Patents

Literature

38results about How to "Fulfill production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-site semaphore detection and failure determining system and method

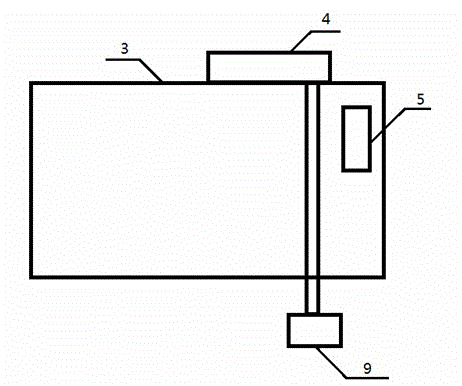

InactiveCN107544018AEasy to handleRealize automatic controlElectronic circuit testingMulti siteVoltage control

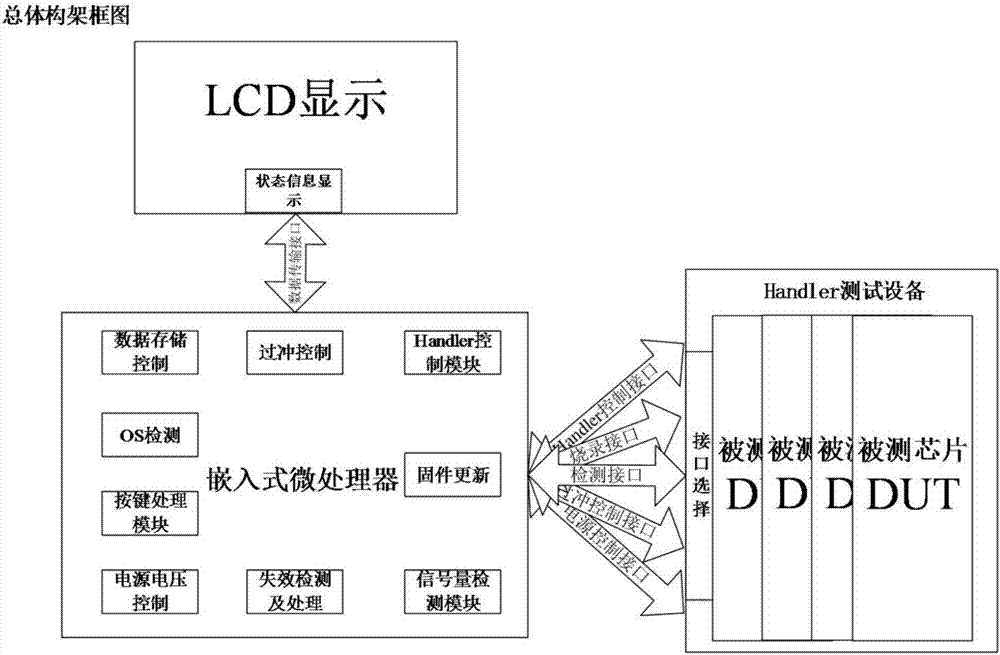

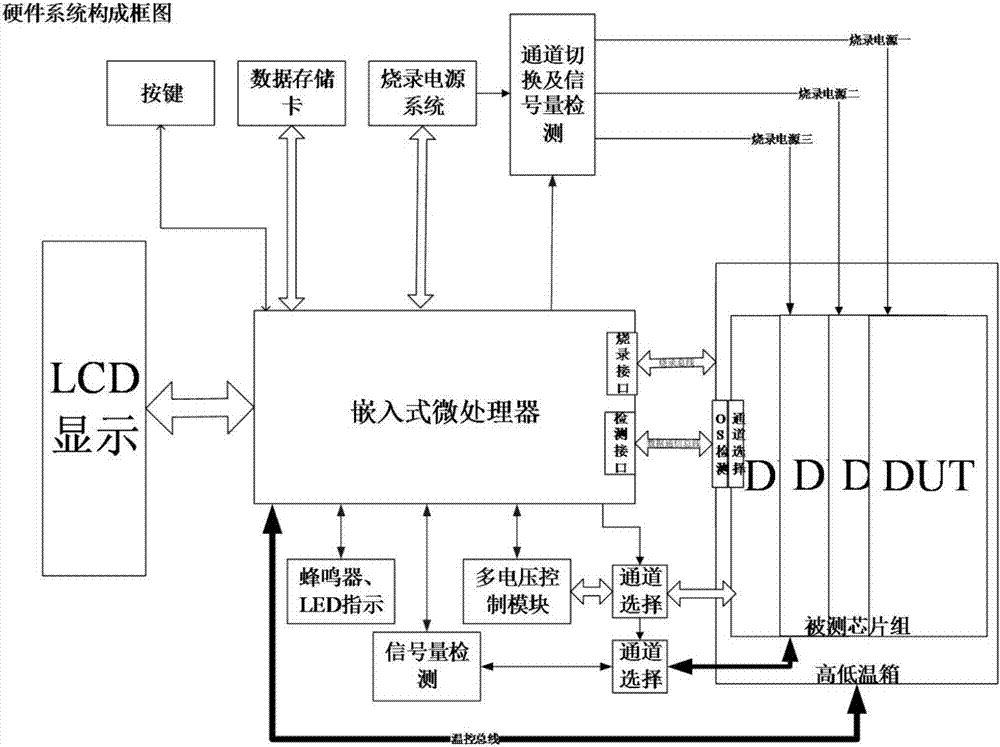

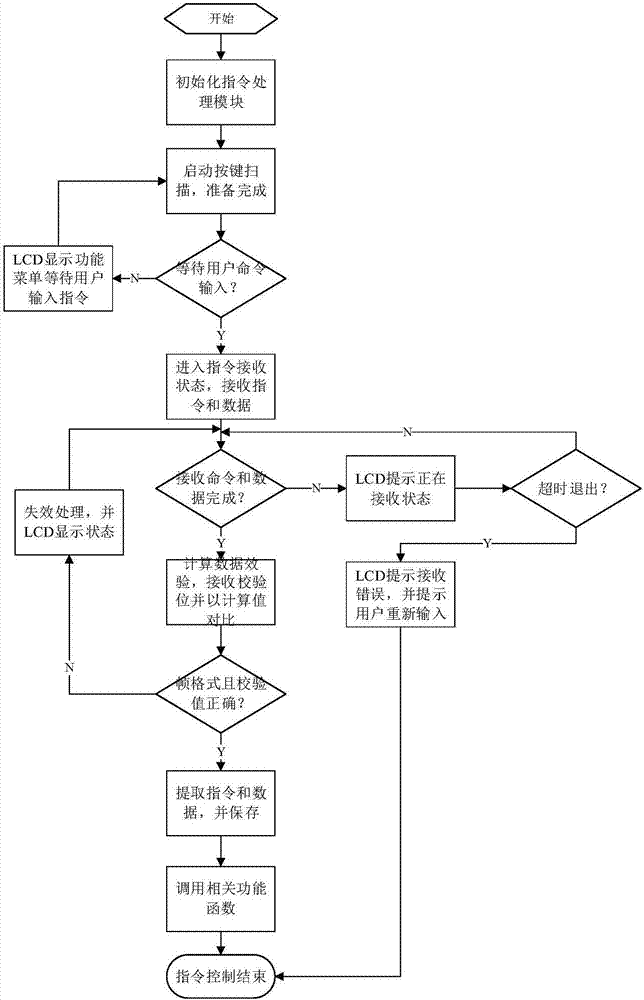

The invention discloses a multi-site semaphore detection and failure determining system and method. The system herein implements through an embedded microprocessor and a LCD display module. The embedded microprocessor includes a command processing module, a data storage module, a firmware updating module, an OS detection and repair module, a power voltage control module, an input and output semaphore detection module, a key processing module, a failure processing module, and a handler control module. The system provides necessary means for analyzing and detecting chip DC characteristic indexesby a mass production terminal, integrates a multi-index semaphore set to one system for performing detection and failure determination, comprises detection of chip physical connection characteristics, and greatly increases working efficiency.

Owner:CHIPSEA TECH SHENZHEN CO LTD

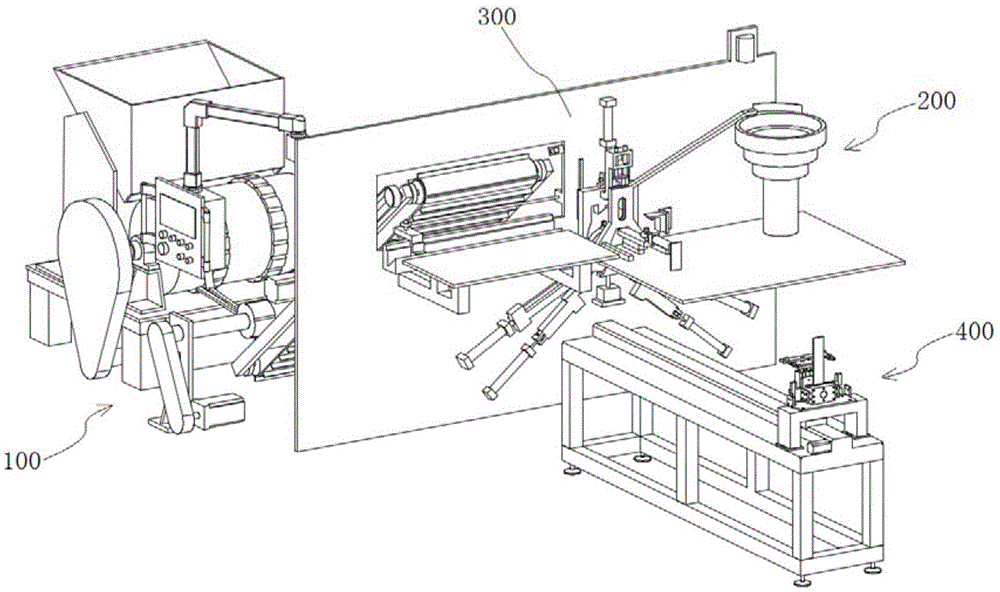

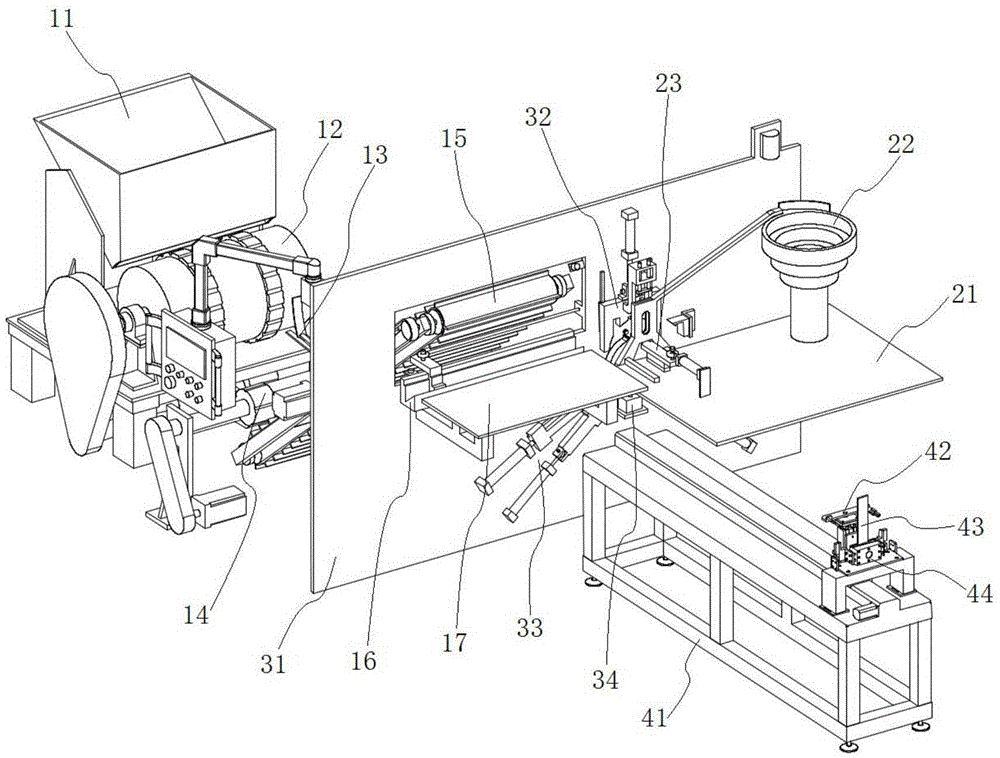

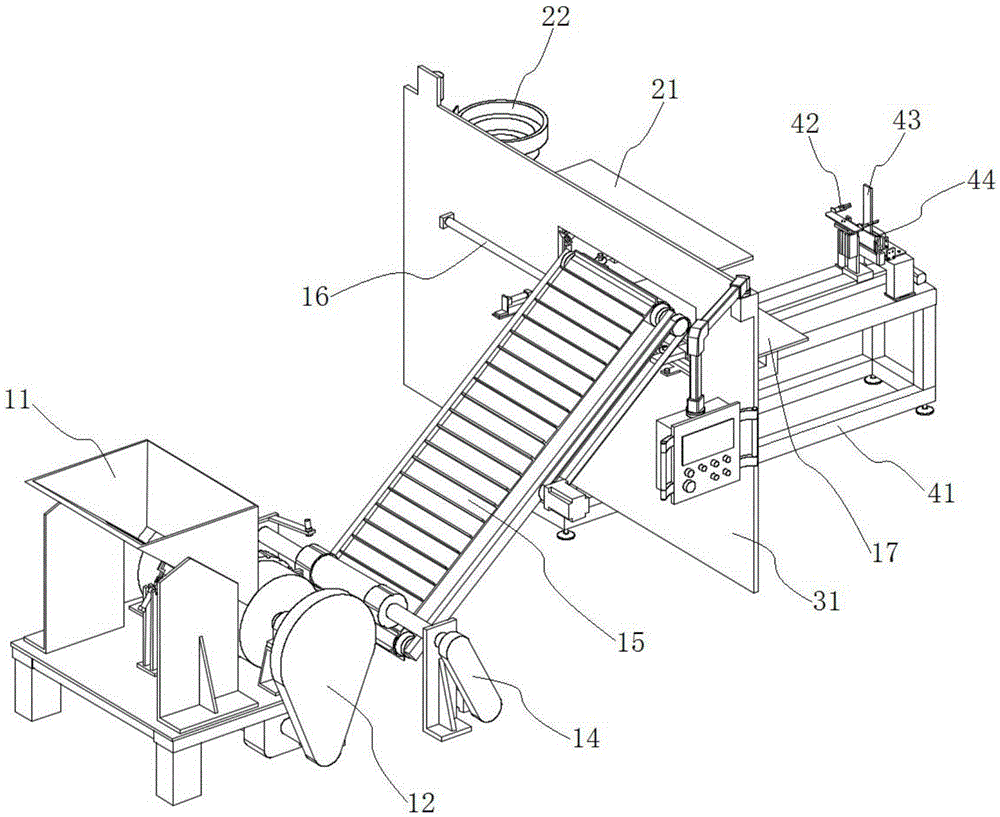

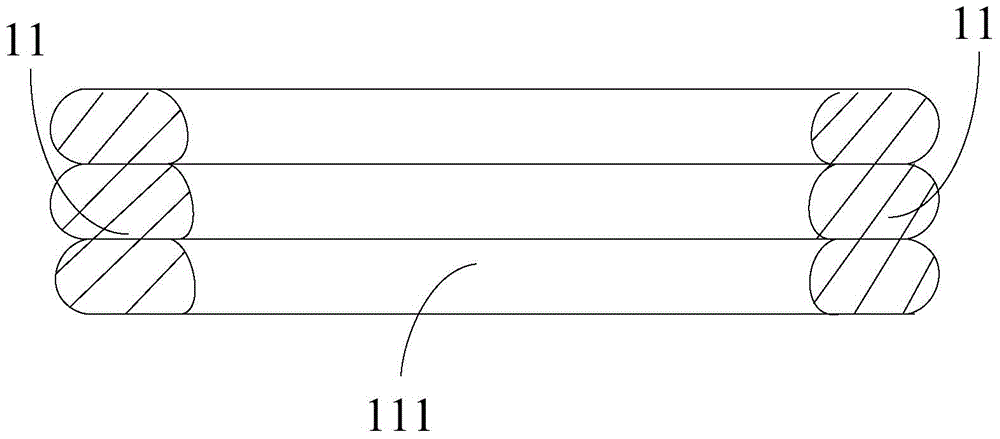

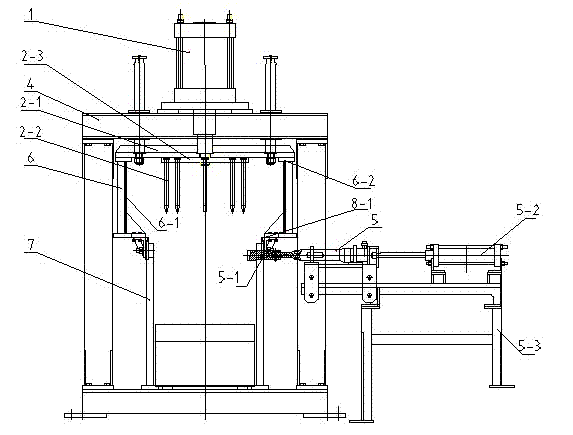

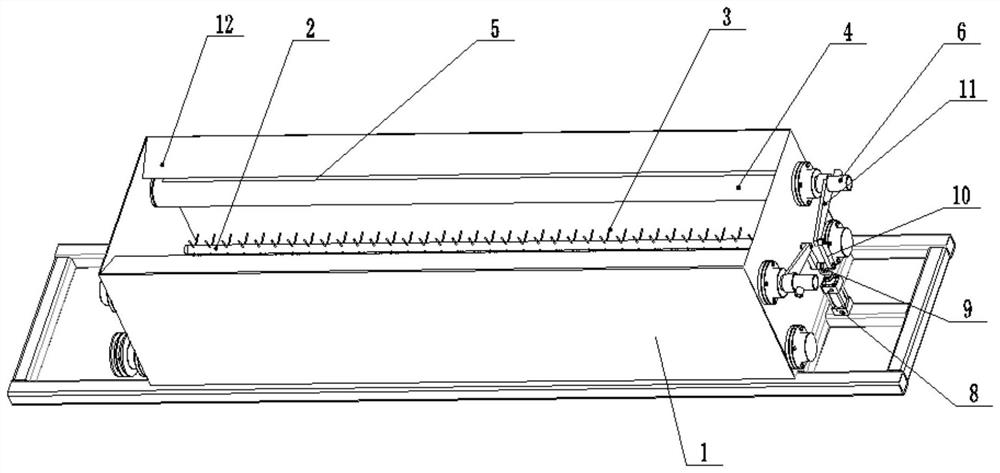

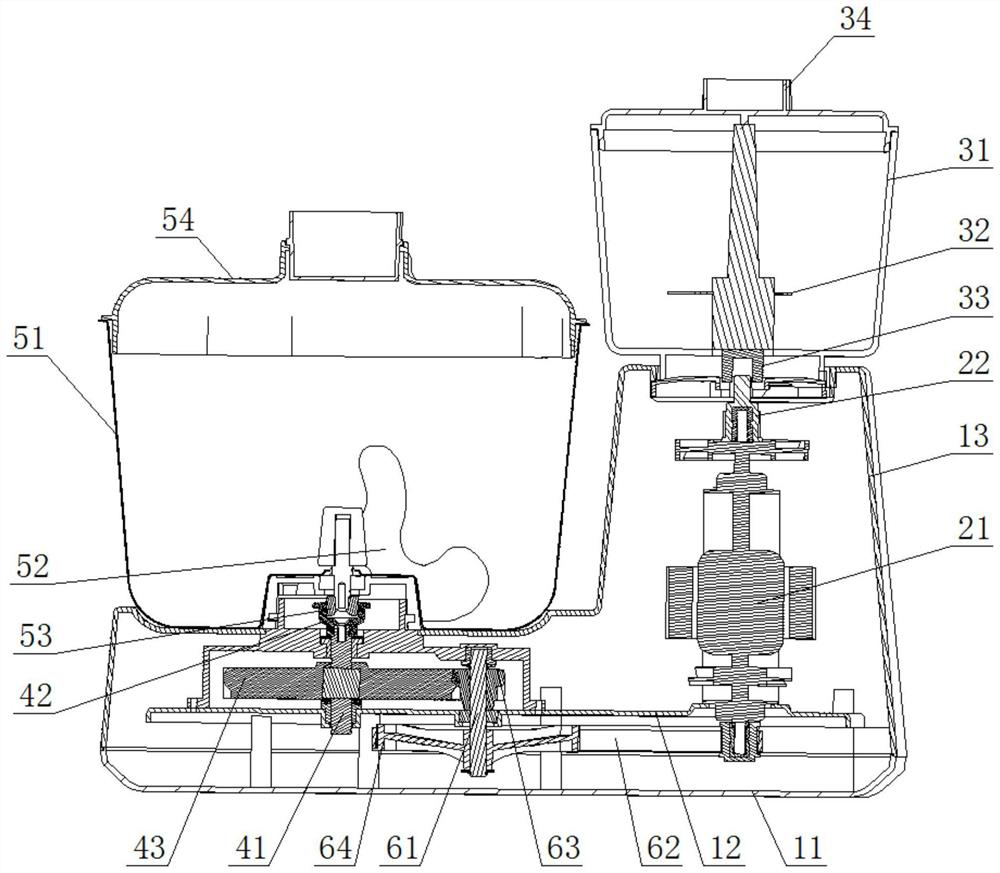

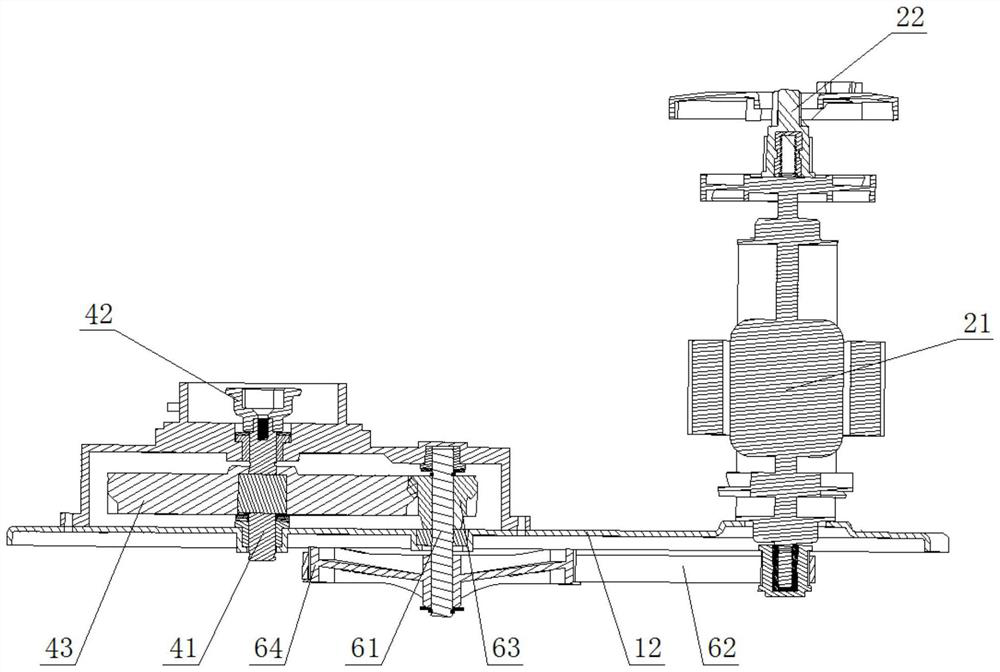

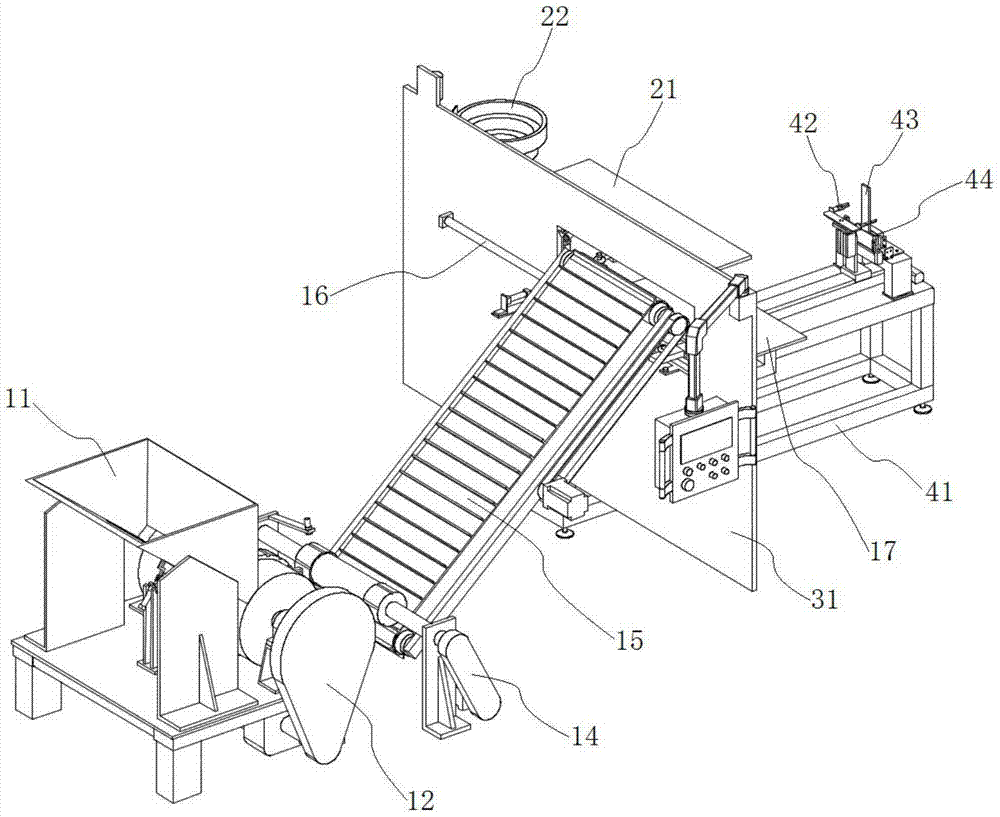

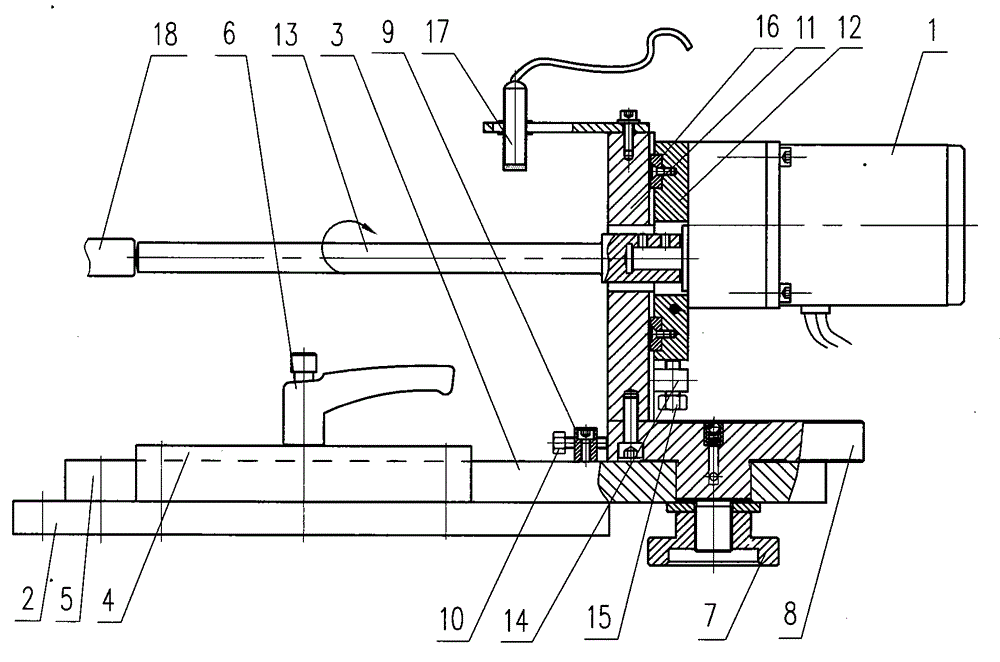

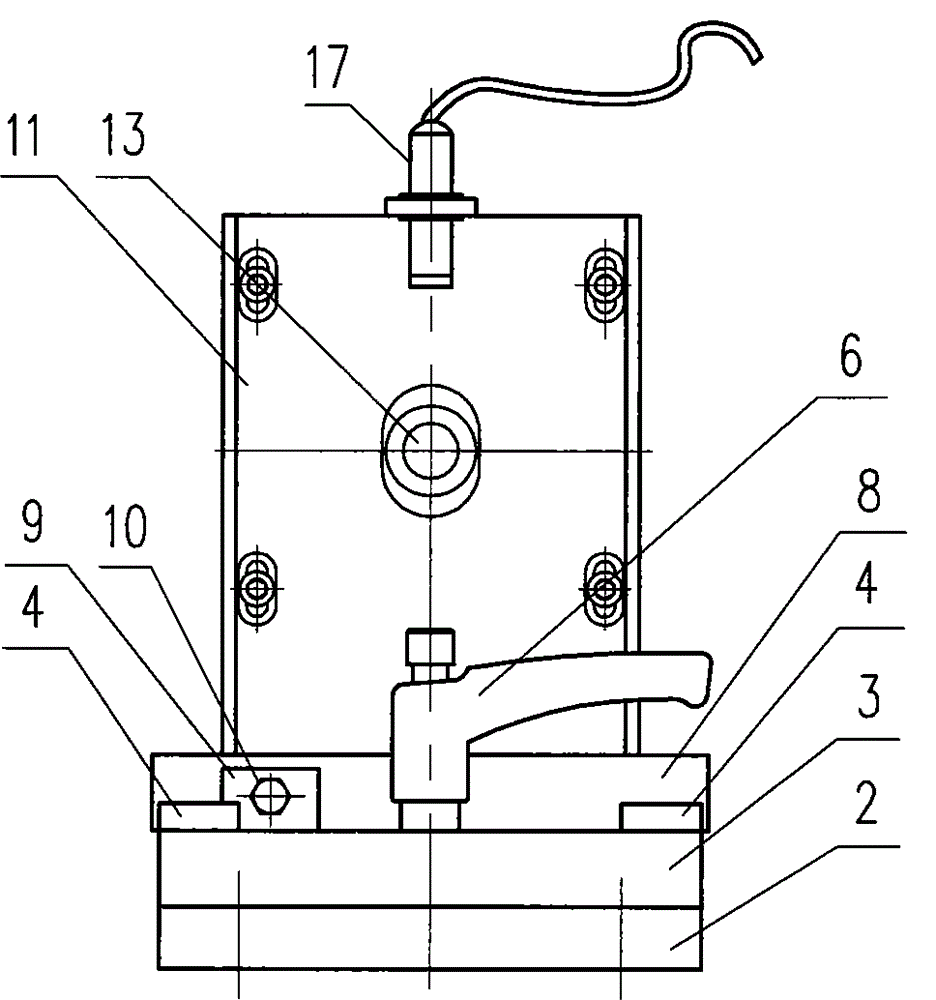

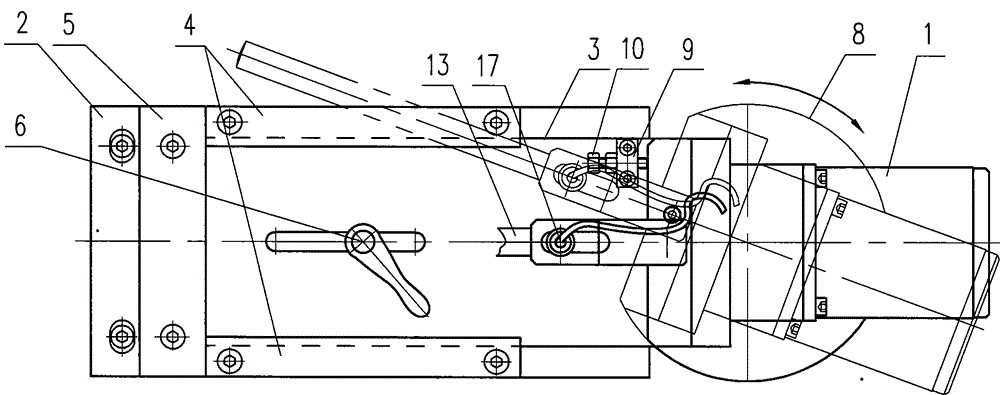

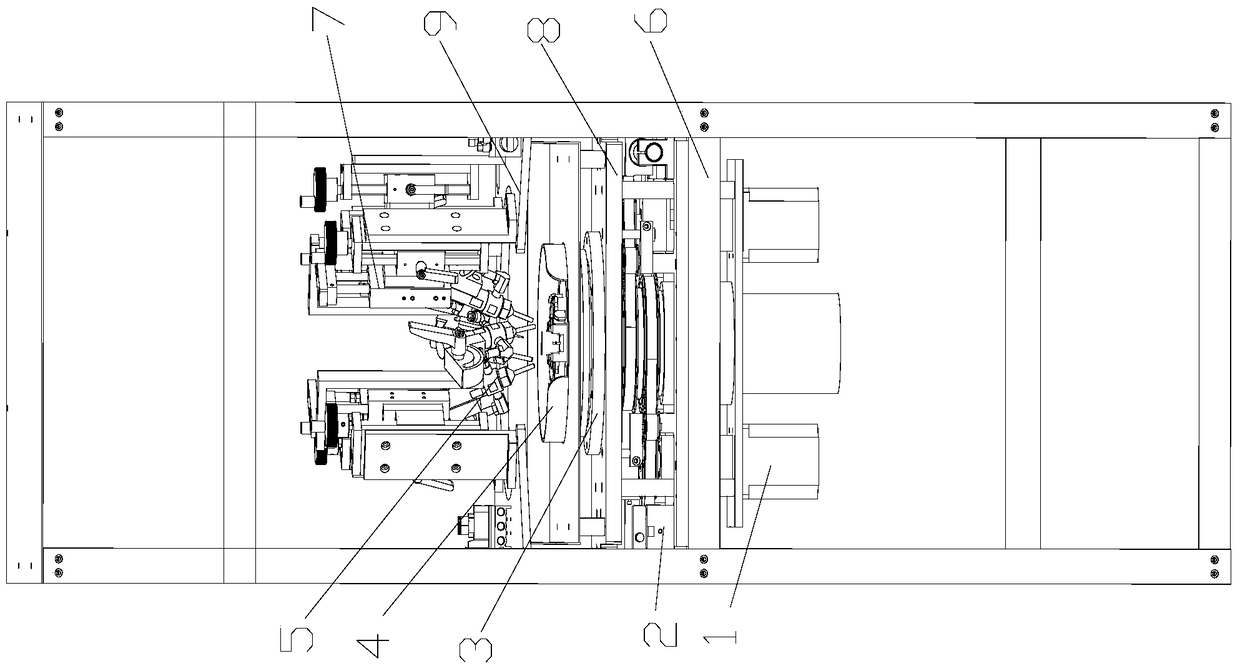

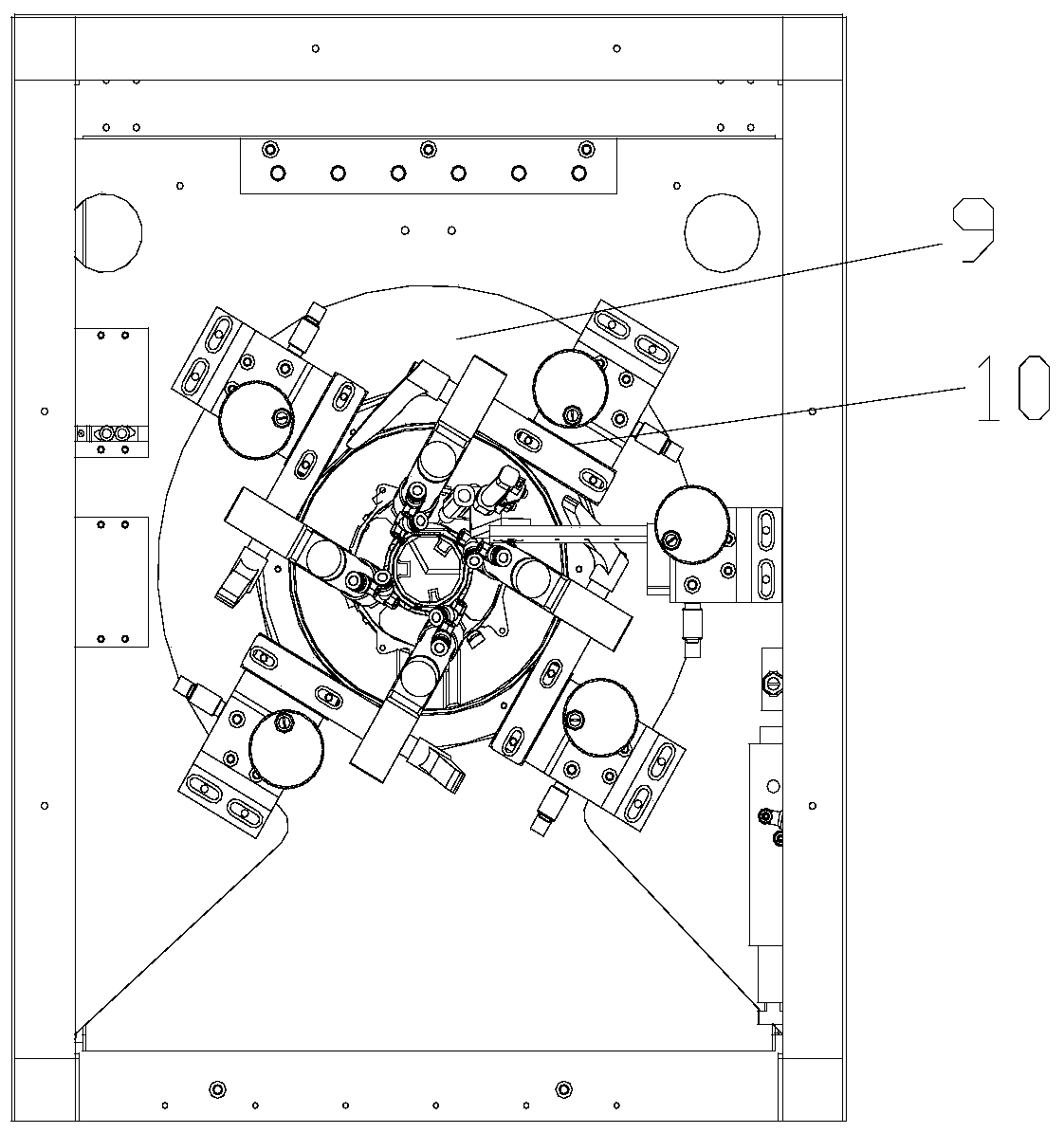

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

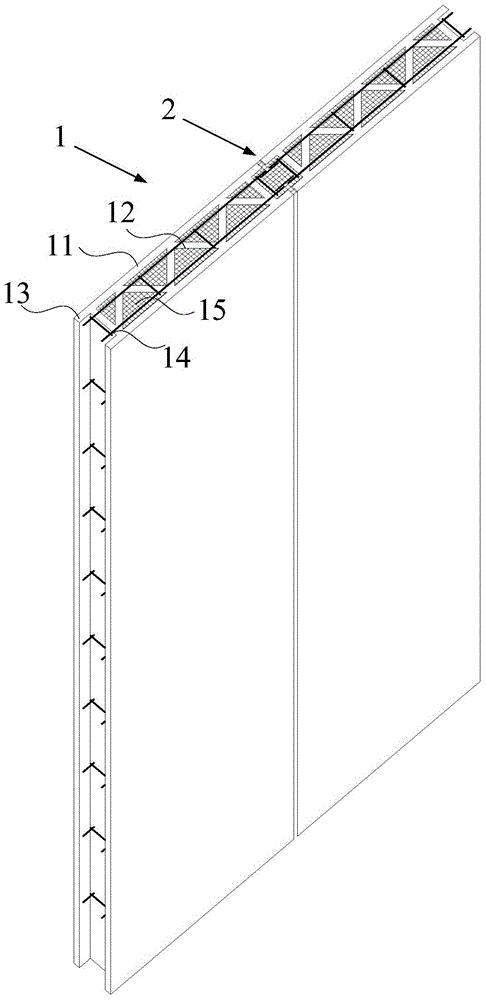

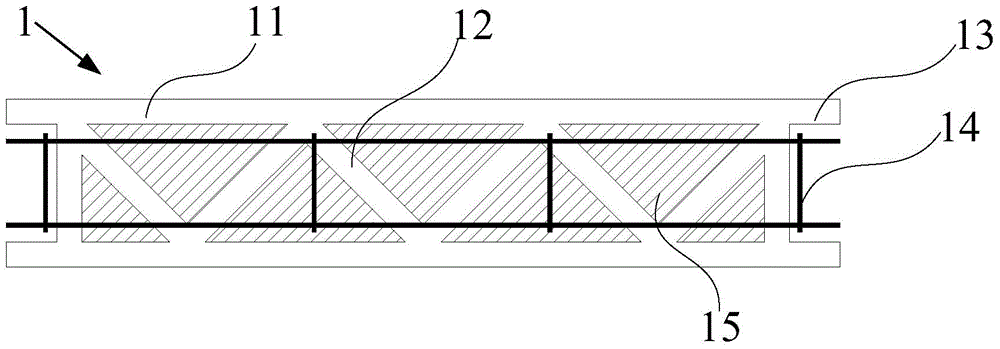

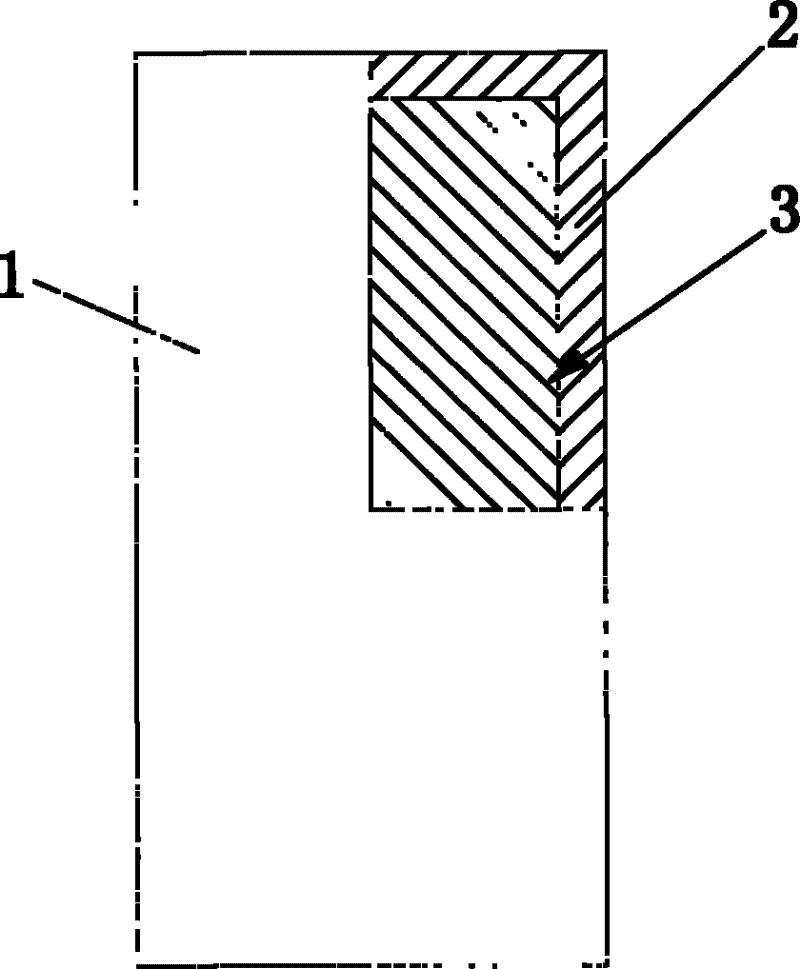

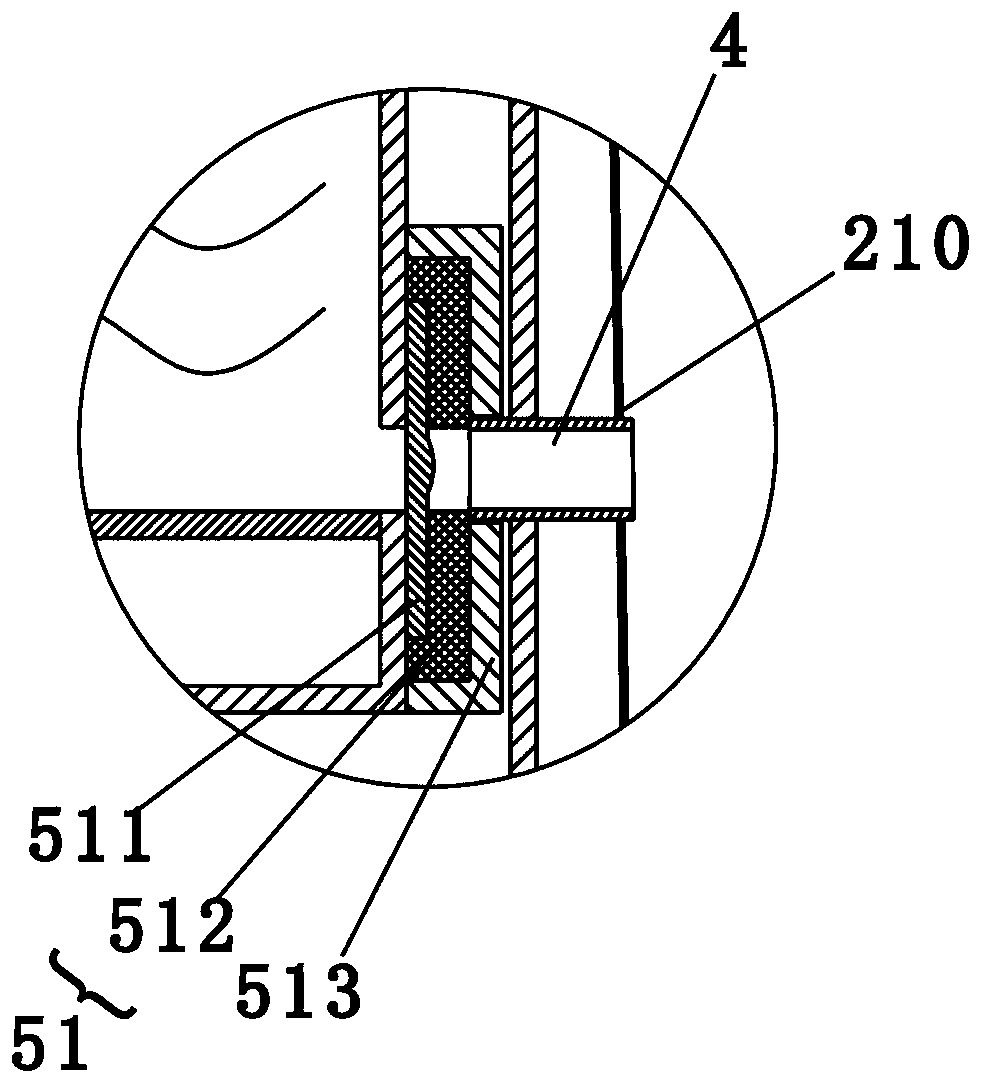

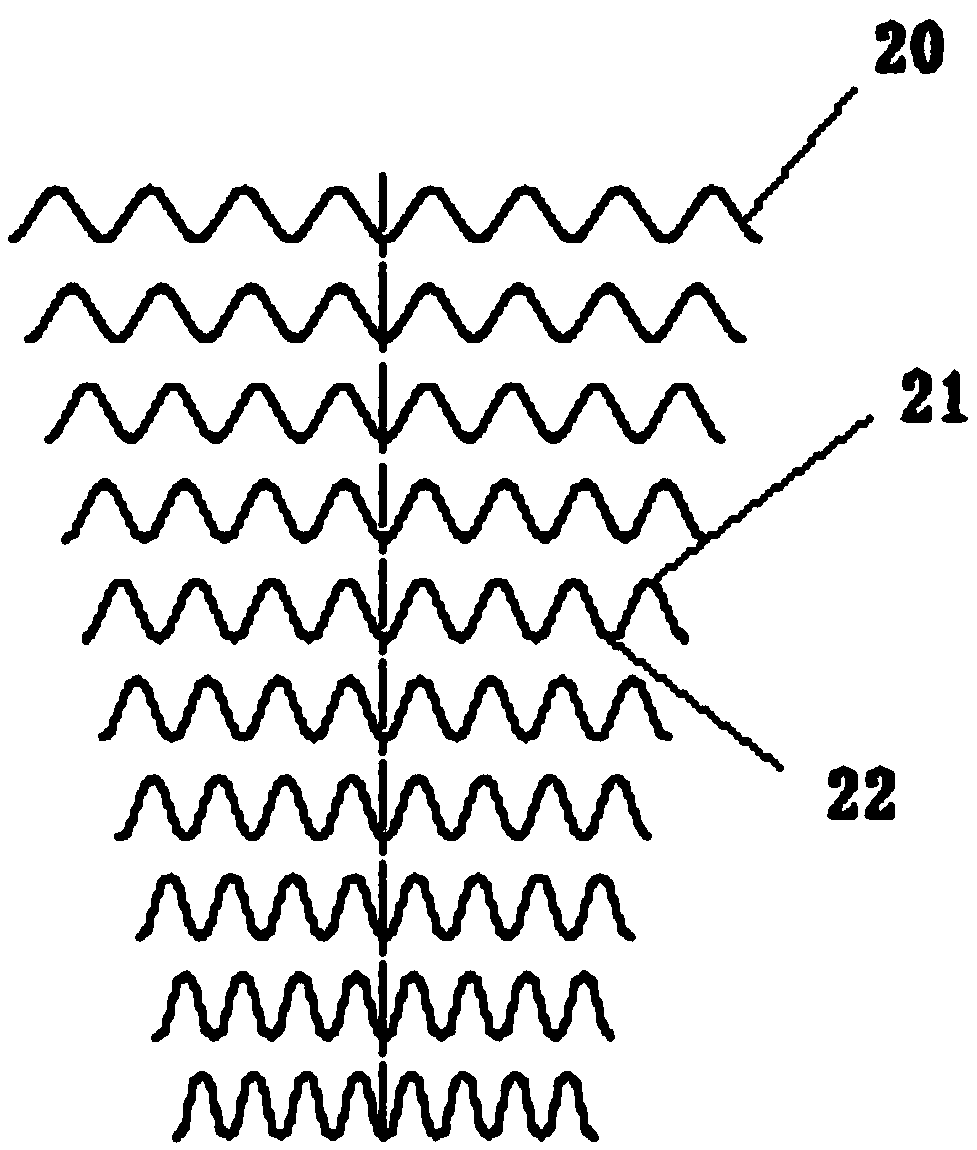

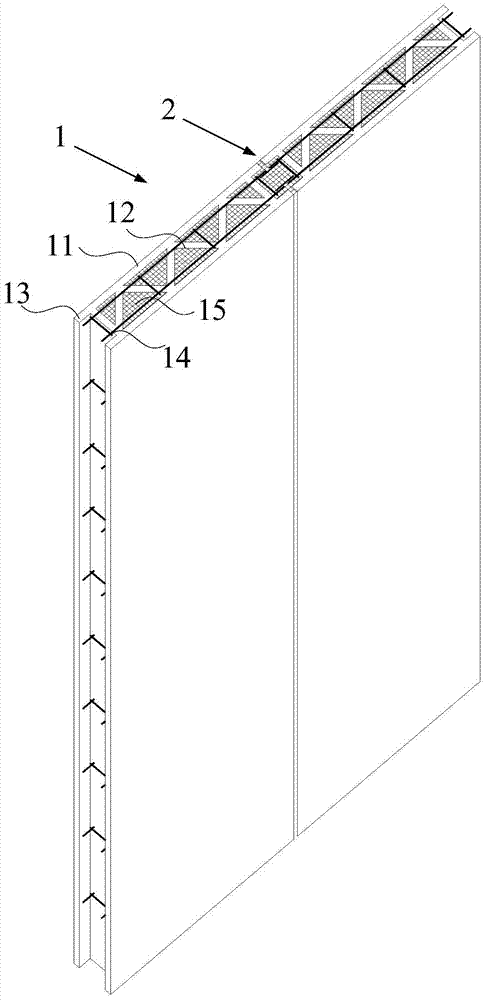

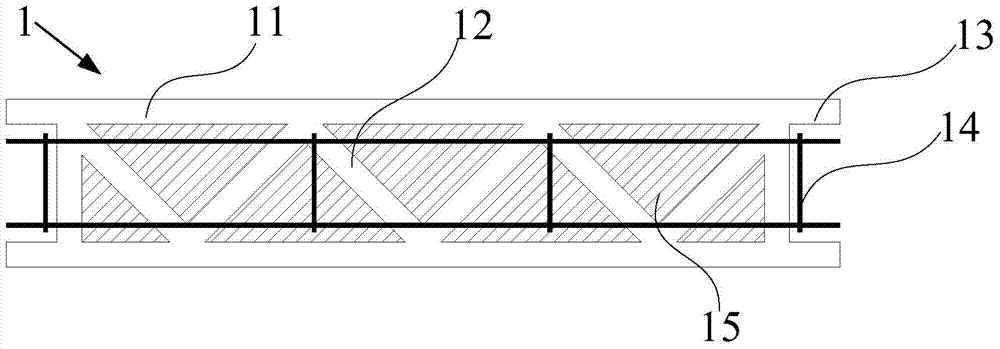

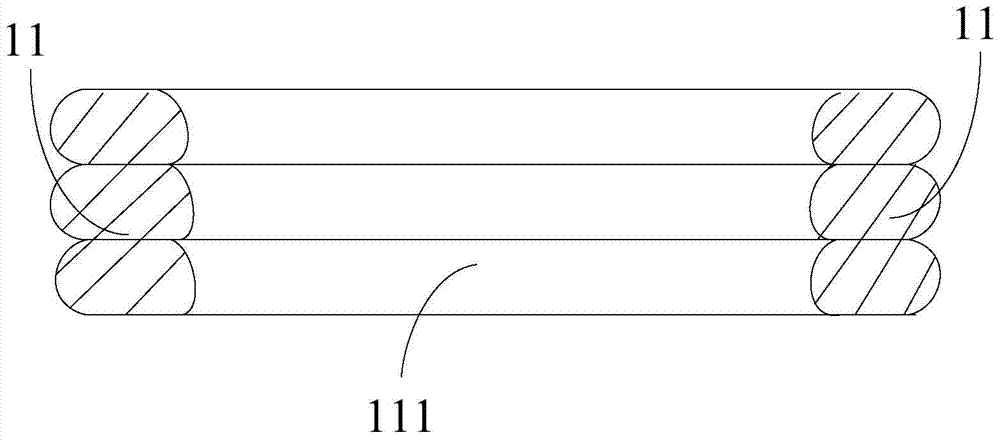

3D printing internal parting wall and construction method of 3D printing internal parting wall

The invention discloses a 3D printing internal parting wall and a construction method of the 3D printing internal parting wall. The 3D printing internal parting wall comprises a plurality of prefabricated internal parting wall units formed according to the 3D printing technology and arranged side by side, first packing materials arranged in the prefabricated internal parting wall units, steel wire gauze sheets arranged in column space and second packing materials arranged in the column space, wherein butt joint grooves are formed in the two ends of each prefabricated internal parting wall unit, and the column space is formed by butt joint of every two adjacent butt joint grooves. A truss system is applied to an internal parting wall system, overall printing molding is achieved through a 3D printing machine, and the building requirements of walls with special-shaped building models are met; meanwhile, the performance of 3D printing materials is sufficiently played, the automatic degree is high, a large amount of manpower and a large number of materials are saved, and building rubbish is not generated. Continuous concave-convex lines are formed on the surfaces of the prefabricated internal parting wall units; the connection strength between the prefabricated internal parting wall units and the packing materials is improved; compared with a smooth surface, the force of friction is improved, and the combination strength is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

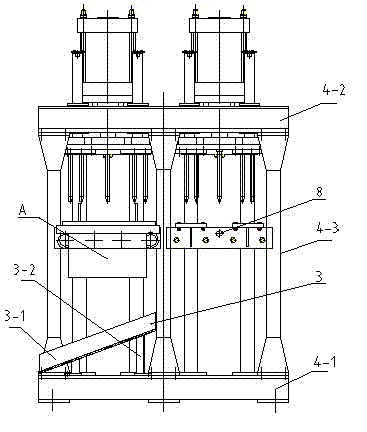

Device for separating iron mold with casting piece during casting production of sand coated iron mold of wheel castings and method thereof

The invention relates to a device for separating iron mold with casting piece during casting production of sand coated iron mold of wheel castings. The ejecting cylinder is arranged on the upper cover plate of the rack, the ejecting cylinder being connected with the ejector rod plate which is provided with a multiplicity of ejector rods. The number and the distributing position on the ejector plate of the ejector rods are in one-to-one correspondence with the number and position of the core-shooting holes of the iron mold. A casting part-connecting device is fixed on the foundation of the rack. One side of the rack is provided with a vibrating device which is in contact with the casting while at work. The iron mold rollgang is arranged below the ejector rod plate and is fixed on the back side of the ejector rod plate, the iron mold rollgang being synchronized with the ejector rod plate. The iron mold stack is fixed on the bottom of the rack and is positioned below the iron mold rollgang. The iron mold positioning device is fixed in the middle of the working position of the iron mold rollgang, the iron mold positioning device being synchronized with the iron mold rollgang. By adopting the aforementioned device, the invention completely separates the casting piece with iron mold through ejecting pressure and vibrating force, and at the same time cleans up residual sands in the cavity of iron mold, which satisfies the production requirement of mass production.

Owner:浙江省机电设计研究院有限公司

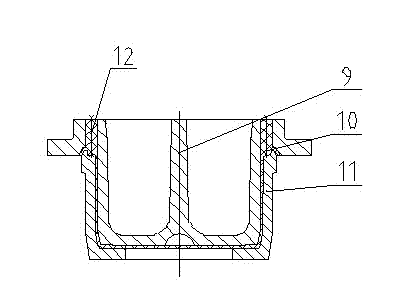

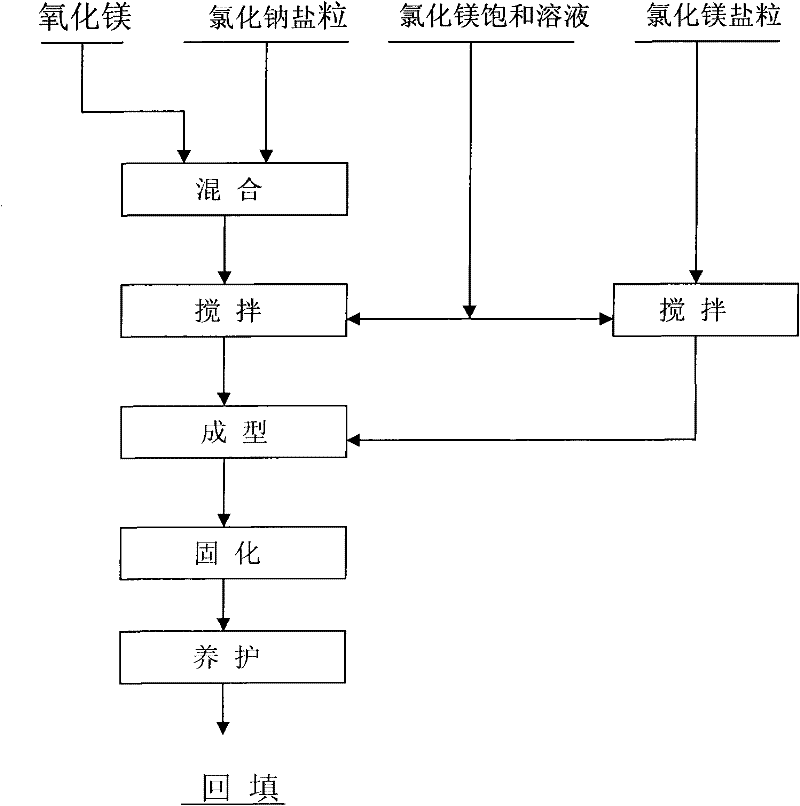

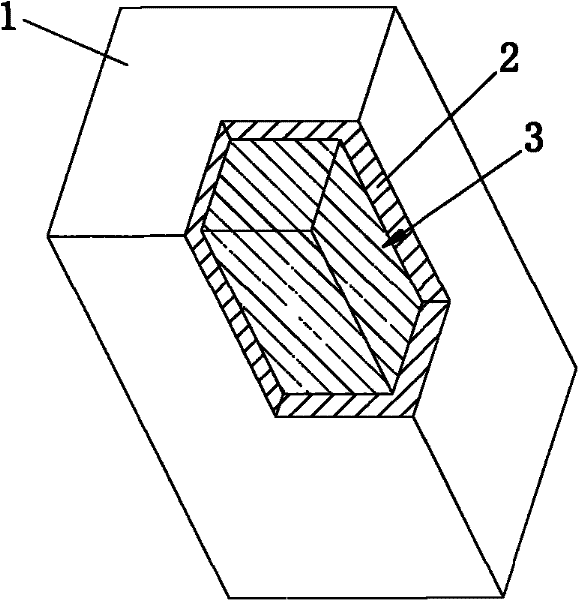

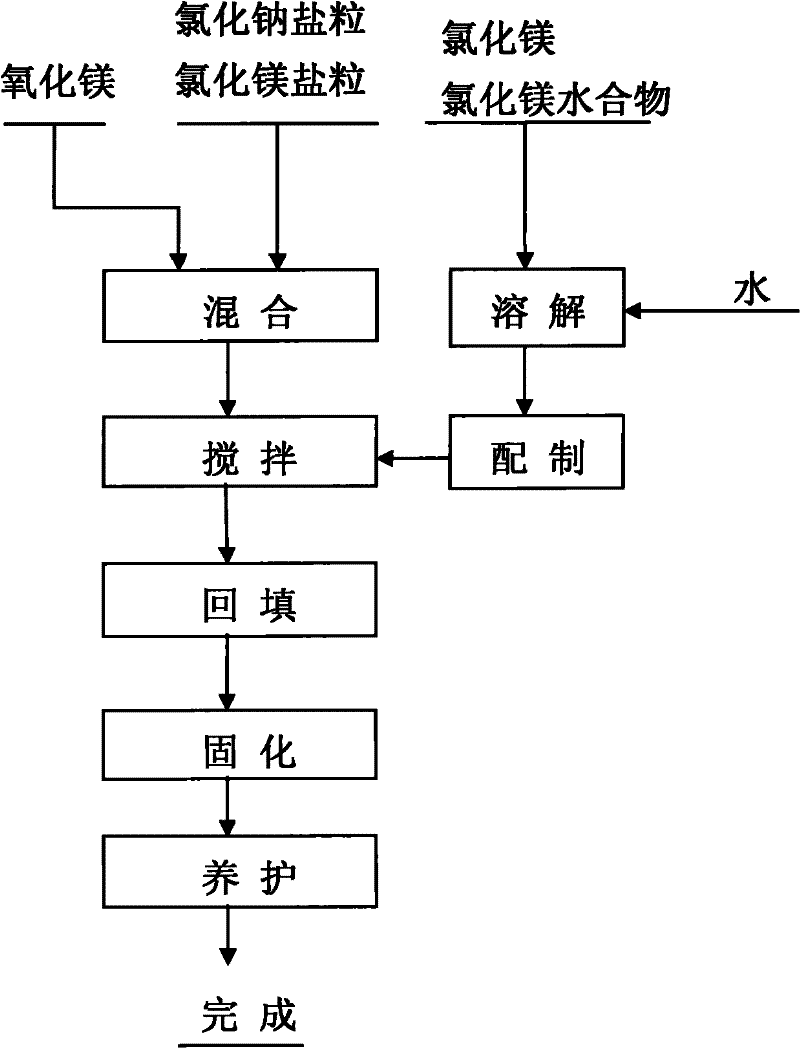

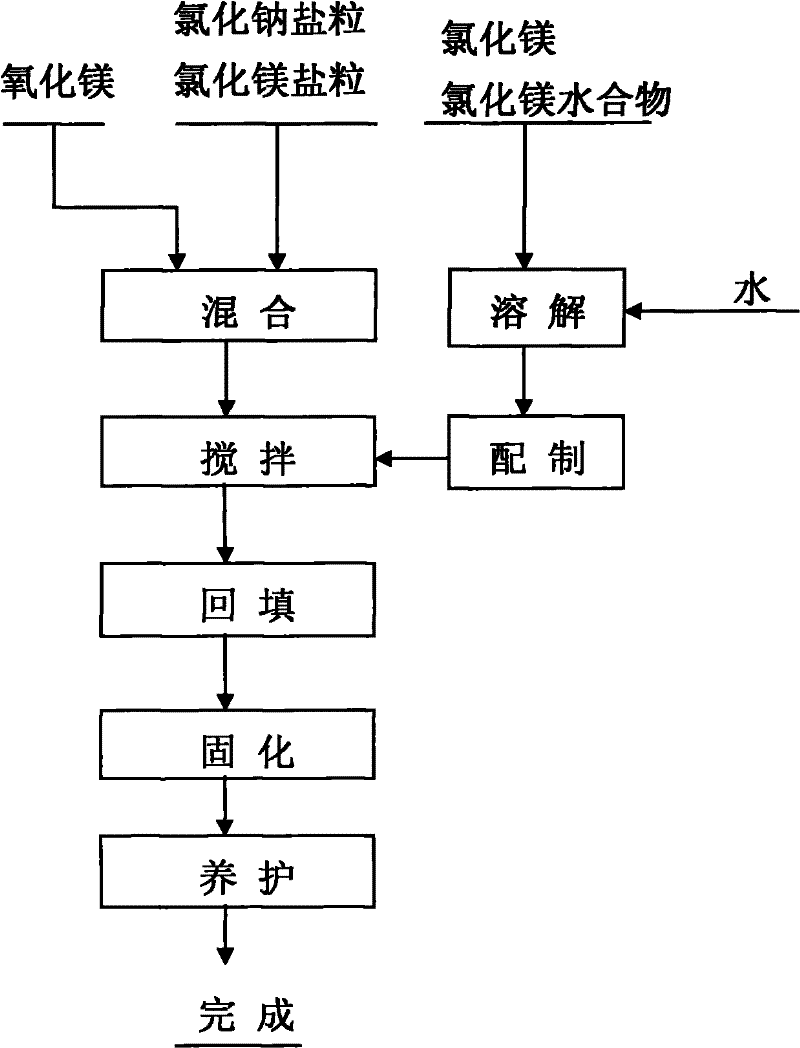

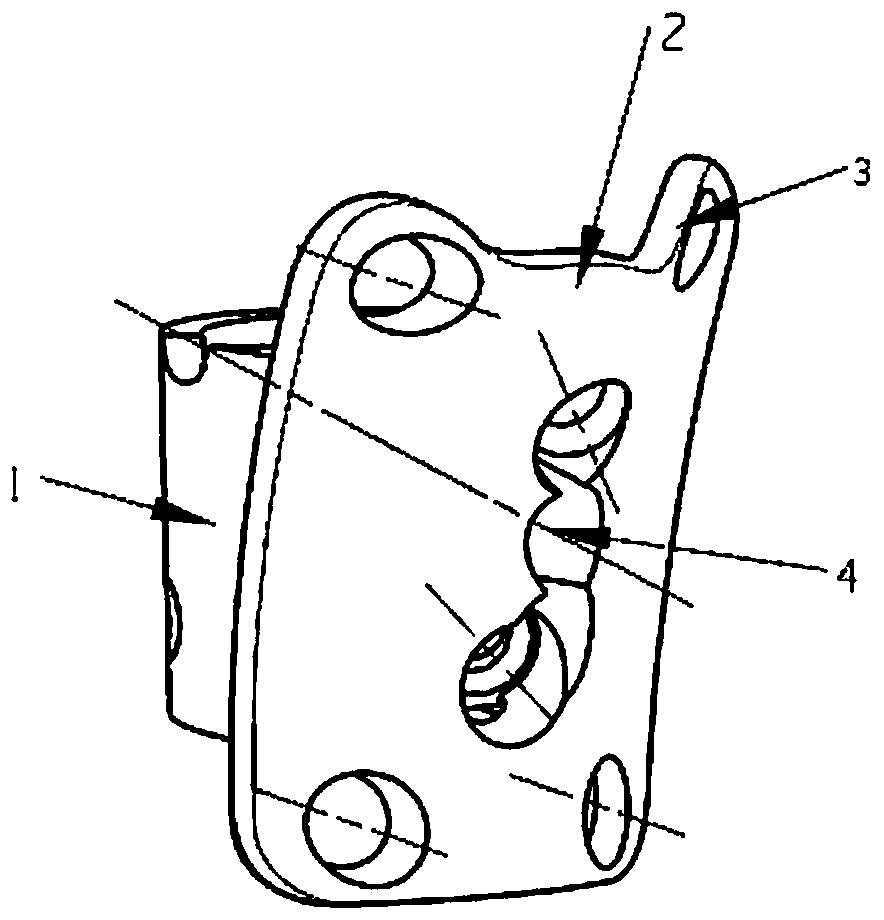

Coagulation salt block for sylvite solid mine backfilling and manufacturing method thereof

The invention relates to a sylvite solid mine backfilling technology, in particular to a manufacturing method of a coagulation salt for sylvite solid mine backfilling. The manufacturing method of the coagulation salt for the sylvite solid mine backfilling comprises the following steps of: mixing and uniformly stirring magnesium oxide, a magnesium chloride saturated solution and sodium chloride salt particles contained in tailings according to the mass ratio of 1.00:(0.80-1.20):(5.00-15.00) to form a first slurry; also mixing and uniformly stirring the magnesium chloride saturated solution and the sodium chloride salt particles according to the mass ratio of 1.00:(8.00-15.00) to form a second slurry; finally pouring the first slurry and the second slurry, carrying out press forming, and then solidifying for 12-24 hours; and conserving under the condition that environmental temperature and humidity is less than 70 percent to prepare a coagulation salt block, wherein the coagulation salt block structurally comprises an outer layer (1) and an inner core (3). The invention has simple manufacturing process, low cost and good social benefit and economic benefit, solves the problems of pollution and stack caused by the tailings on the vegetation of a surrounding environment and realizes the requirements for clean production and environmental protection.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

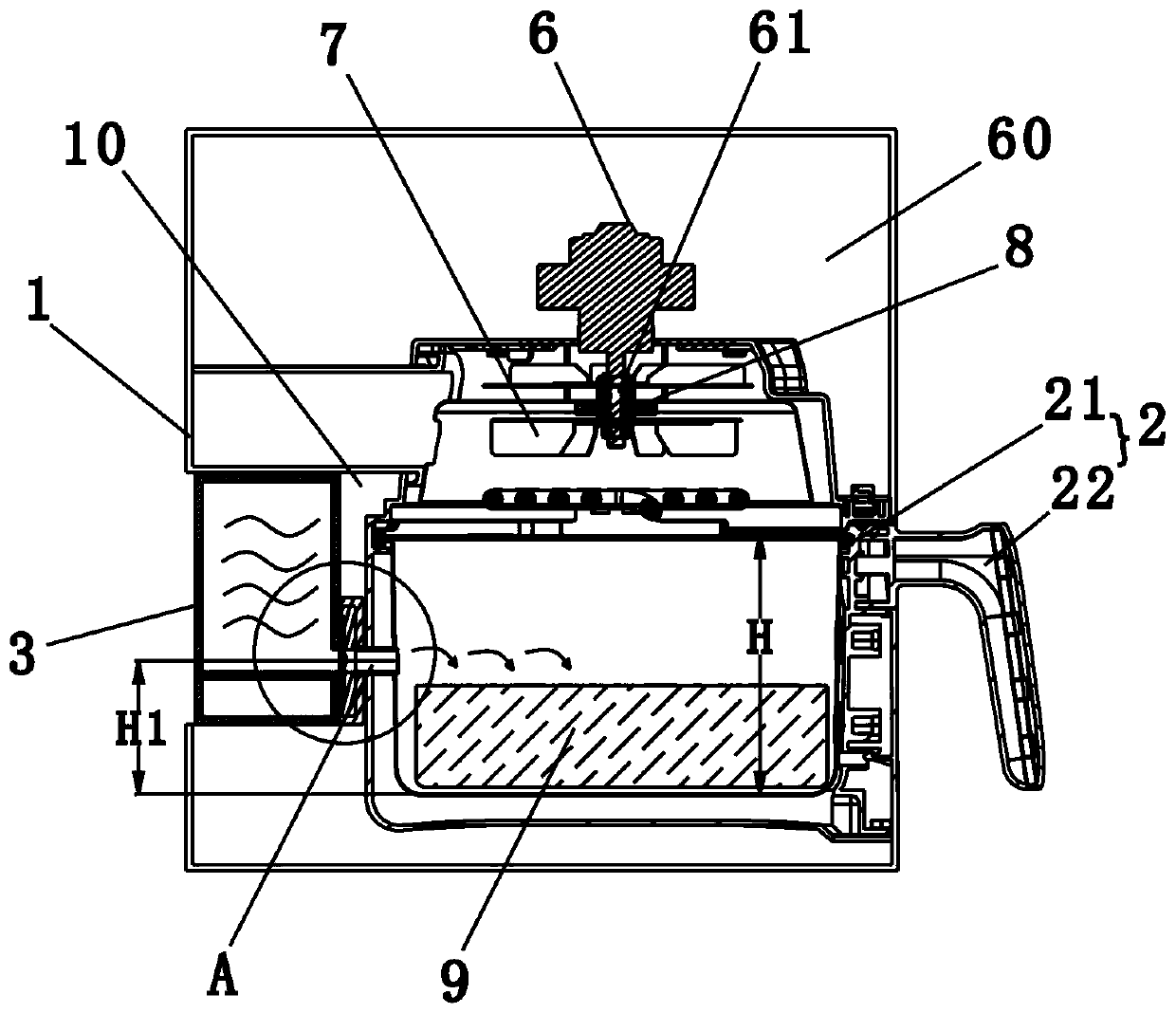

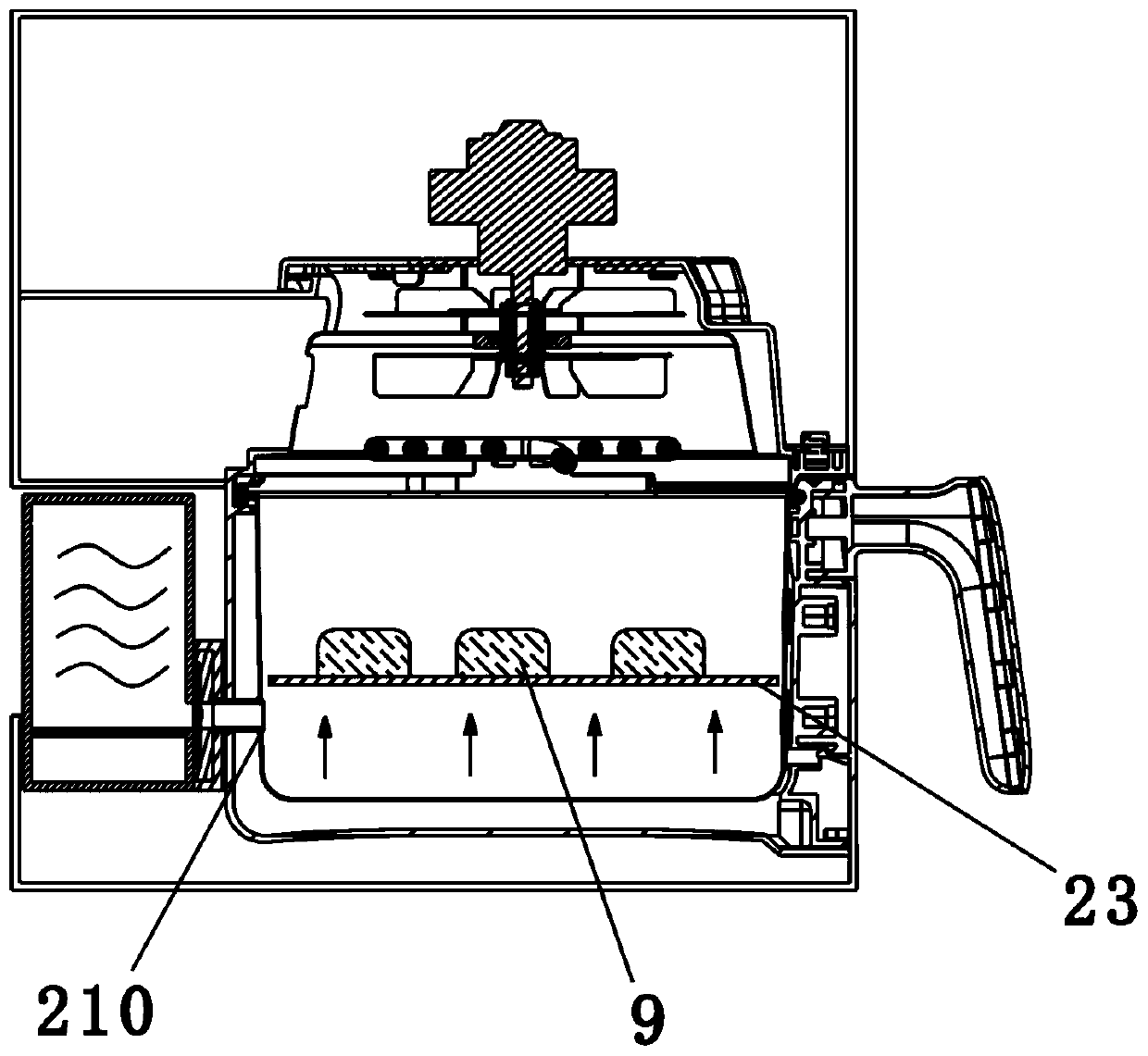

Food processor

InactiveCN110074685ASolve dry and hard problemsFulfill production requirementsSteam cooking vesselsRoasters/grillsEngineeringCooked food

The invention relates to a kitchen cooking appliance. The invention relates to a food processor. The food processor comprises a machine body and a fryer assembly installed in the machine body. The food processor is characterized in that a containing cavity with an opening is formed in the side wall of the machine body, the fryer assembly is detachably inserted into the containing cavity, the foodprocessor further comprises a water tank, the water tank is communicated with the fryer assembly through a communicating pipe, and a control device for controlling water in the water tank to enter thefryer assembly is arranged on the communicating pipe. When the food processor disclosed by the invention is used for heating steamed stuffed buns or steamed buns, water is fed into the fryer assemblythrough the control device, and water entering the fryer assembly is heated by circulating hot air to form steam, so that cooked wheaten food can be steamed, cooked food is softer and more delicious,the problem that food made by an existing air fryer is dry and hard is solved, and the requirements of different consumers for food making are met.

Owner:宁波市悦达电子科技有限公司

Coagulating salt for potassium salt solid mine backfilling and manufacturing method thereof

The invention relates to a coagulating salt for potassium salt solid mine backfilling and a manufacturing method thereof. The manufacturing method comprises the following steps: 1. preparing a magnesium chloride saturated solution; 2. evenly mixing 1.00 part by mass of magnesium oxide, 0.80-1.20 parts by mass of magnesium chloride saturated solution, 1.00-15.00 parts by mass of sodium chloride particle in tailings and 1.00-12.00 parts by mass of magnesium chloride particle in tailings to form a slurry; 3. casting the slurry, and curing to form; and 4. curing at ambient temperature under the humidity of lower than 70% for 6-12 hours to obtain the coagulating salt. By manufacturing the coagulating salt with a certain strength from magnesium oxide and a great deal of tailings containing sodium and magnesium salts, the invention has the advantages of simple manufacturing process, low cost and wide sources of magnesium oxide, can maximally backfill the tailings into the mine, meets the requirement of safety in production, and solves the problem of pollution of tailings for the vegetation in the ambient environment as well as the problem of stacking of the tailings, thereby having favorable social benefit and economic benefit.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Pre-molten type square billet crystallizer casting powder and preparation method thereof

The invention discloses a pre-molten type square billet crystallizer casting powder and a preparation method thereof. The pre-molten type square billet crystallizer casting powder is composed of the raw materials, by weight percentage, 60-80% of premelting agent, 4-14% of wollastonite, 2-5% of fluorite, 3-8% of sodium carbonate, 4-8% of carbonaceous materials, 0-3% of bentonite, 2% of dextrin, 0-8% of quartz and 0-3% of lithium carbonate, wherein the premelting agent is composed of 60-70% of red mud, 6-24% of quartz, 4-12% of calcite, 2-4% of clay and 2-8% of barium sulfate. The preparation method comprises adding the raw materials into water for uniform mixing; performing ball milling; performing atomizing, drying and prilling after ball milling to obtain the pre-molten type square billet crystallizer casting powder. According to the pre-molten type square billet crystallizer casting powder and the preparation method thereof, the red mud is applied to the crystallizer casting powder and reaches an adding quantity up to 50%, so that a breakthrough on the application quantity of recycled waste red mud can be achieved; meanwhile, the square billet casting powder prepared through the premelting agent is uniform in component, stable in melting performance and relatively low in cost.

Owner:郑州市裕丰耐火材料有限公司

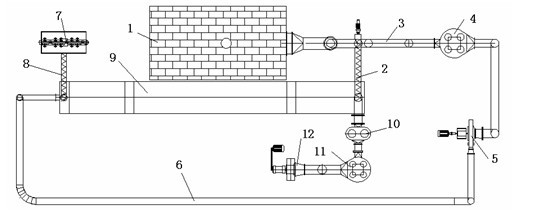

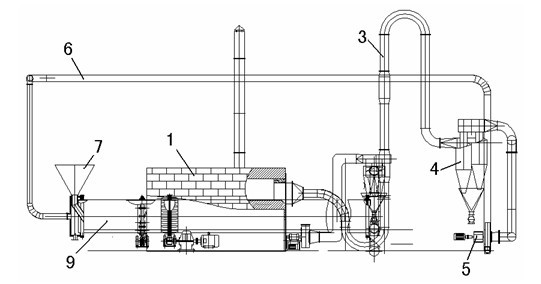

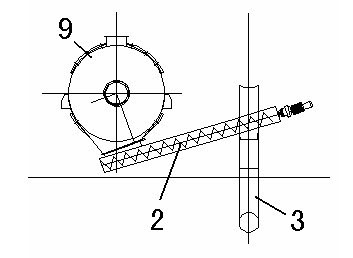

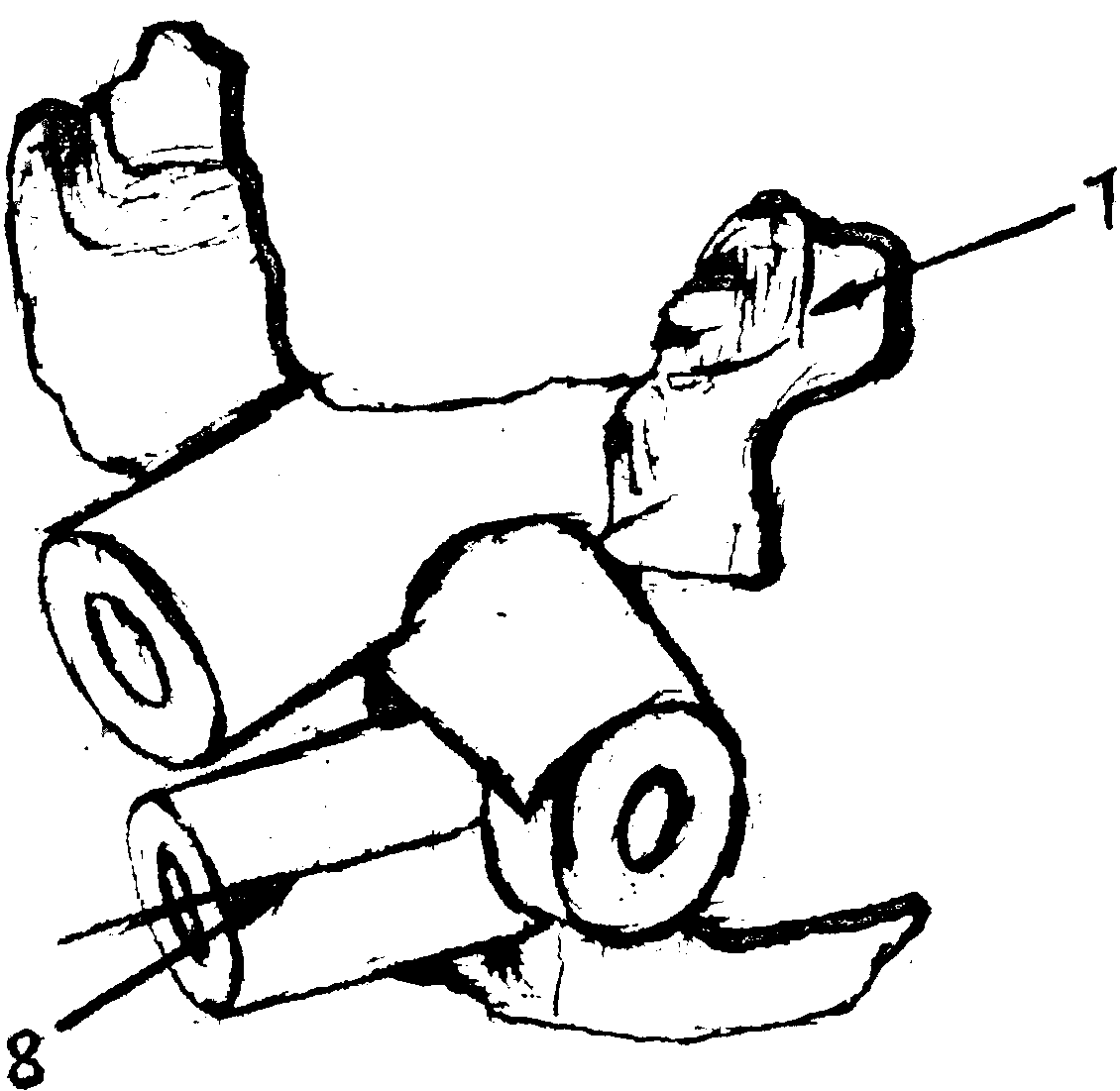

Rotary drum and airflow mixed flow drying device for oil-tea fruit shell wastes

InactiveCN102322733AAchieve sustainable useEmission reductionDrying machine combinationsCycloneCamellia oleifera

The invention discloses a rotary drum and airflow mixed flow drying device for oil-tea fruit shell wastes. An air outlet of a primary rotary drum dryer is connected with a bigeminal cyclone dust collector, and the primary rotary drum dryer, the bigeminal cyclone dust collector, a quadrigeminal cyclone dust collector and a primary drying ventilator form a primary drying ventilation dust removal passage; a feed port of the primary rotary drum dryer is vertically connected with a primary drying feeder; the primary drying feeder is connected with a breaking device; a discharge port of the primary rotary drum dryer is connected with a secondary drying feeder; and the secondary drying feeder is connected with a secondary airflow dryer. The rotary drum and airflow mixed flow drying device has the advantages that: waste oil-tea fruit shells which are subjected to active ingredient extraction are dried by adopting rotary drum and airflow mixed flow to ensure that the water ratio of the waste oil-tea fruit shells is less than 18 percent and meets the requirement on oil-tea fruit shell granular fuel production.

Owner:NANCHANG HANGKONG UNIVERSITY

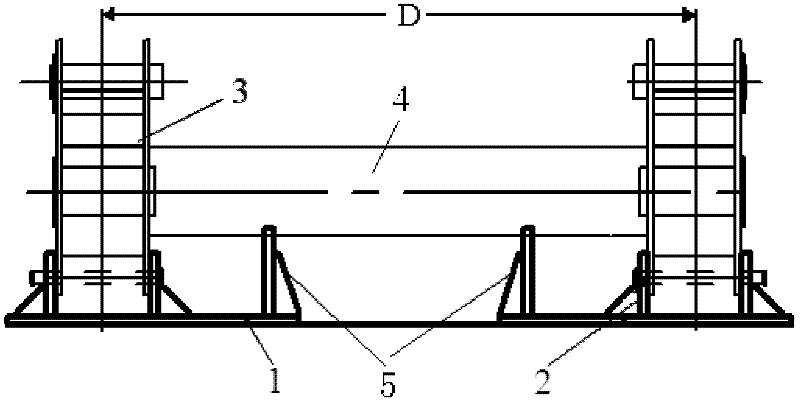

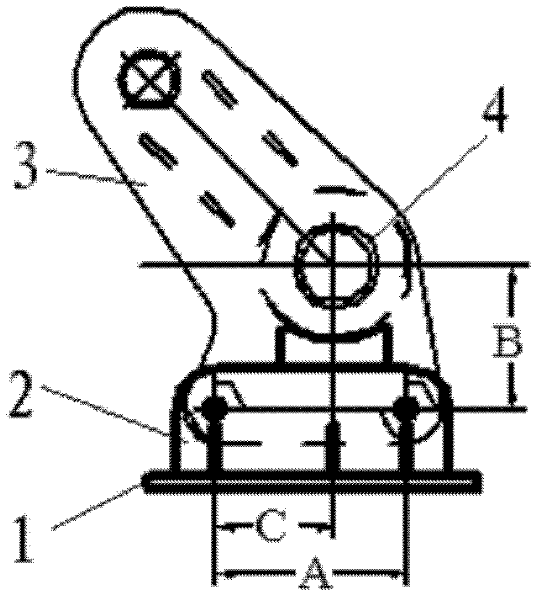

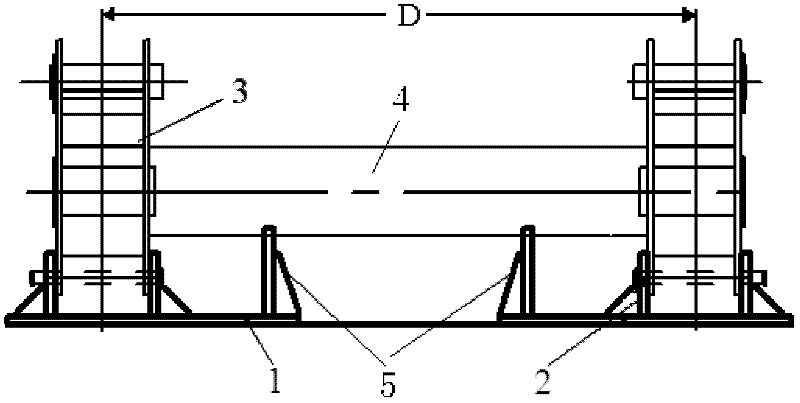

Processing method of large beam member with connecting seat

InactiveCN102284798AFulfill production requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAxis distance

The invention discloses a method for processing a large beam member with connecting seats, which comprises the following steps of: firstly, determining the axis distance A between two tool sleeves on a tool support on each side, the height B between a central line of a beam body and the centers of lug holes of the connecting seats, the horizontal positioning size C of the central line of the beambody, and the size D of an opening between two connecting seats according to the product sizes of the beam body and the connecting seats; secondly, arranging two tool supports on a combined platform according to size data determined in the previous step, arranging the tool sleeves and support frames, hinging the two tool sleeves of the tool support on each side with two lugs of one connecting seat, and arranging the beam body on the two support frames; and finally, assembling and welding the beam body and the connecting seats to finish the processing of the large beam member with the connecting seats. By the method, the problems that the connecting seats of the large beam member with the connecting seats have a long hole distance, are needed to be coaxial, and are difficultly processed bygeneral equipment are solved.

Owner:BAOJI PETROLEUM MASCH CO LTD

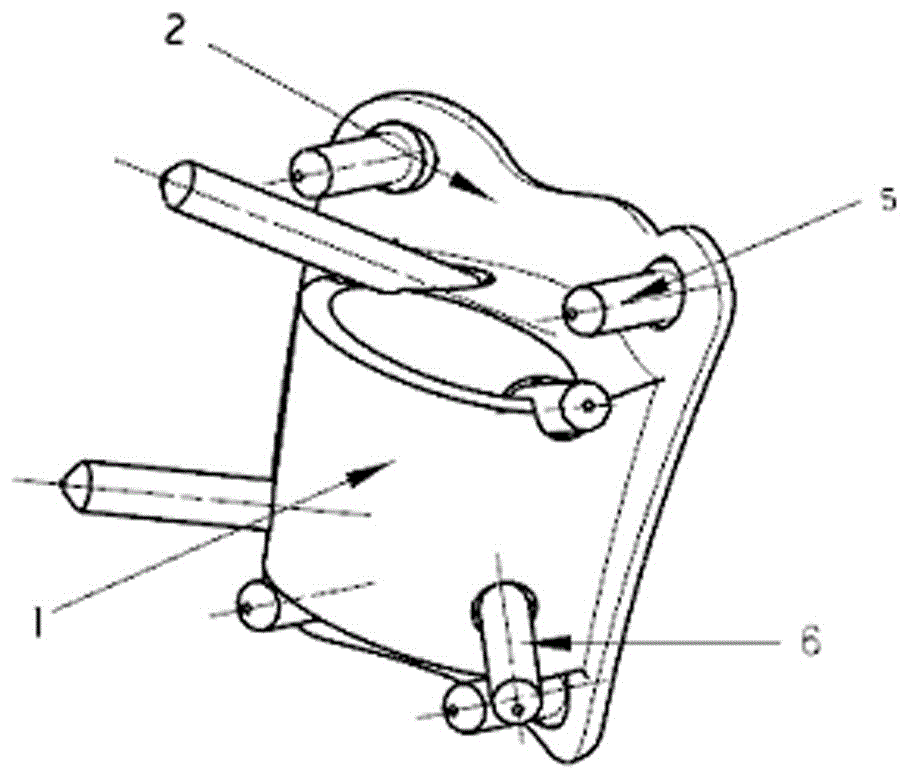

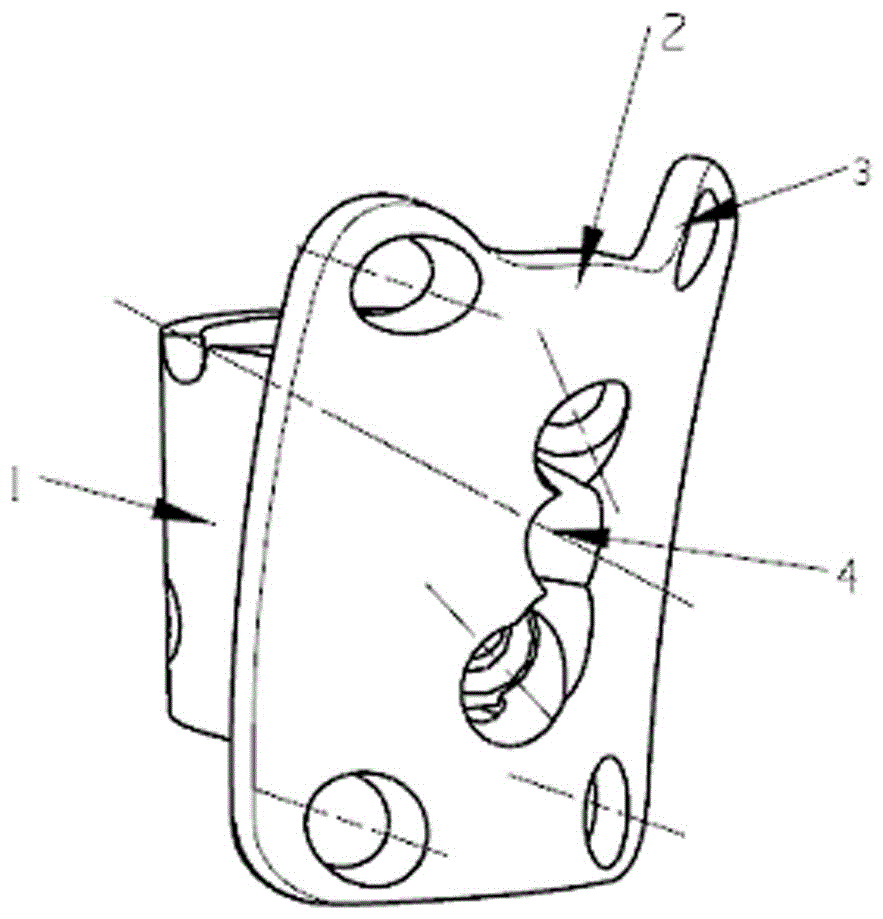

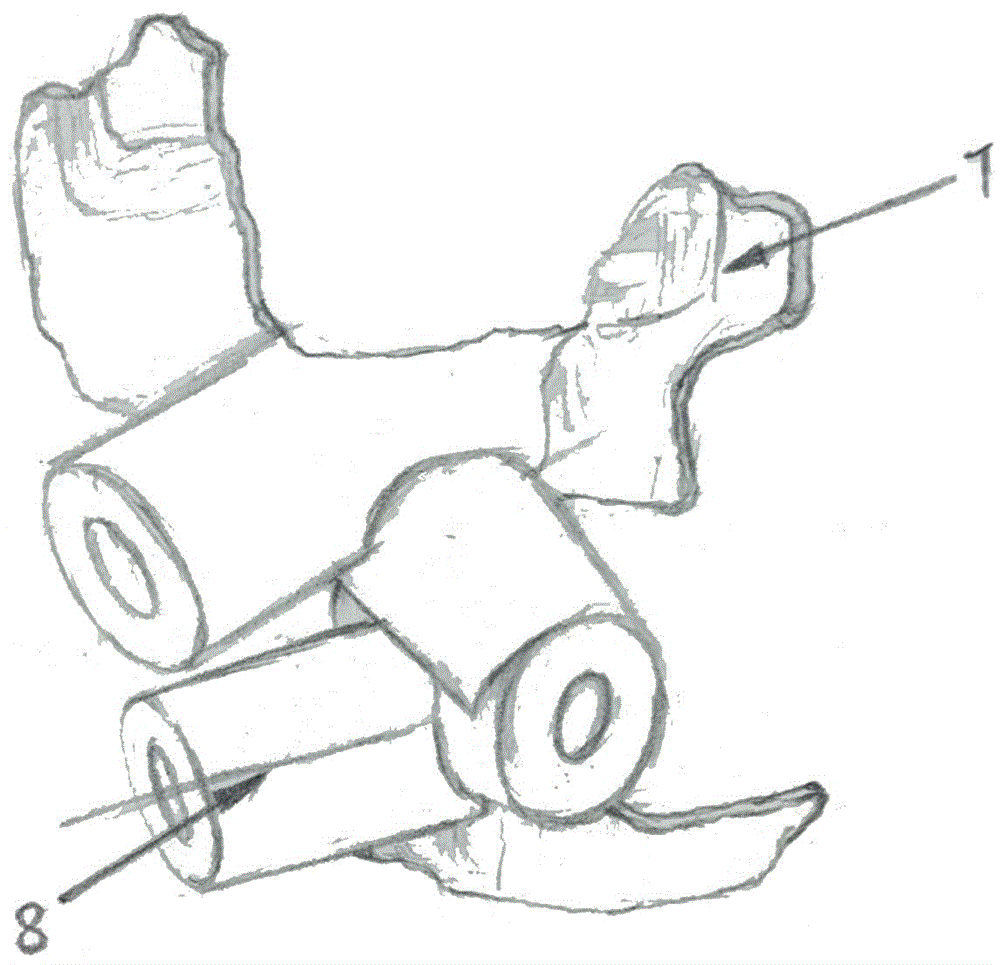

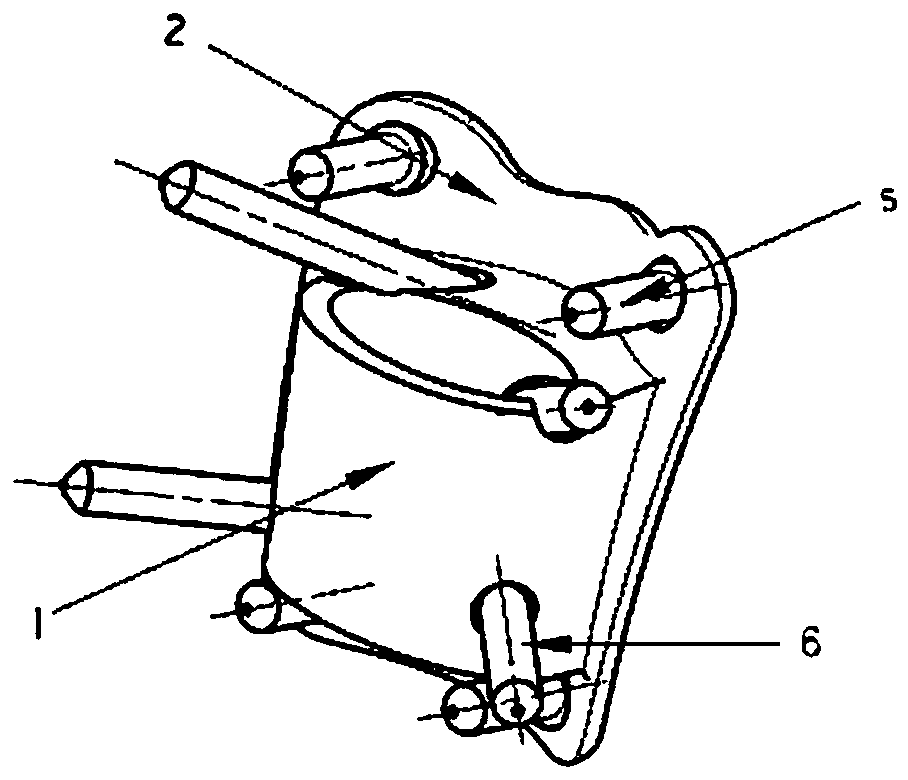

Artificial vertebra by anterior pedicle screw fixation and positioning assembly tool

ActiveCN106236333AFulfill production requirementsPrevent subsidenceAdditive manufacturing apparatusSpinal implantsVertebraPedicle screw fixation

The invention provides an artificial vertebra by anterior pedicle screw fixation and a positioning assembly tool. The artificial vertebra is characterized in that a pedicle screw fixing hole is formed in the artificial vertebra, and the screw is accurately guided to fix the artificial vertebra on two bilateral vertebral pedicles to realize firm self-stabilization. According to the artificial vertebra, a steel plate can be integrated into the artificial vertebra according to requirements, upper and lower ends of the steel plate exceed the length of the artificial vertebra, or only the upper end of the steel plate is longer than the artificial vertebra; the long end of the steel plate is provided with a screw hole coaxial with the vertebral pedicle and a screw hole oriented to the pedicle; a drill positioning guide plate and an osteotomy guide plate are simultaneously provided to ensure that an anterior pedicle screw can be safely and accurately implanted; and the artificial vertebra as well as the drill, osteotomy guide plate and other assembly tools thereof are designed and printed by utilizing a 3D printing technology based on medical imaging data. By adopting the artificial vertebra, the fixing strength of anterior spine stability can be maximized safely and quickly.

Owner:董谢平

Wear-resistant and aging-resistant polyurethane resin and preparation method thereof

ActiveCN112111045ARealize continuous productionMeet production requirementsPolymer sciencePtru catalyst

The invention discloses a wear-resistant and aging-resistant polyurethane resin, wherein the polyurethane resin is prepared from the following raw materials in parts by weight: 10 to 15 parts of polyadipic acid 1,6-hexanediol ester glycol, 12 to 18 parts of polycarbonate diol, 3 to 5 parts of 1,6-hexanediol, 2 to 4 parts of trimethylolpropane, 8 to 10 parts of hexamethylene diisocyanate, 0.35 to 0.55 part of an antioxidant, 0.15 to 0.25 part of an organic bismuth catalyst, 0.5 to 0.8 part of isophorone diamine, 0.15 to 0.25 part of KH-560, and 45 to 75 parts of a solvent. The wear-resistant and aging-resistant polyurethane resin disclosed by the invention has the advantages of good wear resistance, high anti-aging yellowing grade, good anti-aging performance, good hydrolysis resistance andthe like. The wear-resistant and aging-resistant polyurethane resin can be directly coated on a textile fabric or a non-woven fabric to form a film, and the film has the advantages of good wear resistance, high anti-aging yellowing grade, good anti-aging performance, good wear resistance and the like; the textile fabric or non-woven fabric finished product coated with the coating also has good wear resistance, high anti-aging yellowing grade, good anti-aging performance, good hydrolysis resistance and the like.

Owner:JIAXING HEXIN CHEM IND

Ta metallurgical by-product composite salt recycling method

The invention discloses a Ta metallurgical by-product composite salt recycling method. The method comprises the following steps: (1) after separating by-product composite salt produced during the Ta metallurgical process from Ta powder, the composite salt is rinsed with deionized water to remove the residue Na, and then the rinsed composite salt is crushed by a crusher and dried to obtain the treated composite salt; and (2) the treated composite salt is used as diluent, and is mixed with potassium fluotantalate based on certain proportion according to the process requirements and the mixture is taken to a furnace, and the Na is inlet for metallurgy process restoration to obtain the Ta powder. The by-product composite salt produced during the Ta metallurgical production process is used to produce the metallurgical-level Ta powder as the diluent, so that the recycling of the by-product composite salt is realized, the environmental problem caused by the by-product composite salt is avoided, and at the same time, cost is greatly saved. The method also has the advantages that the reuse of waste resources is realized, environmental pollution is reduced, direct yield of the Ta powder is effectively improved, and the Ta powder prepared according the recycling method meets the industry standard of metallurgical Ta powder.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

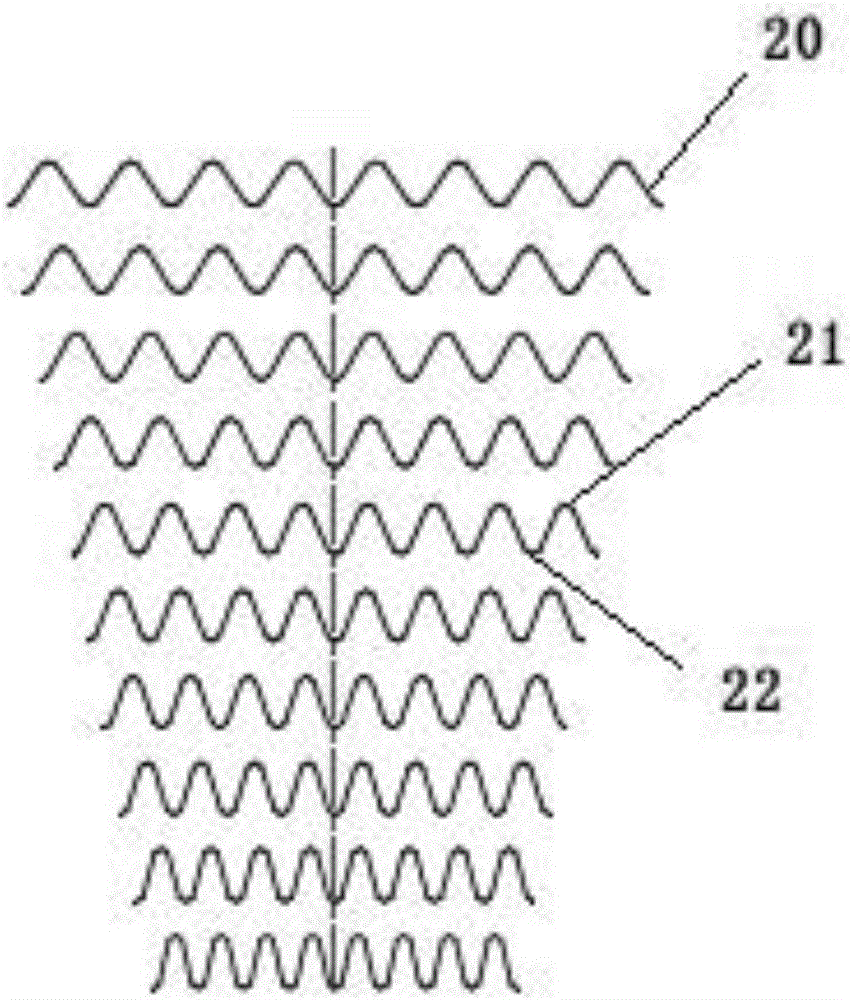

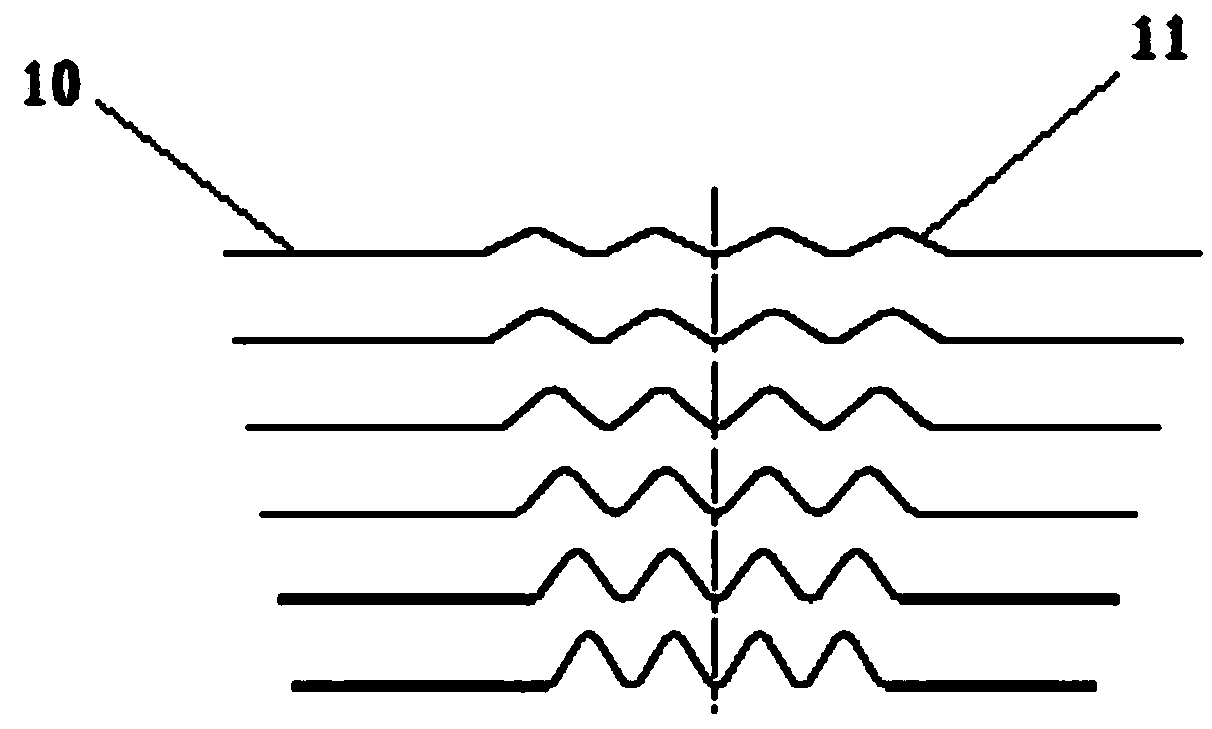

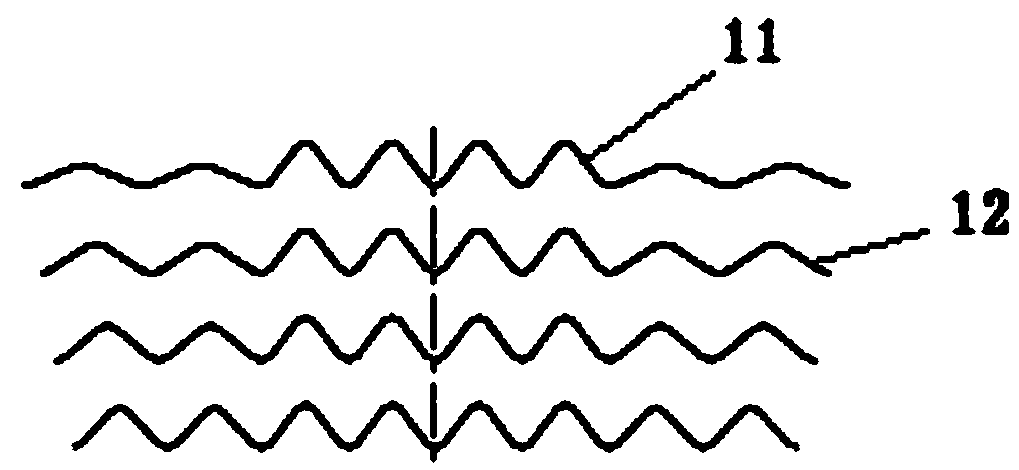

Method for manufacturing fin and flat tube assembly for heat exchanger

ActiveCN106345871AFulfill production requirementsIncrease productivityHeat exchange apparatusEngineeringUltimate tensile strength

The invention provides a method for manufacturing fin and flat tube assembly for heat exchanger, comprising the steps of step 1: taking a metal substrate and straightening, rolling the middle part of the metal substrate and forming the paired first wave-like protrusions; step 2: rolling the parts between the both ends of the metal substrate and the first wave-like protrusions, respectively, and forming the paired second wave-like protrusions;step 3: rolling the first wave-like protrusions and the second wave-like protrusions so that the wave pitch and the amplitude of the first wave-like protrusions and the second wave-like protrusions coincide with each other to form a wave-like fin; step 4: rolling each of the crest portion and trough portion of the wave-like fins and shaping the crest portion and the trough portion into a rectangle with rounded corners;and step 5: rolling each of the crest portion and trough portion so that the crests and troughs are inwardly formed. The invention further provides a method for manufacturing the flat tube. When the technical solution is applied, the requirements of having sufficient strength, free of welding and better welding of the flat tube assembly are met.

Owner:SDAAC AUTOMOTIVE AIR CONDITIONING SYST CO LTD SHANGHAI

Preparation formula and process of cubic silicon carbide oil stone

PendingCN107473747AAvoid breakingImprove the finishGrinding/polishing hand toolsCeramicwarePorositySurface finish

The invention discloses a preparation formula and process of a cubic silicon carbide oil stone. The cubic silicon carbide oil stone comprises the following raw materials by weight: 95-100 parts of cubic silicon carbide, 20-35 parts of potassium feldspar, 9-11 parts of refined naphthalene, 6-7 parts of talcum powder, 3-5 parts of dextrin, 23-28 parts of syrup, 5-8 parts of boron glass, and 13-15 parts of kaolin. With the formula and method, the cubic silicon carbide oil stone can have high cutting rate, good grinding effect, excellent plasticity and uniform hardness, and meets the production requirements, especially by using boron glass as the sintering aid, the sintering temperature is significantly lowered, thus realizing low temperature firing. The adopted kaolin improves the plasticity, and the oil stone is not broken off easily. The used talcum powder improves the lubricating effect, and the ground surface has better smoothness. Use of refined naphthalene as the pore-forming agent realizes control of the porosity. The product prepared by the reasonable process and preparation parameters has good color and is free of crack, foaming, inclusion or other defects, has controllable porosity, strong chip holding capacity, and good heat dissipation, and meets the fine finishing requirements.

Owner:扬中市远东轴承专用油石厂

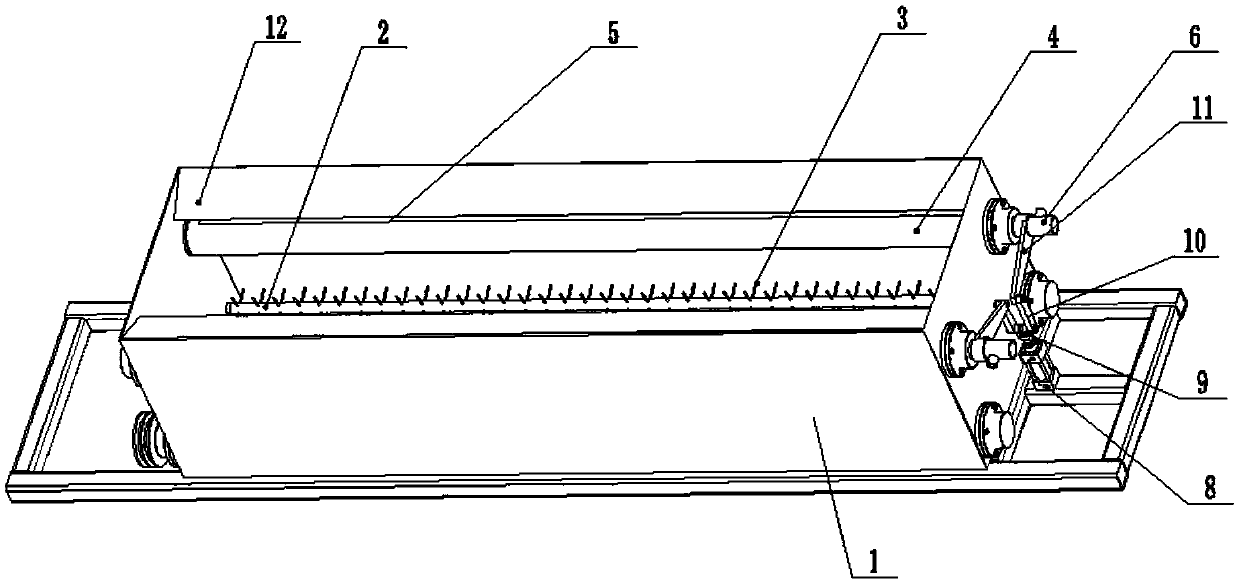

Spraying particle mechanism

ActiveCN109530171AUniform densityProduct quality controllableLiquid surface applicatorsSpraying apparatusEngineeringVolumetric Mass Density

The invention discloses a spraying particle mechanism. The mechanism comprises a box body with an opening at the upper end, a rotating rod capable of rotating is arranged at the bottom in the box body, protrusions are arranged on the surface of the rotating rod, a feeding pipe capable of rotating relative to the rotating rod is arranged in the box body and above the rotating rod, an opening is formed in the wall of the feeding pipe, a hole plate is arranged at the tail end of the feeding pipe, the other end is communicated with the material conveying pipe, the rotating rod drives the protrusions to rotate, particles which are in contact with the protrusions are scattered, and the scattered particles are sprayed on the gum dipping gloves located in the box body. According to the mechanism,the spraying requirements of the impregnated glove on certain density particles are met, the particle spraying density is uniform and attractive, the rotating speed of the rotating rod and the numberof particles are adjusted, the intensity and the density of the sprayed particles are controlled, the product quality is controllable, and the particles with different sizes and densities can be sprayed by adjusting the distance between the adjacent protrusions.

Owner:SHANDONG XINGYU GLOVES

A method of manufacturing a fin and flat tube assembly for a heat exchanger

ActiveCN106345871BFulfill production requirementsIncrease productivityHeat exchange apparatusUltimate tensile strengthMetallic substrate

Owner:SDAAC AUTOMOTIVE AIR CONDITIONING SYST CO LTD SHANGHAI

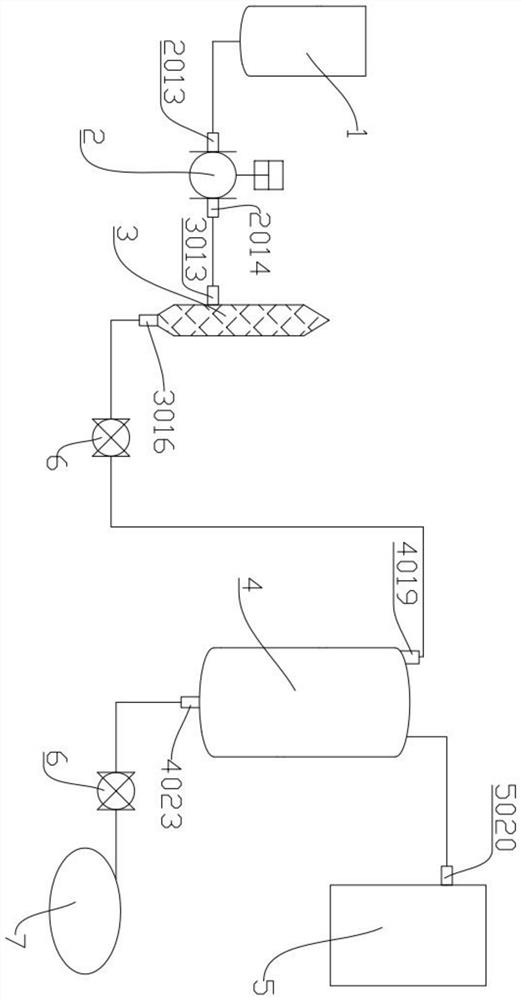

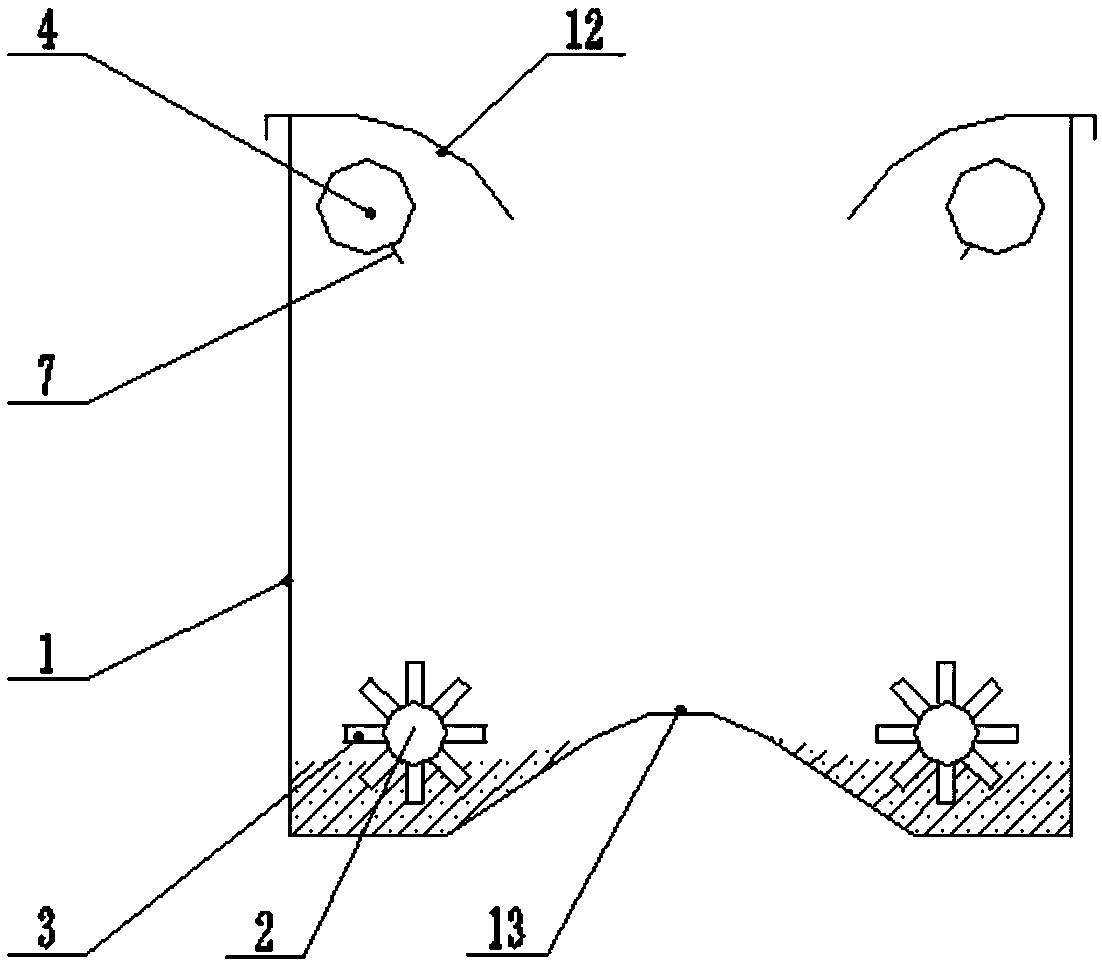

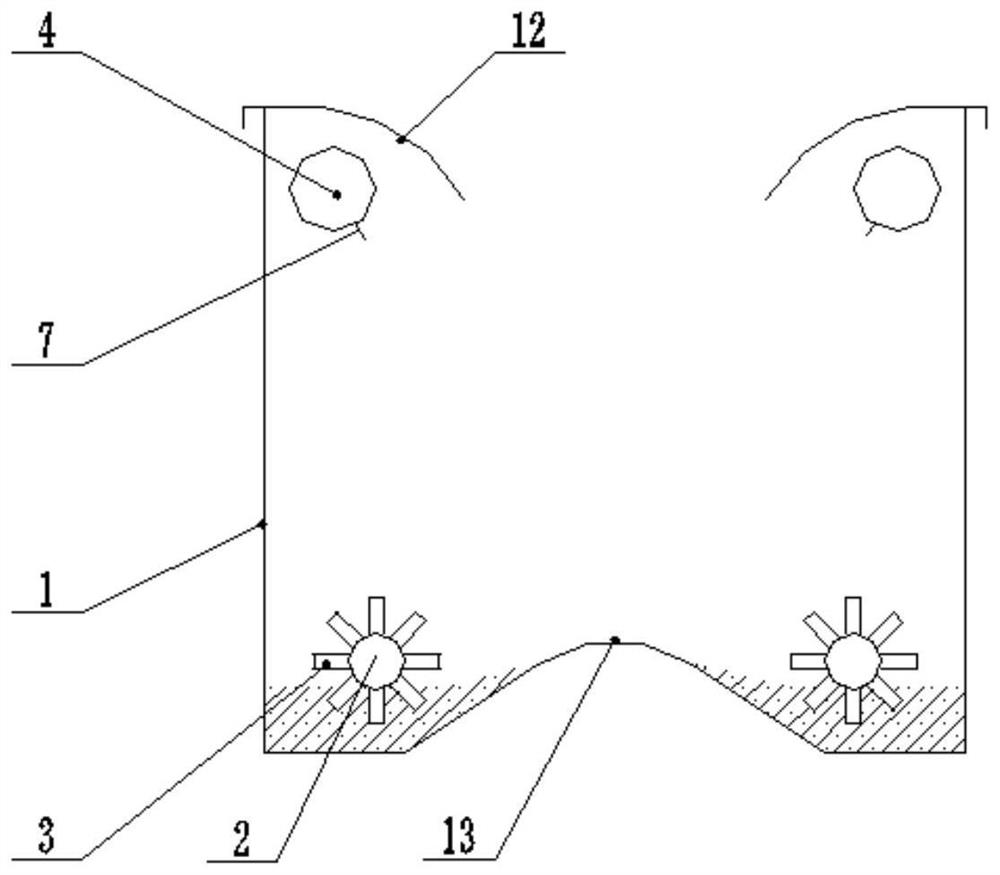

Ordinary-pressure vertical cyclone solid-liquid separation method and equipment

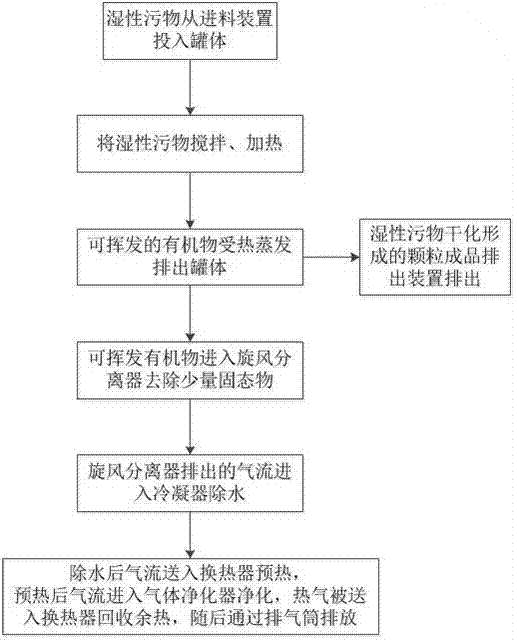

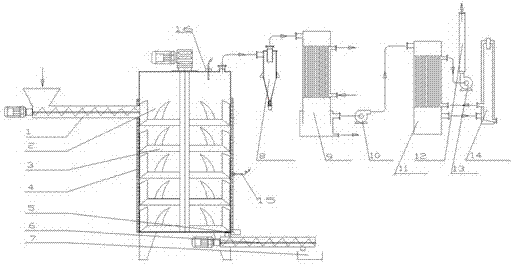

InactiveCN107572749ASimplified applicable conditionsAccelerates drying and granulationSludge treatment by de-watering/drying/thickeningDispersed particle separationElectric heatingEngineering

The invention discloses an ordinary-pressure vertical cyclone solid-liquid separation method and equipment. The method comprises the following steps: feeding wet materials into a vertical tank body (2) by virtue of a feeding device (1); and stirring the wet materials by virtue of a compound stirring device (3), heating the wet materials by virtue of a heating device (4) of the tank body (2) to evaporate moisture to dry the wet materials to form particles, evaporating the moisture and volatile organic maters in the wet materials through heating and discharging from the top of the tank body (2),and discharging the particles formed after the wet materials are dried from the bottom of the tank body (2). According to the method and the equipment, the space volume is well utilized, the occupiedarea of the equipment is reduced, and the efficiency is relatively high; by utilizing an electric heating manner, the temperature increase speed is high, the pollution is avoided, and the use is convenient; and furthermore, matched facilities such as a steam boiler are not used, so that an equipment system is simplified.

Owner:WUHAN JILONG FILTRATION TECH

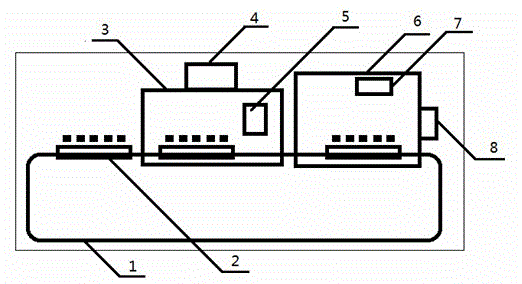

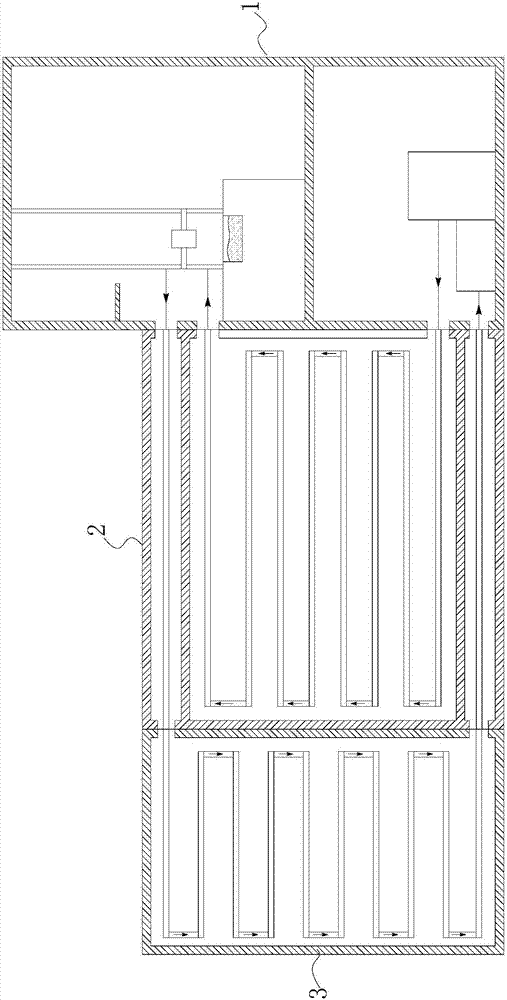

A spray coater of an electric control system

InactiveCN104549908AImprove painted surface qualitySave human effortLiquid surface applicatorsCoatingsControl systemElectrical control

The invention relates to a spray coater of an electric control system. The spray coater comprises a conveyor belt, a plurality of object carrying plates, a paint spraying chamber, a brushing supplement device, a sewerage system of the paint spraying chamber, an air supplying system, the electric control system and a drying chamber. The object carrying plates are fixed on the conveyor belt through screw devices. The conveyor belt is installed on a guide rail on the ground in the front of the paint spraying chamber. The sewerage system of the paint spraying chamber is installed at the outside of the middle of the paint spraying chamber. The brushing supplement device is installed at the tail end of the pain spraying chamber. The drying chamber is connected to the paint spraying chamber. The air supplying system is disposed in the drying chamber. The electric control system is installed at the outside of the drying chamber. The spray coater is simple in structure, economical and practical, provides a coating device with a simple structure, improves paint coating quality of components and largely increases the working efficiency.

Owner:HEILONGJIANG KANGGEER TECH

A mechanism for spraying particles

ActiveCN109530171BSpray evenlySpray to achieveLiquid surface applicatorsSpraying apparatusMechanical engineeringPhysics

The invention discloses a spraying particle mechanism. The mechanism comprises a box body with an opening at the upper end, a rotating rod capable of rotating is arranged at the bottom in the box body, protrusions are arranged on the surface of the rotating rod, a feeding pipe capable of rotating relative to the rotating rod is arranged in the box body and above the rotating rod, an opening is formed in the wall of the feeding pipe, a hole plate is arranged at the tail end of the feeding pipe, the other end is communicated with the material conveying pipe, the rotating rod drives the protrusions to rotate, particles which are in contact with the protrusions are scattered, and the scattered particles are sprayed on the gum dipping gloves located in the box body. According to the mechanism,the spraying requirements of the impregnated glove on certain density particles are met, the particle spraying density is uniform and attractive, the rotating speed of the rotating rod and the numberof particles are adjusted, the intensity and the density of the sprayed particles are controlled, the product quality is controllable, and the particles with different sizes and densities can be sprayed by adjusting the distance between the adjacent protrusions.

Owner:SHANDONG XINGYU GLOVES

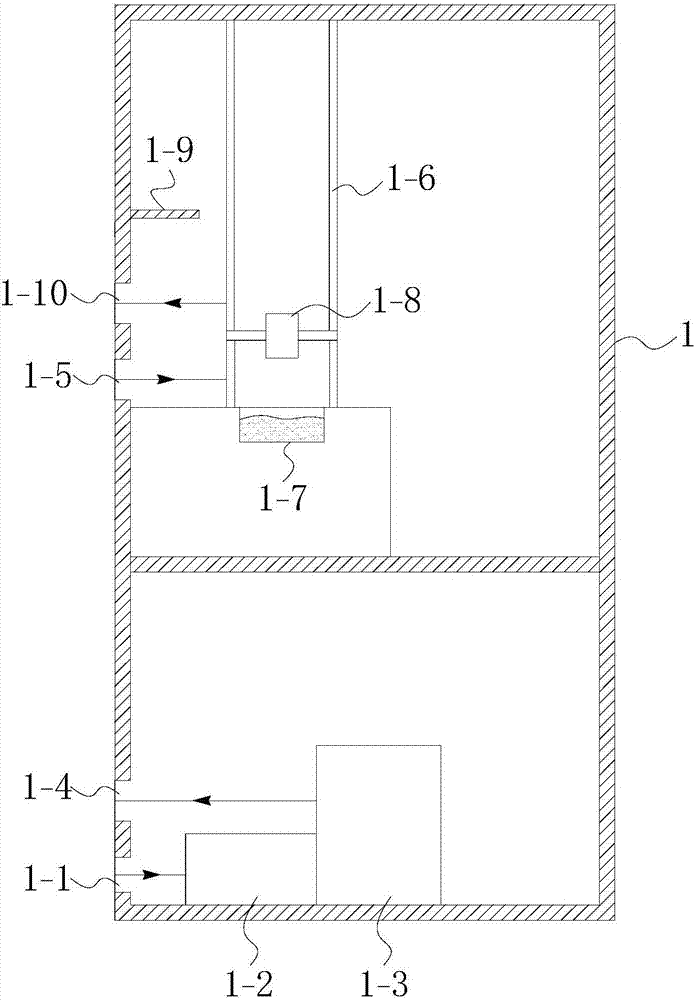

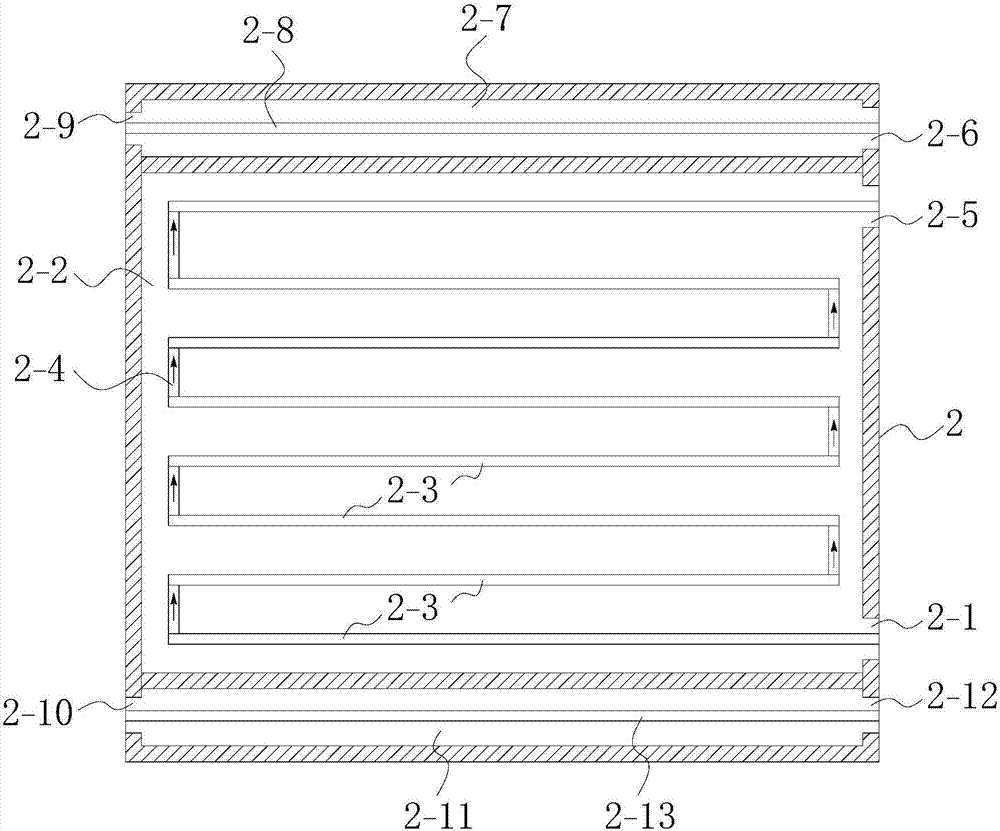

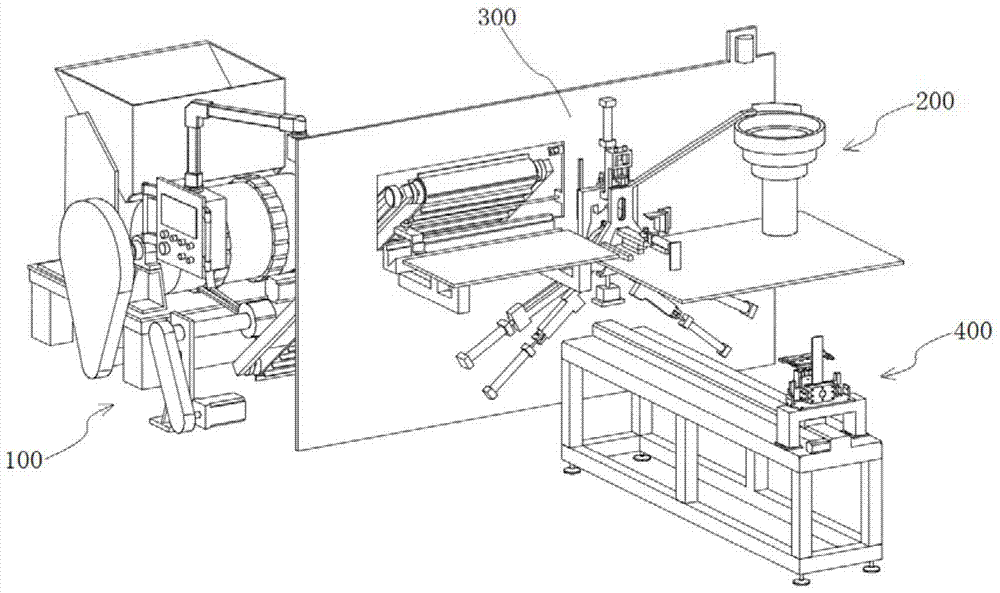

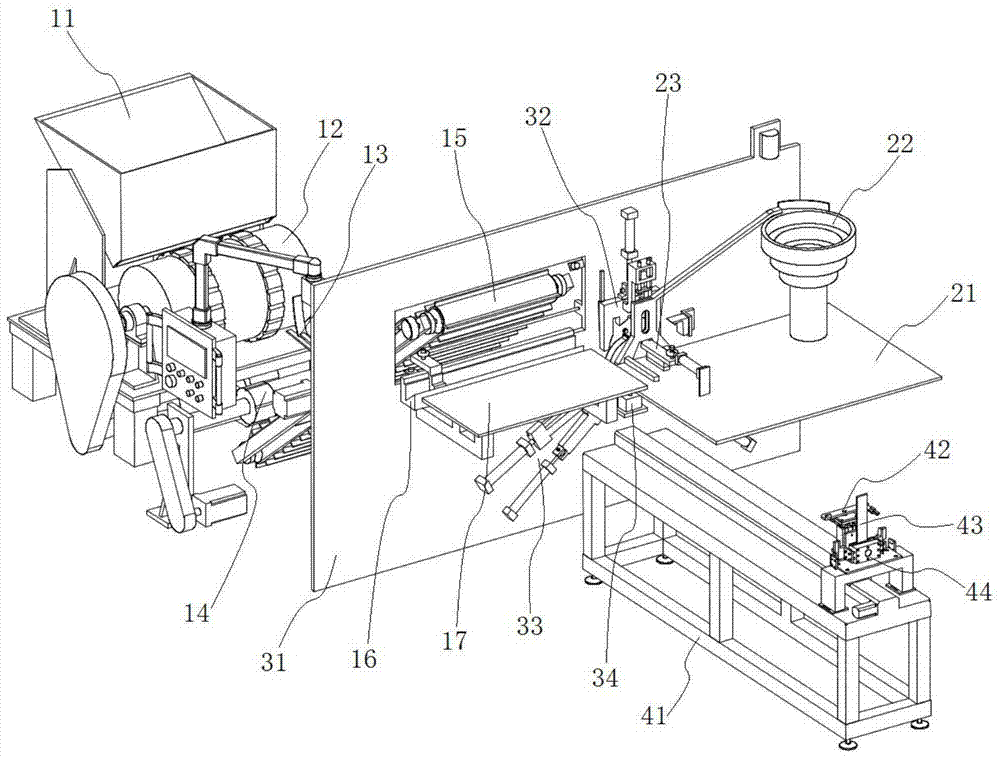

A production line for hard hollow capsules using thermogel performance materials

The invention discloses a manufacturing production line for a hard hollow capsule adopting a thermal gel performance material. The manufacturing production line comprises a dipping glue mold unloading part, a preheating part and a drying part, wherein the dipping glue mold unloading part, the preheating part and the drying part are independent of one another; the dipping glue mold unloading part has a structure with an upper layer and a lower layer, the upper layer is a dipping glue molding part, and the lower layer is a mold unloading oil brushing part; the preheating part has a structure with an upper layer, a middle layer and a lower layer, the upper layer is a thermal buffering passage, the middle layer is a mold body preheating chamber, and the lower layer is a cooling passage; and a drying inlet is formed above the front end of the drying part, and a drying outlet is formed below the front end of the drying part. The manufacturing production line for the hard hollow capsule adopting the thermal gel performance material adopts a production mode of a hot mold normal temperature preparation solution, and is particularly applicable to the production of a hard hollow capsule adopting a thermosetting material, the stability and uniformity of a product are effectively controlled, the utilization ratio of raw materials and the production efficiency are greatly improved, and the rapid development of the hard hollow capsule is promoted.

Owner:浙江睿码科技有限公司

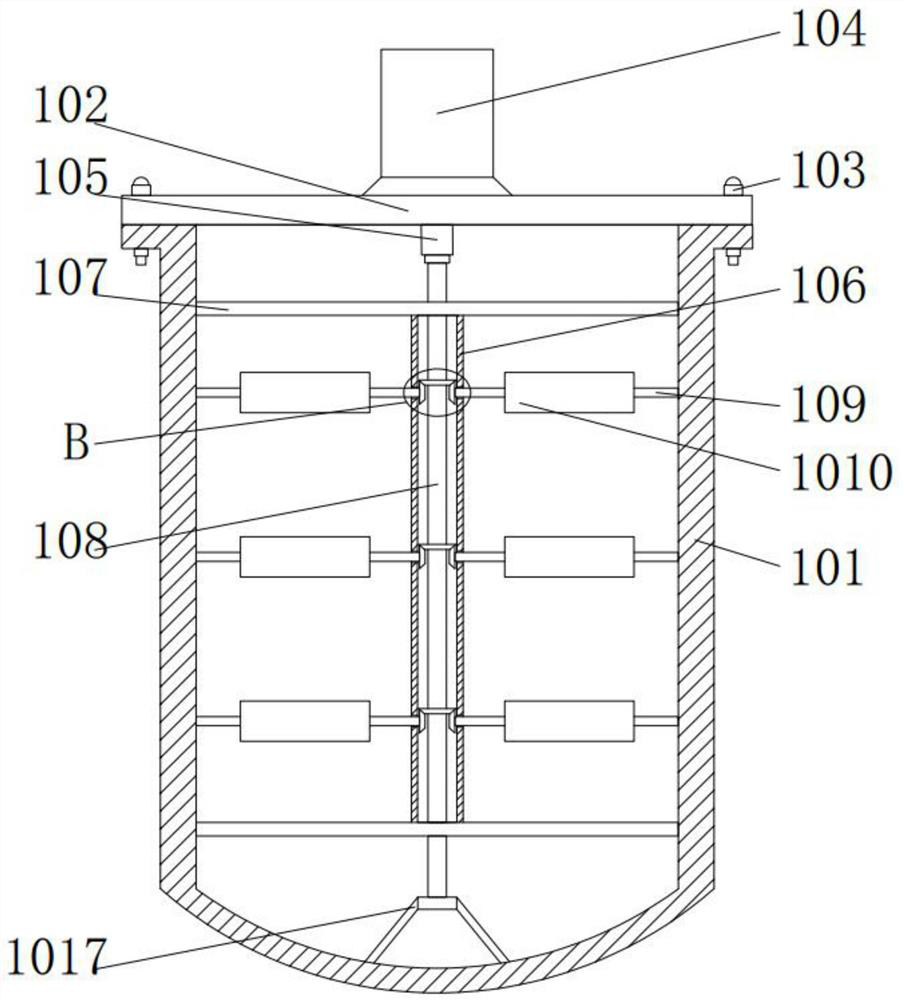

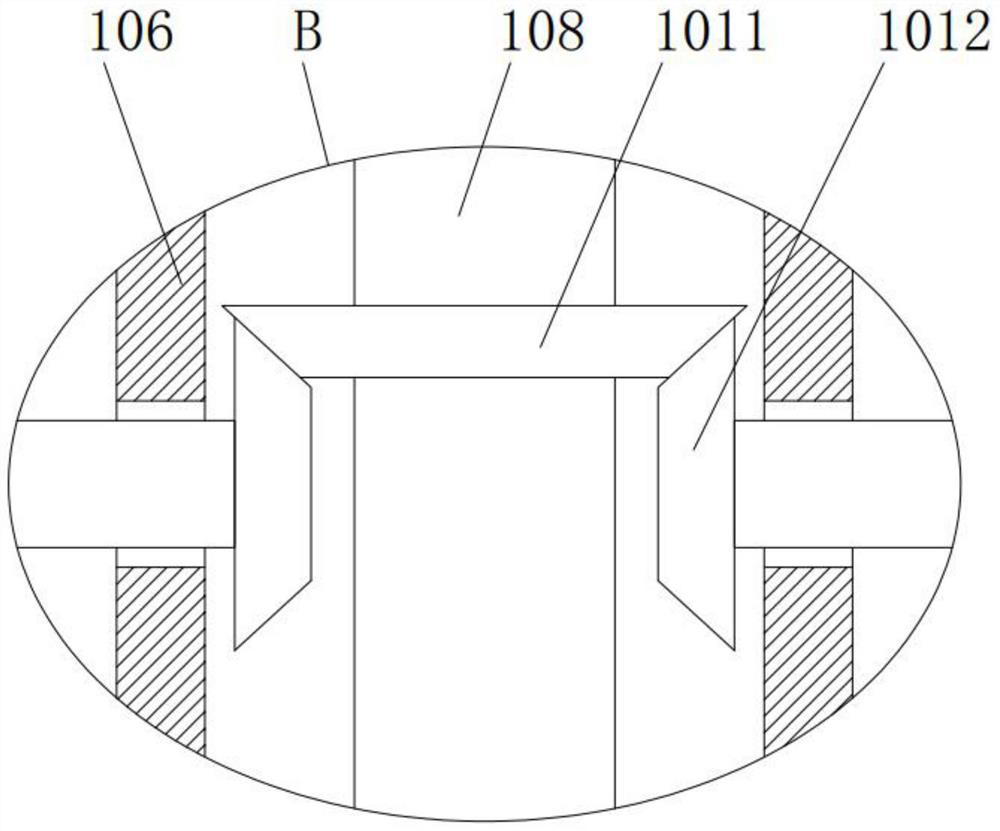

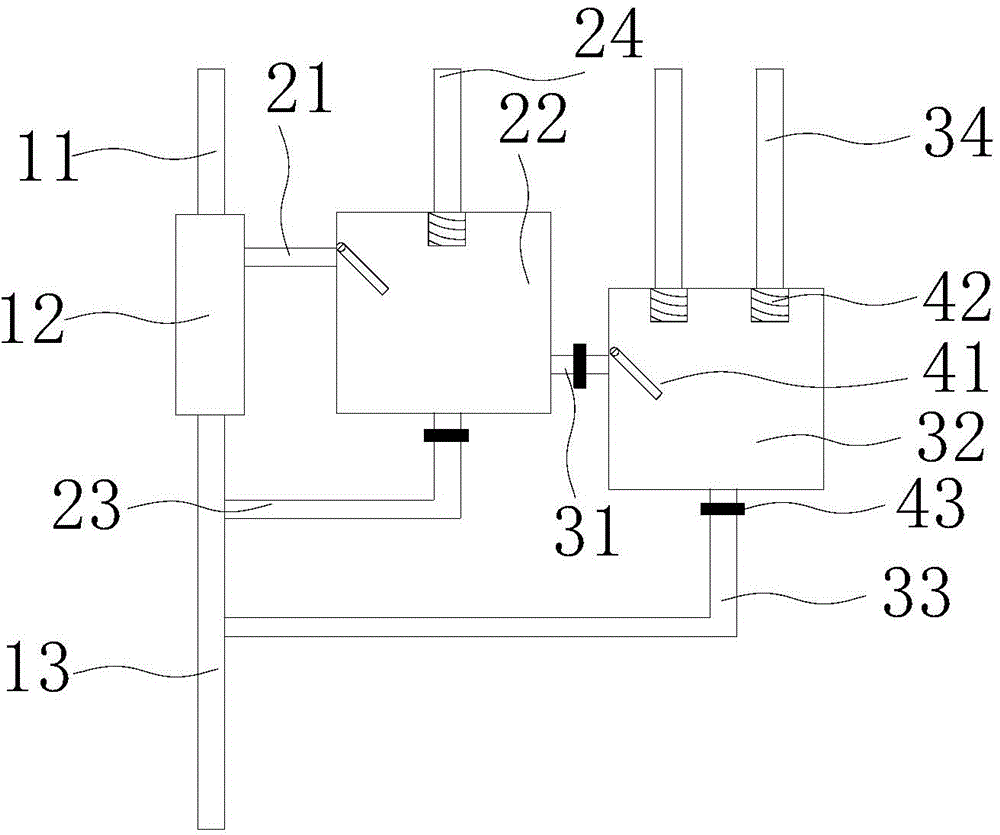

Dosing tank premixing device

InactiveCN105013381AWith graded blendingWith production requirementsMixing methodsMixersAssembly lineEngineering

The invention provides a dosing tank premixing device which comprises a main input pipeline and a main output pipeline which are connected with each other through a three-way valve, the three-way valve is connected with a first-stage mixing tank and a second-stage mixing tank through pipelines, intercepting plates are arranged on the joints of the mixing tanks and corresponding input pipes, and diversion nozzles are arranged on the joints of the mixing tanks and corresponding injection pipes. The dosing tank premixing device has the advantages that a brand-new dosing tank premixing device is designed, staged mixing treatment of multiple liquid raw materials can be achieved, parameters of mixing temperature, dosage and the like of the raw materials can be controlled accurately, multiple-stage treatment can be achieved, the extendibility is achieved, and the production requirements of an industrial assembly line are met.

Owner:TIANJIN YUFENG CHEM

Mold powder for premelted billet mold and its preparation method

The invention discloses a pre-molten type square billet crystallizer casting powder and a preparation method thereof. The pre-molten type square billet crystallizer casting powder is composed of the raw materials, by weight percentage, 60-80% of premelting agent, 4-14% of wollastonite, 2-5% of fluorite, 3-8% of sodium carbonate, 4-8% of carbonaceous materials, 0-3% of bentonite, 2% of dextrin, 0-8% of quartz and 0-3% of lithium carbonate, wherein the premelting agent is composed of 60-70% of red mud, 6-24% of quartz, 4-12% of calcite, 2-4% of clay and 2-8% of barium sulfate. The preparation method comprises adding the raw materials into water for uniform mixing; performing ball milling; performing atomizing, drying and prilling after ball milling to obtain the pre-molten type square billet crystallizer casting powder. According to the pre-molten type square billet crystallizer casting powder and the preparation method thereof, the red mud is applied to the crystallizer casting powder and reaches an adding quantity up to 50%, so that a breakthrough on the application quantity of recycled waste red mud can be achieved; meanwhile, the square billet casting powder prepared through the premelting agent is uniform in component, stable in melting performance and relatively low in cost.

Owner:郑州市裕丰耐火材料有限公司

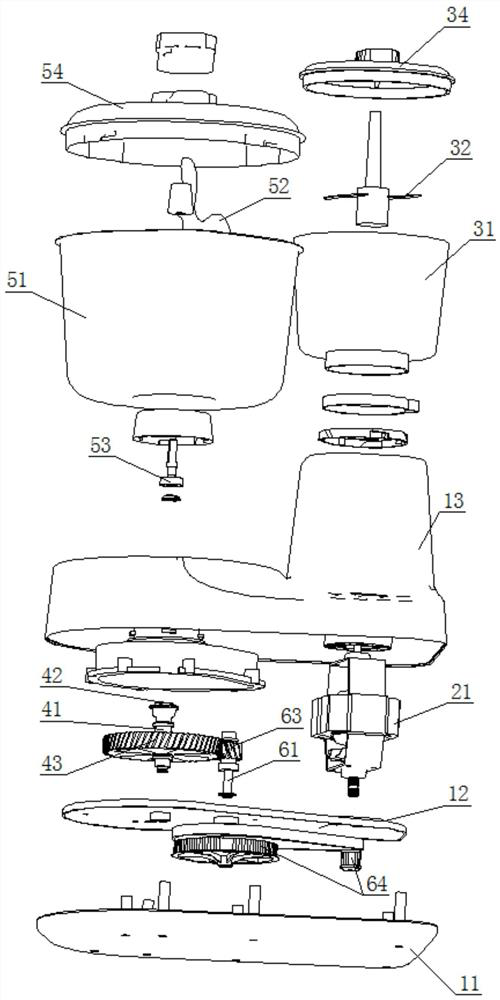

Multifunctional dough mixing all-in-one machine

InactiveCN112741516AReduce noiseGood experienceKitchen equipmentDrive motorElectrical and Electronics engineering

The invention discloses a multifunctional dough mixer which comprises a mixer body. A driving motor and a power-driven turntable are arranged in the mixer body, a high-rotating-speed shaft is arranged in the power-driven turntable in a hollow manner and penetrates through the power-driven turntable, and a speed increasing gear is connected between the power-driven turntable and the high-rotating-speed shaft in an engaged manner; the upper end of the high-rotating-speed shaft extends out of the power-driven turntable and is connected with a high-rotating-speed output spline sleeve; and the power-driven turntable is upwards and fixedly connected with a low-rotating-speed output spline. The multifunctional dough mixing all-in-one machine also comprises a basin body, a connecting shaft is arranged at the bottom of the basin body in a penetrating mode, the lower end of the connecting shaft is connected with a low-rotating-speed input spline sleeve or a high-rotating-speed input spline, the low-rotating-speed input spline sleeve is connected with the low-rotating-speed output spline in a matched mode, the high-rotating-speed input spline is connected with the high-rotating-speed output spline sleeve in a matched mode, and the upper end of the connecting shaft is connected with a rotating working head. Low-speed large torque can be output, dough mixing and stirring functions can be realized, high-speed output can be realized, noise is low, and beating and vegetable cutting functions can be realized.

Owner:青岛汉尚电器有限公司

A fully automatic round head barrel hook forming machine

ActiveCN105414415BMeet production requirementsFulfill production requirementsWire articlesWire rodProduction line

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

An artificial vertebral body fixed by anterior pedicle screw and positioning installation tool

ActiveCN106236333BFulfill production requirementsPrevent subsidenceAdditive manufacturing apparatusSpinal implantsSpinal columnMedical imaging data

The invention provides an artificial vertebra by anterior pedicle screw fixation and a positioning assembly tool. The artificial vertebra is characterized in that a pedicle screw fixing hole is formed in the artificial vertebra, and the screw is accurately guided to fix the artificial vertebra on two bilateral vertebral pedicles to realize firm self-stabilization. According to the artificial vertebra, a steel plate can be integrated into the artificial vertebra according to requirements, upper and lower ends of the steel plate exceed the length of the artificial vertebra, or only the upper end of the steel plate is longer than the artificial vertebra; the long end of the steel plate is provided with a screw hole coaxial with the vertebral pedicle and a screw hole oriented to the pedicle; a drill positioning guide plate and an osteotomy guide plate are simultaneously provided to ensure that an anterior pedicle screw can be safely and accurately implanted; and the artificial vertebra as well as the drill, osteotomy guide plate and other assembly tools thereof are designed and printed by utilizing a 3D printing technology based on medical imaging data. By adopting the artificial vertebra, the fixing strength of anterior spine stability can be maximized safely and quickly.

Owner:董谢平

Automatic H-shaped piston pushing ring arranging device

InactiveCN105013962AMeet production requirementsTake it out in timeMetal-working feeding devicesPositioning devicesFrequency conversionKnurling

The invention discloses an automatic H-shaped piston pushing ring arranging device. The device is composed of a frequency conversion speed reduction motor, a base plate, a sliding block, a sliding block pressing plate, a front baffle, a tight brake handle, a knurling hand wheel, a rotating disc, a rotating disc adjusting block, a rotating disc adjusting screw, a motor adjusting plate, a motor fixing plate, a ring guiding rod, a motor adjusting block, a motor adjusting screw, a guiding key and a signal sensor. The base plate, the sliding block and the sliding block pressing plate form a guide rail pair. The tight brake handle for locking the sliding block is installed on the sliding block. The knurling hand wheel and the rotating disc are installed at the right end of the sliding block. The motor adjusting plate is fixed to the rotating disc. The motor fixing plate and the ring guiding rod are installed on the motor adjusting plate. The frequency conversion speed reduction motor is fixed to the motor fixing plate. The signal sensor is arranged above the motor adjusting plate. By the adoption of the technical scheme, ring guiding, ring arranging and detection are integrated, automatic production is achieved, the manual ring arranging and detecting time is shortened, the labor intensity is lowered, the production efficiency is improved, and the production requirement for H-shaped piston bushing rings is met.

Owner:安徽金斗机械制造有限责任公司

3D printing inner partition wall and its construction method

The invention discloses a 3D printing internal parting wall and a construction method of the 3D printing internal parting wall. The 3D printing internal parting wall comprises a plurality of prefabricated internal parting wall units formed according to the 3D printing technology and arranged side by side, first packing materials arranged in the prefabricated internal parting wall units, steel wire gauze sheets arranged in column space and second packing materials arranged in the column space, wherein butt joint grooves are formed in the two ends of each prefabricated internal parting wall unit, and the column space is formed by butt joint of every two adjacent butt joint grooves. A truss system is applied to an internal parting wall system, overall printing molding is achieved through a 3D printing machine, and the building requirements of walls with special-shaped building models are met; meanwhile, the performance of 3D printing materials is sufficiently played, the automatic degree is high, a large amount of manpower and a large number of materials are saved, and building rubbish is not generated. Continuous concave-convex lines are formed on the surfaces of the prefabricated internal parting wall units; the connection strength between the prefabricated internal parting wall units and the packing materials is improved; compared with a smooth surface, the force of friction is improved, and the combination strength is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Oiling device for clock spring parts

InactiveCN105478275BEffective atomizationEasy oiling operationLiquid surface applicatorsSpraying apparatusDrive motorWork in process

The invention discloses an oiling device for clock spring parts, which includes a frame assembly and a clamp assembly. The frame assembly includes a frame and a first-layer installation frame connected with the frame. A clamp assembly is installed on the rotating disc, a horizontal drive cylinder and a drive motor are arranged on the frame, an oil injection assembly is arranged above the clamp assembly, and the oil injection assembly is connected to the frame. The fixture assembly and semi-finished products are driven by the servo motor, which facilitates the oiling operation, meets the production requirements, and improves the work efficiency; the design of the adjustment device and the quick installation handle realizes the free adjustment of the height and the free adjustment of the angle. It is driven by a servo motor to avoid uneven oil injection caused by uneven speed. The regular arrangement of multiple oil injection components and the cooperation with the baffle plate can effectively atomize the oil stains and better from point to surface. Radiation, to achieve all-round oiling of the product, to better meet the production needs.

Owner:JIAXING HUACHANG DENSO

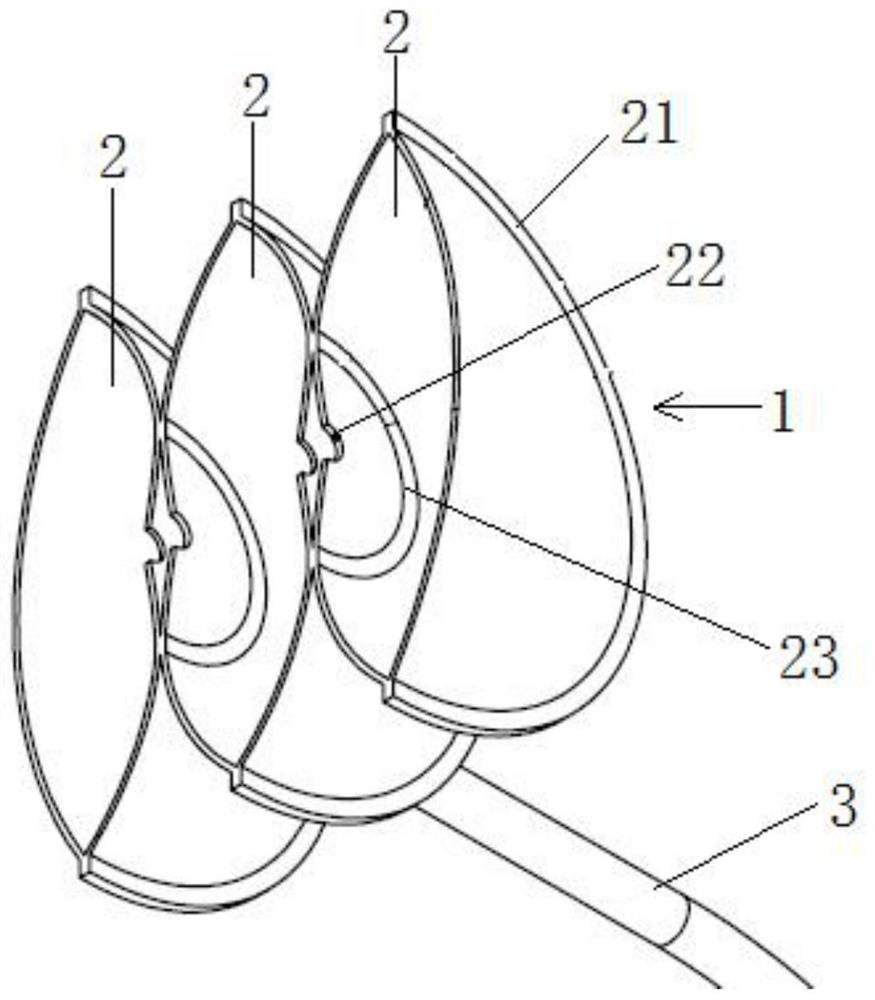

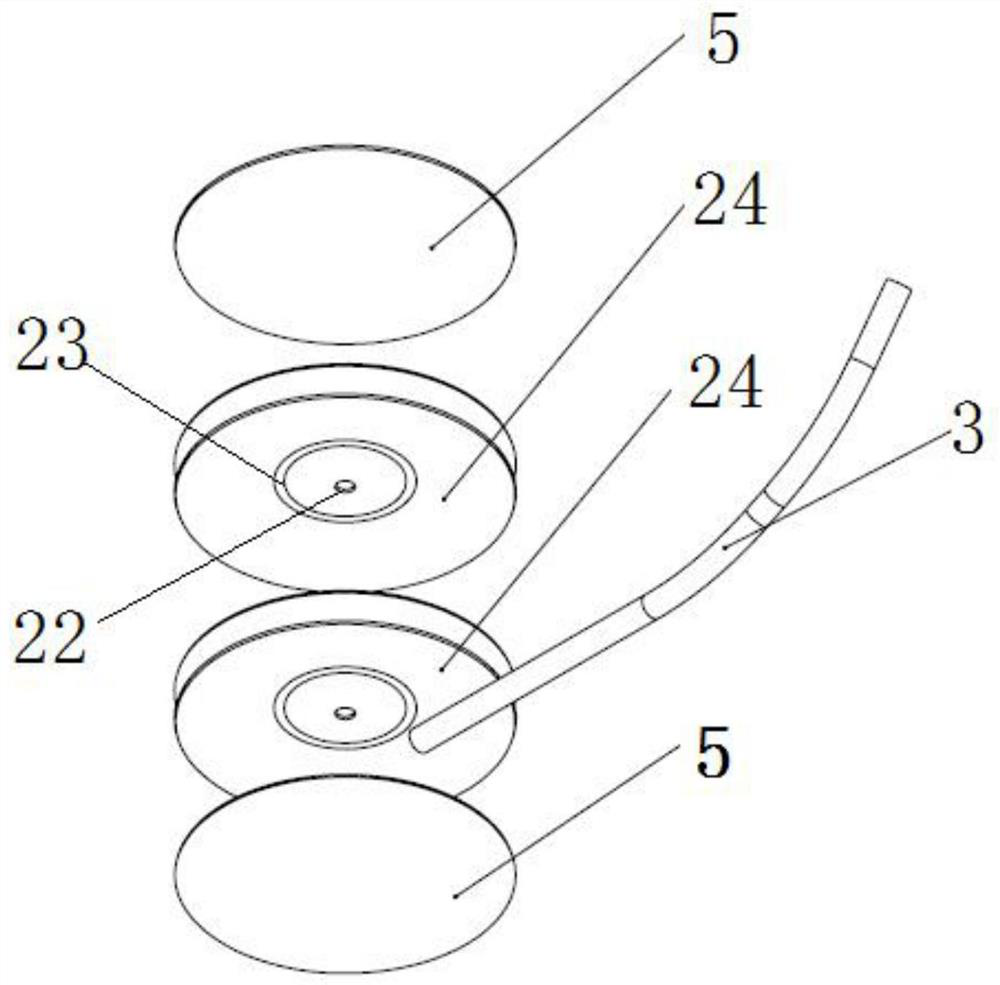

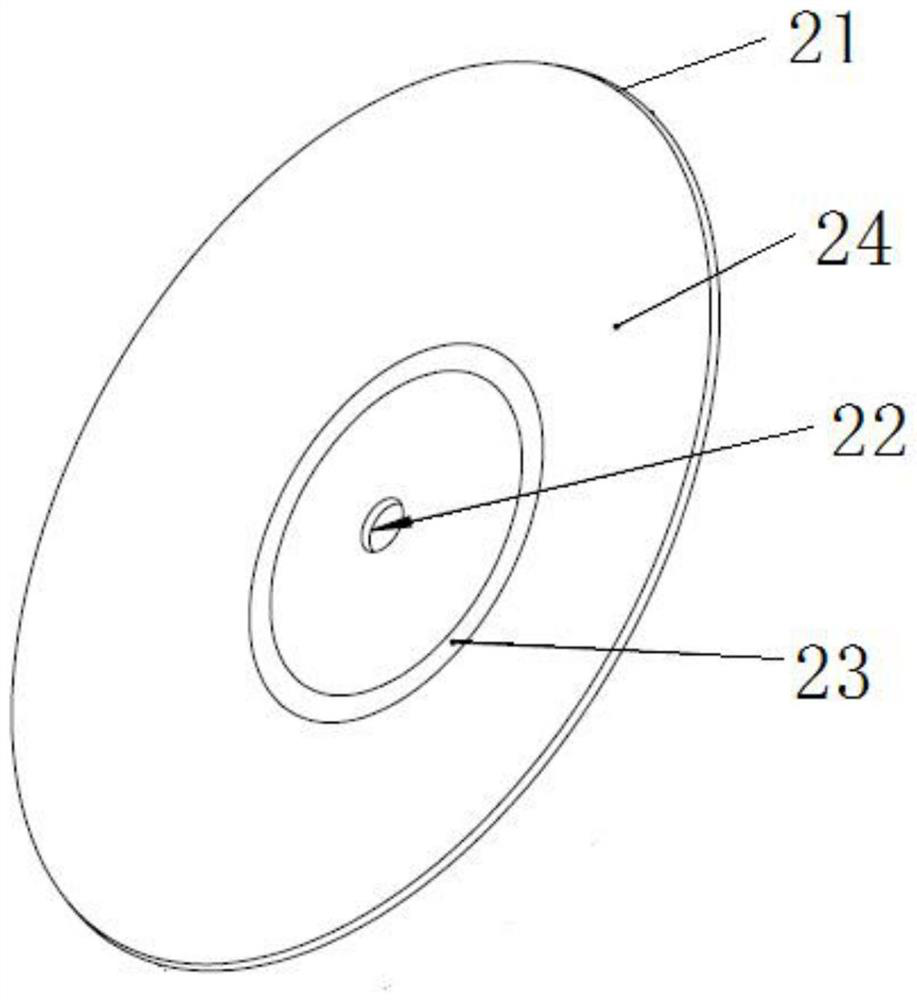

Massage air bag, massage cushion and massage system

PendingCN113306470ALow manufacturing costEjection height changeVehicle seatsPneumatic massageCar manufacturingPhysical therapy

Owner:微赛技术(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com