Method for preparing peanut oil by aqueous enzymatic method based on fatty acid demulsification

A peanut oil and fatty acid technology, which is applied in the fields of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve problems such as hindering the release of peanut oil and difficulty in demulsification of stable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

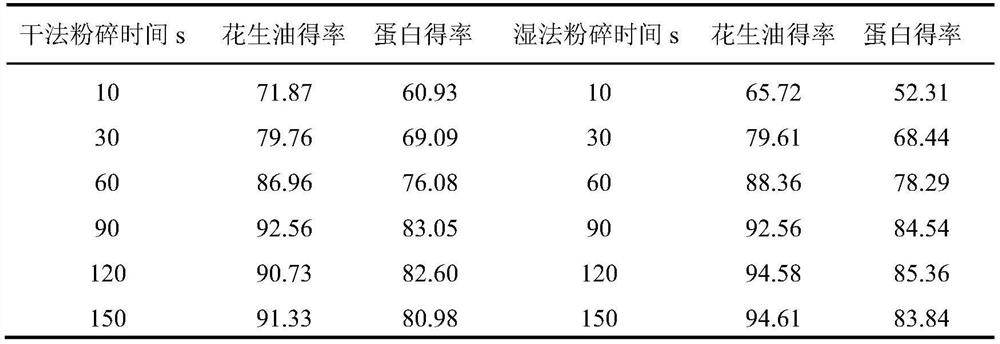

[0031] In this example, the processing method of peanut samples-dry crushing and wet crushing were studied in the early stage, so as to compare the yield, composition, stability, and yield of peanut oil body and peanut protein of the obtained oil body emulsion, in order to Select the optimal processing method for peanut samples.

[0032] The operation steps of dry crushing are as follows: In order to compare the effect of particle size on the extraction rate of peanut oil and protein, high-speed universal grinder is used to crush peeled peanuts for 10s, 30s, 60s, 90s, 120s and 150s respectively. The ratio of solid to liquid is 1:4, add deionized water, stir evenly, and then add enzyme for enzymatic hydrolysis.

[0033] The operation steps of wet crushing are as follows: add deionized water to peeled peanuts according to the ratio of 1:4, put them in a refrigerator at 4°C for 18 hours, use a multi-functional cooking machine to crush them for 10s, 30s, 60s, 90s, 120s and 150s re...

Embodiment 2

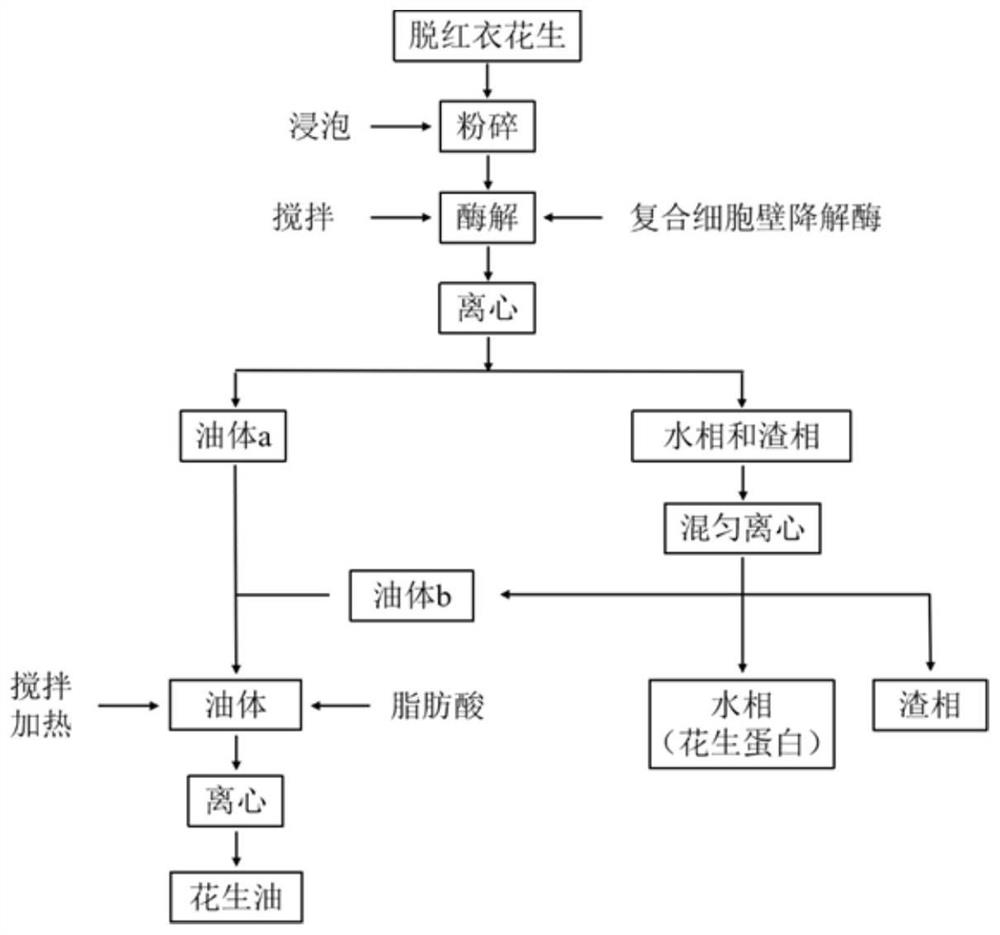

[0046] This embodiment is a method for preparing peanut oil based on the aqueous enzymatic method of fatty acid demulsification, and its technological process is as follows figure 1 shown, including:

[0047] (1) Peanut sample treatment: add deionized water to the predetermined weight at a mass ratio of 1:3~5 for the peanuts, and place them in a refrigerator at 3~6°C for 12~24 hours. Wash with water, add deionized water to make up to the predetermined weight, and pulverize for 1-2.5 minutes to obtain a mixed solution.

[0048] (2) Oil body preparation: add the compound cell wall degrading enzyme to the mixture at 1-2% of the mass of the peanut sample, stir at a constant temperature of 45-55°C for 1.5-3 hours, fully enzymolyze and inactivate it in a boiling water bath 4-8min, the cooled suspension was centrifuged at 4000-6000×g for 15-30min, and the upper oil body a was collected; the lower aqueous phase and residue were enzymatically hydrolyzed at 45-55°C for 20-40min, after ...

Embodiment 3

[0054] This example is a preferred method for preparing peanut oil by aqueous enzymatic method, which studies the influence of different fatty acid types and addition amounts on the demulsification rate of oil bodies. The above-mentioned method includes:

[0055] (1) Peanut sample processing: add deionized water to 20g of red-coated peanuts at a mass ratio of 1:4, place in a refrigerator at 4°C for 18 hours, wash the peanuts with deionized water at 4°C after absorbing water, and add deionized water to the total mass 100g, crushed for 2 minutes with a multifunctional cooking machine to obtain a mixed solution;

[0056] (2) Oil body preparation: L (1.5% of the mass of the peanut sample) was added to the above mixture, stirred at 50°C for 2 hours, fully enzymatically hydrolyzed, inactivated in a boiling water bath for 5 minutes, and the cooled suspension was centrifuged at 5000×g for 20 minutes, and the upper layer was collected. Oil body a; continue to enzymatically hydrolyze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com