Method for preparing mercaptosilane coupling agent by using channel reactor

A technology of mercaptosilane coupling agent and channel reaction device, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, and organic chemistry, etc., can solve the problems of long reaction period, poor stability, and polymers, etc. , to achieve the effect of long conversion cycle, large output elasticity and fixed output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 prepares 3-mercaptopropyltriethoxysilane

[0063] The equation for the reaction of the two main raw materials is:

[0064] (C 2 h 5 O) 3 SiC 3 h 6 Cl+NaHS→(C 2 h 5 O) 3 SiC 3 h 6 SH+NaCl

[0065] Mass ratio of raw materials, 3-chloropropyltriethoxysilane (content 98%): sodium hydrosulfide hydrate (content 71%): solvent water: phase transfer catalyst tetrabutylammonium bromide: pH regulator sodium carbonate For 650:200:380:8:50.

[0066] Proceed as follows:

[0067] (1) Prepare sodium hydrosulfide aqueous solution: dissolve 200 parts of sodium hydrosulfide in 360 parts of water to prepare an aqueous solution.

[0068] (2) Preparation of aqueous solution of phase transfer catalyst: Dissolve 8 parts of phase transfer catalyst tetrabutylammonium bromide in 20 parts of water. (3) Mix the sodium hydrosulfide aqueous solution, the phase transfer catalyst aqueous solution, and the pH regulator sodium carbonate evenly, and heat the temperature to 60°C....

Embodiment 2

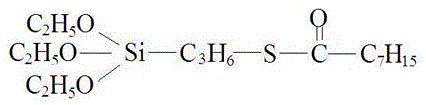

[0077] Example 2 Preparation of 3-octanoylthio-1-propyltriethoxysilane

[0078] The equation for the reaction of the two main raw materials is:

[0079] (C 2 h 5 O) 3 SiC 3 h 6 Cl+NaS(C=O)C 7 h 15 →(C 2 h 5 O) 3 SiC3 h 6 S(C=O)C 7 h 15 +NaCl

[0080] The mass ratio of raw materials, 3-chloropropyltriethoxysilane:sodium thiooctanoate aqueous solution (content 30%):phase transfer catalyst tetrabutylammonium bromide aqueous solution (content 25%) is 435:1060:24.

[0081] The steps are: add the aqueous solution of phase transfer catalyst tetrabutylammonium bromide to the aqueous solution of sodium thiooctanoate, mix well and heat to 75°C, the mixed solution, 3-chloropropyltriethoxy Silane is passed into the channel reaction device to react at the same time, and the reaction temperature is controlled at 90°C. The crude product is taken from the post-processing device connected to the channel reaction device, cooled and layered, and the upper organic phase is taken for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com