Preparation method of drag reducing agent for shale gas fracturing and drag reducing agent for fracturing

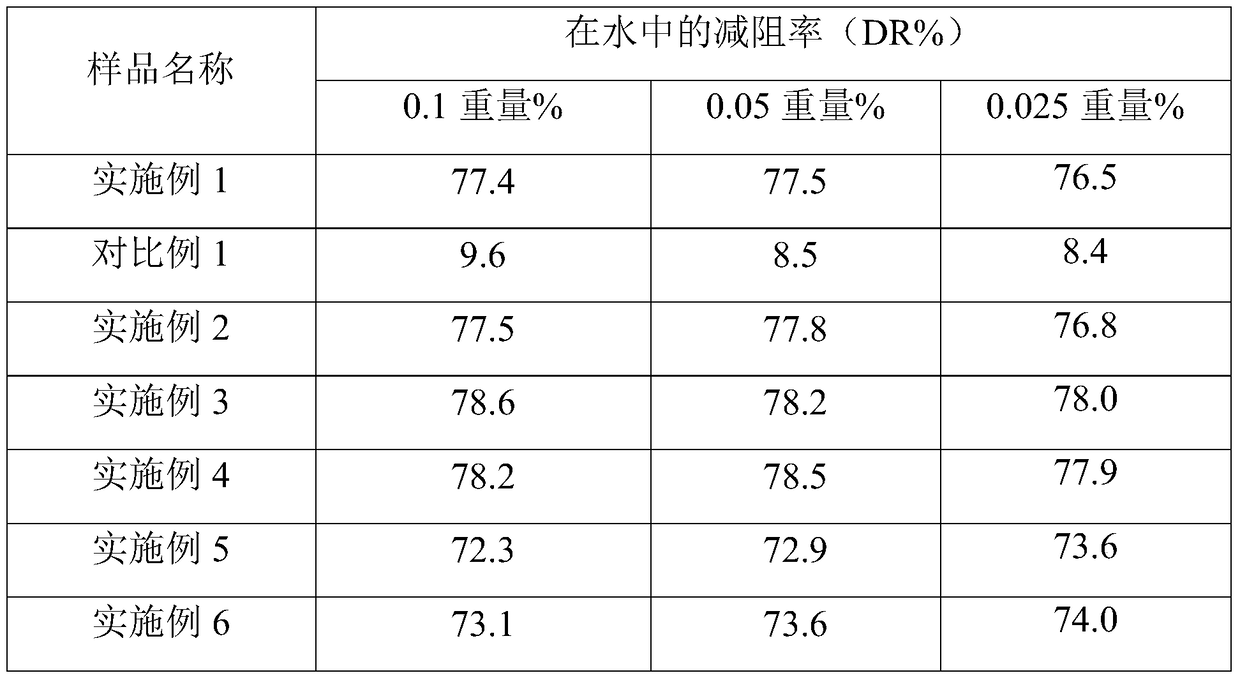

A drag reducing agent and gas pressure technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to meet the requirements of large displacement and large flow online preparation of shale gas fracturing, inability to meet the requirements of environmental protection, and unfavorable conditions. Practical application and other issues, to achieve the effects of cheap production cost, high drag reduction efficiency and shear resistance, and obvious drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] On the one hand, the present invention provides a kind of preparation method of drag reducer for shale gas fracturing, and the method comprises:

[0020] (1) In the presence of water, at least part of the polymerized monomers, inorganic salts, stabilizers and chelating agents are mixed to obtain a mixed solution;

[0021] (2) adjust the pH value of the mixed solution to be 3-7;

[0022] (3) In the presence of a protective gas, add an initiator and the remaining part of the polymerized monomer to the reaction system obtained in step (2) to react, wherein the weight ratio of at least part of the polymerized monomer to the remaining part of the polymerized monomer is 1 : 1-20.

[0023] The invention provides a preparation method of a drag reducer for shale gas acidification fracturing with low viscosity and high solid content. The method introduces acid-resistant monomers, and dynamically adjusts the concentration of polymerized monomers during the polymerization process...

specific Embodiment approach

[0044] According to a preferred embodiment of the present invention, the method of the present invention comprises:

[0045] (1) Mix at least part of the polymerized monomers, inorganic salts, stabilizers, chelating agents and deionized water, and adjust the pH value of the resulting mixed liquid to 3-7 with NaOH aqueous solution;

[0046] (2) The reaction solution obtained in step (1) is warmed up to 20-70° C., and the oxygen in the reaction solution is exhausted with nitrogen;

[0047] (3) Stir the reaction for 2-8 hours under the protection of nitrogen, and add the initiator and the remaining polymerization monomers into the reaction system at least once during the reaction process.

[0048] In another aspect, the present invention provides a drag reducer for shale gas fracturing prepared by the above-mentioned method of the present invention.

[0049] The present invention will be described in detail below by way of examples.

[0050] According to the present invention, ...

Embodiment 1

[0055] This example is used to illustrate the preparation method of the drag reducing agent for shale gas fracturing of the present invention and the preparation of the drag reducing agent for shale gas fracturing of the present invention.

[0056] Add 405g of deionized water, 280g of ammonium sulfate, 85.5g of acrylamide, 4.5g of acrylic acid, poly 9 g of sodium 2-acrylamido-2-methylpropanesulfonate (molecular weight: 100,000), 0.4 g of disodium ethylenediamine tetraacetate, 5.5 g of 30% by weight potassium hydroxide, stir to completely dissolve the solid, and then heat up to 35°C After 30 minutes of nitrogen flow; add 2,2'-azobisisobutylamidine hydrochloride 0.05g, continue nitrogen flow, and within 3 hours, the remaining acrylamide (199.5g) and acrylic acid (10.5g ) into the polymerization tank, after the reaction, the milky white dispersion with an apparent viscosity of 375 mPa.s was obtained, which can be stored stably for more than 6 months at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com