Spraying particle mechanism

A particle and particle detection technology, which is applied in spraying devices, coatings, devices for coating liquid on the surface, etc., to achieve the effects of low cost, meeting production requirements, and controllable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

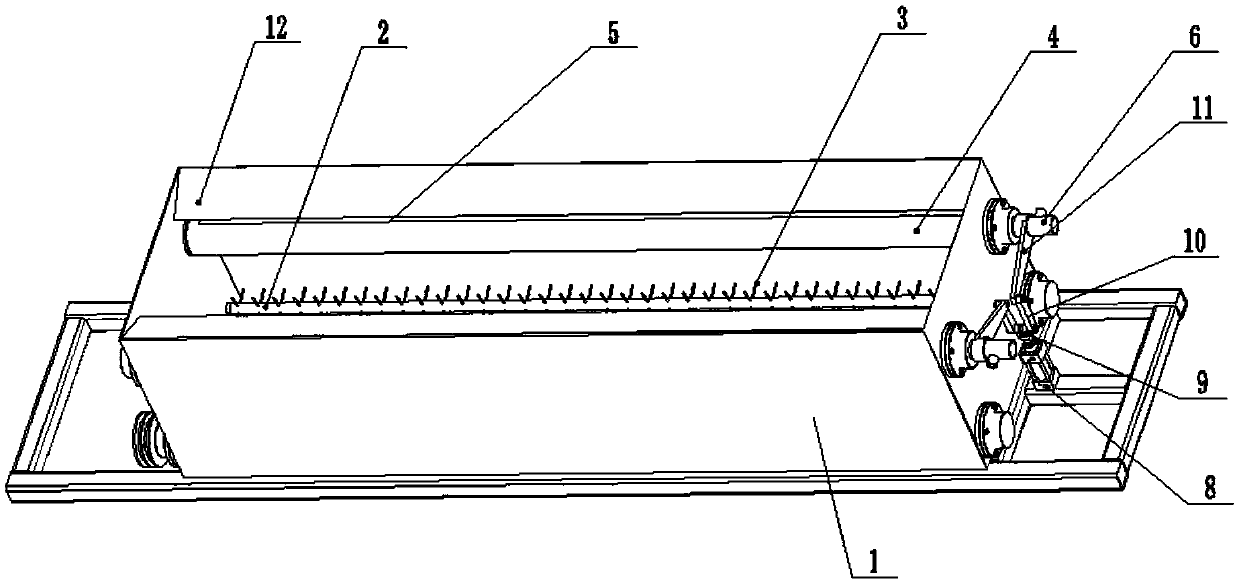

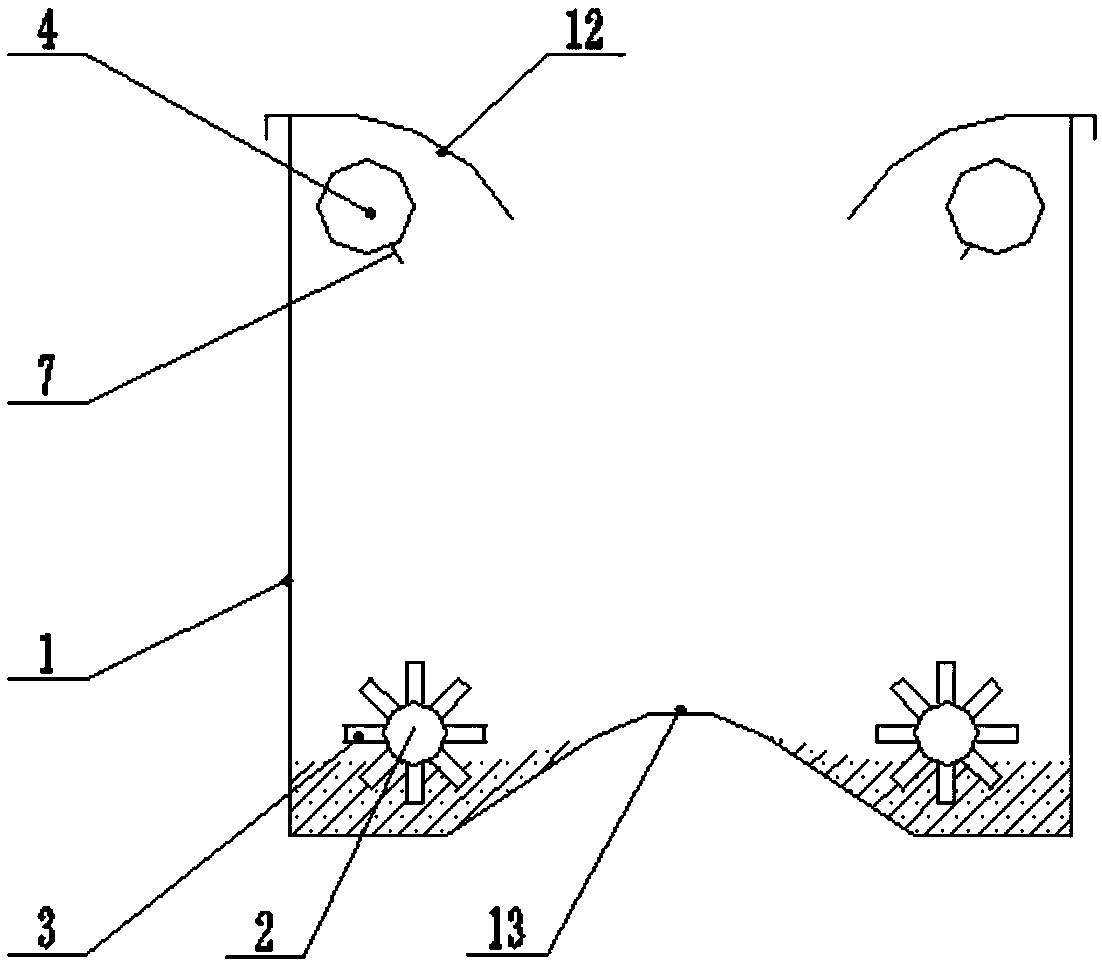

[0026] Such as figure 1 and figure 2 As shown, this embodiment proposes a particle spraying mechanism, which includes a controller and a box body 1. The upper end of the box body 1 is open, so that it is convenient to insert a gloved hand mold into the box body 1 to spray particles. .

[0027] In this embodiment, there are two groups of rotatable rotating rods 2 at the inner bottom of the box body 1 , and the two groups of rotating rods 2 are assembled horizontally, and several protrusions 3 are arranged on the surface of each group of rotating rods 2 . Inside the box 1 and above each set of rotating rods 2, there is a feeding pipe 4, two feeding pipes 4 are parallel to the two groups of rotating rods 2, and each feeding pipe 4 has one or more openings on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com