Dosing tank premixing device

A technology of premixing and mixing box, applied in the direction of mixer, mixing method, dissolution, etc., can solve the problems of high processing cost, unrealizable, simple structure of batching pool, etc., meet production requirements, realize multi-level processing, and have The effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

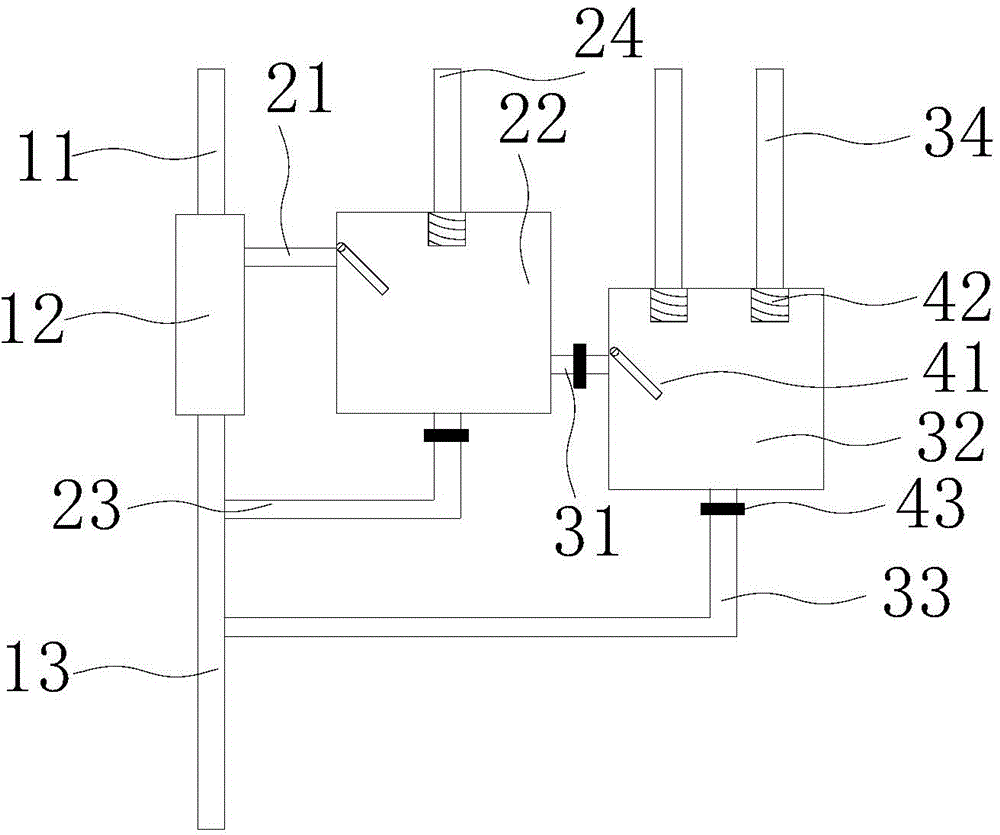

[0017] Such as figure 1 As shown, it is a structural schematic diagram of a batching tank premixing device, including a main input pipeline 11 and a main output pipeline 13, wherein the main input pipeline 11 and the main output pipeline 13 are connected by a three-way valve 12, and the first three-way valve 12 Two outlets are connected with primary input pipe 21, and described primary input pipe 21 is connected with primary mixing box 22, and the top of described primary mixing box 22 is provided with primary injection pipe 24, and the bottom is provided with primary output pipe 23. The first-stage output pipe 23 is connected to the main output pipe 13, the first-stage output pipe 23 is provided with an on-off valve 43, and the first-stage mixing tank 22 is provided with a spoiler at the connection with the first-stage input pipe 21 41, a diversion nozzle 42 is provided at the connection between the primary mixing tank 22 and the primary injection pipe 24;

[0018] Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com