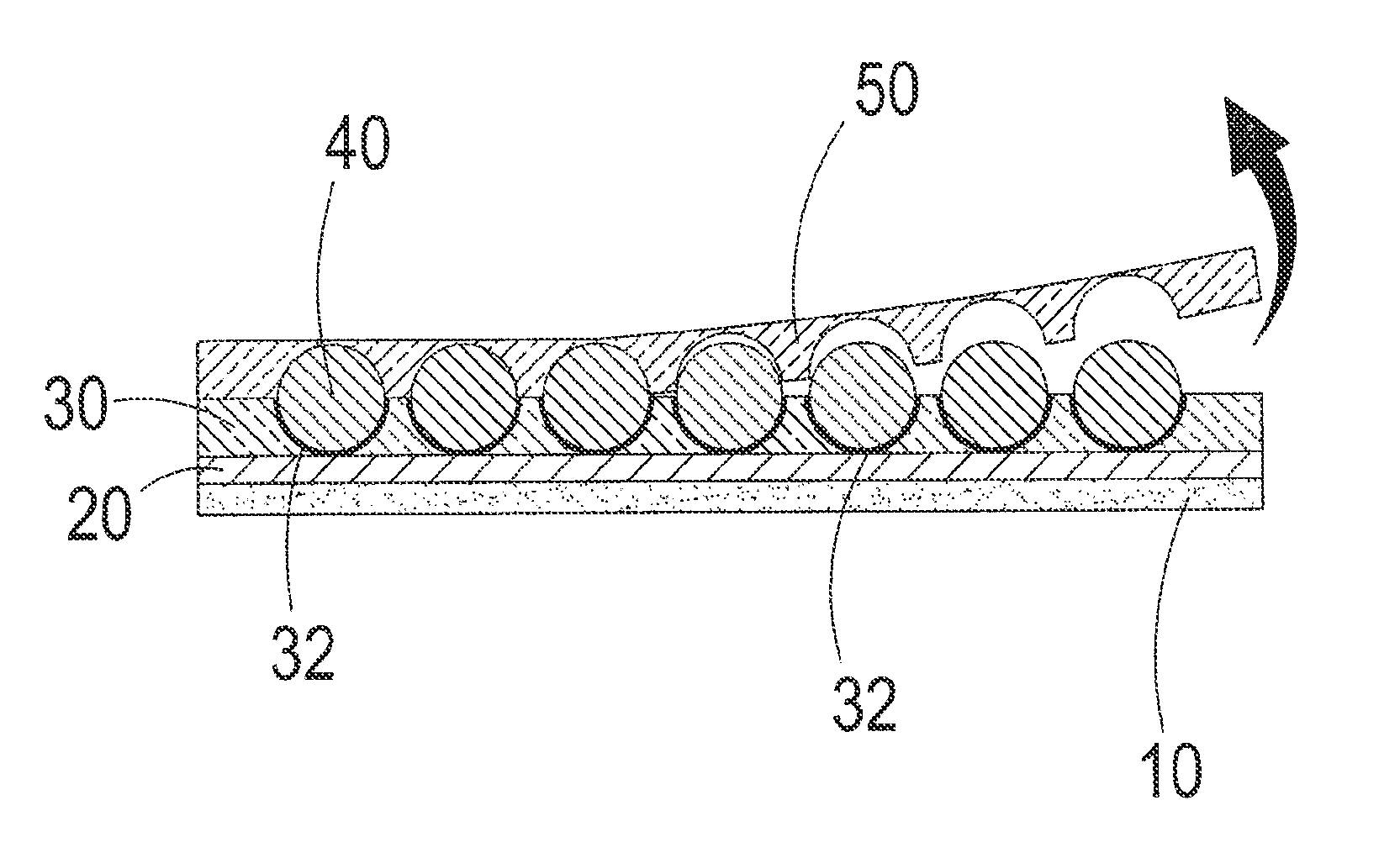

Wettable fluoropolymer fiber material

ActiveUS20170275487A1Readily dispersible dispersionIncrease surface areaConjugated cellulose/protein artificial filamentsBeltsFiberFluoropolymer

A wettable, dispersion spun fluoropolymer fiber prepared from non-melt-processible fluoropolymer particles.

Owner:TORAY FLUOROFIBERS AMERICA

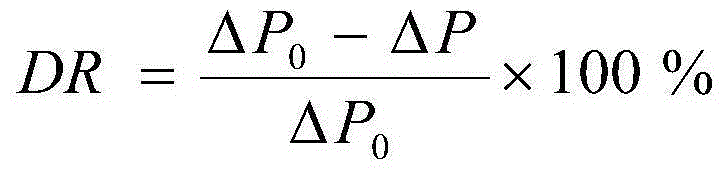

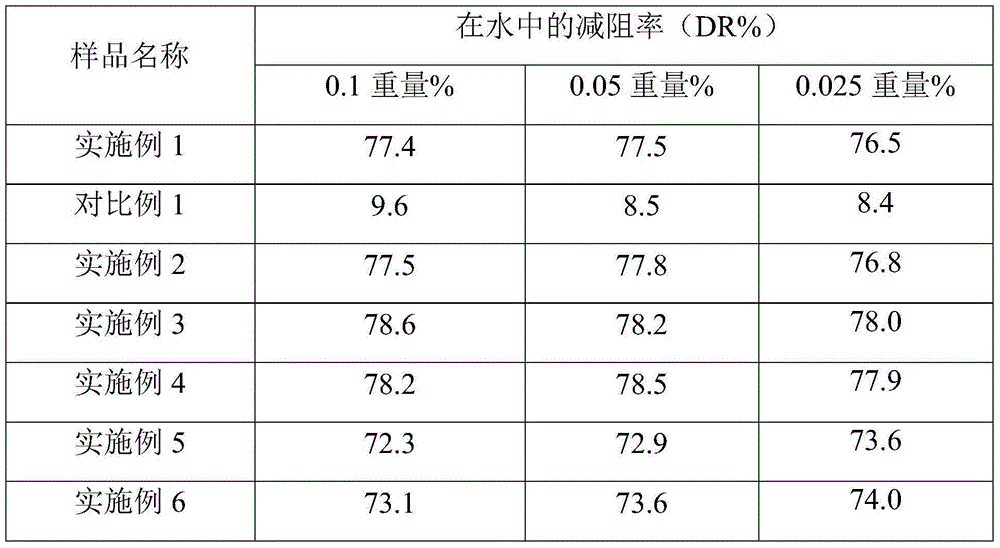

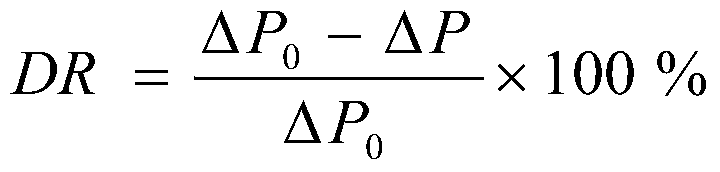

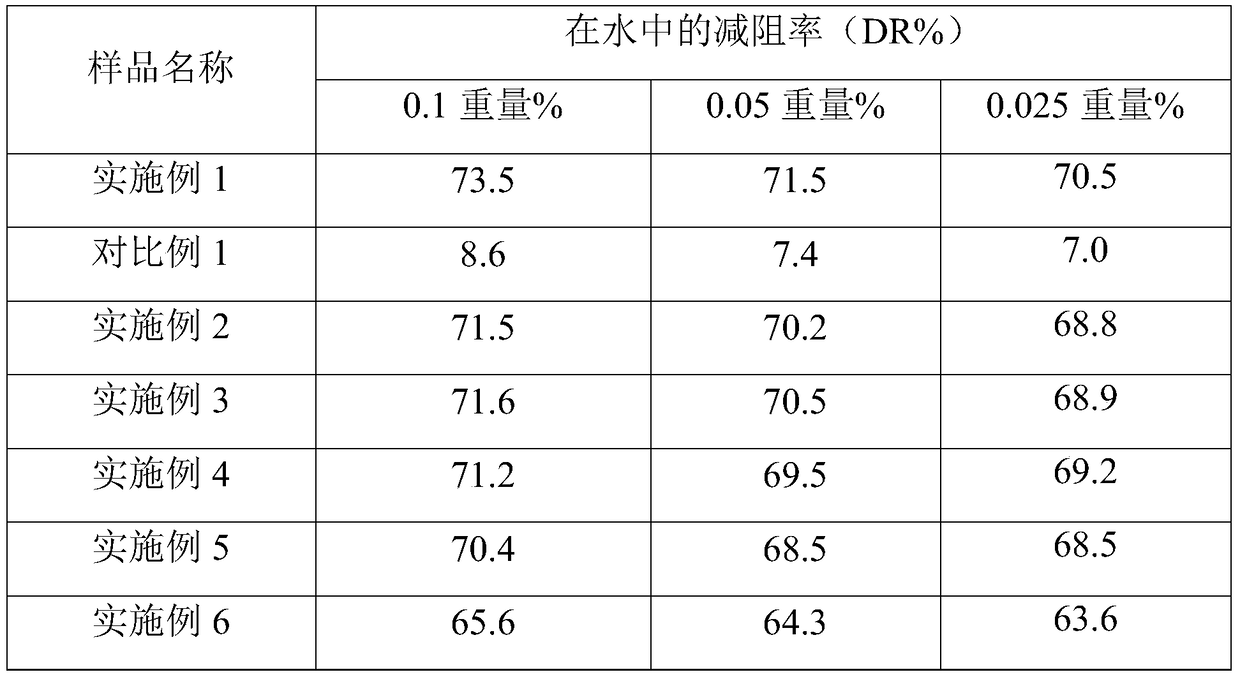

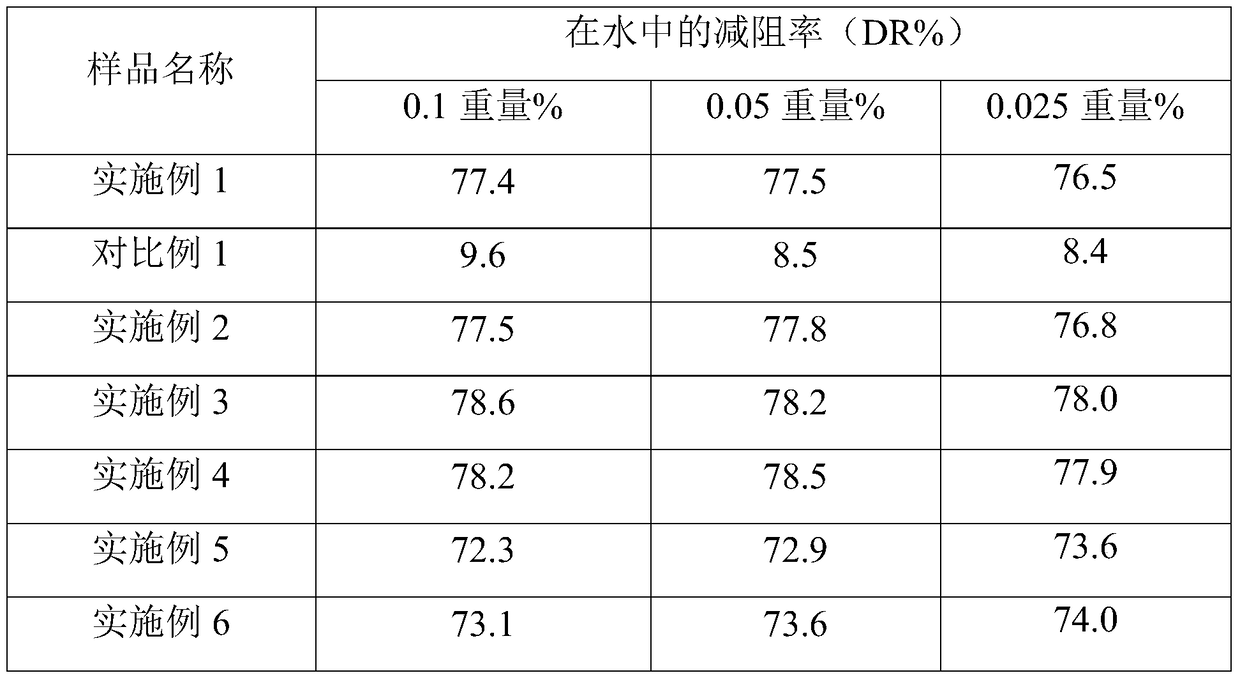

Preparation method of drag reducer for shale gas fracturing and drag reducer for fracturing

ActiveCN106317316AImprove efficiencyImprove shear resistanceDrilling compositionInorganic saltsReducer

The invention relates to the field of shale gas exploitation, fracturing, and yield increasing, and discloses a preparation method of a drag reducer for shale gas fracturing and a drag reducer prepared by the provided preparation method. The preparation method comprises the following steps: (1) in the presence of water, mixing at least part of polymeric monomers, inorganic salts, a stabilizer and a chelating agent to obtain a mixed solution; (2) adjusting the pH of the mixed solution to 3-7; and (3) adding an initiator and residual polymeric monomers into the reaction system obtained in the step (2) to carry out reactions; wherein the weight ratio of at least part of polymeric monomers to residual polymeric monomers is 1:1-20. The shale gas fracturing drag reducer prepared by the provided preparation method has the advantages of high drag reducing efficiency, strong shearing resistant performance, low viscosity, good fluidity, quick dissolving speed, and environment-friendliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

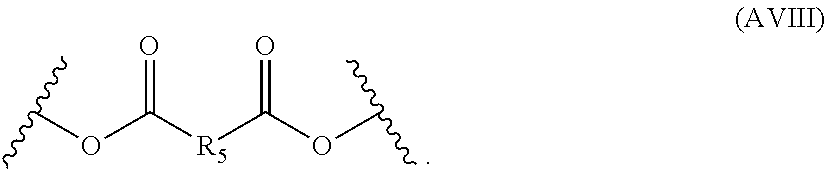

Silane-modified polyurea compounds based on polyisocyanates having isocyanurate and allophanate groups

PendingUS20200347183A1Less solventFaster through drying of the coatingAnti-corrosive paintsPolyurea/polyurethane coatingsArylPolymer science

The invention relates to a polyurea compound that can be produced by reacting a polyisocyanate based on isophorone diisocyanate, which has isocyanurate and allophanate groups, with an amino silane according to general formula (I): R1a(R1O)(3-a)Si(CH2)nNHCHR2CH2COOR3 (I), wherein the groups R1 are selected independently from one another from C1-C20-alkyl or C6-C20-aryl, a is a whole number between 0 and 2, n is a whole number between 1 and 4, R2 is selected from H, C1-C20-alkyl, C6-C12-aryl and —COOR3, and R3 is a respective C1-C20-alkyl. The invention also relates to the use of the compound as a binder for producing coatings.

Owner:COVESTRO DEUTSCHLAND AG

Process for preparing human serum albumin

ActiveCN103394076BNon-deterministicHigh yieldPeptide/protein ingredientsSerum albuminUltrafiltrationFiltration

Owner:华润博雅生物制药集团股份有限公司

Wettable fluoropolymer fiber material

ActiveUS11242630B2Readily dispersible dispersion spunIncrease surface areaDomestic sealsSynthetic resin layered productsFiberPolymer science

A wettable, dispersion spun fluoropolymer fiber prepared from non-melt-processible fluoropolymer particles.

Owner:TORAY FLUOROFIBERS AMERICA

A tumor necrosis factor-related apoptosis ligand fusion protein and its preparation method and application

ActiveCN104177500BImprove biological activityHigh polymer formBacteriaPeptide/protein ingredientsTherapeutic effectApoptosis protein

The invention belongs to the field of biological technology, and specifically discloses a tumor necrosis factor family cell apoptosis protein fusion protein, a preparation method and application thereof. The fusion protein is composed of annexin, connecting peptide and tumor necrosis factor family cell apoptosis protein, and the coding gene of the fusion protein is constructed by cloning. The tumor necrosis factor family cell apoptosis protein fusion protein has significantly enhanced effect of inducing apoptosis, can induce apoptosis of tumor cells insensitive to cell apoptosis, and can reduce protein dosage required for obtaining therapeutic effect.

Owner:JIANGSU TARGET BIOMEDICINE RES INST

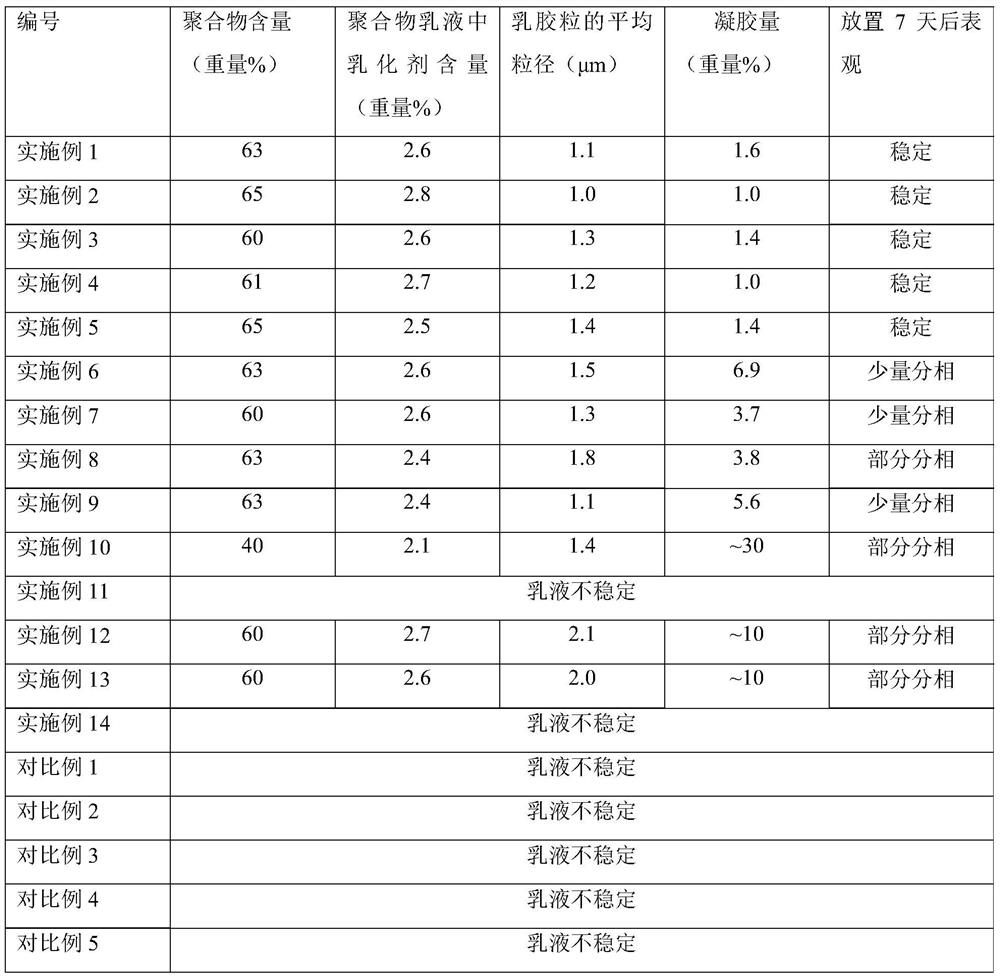

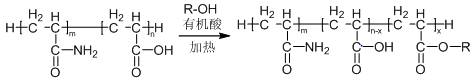

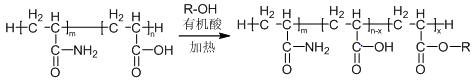

Polymer emulsion and preparation method thereof

The invention relates to a polymer emulsion, and discloses a polymer emulsion and a preparation method thereof. The method includes an emulsification step and at least one step of separating and concentrating the emulsion, combining a polymer solution containing a polymer and an organic solvent with an aqueous solution containing an emulsifier Mixing and emulsifying the mixed solution; the step of separating and concentrating the emulsion includes successive organic solvent removal sub-steps and centrifugal separation sub-steps, the emulsion is subjected to at least one distillation, and the thin emulsion is subjected to at least one centrifugation; the emulsifier is an anion Type emulsifier, the polymer is a polymer formed by homopolymerization and / or copolymerization of dienes or a polymer formed by copolymerization of dienes and C2-C4 alkenyl-substituted aromatic compounds, measured according to HG / T3323-2008 The apparent viscosity of the polymer solution at a concentration of 6-20% by weight at 25°C is 5000-20,000 cP. The method obtains a polymer emulsion with high polymer content, and the product has good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of drag reducing agent for shale gas fracturing and drag reducing agent for fracturing

ActiveCN106279524BImprove efficiencyImprove shear resistanceDrilling compositionInorganic saltsReducer

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of drag reducing agent for shale gas fracturing and drag reducing agent for fracturing

ActiveCN106317316BImprove efficiencyImprove shear resistanceDrilling compositionInorganic saltsReducer

The invention relates to the field of shale gas exploitation, fracturing, and yield increasing, and discloses a preparation method of a drag reducer for shale gas fracturing and a drag reducer prepared by the provided preparation method. The preparation method comprises the following steps: (1) in the presence of water, mixing at least part of polymeric monomers, inorganic salts, a stabilizer and a chelating agent to obtain a mixed solution; (2) adjusting the pH of the mixed solution to 3-7; and (3) adding an initiator and residual polymeric monomers into the reaction system obtained in the step (2) to carry out reactions; wherein the weight ratio of at least part of polymeric monomers to residual polymeric monomers is 1:1-20. The shale gas fracturing drag reducer prepared by the provided preparation method has the advantages of high drag reducing efficiency, strong shearing resistant performance, low viscosity, good fluidity, quick dissolving speed, and environment-friendliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

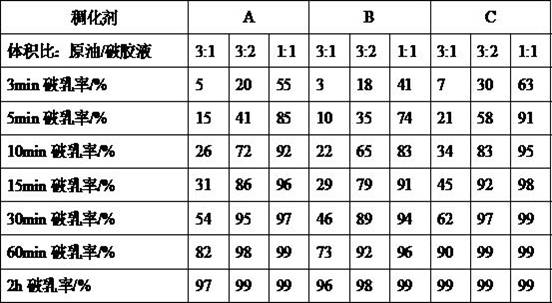

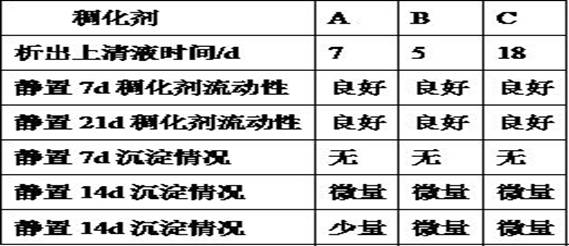

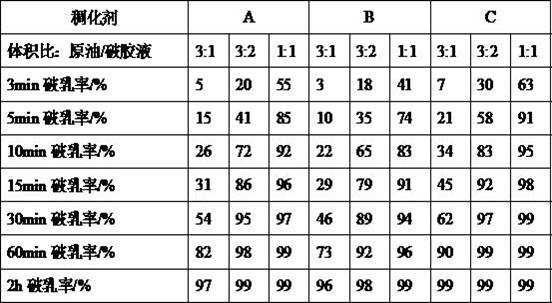

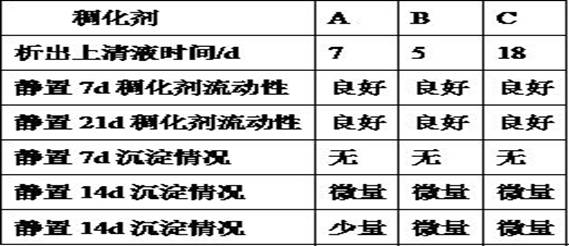

Oil-based self-suspending polymer thickening agent and preparation method thereof

ActiveCN114057920AHigh demulsification rateHigh polymer contentDrilling compositionPolymer scienceSuspending Agents

The invention discloses an oil-based self-suspending polymer thickening agent and a preparation method thereof, belongs to the field of oilfield yield increasing chemical agents, and relates to a thickening agent for fracturing fluid. According to the thickening agent disclosed by the invention, a polymer is modified to obtain a certain self-suspending property, and the polymer is added into solvent oil to obtain an oil-based self-suspending polymer thickening agent suspension. The polymer of the thickening agent is self-suspended in the solvent oil, so that a stabilizer, a shear strength improving agent, a suspending agent and other auxiliaries do not need to be added; and the oil-based self-suspending polymer thickening agent has the advantage of high polymer content of a suspension type thickening agent, no additional suspending auxiliaries are added, the residue content of a gel breaking solution is low, and the demulsification rate is high.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

A kind of oil-based self-suspending polymer thickener and preparation method thereof

ActiveCN114057920BHigh demulsification rateHigh polymer contentDrilling compositionPolymer scienceFracturing fluid

The invention discloses an oil-based self-suspension polymer thickener and a preparation method thereof, belongs to the field of oil field stimulation chemical agents, and relates to a thickener for fracturing fluid. The thickener of the present invention obtains a certain self-suspension performance by modifying the polymer, and adding it to solvent oil to obtain the oil-based self-suspension polymer thickener suspension. The polymer of the thickener of the present invention is self-suspended in mineral spirits, without adding other auxiliary agents such as stabilizer, cutting agent, suspending agent, etc., and has the advantage of high polymer content of the suspension-type thickener without additional With the addition of suspending aids, the residue content of gel breaking solution is low and the demulsification rate is high.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

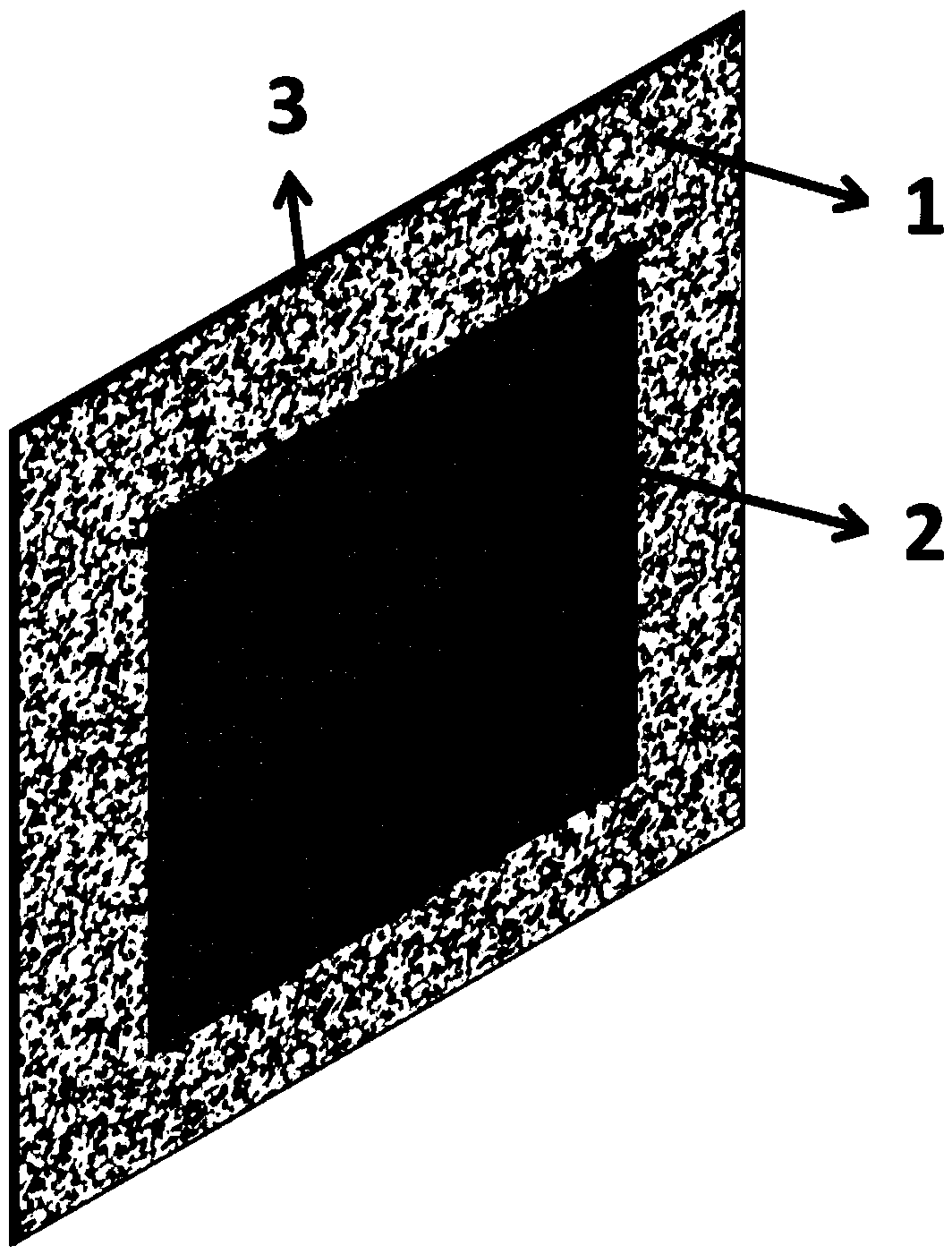

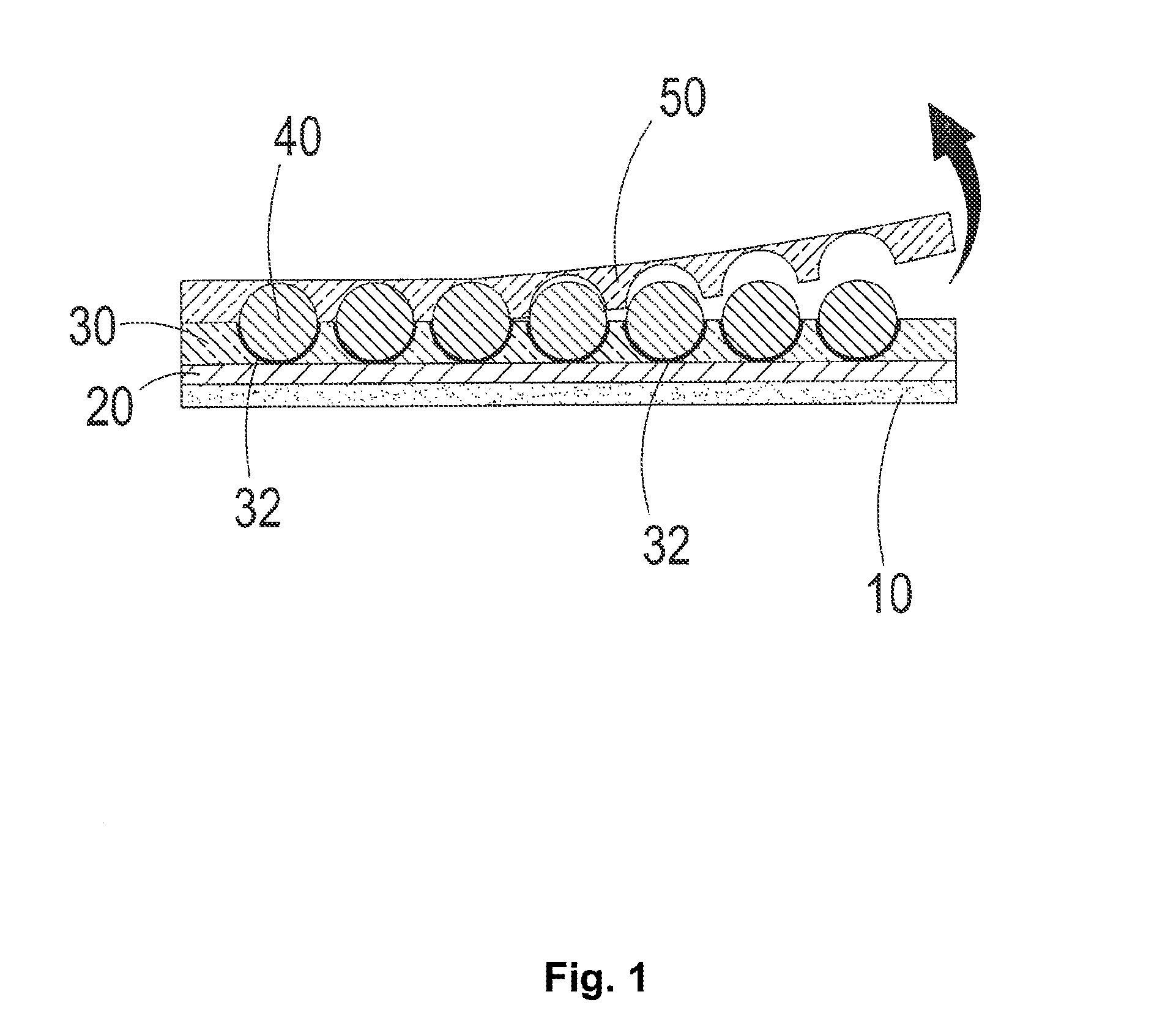

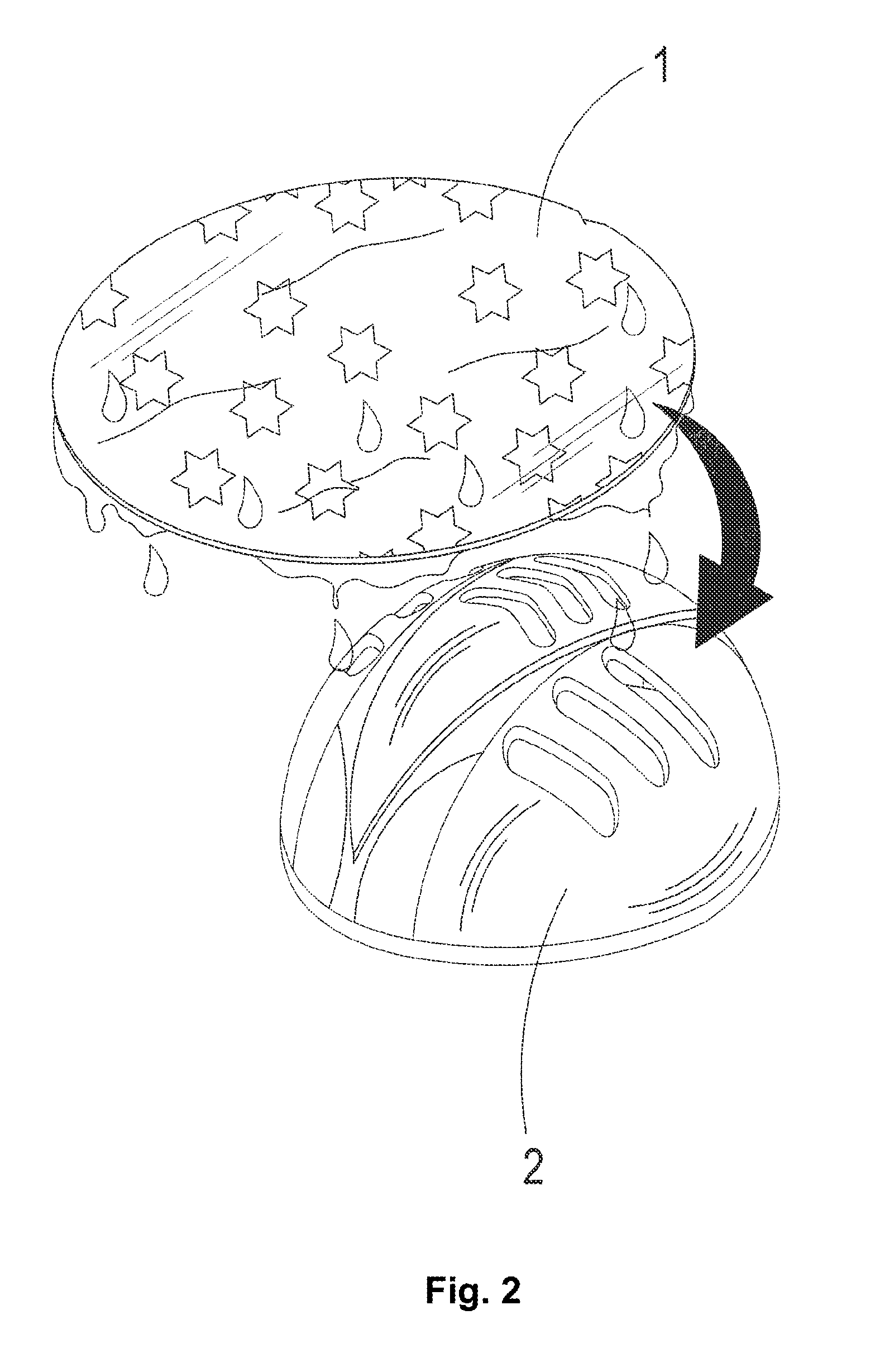

Reflective structure

InactiveUS20110141563A1Improved reflective structureSimple structureOptical elementsIsolation layerEngineering

An improved reflective structure utilizing a water transfer printing means for adhesion onto an object in a detachable / non-detachable manner includes a substrate, an isolation layer, an ink layer and a cover layer. The substrate is used for adhesion onto an object, and the isolation layer (an essential oil) is disposed over the substrate and dissolvable in water such that the thickness of the entire structure is reduced. The ink layer has a high polymer content and is printed onto the surface of the isolation layer to provide different patterns. The glass bead layer is capable of reflecting light and is disposed onto the ink layer surface. The cover layer is disposed over the surface of the glass bead layer. Alternatively, the glass bead layer is disposed over the cover layer, and the cover layer is disposed on the ink layer, so that the reflective structure is flexible for complicated, curved shapes.

Owner:CHEN SHIH YU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com