Alcohol-soluble slickwater system for fracturing as well as preparation method and application of alcohol-soluble slickwater system

A slick water, alcohol-soluble technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low polymer addition, high use cost, poor resistance reduction rate, etc., to inhibit swelling, reduce the use of and transportation costs, the effect of enhancing suspension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of alcohol-soluble slippery water system:

[0027] 1.1 Raw materials:

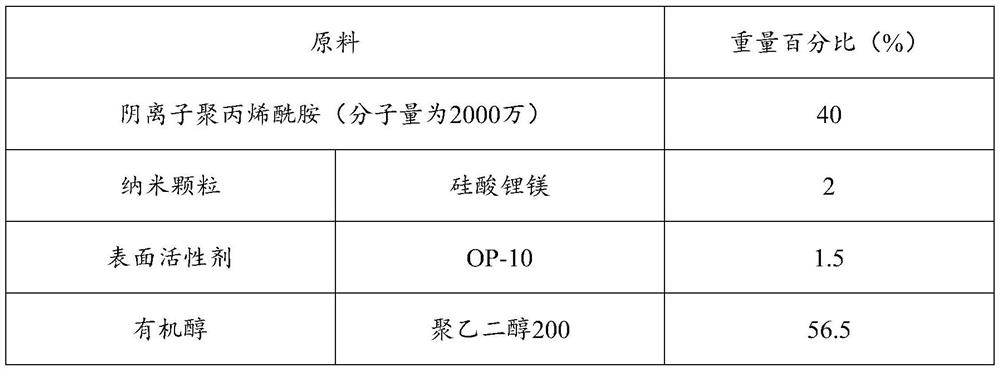

[0028] Each raw material is by weight percentage, as shown in table 1 below:

[0029] Table 1 Embodiment 1 raw material list

[0030]

[0031] 1.2 Preparation method:

[0032] Put the organic alcohol into the reaction vessel, control the stirring rate at 2000r / min, add nanoparticles, surfactant, and anionic polyacrylamide in sequence, adjust the stirring rate to 1500r / min after the addition, and stir for 30 minutes to complete the fracturing process. Preparation of alcohol-soluble slippery water system.

Embodiment 2

[0034] Preparation of alcohol-soluble slippery water system:

[0035] 2.1 Raw materials:

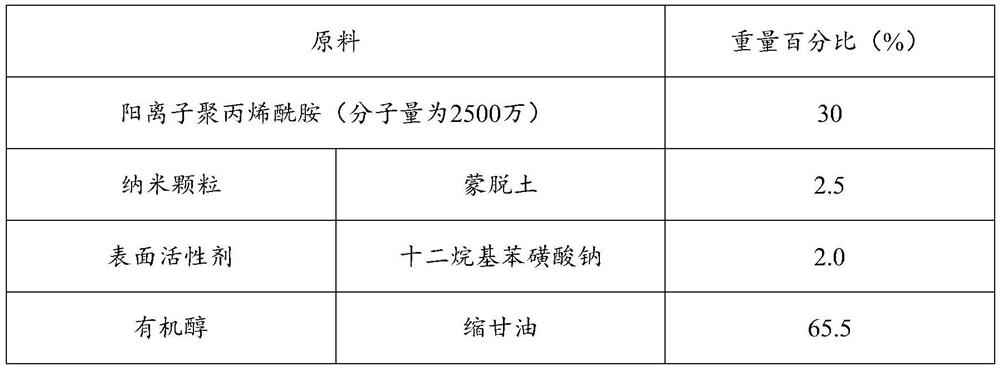

[0036] Each raw material is by weight percentage, as shown in table 2 below:

[0037] Table 2 Embodiment 2 raw material table

[0038]

[0039] 2.2 Preparation method:

[0040] Put the organic alcohol into the reaction vessel, control the stirring rate at 3000r / min, add nanoparticles, surfactant, and cationic polyacrylamide in sequence, adjust the stirring rate to 1000r / min after the addition, and stir for 20 minutes to complete the fracturing process. Preparation of alcohol-soluble slippery water system.

Embodiment 3

[0042] Preparation of alcohol-soluble slippery water system:

[0043] 3.1 Raw materials:

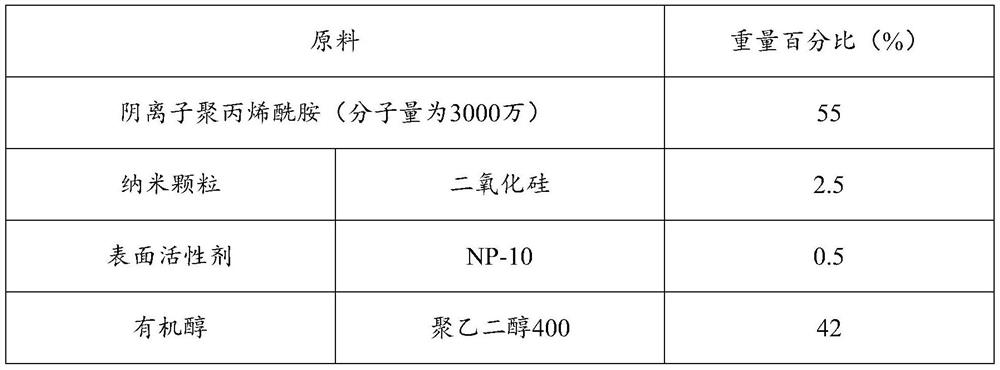

[0044] Each raw material is by weight percentage, as shown in the following table 3:

[0045] Table 3 Embodiment 3 raw material table

[0046]

[0047] 3.2 Preparation method:

[0048] Put the organic alcohol into the reaction vessel, control the stirring rate at 2500r / min, add nanoparticles, surfactant, and anionic polyacrylamide in sequence, adjust the stirring rate to 1800r / min after the addition, and stir for 60 minutes to complete the fracturing process. Preparation of alcohol-soluble slippery water system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com