A kind of oil-based self-suspending polymer thickener and preparation method thereof

A polymer and self-suspension technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as large amount of addition, many types of addition, adverse effects on performance such as fracturing fluid residue flowback, etc., to achieve residue less, high demulsification rate, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

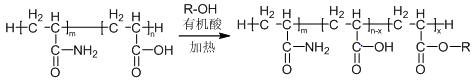

Method used

Image

Examples

Embodiment 1

[0024] Add 1000g of n-hexane to the four-neck flask, add 100g of partially hydrolyzed polyacrylamide powder (100 mesh, molecular weight of 30 million, degree of hydrolysis 40%), add 6g of n-octanol, and add 1g of p-toluenesulfonic acid. Add a condenser and a water separator to the four-necked bottle, stir it with a magnetic force, and heat it in an oil bath. After the reflux reaction for 4 hours, the water level in the water separator does not change anymore, stop heating, cool down to room temperature, filter, put the obtained solid powder in a vacuum drying oven, and dry it in vacuum at 120°C for 4 hours to obtain the modified polymer powder 104.2g.

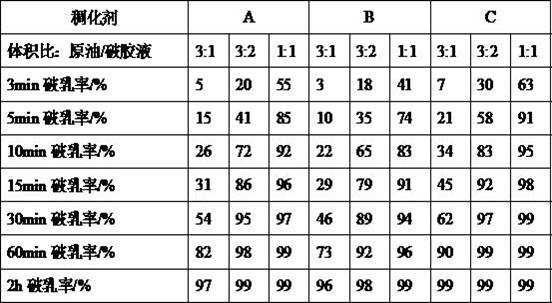

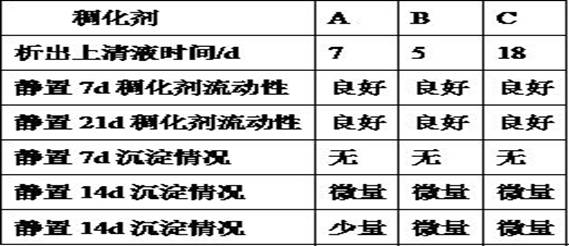

[0025] Take 50g of the above-mentioned modified polymer powder, add it into 50g of 10# white oil, and mechanically stir at 500r / min for 1h to obtain oil-based self-suspension polymer thickener A.

Embodiment 2

[0027] Add 1000g of petroleum ether with a boiling point of 60~90°C to the four-necked bottle, add 200g of partially hydrolyzed polyacrylamide powder (80 mesh, molecular weight of 40 million, degree of hydrolysis 45%), add 15g of lauryl alcohol, and add 2-naphthalenesulfonic acid 4g. Add a condenser and a water separator to the four-necked bottle, stir it with a magnetic force, and heat it in an oil bath. After the reflux reaction for 6 hours, the water level in the water separator does not change anymore, stop heating, cool down to room temperature, filter, put the obtained solid powder in a vacuum drying oven, and vacuum dry at 120°C for 4 hours to obtain the modified polymer powder 211.6g.

[0028] Take 120g of the above-mentioned modified polymer powder, add it into 110g of 15# white oil, and mechanically stir at 600r / min for 2h to obtain oil-based self-suspending polymer thickener B.

Embodiment 3

[0030] Add 2000g of toluene to the four-necked flask, add 100g of partially hydrolyzed polyacrylamide powder (120 mesh, molecular weight of 15 million, degree of hydrolysis 25%), add 10g of isobutanol, and add 5g of benzenesulfonic acid. Add a condenser and a water separator to the four-necked bottle, stir it with a magnetic force, and heat it in an oil bath. After reflux reaction for 3 hours, the water level in the water separator does not change anymore, stop heating, cool down to room temperature, filter, put the obtained solid powder in a vacuum drying oven, and dry it in vacuum at 120°C for 5 hours to obtain the modified polymer powder 107.2 g.

[0031] Take 40g of the above-mentioned modified polymer powder, add it into 50g of 5# white oil, and stir it mechanically at 300r / min for 40min to obtain oil-based self-suspension polymer thickener C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com