Patents

Literature

45results about How to "Neatly assembled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

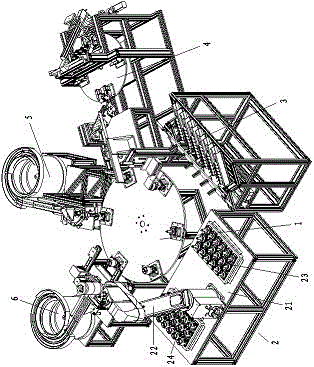

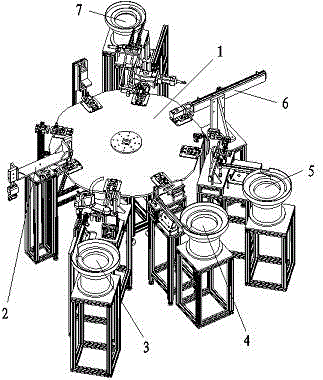

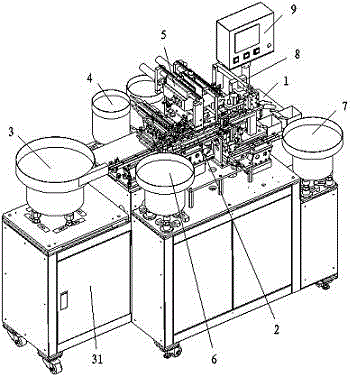

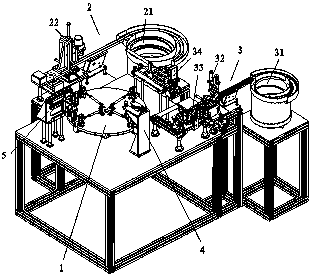

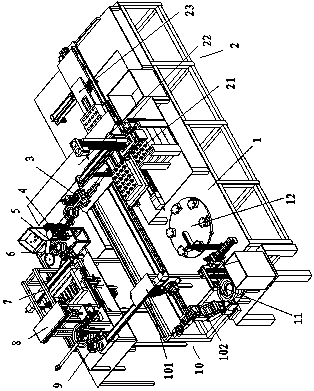

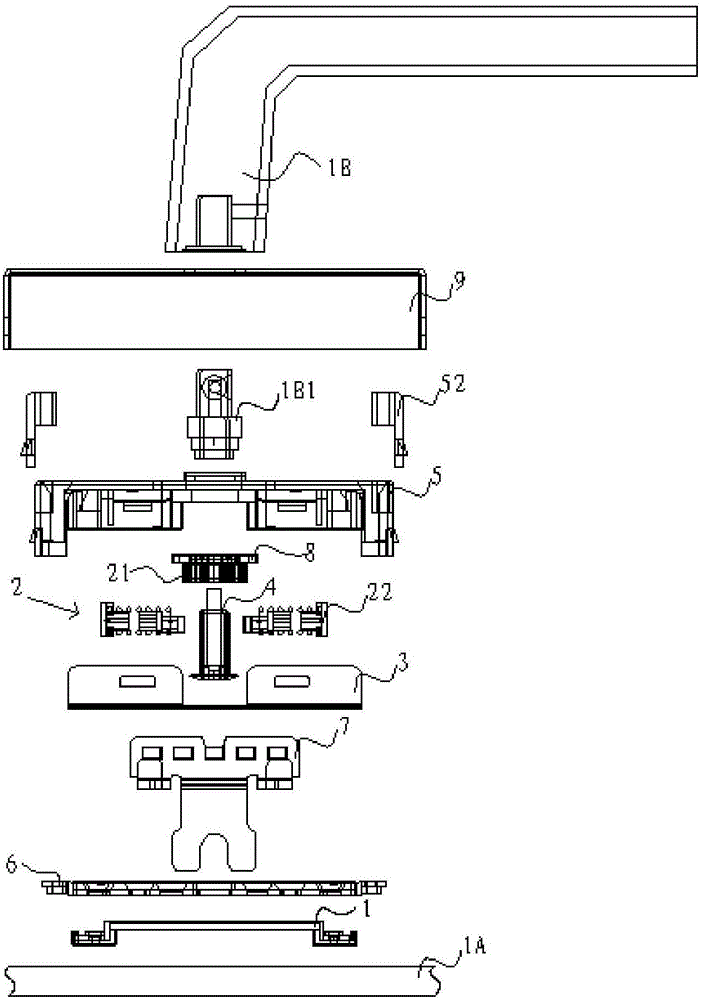

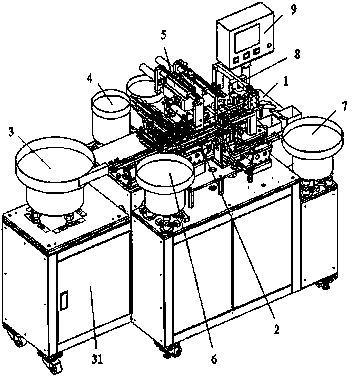

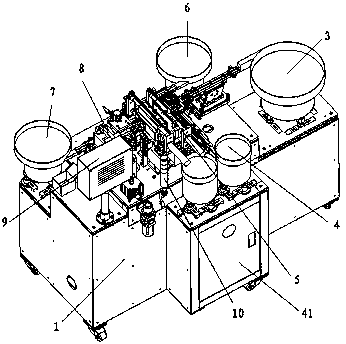

Stroke switch assembly machine

InactiveCN105990053ANeatly assembledLabor savingElectric switchesMetal working apparatusRubber ringAssembly line

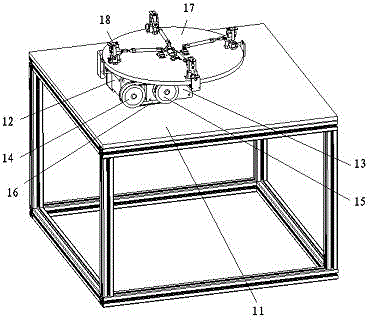

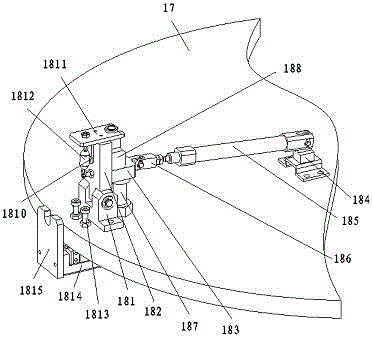

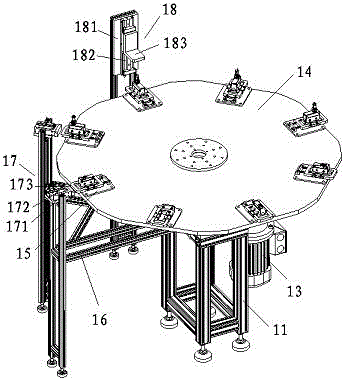

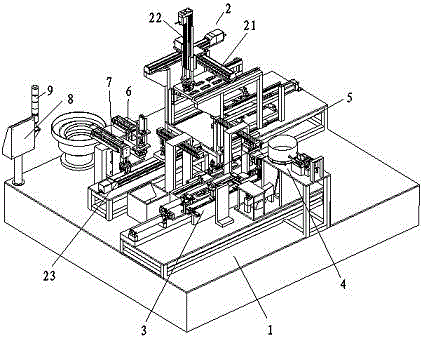

The invention discloses a stroke switch assembly machine, which comprises an eight-working position turntable mechanism, a bottom charging manipulator, a waterproof rubber ring charging mechanism, a clasp charging mechanism, a rubber ring protective cover charging mechanism, a contact charging mechanism, a rivet charging mechanism, a labeling assembly line and a main electric control cabinet, wherein the bottom charging manipulator, the waterproof rubber ring charging mechanism, the clasp charging mechanism, the rubber ring protective cover charging mechanism, the contact charging mechanism and the rivet charging mechanism are annularly located around the eight-working position turntable mechanism; the labeling assembly line is arranged at the left rear side of the eight-working position turntable mechanism; and the rear side of the eight-working position turntable mechanism is provided with the main electric control cabinet. Through the above mode, the manual labor can be replaced, assembly of the stroke switches can be completed automatically, high efficiently and tidily, the labor is saved and the production cost is reduced.

Owner:乐清市华田电力科技有限公司

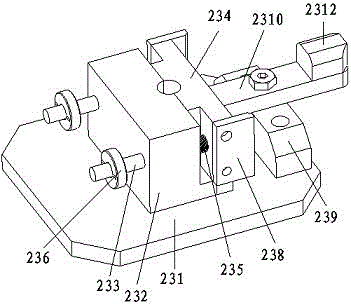

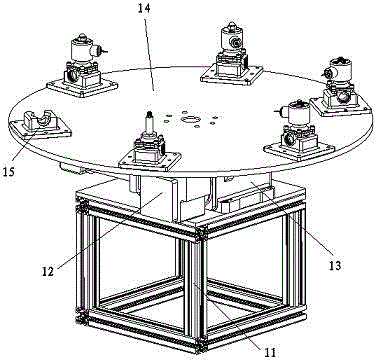

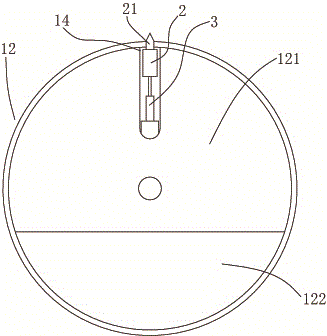

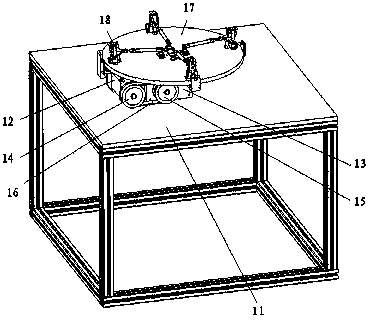

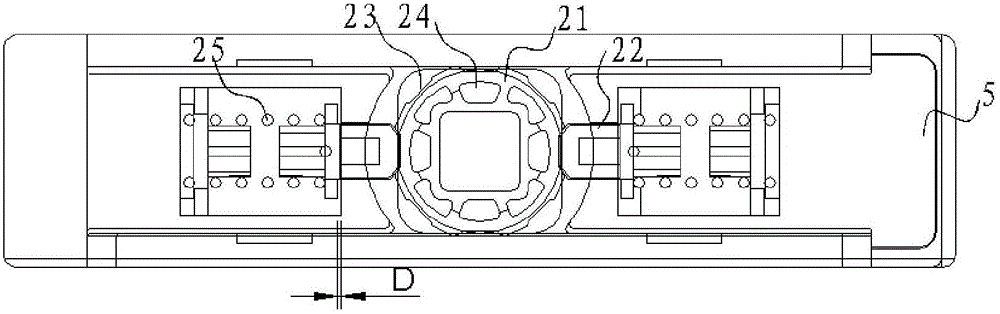

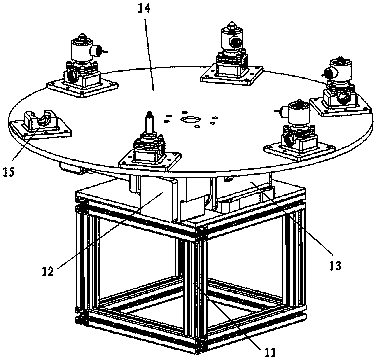

Electromagnetic valve iron core assembly assembling machine

InactiveCN106363400AEfficient assemblyNeatly assembledMetal working apparatusMechanical engineeringElectromagnetic valve

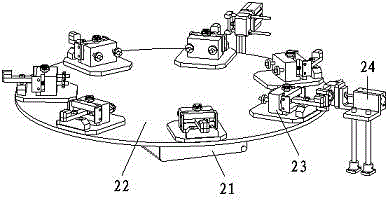

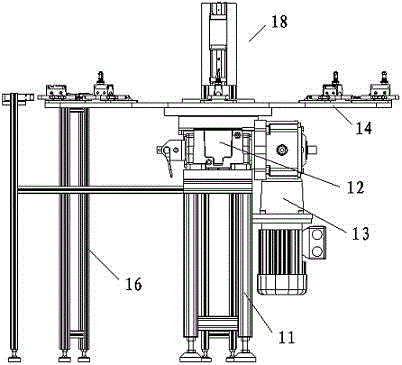

The invention discloses an electromagnetic valve iron core assembly assembling machine. The electromagnetic valve iron core assembly assembling machine comprises a four-station rotary disc mechanism, an iron core rod feeding mechanism, a plug feeding mechanism, a hold-down mechanism and a discharging mechanism. The iron core rod feeding mechanism, the plug feeding mechanism, the hold-down mechanism and the discharging mechanism are annularly located on the periphery of the four-station rotary disc mechanism; and four sets of equant iron core rod clamps are arranged on rotary discs of the four-station rotary disc mechanism and are sequentially opposite to the iron core rod feeding mechanism, the plug feeding mechanism, the hold-down mechanism and the discharging mechanism. By means of the above manner, the electromagnetic valve iron core assembly assembling machine can replace manual work to automatically, efficiently and orderly complete assembling of electromagnetic valve iron core assemblies, the labor force is saved, and the production cost is reduced.

Owner:蚌埠煜明电子科技有限公司

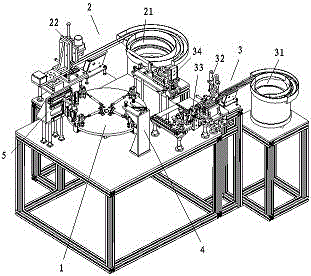

Electronic drain valve core assembling machine

ActiveCN106002161ANeatly assembledLabor savingMetal working apparatusMan machineMechanical engineering

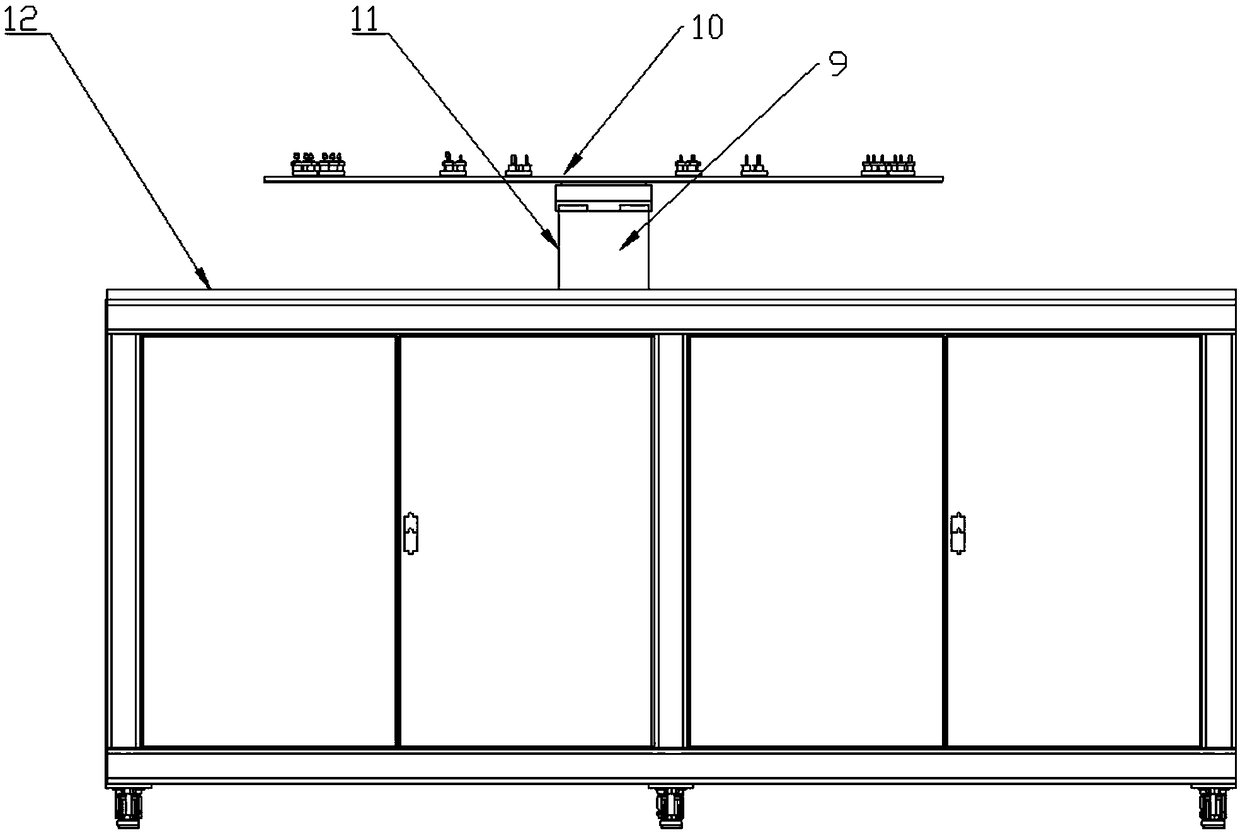

The invention discloses an electronic drain valve core assembling machine which comprises a box type rack, a turntable mechanism, a valve core body feeding mechanism, a seal ring feeding mechanism, a valve core pillar feeding mechanism, a plunger feeding mechanism, a spring feeding mechanism, a valve core plunger feeding mechanism, a stripping mechanism, a man-machine controller and an indication lighthouse, wherein a master control electric cabinet is arranged in the box type rack; the turntable mechanism is arranged on the worktable of the box type rack; the valve core body feeding mechanism, the seal ring feeding mechanism, the valve core pillar feeding mechanism, the plunger feeding mechanism, the spring feeding mechanism, the valve core plunger feeding mechanism and the stripping mechanism are arranged on the worktable at the periphery of the turntable mechanism in an annular shape; and the worktable of the box type rack is also provided with the man-machine controller and the indication lighthouse. According to the manner, the electronic drain valve core assembling machine can replace manpower to automatically, efficiently and neatly complete the valve core assembling of the electronic drain valve, can save labor force, and can lower the production cost.

Owner:YANCHENG LONGWEI MASCH CO LTD

Solenoid valve assembling equipment

The invention discloses solenoid valve assembling equipment. The solenoid valve assembling equipment comprises a rotary disc mechanism, a main body transposition mechanism, an electromagnet feeding mechanism, a sign feeding mechanism, a spring washer feeding mechanism and a screw cap feeding mechanism. The main body transposition mechanism, the electromagnet feeding mechanism, the sign feeding mechanism, the spring washer feeding mechanism and the screw cap feeding mechanism are annularly located on the periphery of the rotary disc mechanism. Six main body mounting dies are mounted on a rotary disc of the rotary disc mechanism. The main body mounting dies sequentially face the main body transposition mechanism, the electromagnet feeding mechanism, the sign feeding mechanism, the spring washer feeding mechanism and the screw cap feeding mechanism. By means of the manner, the solenoid valve assembling equipment can complete assembly of solenoid valves automatically, efficiently and trimly in replacement of manpower, manpower is saved, and the production cost is lowered.

Owner:喷达汽车精密部件(上海)有限公司

Assembly equipment for electronic drain valve

The invention discloses assembly equipment for an electronic drain valve. The assembly equipment for the electronic drain valve comprises a box-type rack, a body loading mechanism, a transposition mechanism, a sealing ring loading mechanism, a rotary valve column loading mechanism, a ball valve element loading mechanism, a ball valve switch loading mechanism, a process sealing head loading mechanism, a sealing head sealing ring loading mechanism, an assembly mechanism, a blow-down sealing cover loading mechanism and a filter screen loading mechanism, wherein the body loading mechanism is used for conveying a body to the transposition mechanism at the rear side of the body loading mechanism; the sealing ring loading mechanism, the rotary valve column loading mechanism, the ball valve element loading mechanism, the ball valve switch loading mechanism, the process sealing head loading mechanism and the sealing head sealing ring loading mechanism are used for sequentially conveying a workpiece to the transposition mechanism; and the transposition mechanism is used for conveying the assembled workpiece to the assembly mechanism at the front side of the transposition mechanism. Through the abovementioned manner, the assembly equipment for the electronic drain valve, which is disclosed by the invention, is capable of replacing manual operation, and automatically, efficiently and regularly completing assembly for the electronic drain valve, thus saving the labour and reducing the production cost.

Owner:江苏荣元铸业有限公司

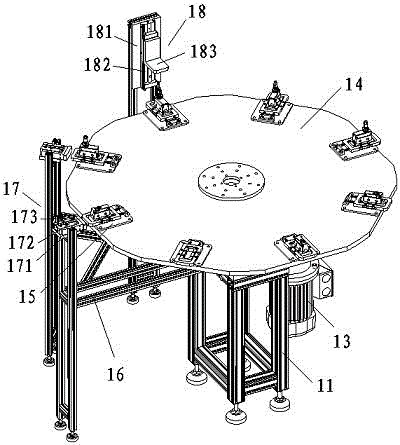

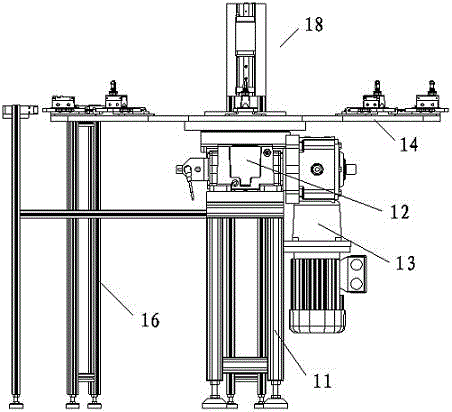

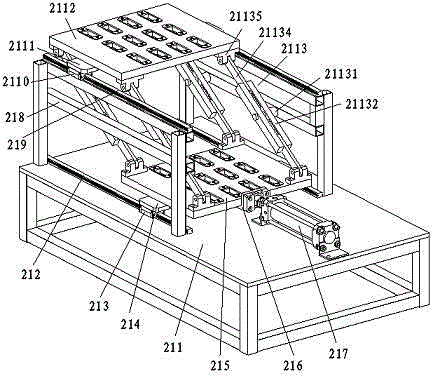

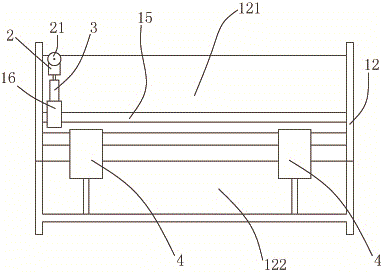

Rotary table unit of travel switch assembling machine

The invention discloses a rotary table unit of a travel switch assembling machine. The rotary table unit of the travel switch assembling machine comprises an eight-station rotary table mechanism, a bottom loading manipulator, a waterproof rubber ring loading mechanism, a clamping ring loading mechanism, a rubber ring protective cover loading mechanism, a contact uploading mechanism and a rivet loading mechanism. The bottom loading manipulator, the waterproof rubber ring loading mechanism, the clamping ring loading mechanism, the rubber ring protective cover loading mechanism, the contact uploading mechanism and the rivet loading mechanism are positioned around the eight-station rotary table mechanism in a ring shape and sequentially convey workpieces to the eight-station rotary table mechanism. In the mode, the rotary table unit disclosed by the invention can replace manual work to automatically and neatly complete assembling of a travel switch, labor is saved, and production cost is reduced.

Owner:NANTONG DONGYUAN XIELI ELECTRIC APPLIANCE CO LTD

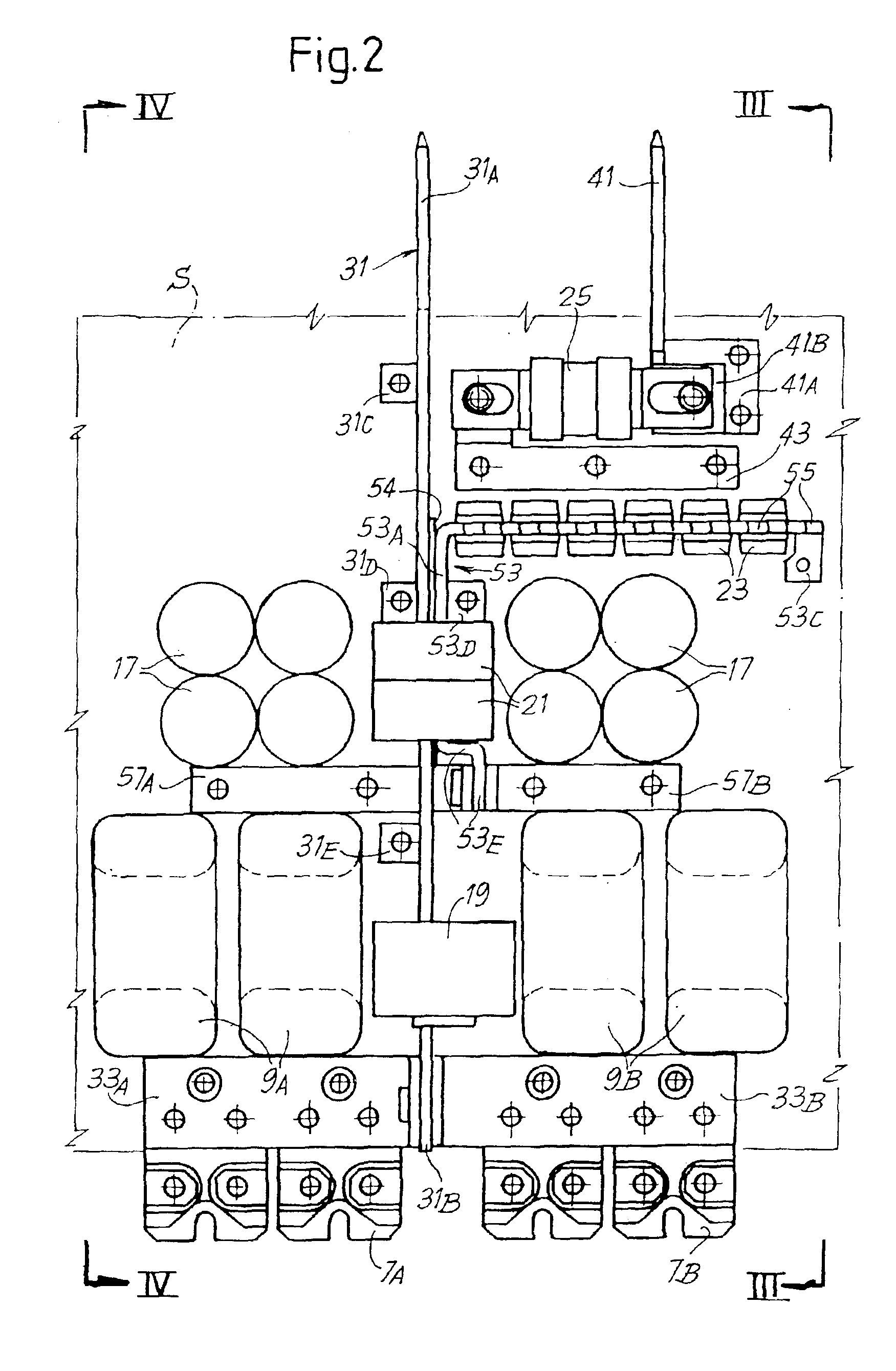

Electric-power supply with rectifier

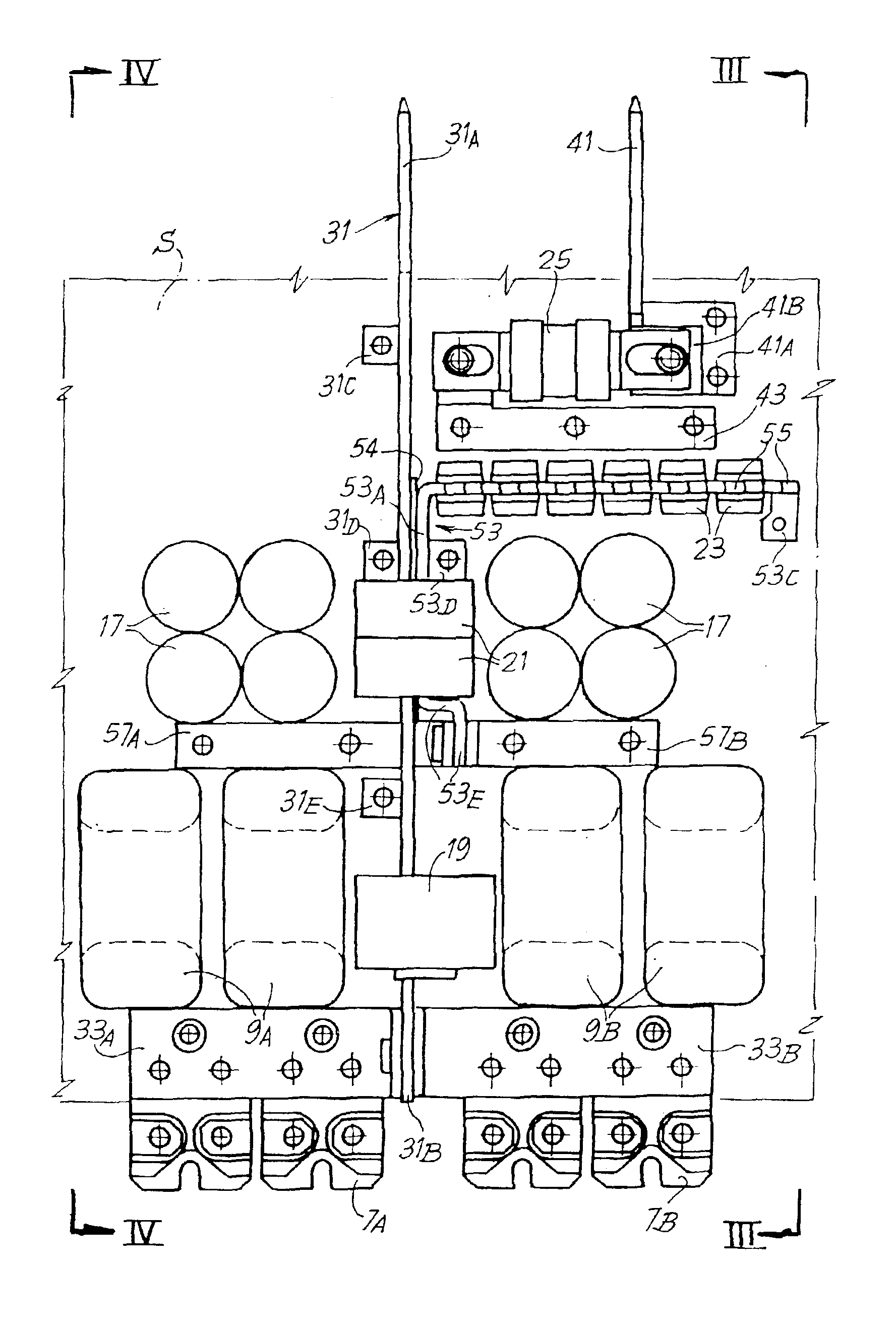

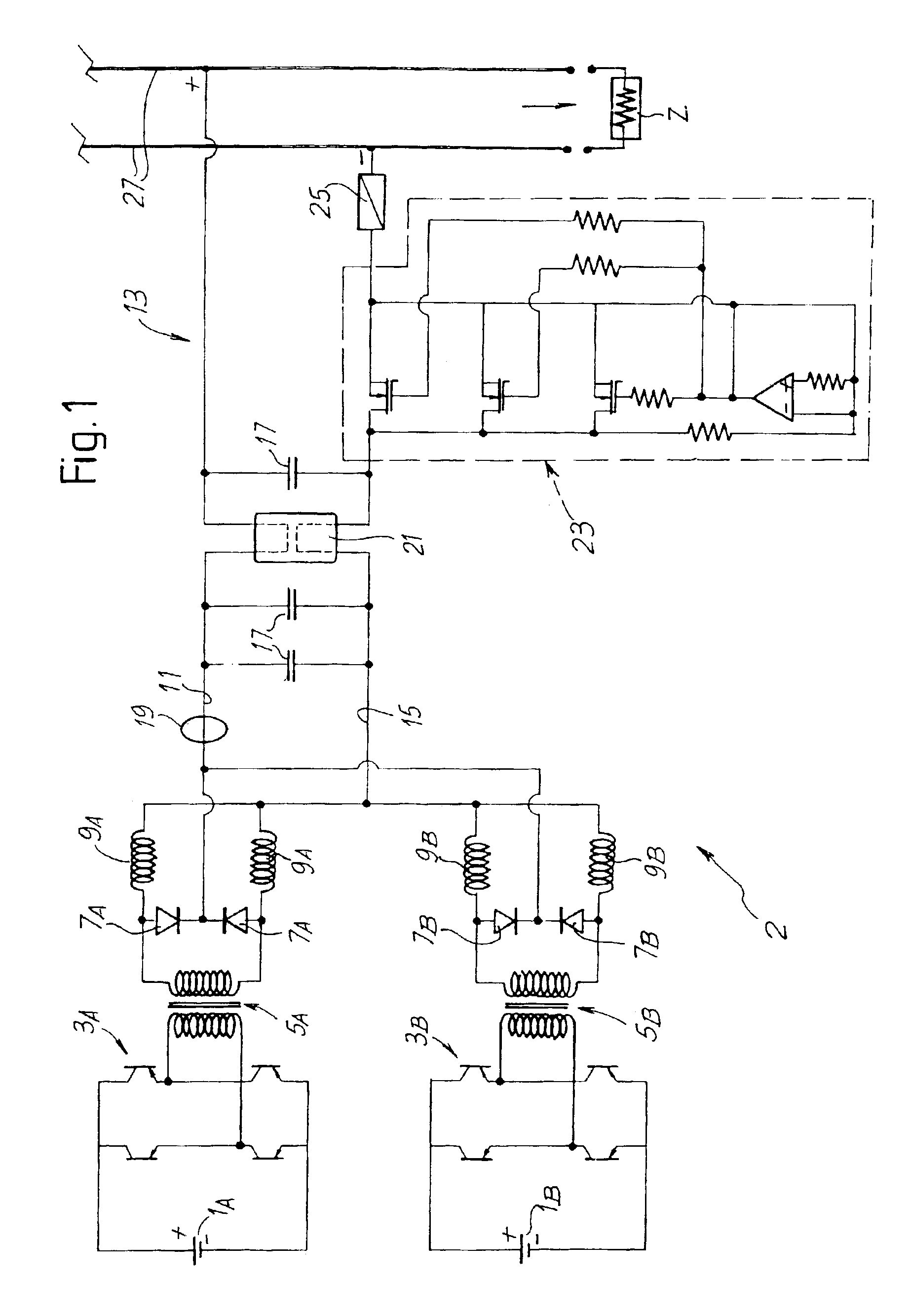

ActiveUS6934156B2Simple conformationSimplify the manufacturing processBus-bar/wiring layoutsConversion constructional detailsEngineeringConductive materials

An electric-power supply incorporates an electronic card with at least one rectifier and one output line of the rectifier. The output line is formed of at least one first bar made of conductive material, terminating with one first output end, and at least one second bar made of conductive material, terminating with one second output end. The two output ends form the positive and negative output poles of the power supply for connection to a load. Means are provided for electrical and mechanical connection for the first bar and the second bar to the card, and on at least one of the two bars is carried at least one electronic component of said rectifier.

Owner:ABB (SCHWEIZ) AG

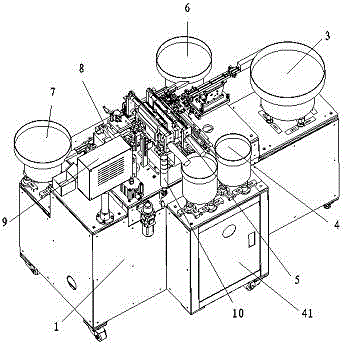

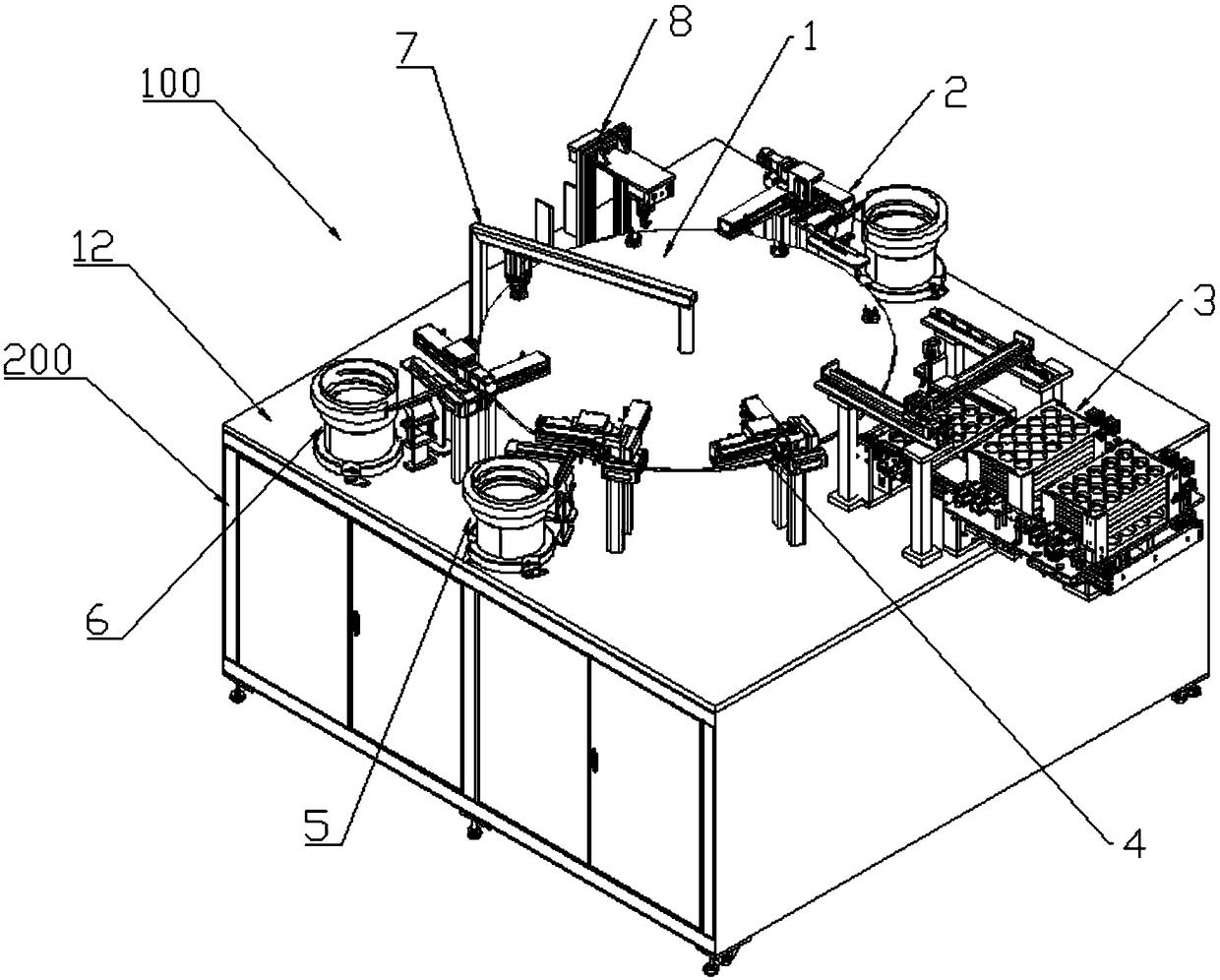

Microswitch assembly equipment

ActiveCN105957756ANeatly assembledImprove assembly efficiencyElectric switchesMan machineEngineering

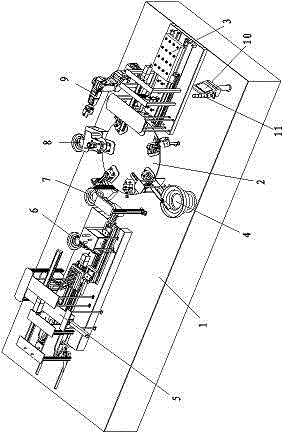

The invention discloses a piece of microswitch assembly equipment. The microswitch assembly equipment comprises a box type rack, a feeding mechanism, a base feeding mechanism, an elastic sheet feeding mechanism, a loading mechanism, a cover plate feeding mechanism, a button feeding mechanism, an integration and riveting mechanism, a man-machine controller and a lighthouse. A master control electric cabinet is arranged in the box type rack. The feeding mechanism is mounted on the worktable of the box type rack. The left side of the feeding mechanism is equipped with the base feeding mechanism. The elastic sheet feeding mechanism, the loading mechanism and the integration and riveting mechanism are arranged on the worktable of the box type rack at the rear side of the feeding mechanism from the left to the right in sequence. The front side of the feeding mechanism is equipped with the cover plate feeding mechanism and the button feeding mechanism. The man-machine controller and the lighthouse are mounted on the worktable of the box type rack. Through adoption of the mode, according to the button feeding mechanism, the assembly of a microswitch can be finished automatically, efficiently and tidily instead of manual work, the assembly efficiency and the product quality can be improved, and the production cost is recued.

Owner:佛山市顺德区百帝电器制造有限公司

Limiting box assembling machine of door check

The invention discloses a limiting box assembling machine of a door check. The limiting box assembling machine of the door check comprises an upper shield feeding mechanism, a sliding block conveying mechanism, a rolling column feeding mechanism, a shifting mechanism, a rubber spring feeding mechanism, a discharging mechanism, a main-machine control machine and a lighthouse which are mounted on a box type rack, wherein the sliding block conveying mechanism is arranged on the front side of the upper shield feeding mechanism; the rolling column feeding mechanism is arranged on the right side of the sliding block conveying mechanism; the shifting mechanism is arranged on the box type rack and positioned between the rolling column feeding mechanism and the upper shield feeding mechanism; the rubber spring feeding mechanism is arranged on the rear side of the upper shield feeding mechanism; and the discharging mechanism is arranged on the left side of the rubber spring feeding mechanism. By the mode, the limiting box assembling machine of the door check can automatically, efficiently and neatly assemble limiting boxes instead of manual work, labor is saved, and production cost is reduced.

Owner:七采蜂(苏州)数字科技有限公司

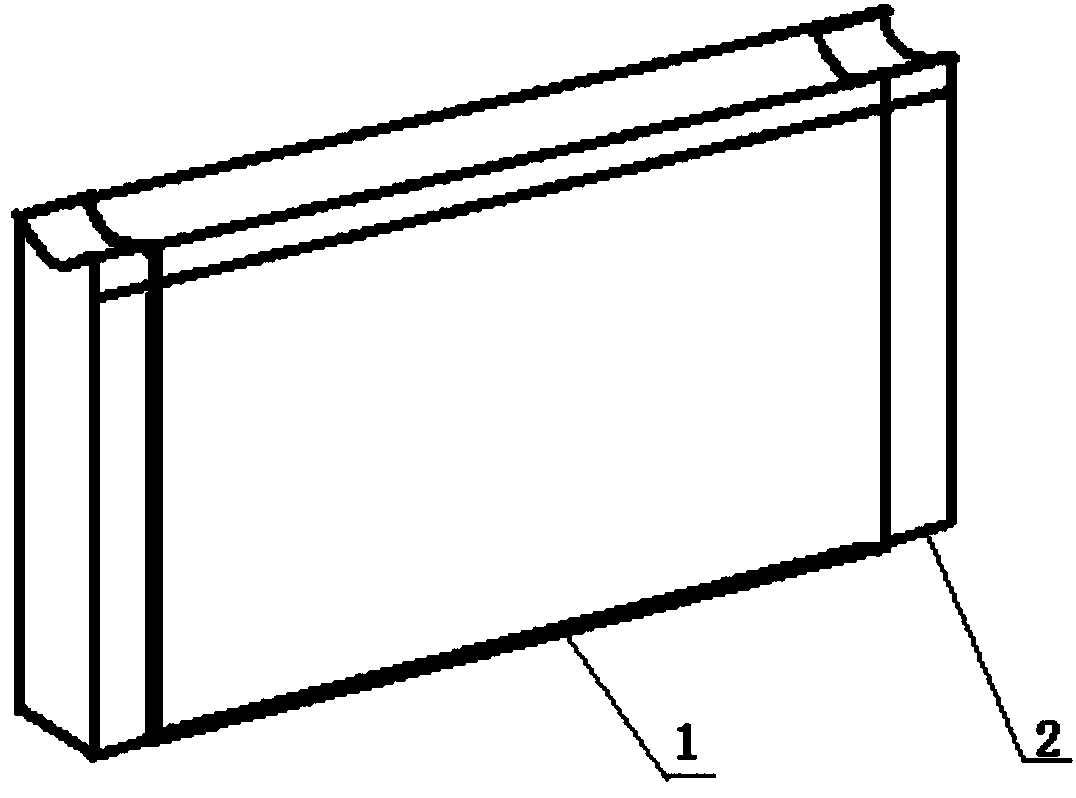

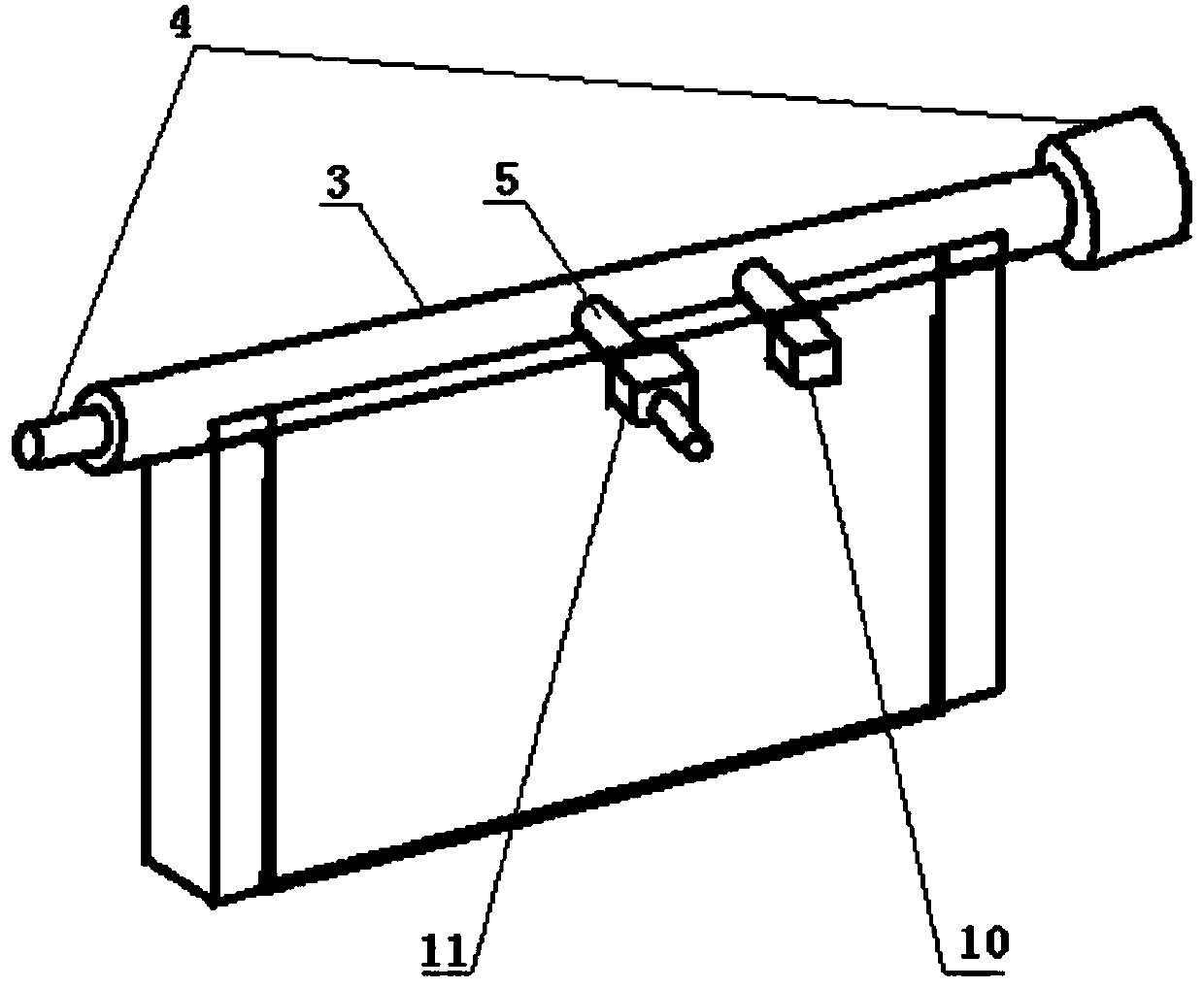

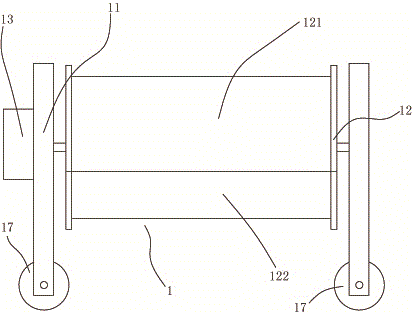

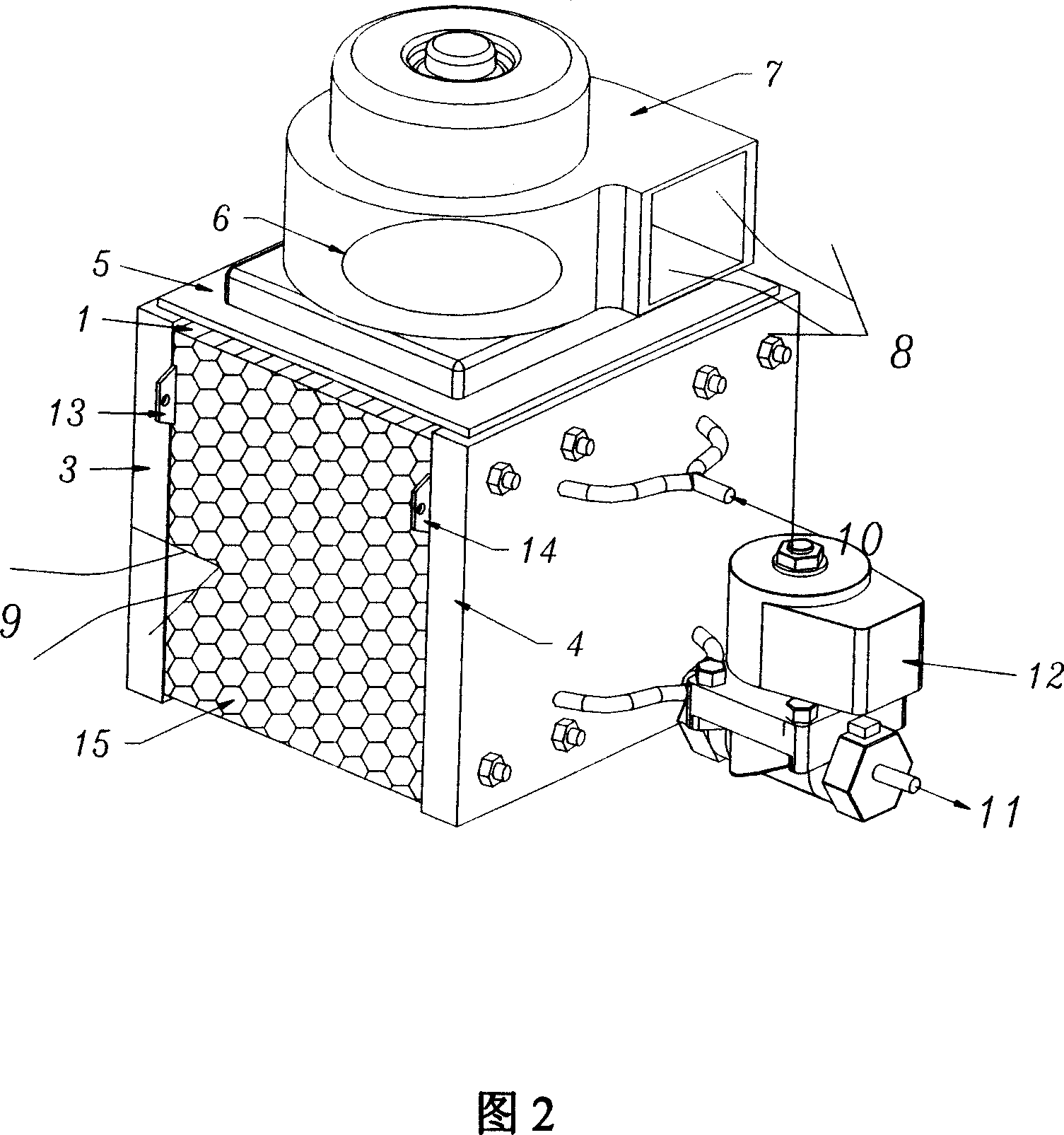

Method for constructing fence with automatic spraying device and fence module

InactiveCN107620280AEasy to assembleNeatly assembledUsing liquid separation agentRoad cleaningEngineeringElectromagnetic valve

The invention relates to the field of construction site dust fall, in particular to a method for constructing a fence with an automatic spraying device and a fence module. The fence module at least comprises a fence plate, fence columns and a spraying pipe, wherein the spraying pipe is a hose and / or a hard pipe, one ore more connecting pipes are arranged in the middle of the pipe wall of the spraying pipe, the connecting pipe is provided with an electromagnetic valve, quick joints are arranged at the two ends of the spraying pipe, the two ends of the fence plate are connected with the fence columns, grooves are formed in the upper end of the fence plate and the upper ends of the fence columns, the grooves are matched with the spraying pipe in size, a dust sensor is arranged on the pipe wall of the spraying pipe, and the dust sensor and the electromagnetic valve are connected with a control module. According to the technical scheme, the dust sensor on the spraying pipe monitors the dustflying condition near the fence in real time, when it is monitored that the flying dust exceeds a set numerical value, spraying is started on a construction site, the area needing to be sprayed can be subjected to dust fall in a targeted mode, the situation that a lot of accumulated water is generated in other areas and influences construction operation is avoided, management automation is achieved, energy conservation and environmental protection are achieved.

Owner:WUHAN CUIYU ENVIRONMENTAL TECH

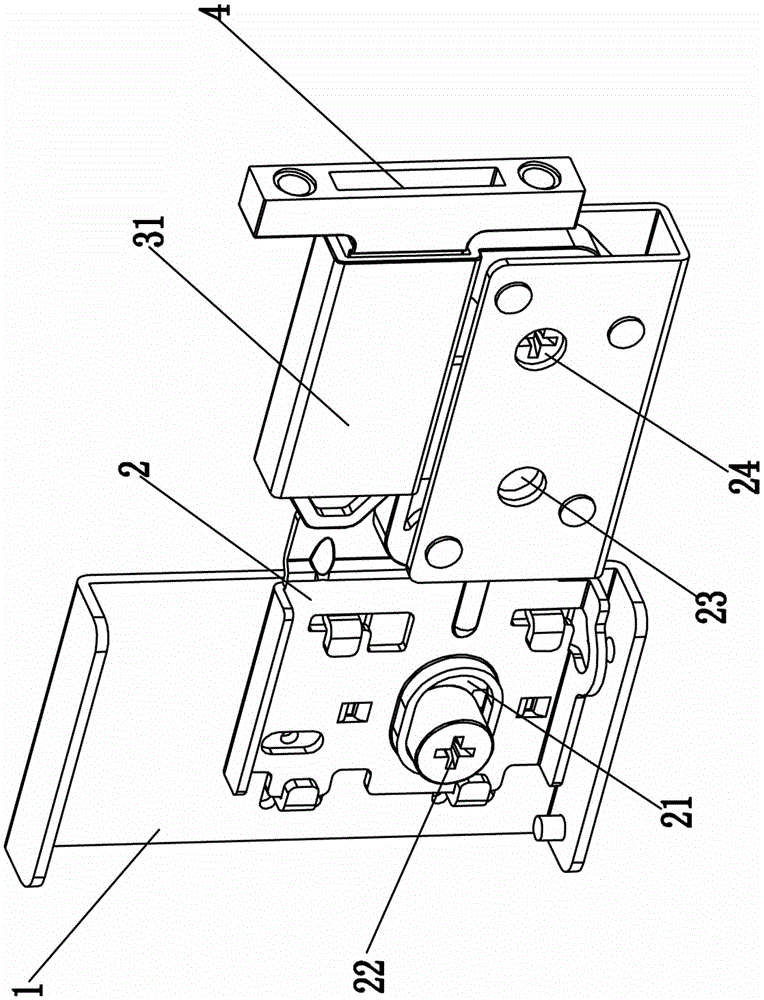

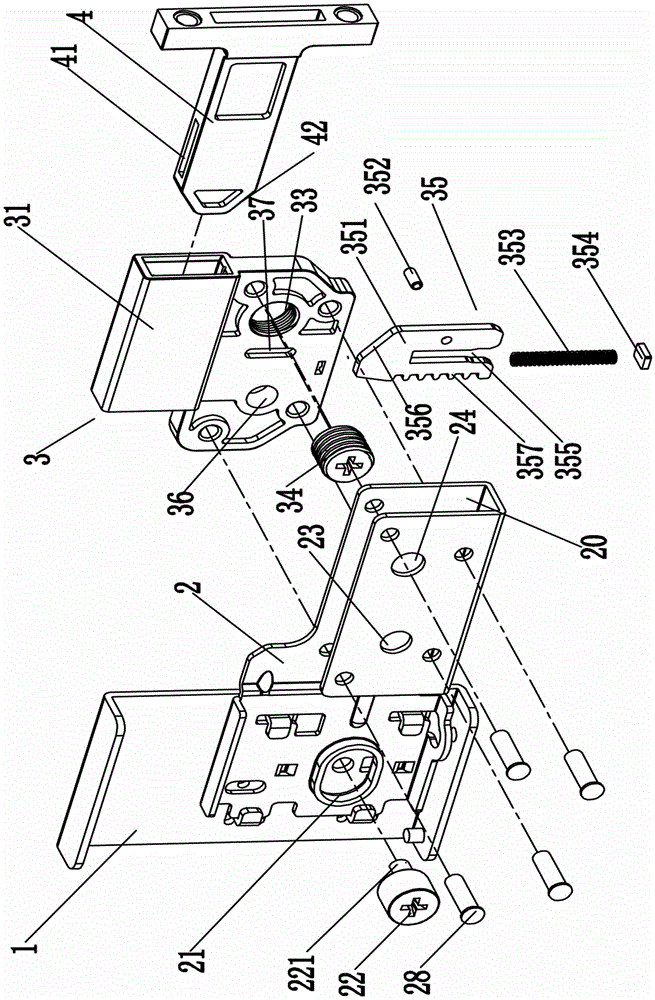

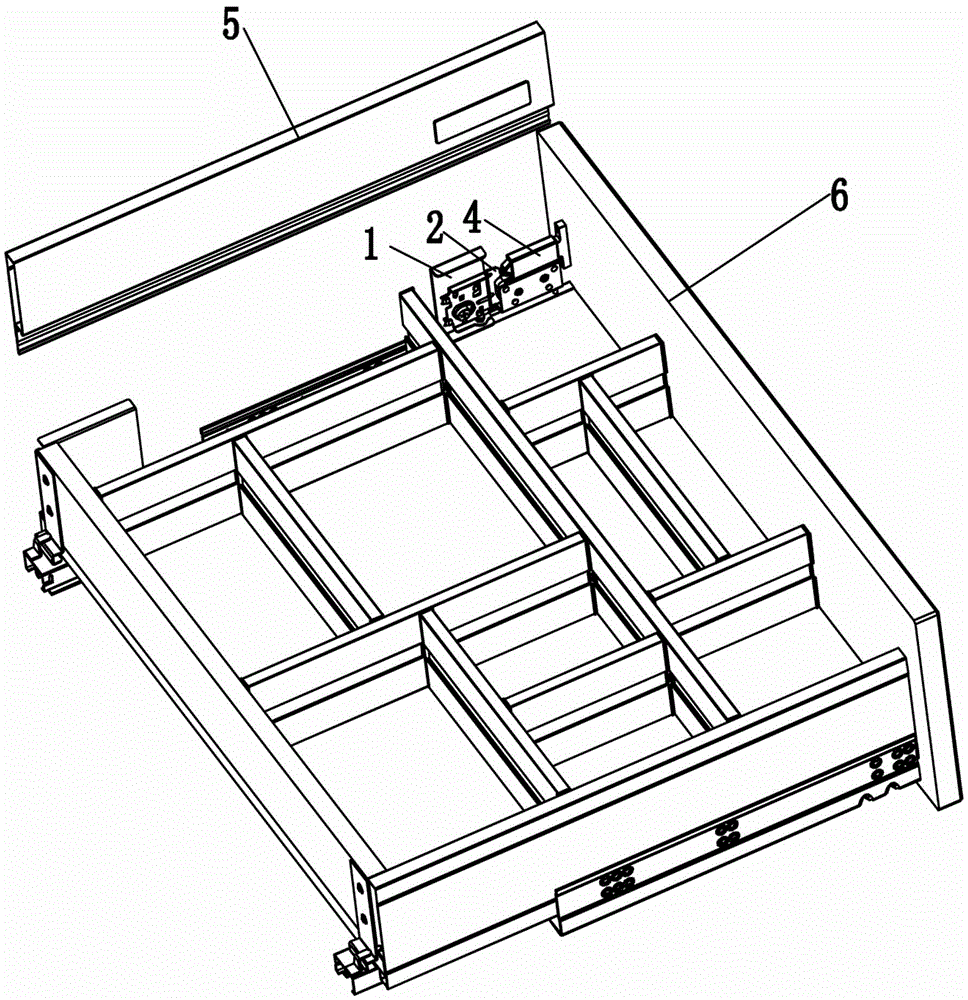

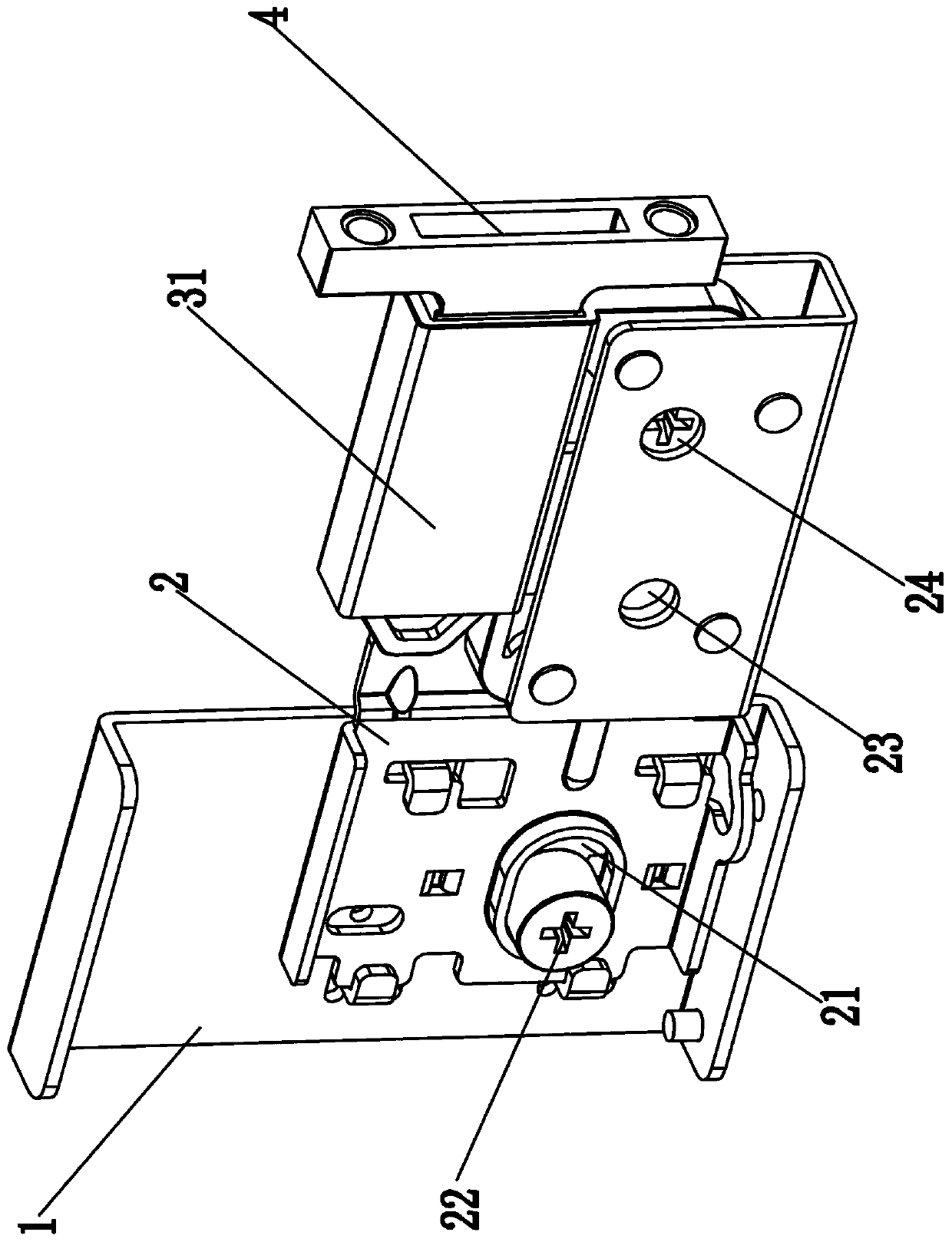

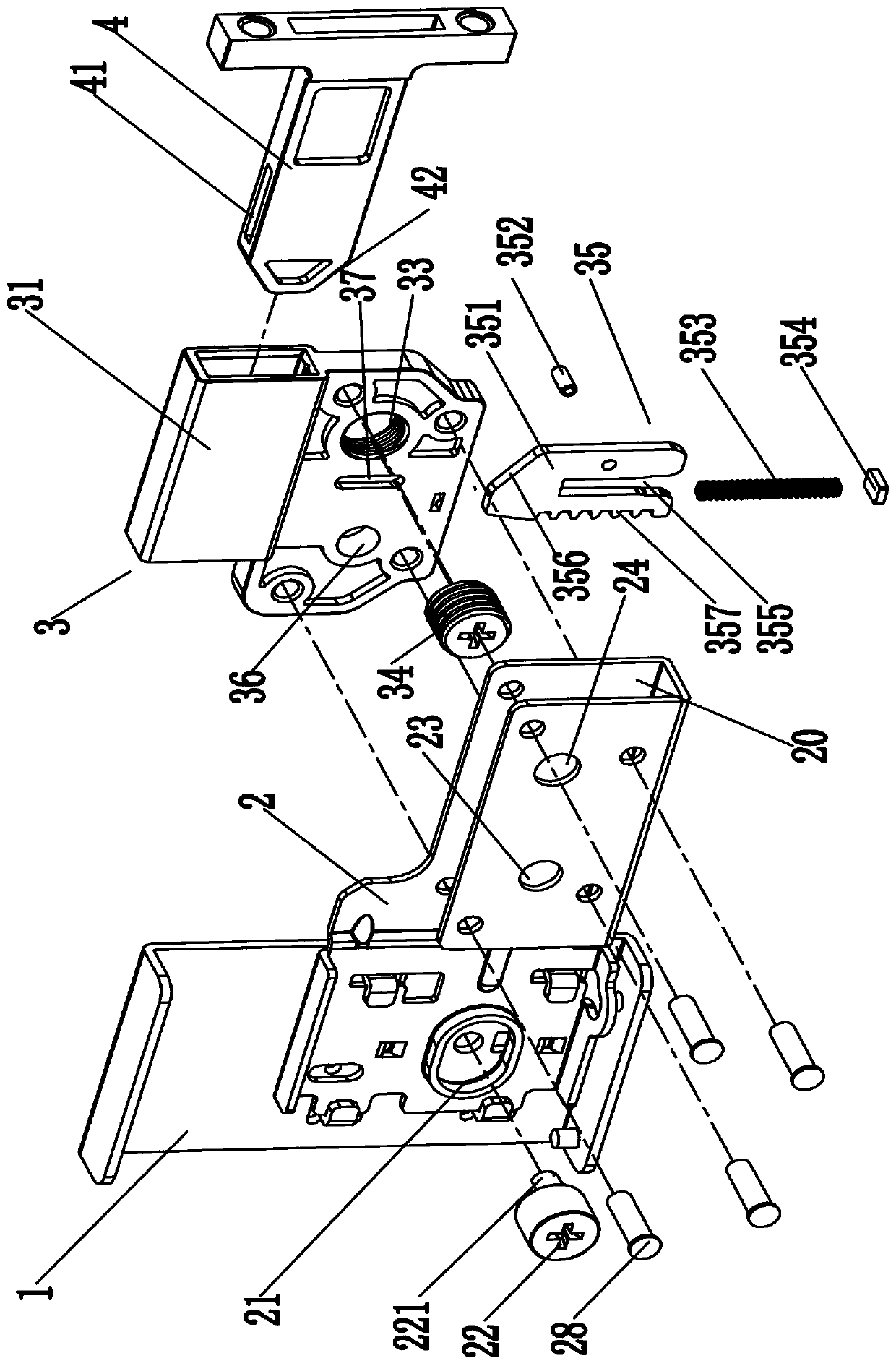

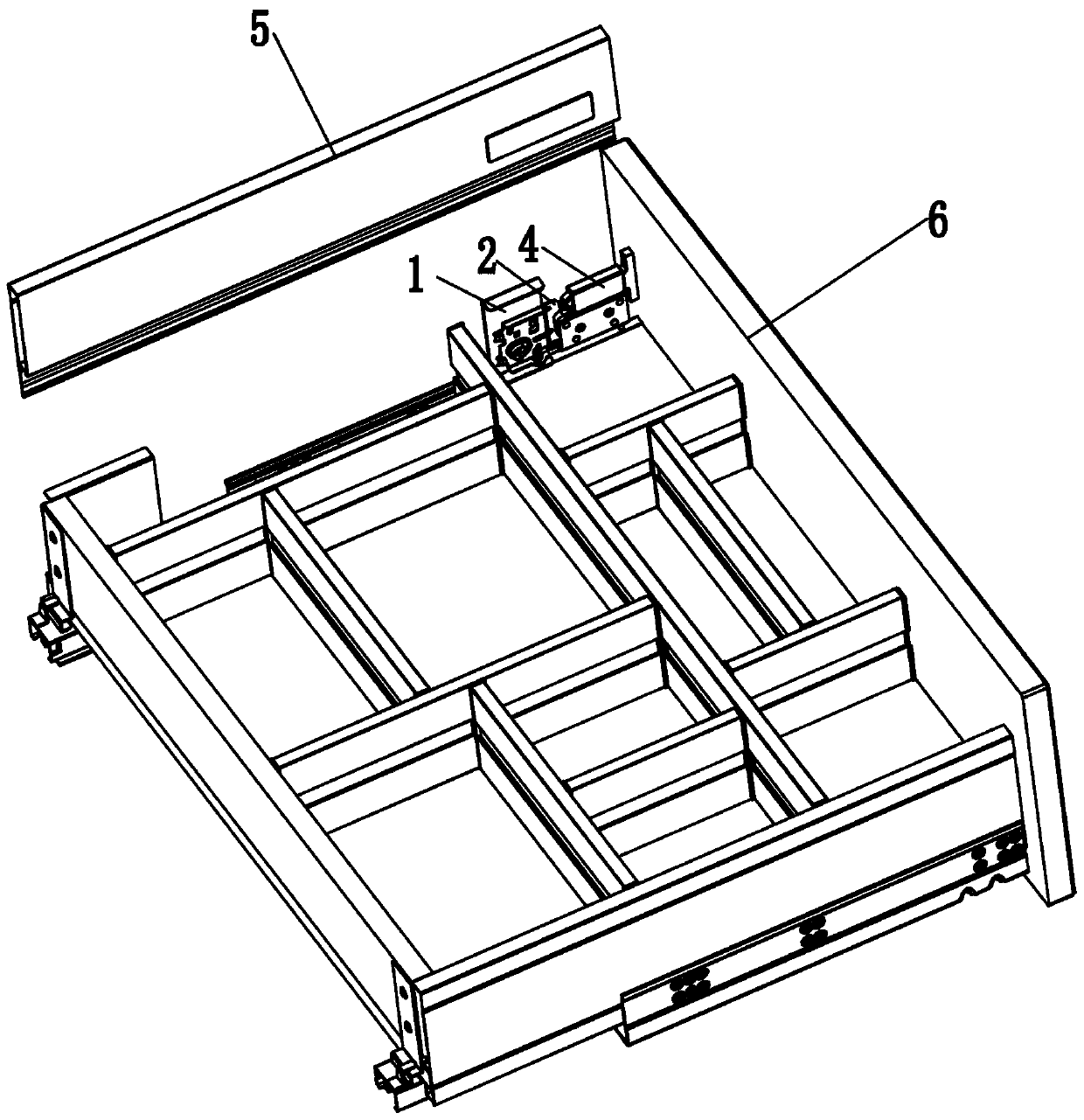

Connecting structure for side plate and face plate of drawer

The invention relates to a connecting structure for a side plate and a face plate of a drawer. The connecting structure comprises a fixed plate, a first movable seat, a second movable seat and a face plate connecting piece, wherein a screw hole, an unlocking hole, a lock tongue accommodating cavity, a sleeve and a locking mechanism are provided on the second movable seat; the locking mechanism comprises a compressed spring and a lock tongue; an opening is formed in the first end of the lock tongue accommodating cavity; the second end of the lock tongue accommodating cavity is communicated with an inner cavity of the sleeve, and the inner wall of the unlocking hole is communicated with the lock tongue accommodating cavity; the lock tongue is slidably arranged in the lock tongue accommodating cavity; a rack is arranged on the lock tongue and is positioned in the unlocking hole; the compressed spring is arranged between the lock tongue accommodating cavity and the lock tongue; the face plate connecting piece is connected with the sleeve in an insertion sleeving manner; the lock tongue extends into a lock groove so as to connect the face plate connecting piece with the second movable seat. The connecting structure is simple and reasonable, the locking mechanism has a firm locking function, unlocking is convenient and easy, and the lock tongue can stably move in or out of the lock groove of the face plate connecting piece, so that the face plate of the drawer and the side plate of the drawer can be quickly assembled and disassembled, and the practicality is high.

Owner:江门市新昊玮五金科技有限公司

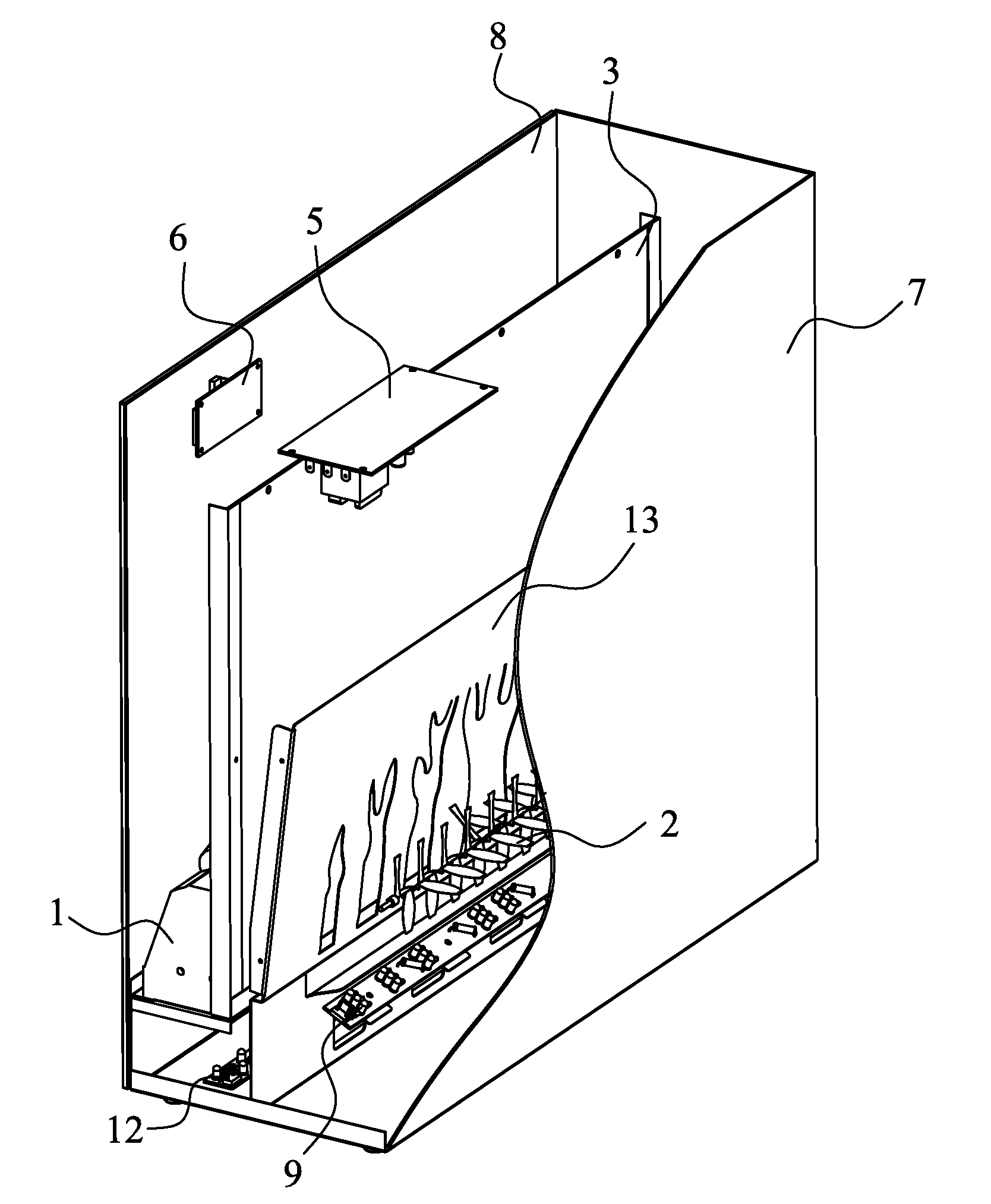

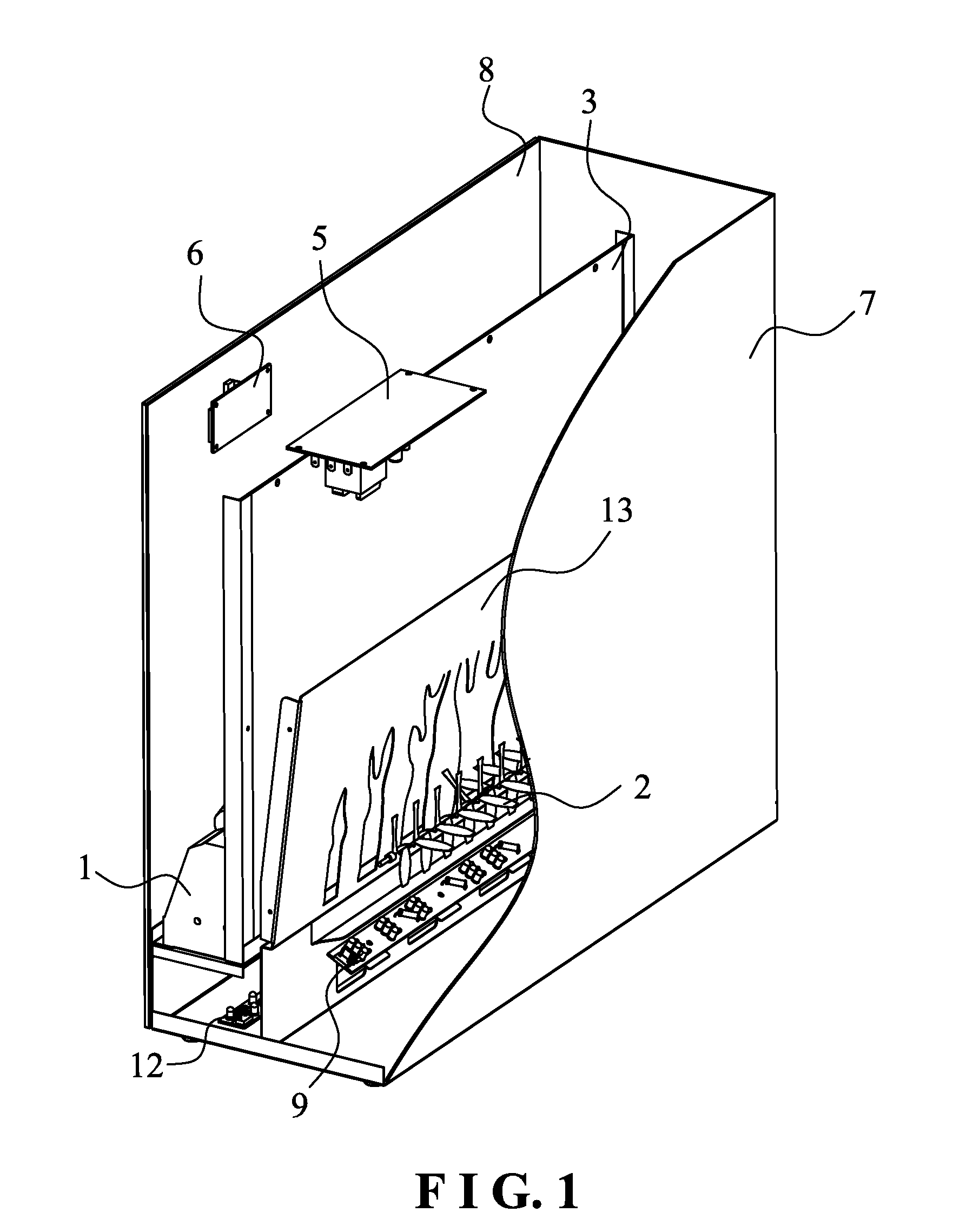

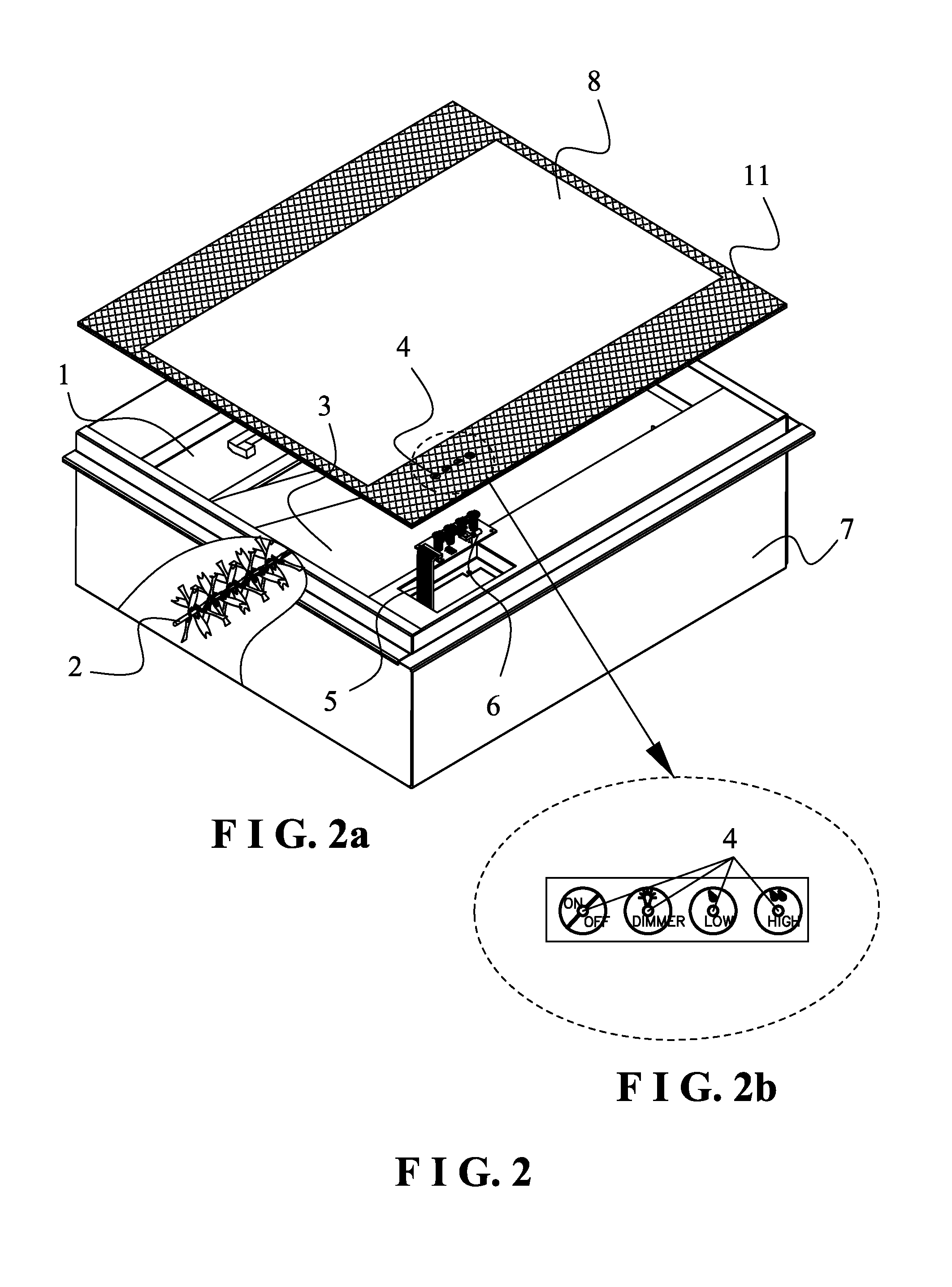

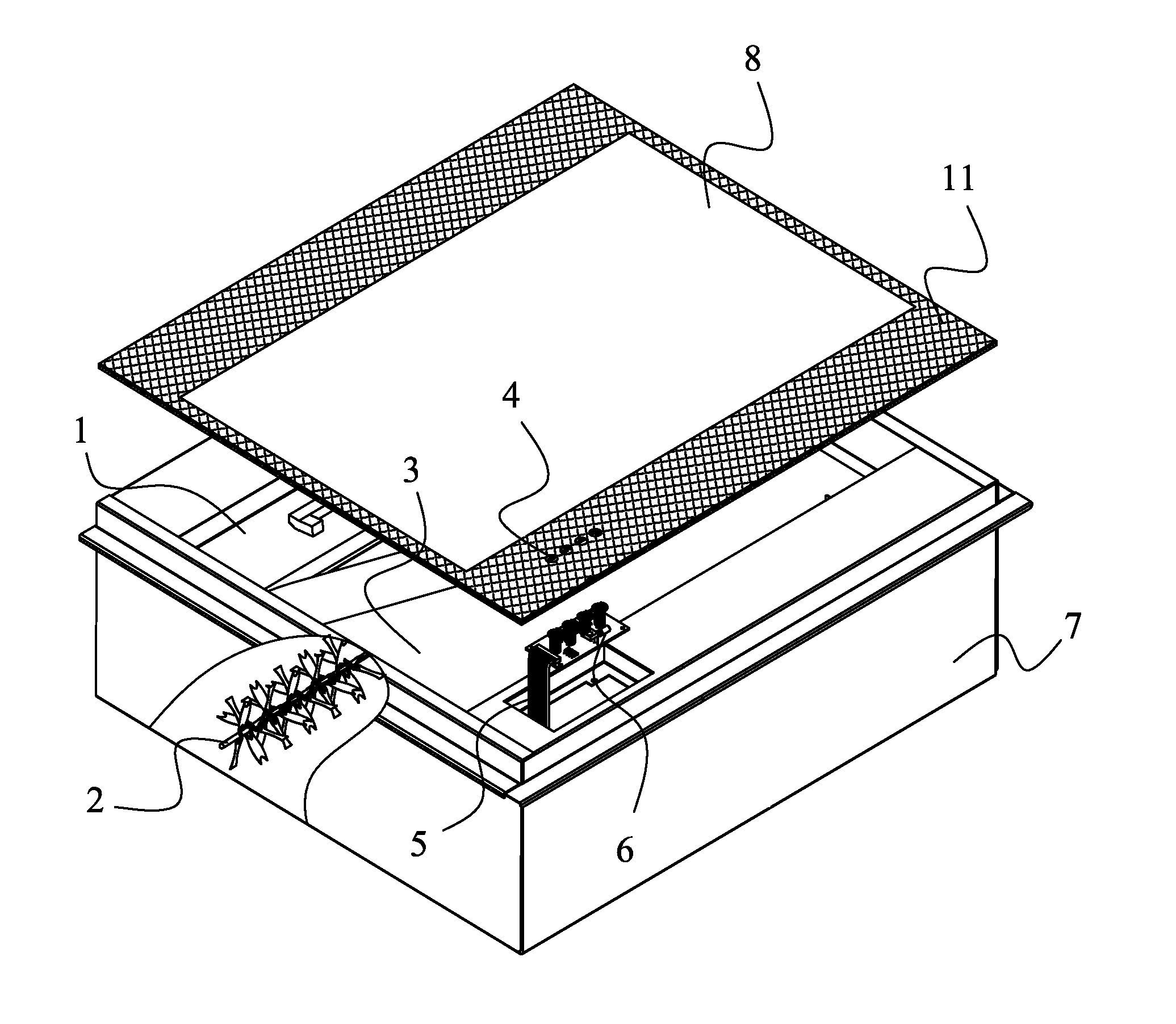

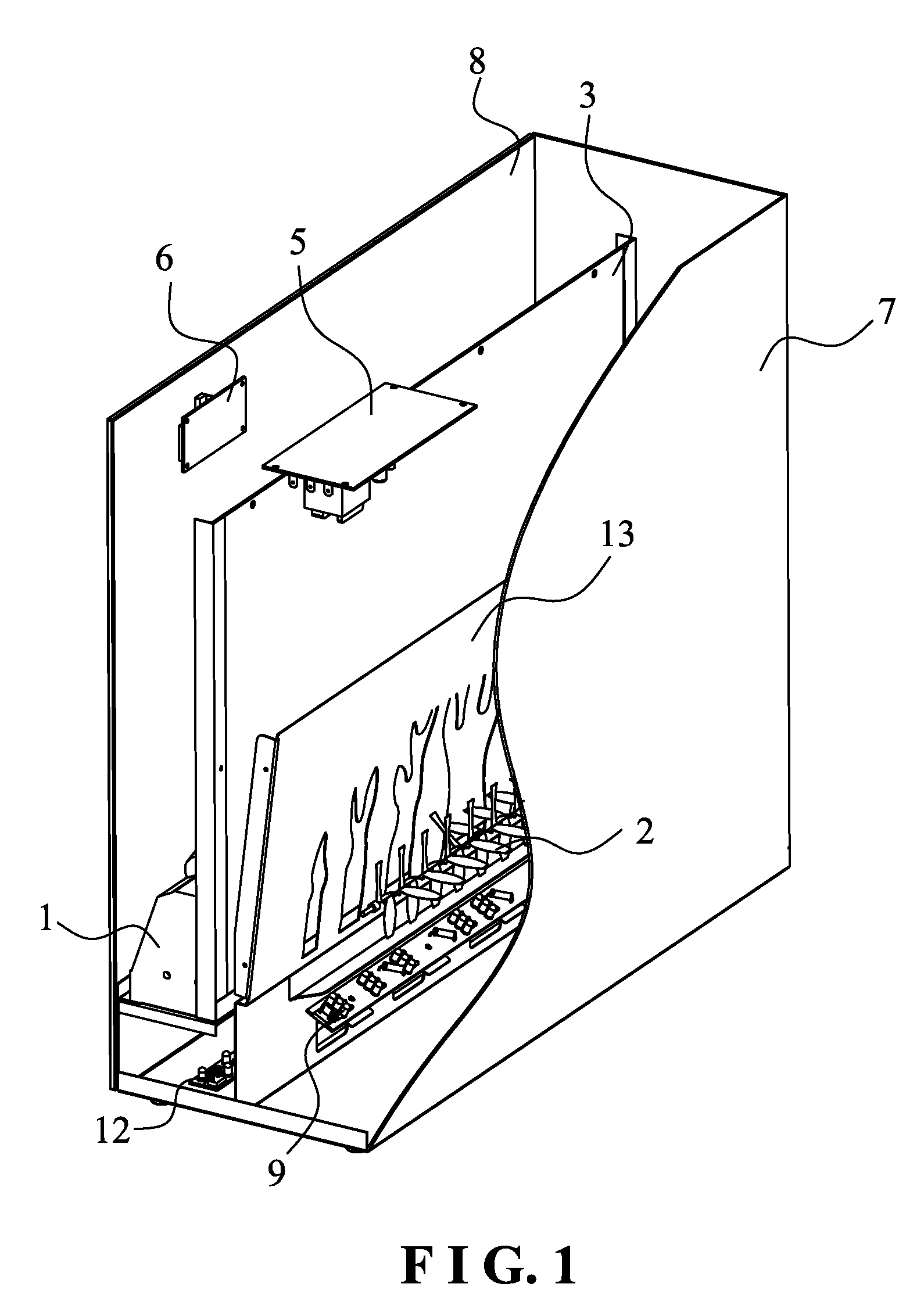

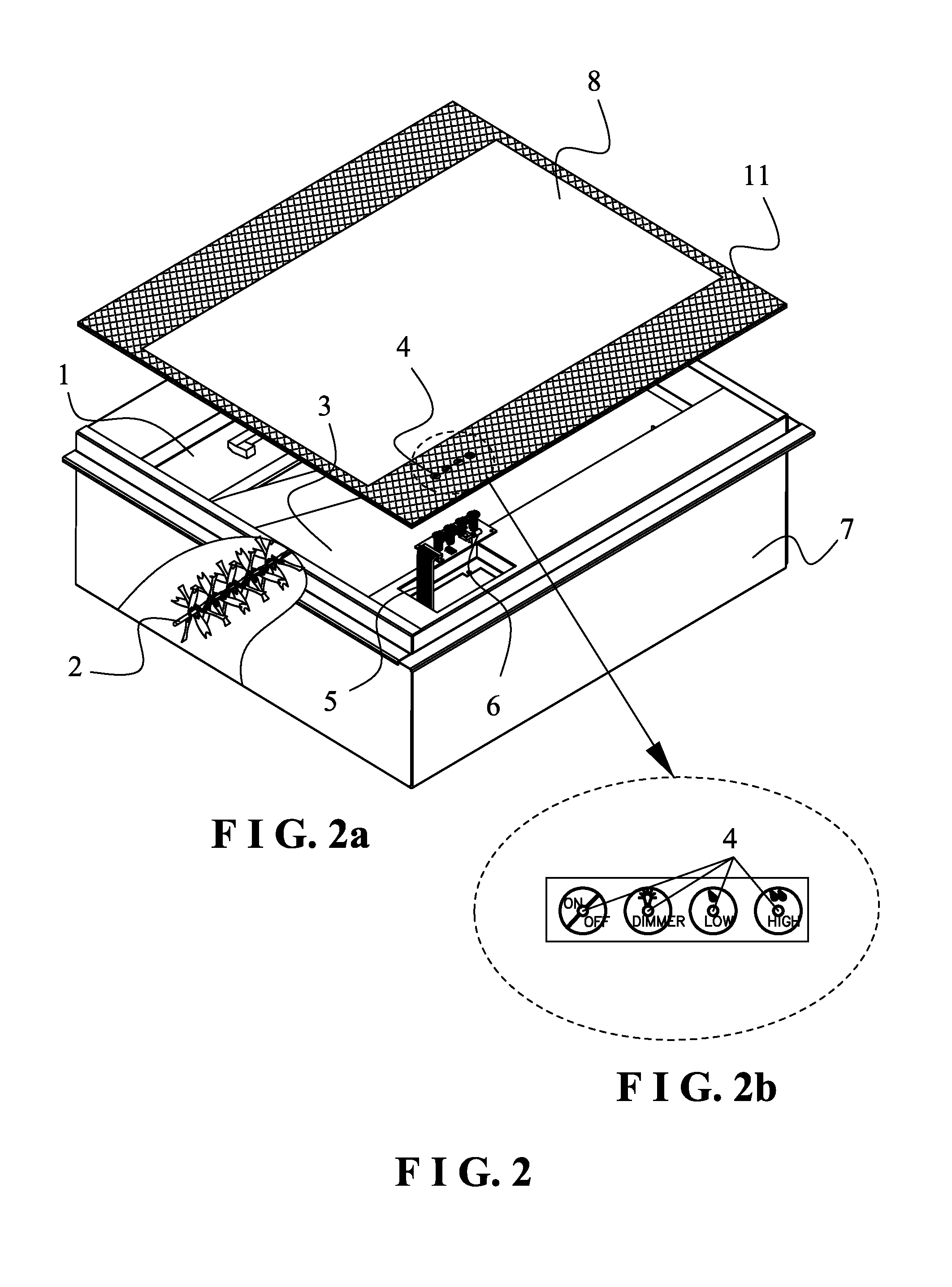

Touch Electric Fireplace

ActiveUS20130077287A1Increased durabilityNeatly assembledDomestic stoves or rangesFurnace componentsElectricityTouchpad

A touch electric fireplace comprises a housing, an imaging screen installed in the housing, a light source, a flame processing device, and a reflecting module. A window is defined on a front wall of the housing, a transparent insulator completely shields the window as well as a rim of the window, a touch area is arranged on the transparent insulator and along the rim of the window, and a touch panel is attached to a front side of the transparent insulator of the touch area; whereby, the electric fireplace is easily operated and controlled by simply touching the touch panel.

Owner:LU MIN HSUN

Wire cutting machine

The invention discloses a wire cutting machine. The machine comprises a winding unit and a cutting unit. The winding unit comprises a support and a roll arranged on the support. A first motor is connected with the roll, an opening is formed in the axial direction of the roll, a first sliding rail is arranged in the roll, a first sliding block is arranged on the first sliding rail, and the cutting unit is arranged on the first sliding block. A cutting sheet of the cutting unit is disposed in the opening. Wheels are arranged at the bottom of the support, and a second motor is connected onto the wheels. By means of the wire cutting machine, the second motor drives the wheels to rotate to enable the whole wire cutting machine to perform translation, and accordingly, wires are wound on the roll uniformly, the cutting sheet is moved at the opening to perform cutting to cut the wires into small uniform sections, a distribution box is in order after assembly, the assembly efficiency is improved, and the consistency of the distribution box after the distribution box is mounted is guaranteed.

Owner:宁波保税区明德工业设计有限公司

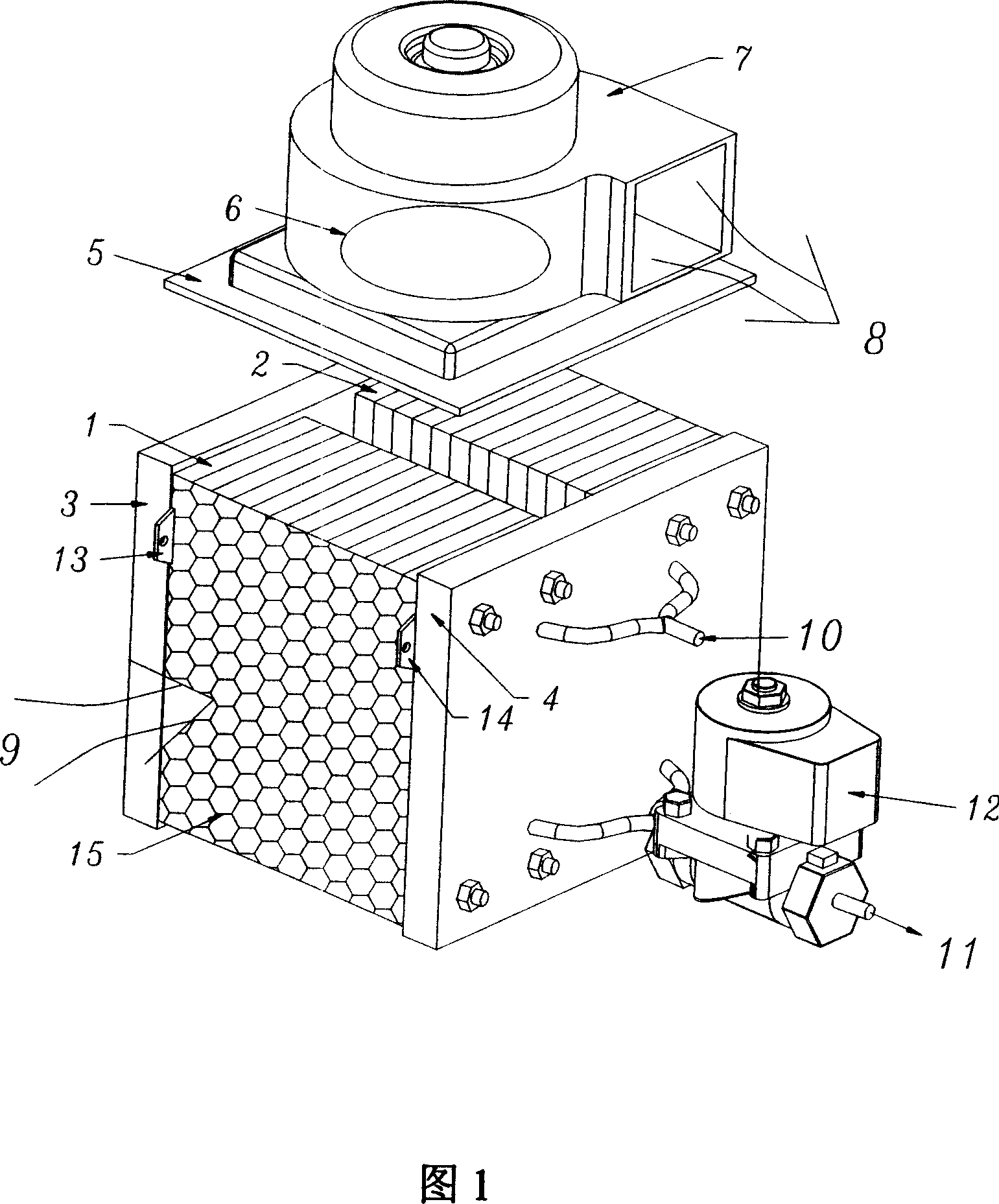

Normal pressure air suction type operation and cooling fuel cell

The related normal-air suction fuel cell comprises: two cell modules shared one front and back end, a set of air supply device on module top, and a set of hydrogen supply device connected with hydrogen inlet and outlet on module ends. Wherein, the air exhaust ends of two modules are set oppositely to form a channel. Compared with prior art, this invention is low cost and compact, and needs less power consumption.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Solenoid valve core component assembly machine

InactiveCN106363400BEfficient assemblyNeatly assembledMetal working apparatusSolenoid valveAssembly machine

The invention discloses an electromagnetic valve iron core assembly assembling machine. The electromagnetic valve iron core assembly assembling machine comprises a four-station rotary disc mechanism, an iron core rod feeding mechanism, a plug feeding mechanism, a hold-down mechanism and a discharging mechanism. The iron core rod feeding mechanism, the plug feeding mechanism, the hold-down mechanism and the discharging mechanism are annularly located on the periphery of the four-station rotary disc mechanism; and four sets of equant iron core rod clamps are arranged on rotary discs of the four-station rotary disc mechanism and are sequentially opposite to the iron core rod feeding mechanism, the plug feeding mechanism, the hold-down mechanism and the discharging mechanism. By means of the above manner, the electromagnetic valve iron core assembly assembling machine can replace manual work to automatically, efficiently and orderly complete assembling of electromagnetic valve iron core assemblies, the labor force is saved, and the production cost is reduced.

Owner:蚌埠煜明电子科技有限公司

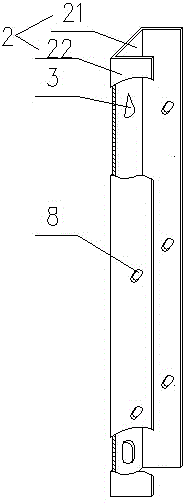

Solderless folding cable support frame

ActiveCN104235505AReduce energy consumptionNo pollution in the processPipe supportsEngineeringStructural engineering

Owner:江苏华雄电气有限公司

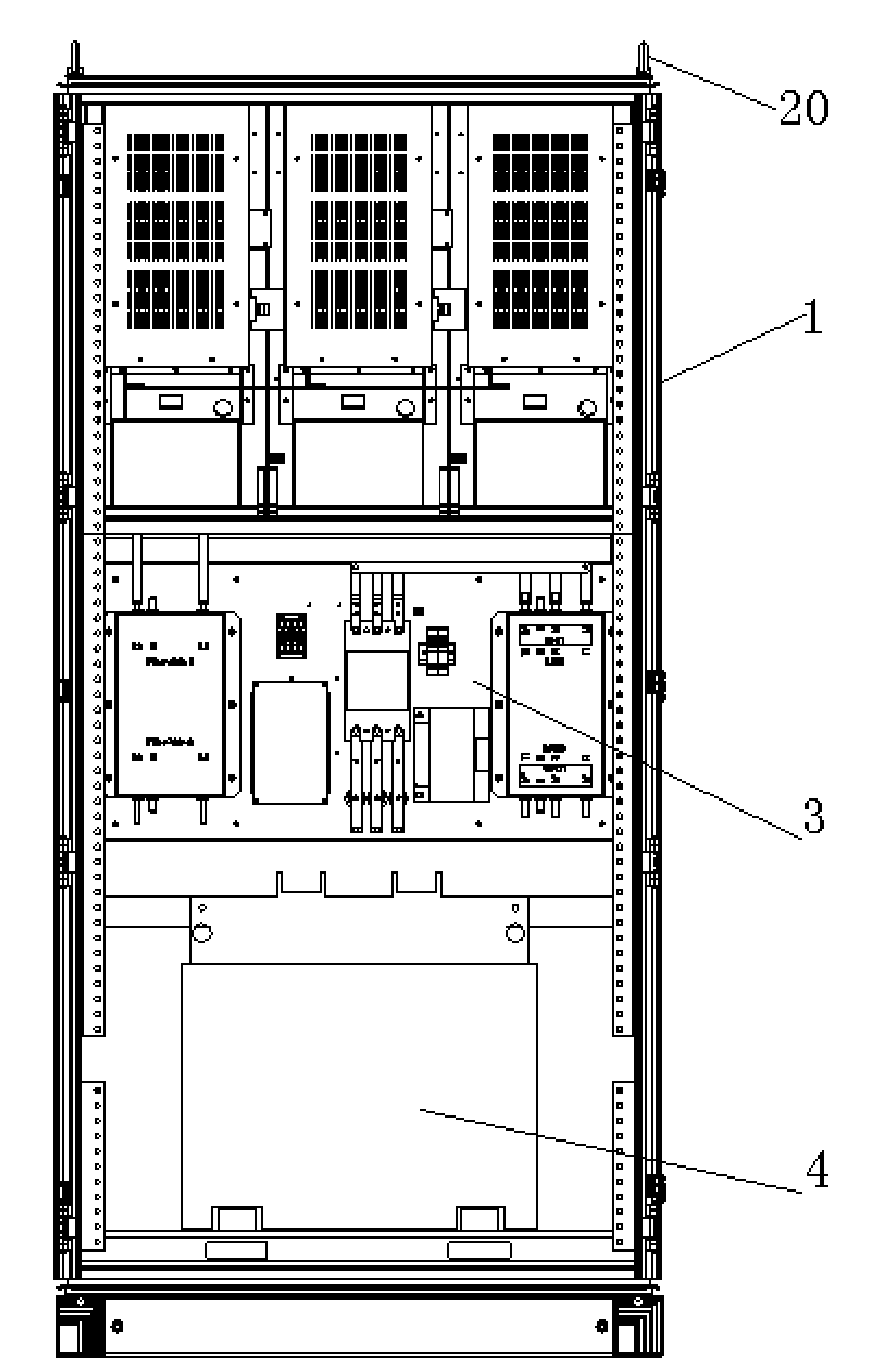

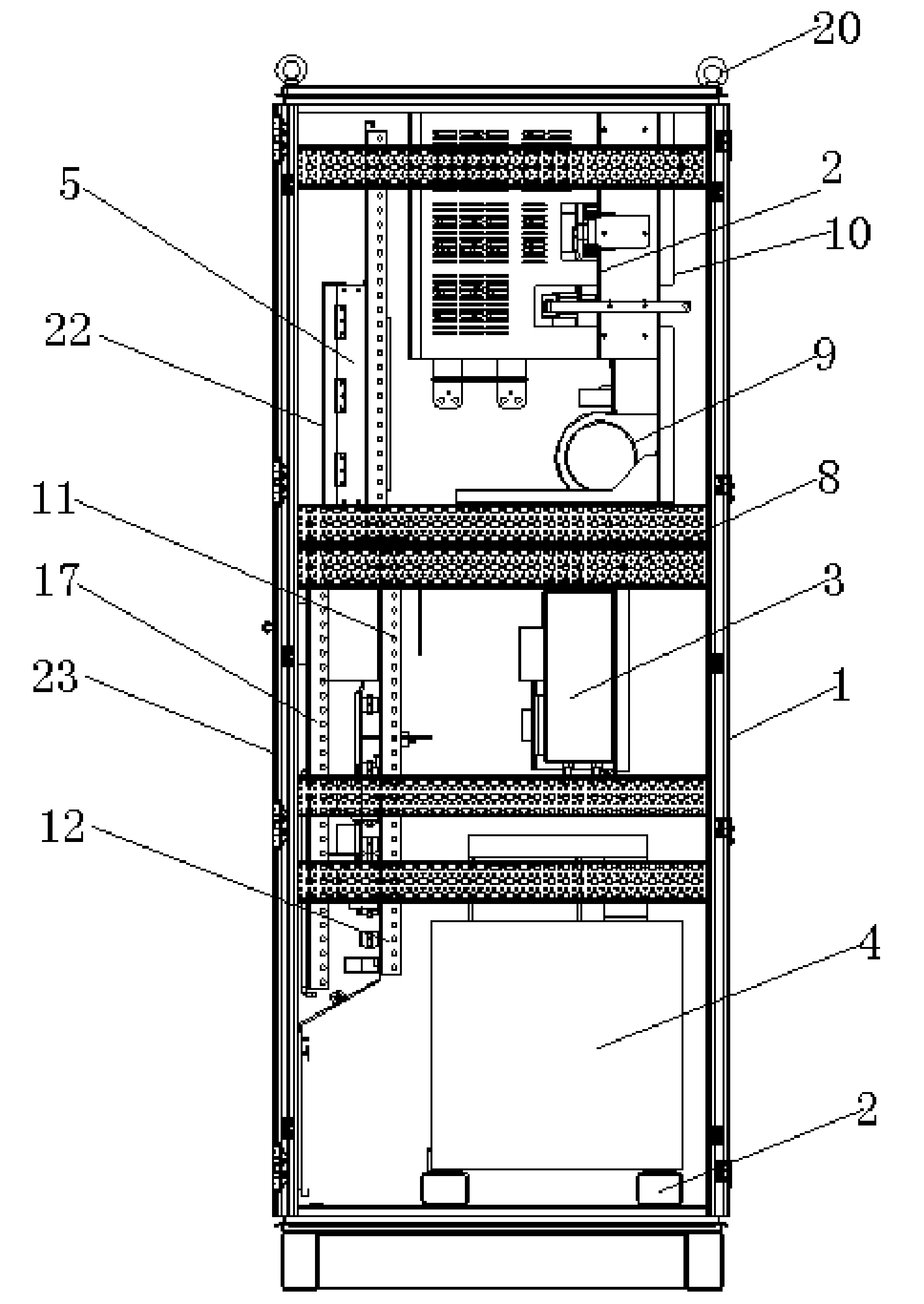

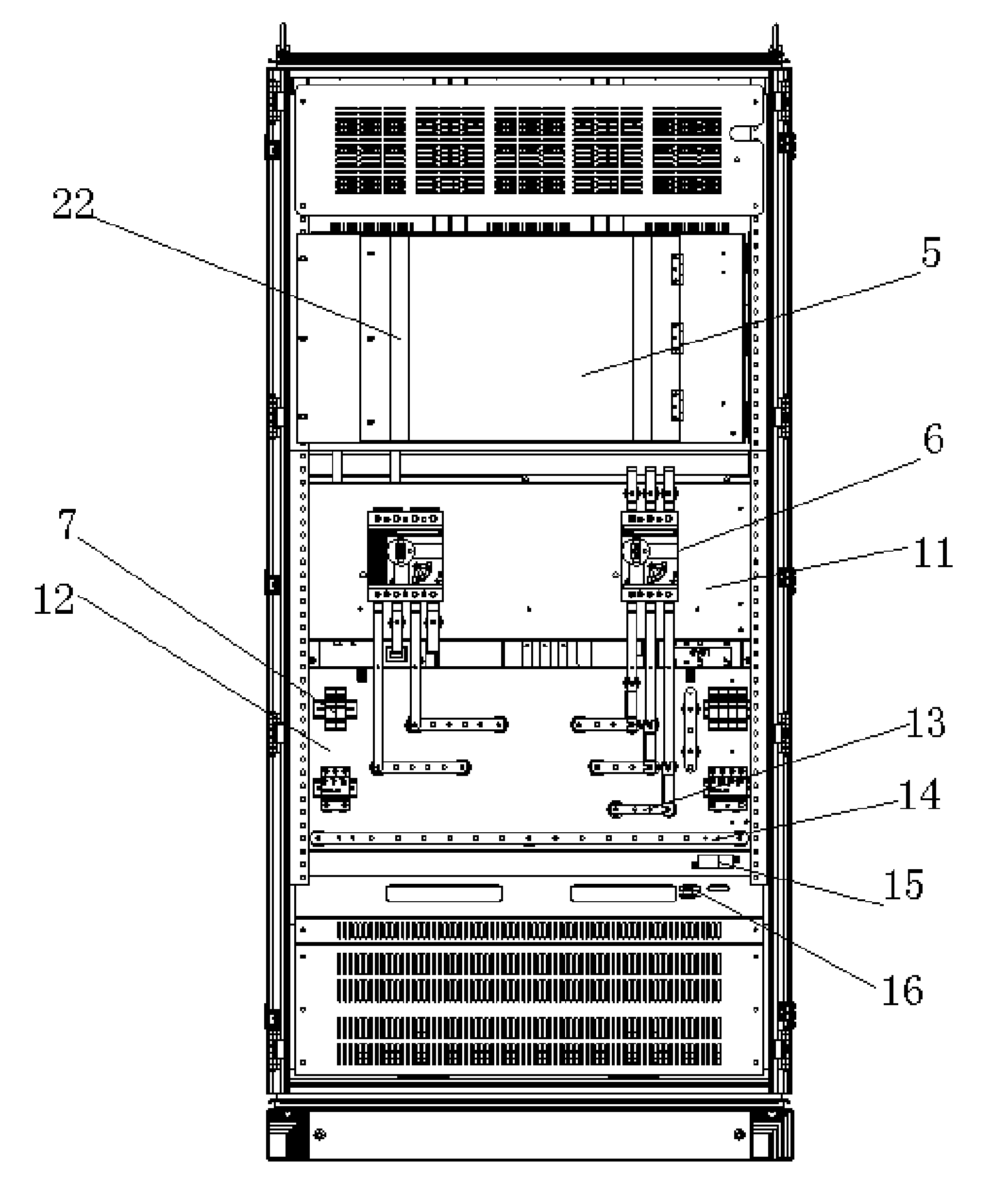

Photovoltaic inverter

InactiveCN102158054AEasy assembly and maintenanceNeatly assembledMagnetic/electric field screeningPhotovoltaic energy generationContactorEngineering

The invention relates to a photovoltaic inverter which comprises a cabinet body, a power module, a filter module, a transformer module, a control plate module, a circuit breaker and a contactor, wherein the power module is arranged in the cabinet body; a plurality of beams for supporting and fixing the power module, the filter module and the transformer module are arranged in the cabinet body; the transformer module is arranged at the lowest part in the cabinet body; the filter module, the contactor and the circuit breaker are arranged on the transformer module; the power module and the control plate module are arranged at the uppermost part in the cabinet body; the power module is arranged on a fixed panel of the power module; the lower end of the power module is provided with a heat radiator; the fixed panel of the power module is fixed to a fixed beam of the power module in the cabinet body; the control plate module is arranged in the front of the power module in the cabinet body; the filter module is arranged on the fixed beam of the filter module under the power module; the circuit breaker is arranged on an installation panel of the circuit breaker; the installation panel of the circuit breaker is arranged under the control plate module; the contactor is arranged on a copper plate installation panel; the copper plate installation panel is arranged under the installation panel of the circuit breaker; a copper plate is connected with the circuit breaker; the contactor is connected with the circuit breaker by a lead; and a ground lead copper plate is arranged on the copper plate installation panel.

Owner:CHANGZHOU GIANTION PHOTOELECTRICITY IND DEV

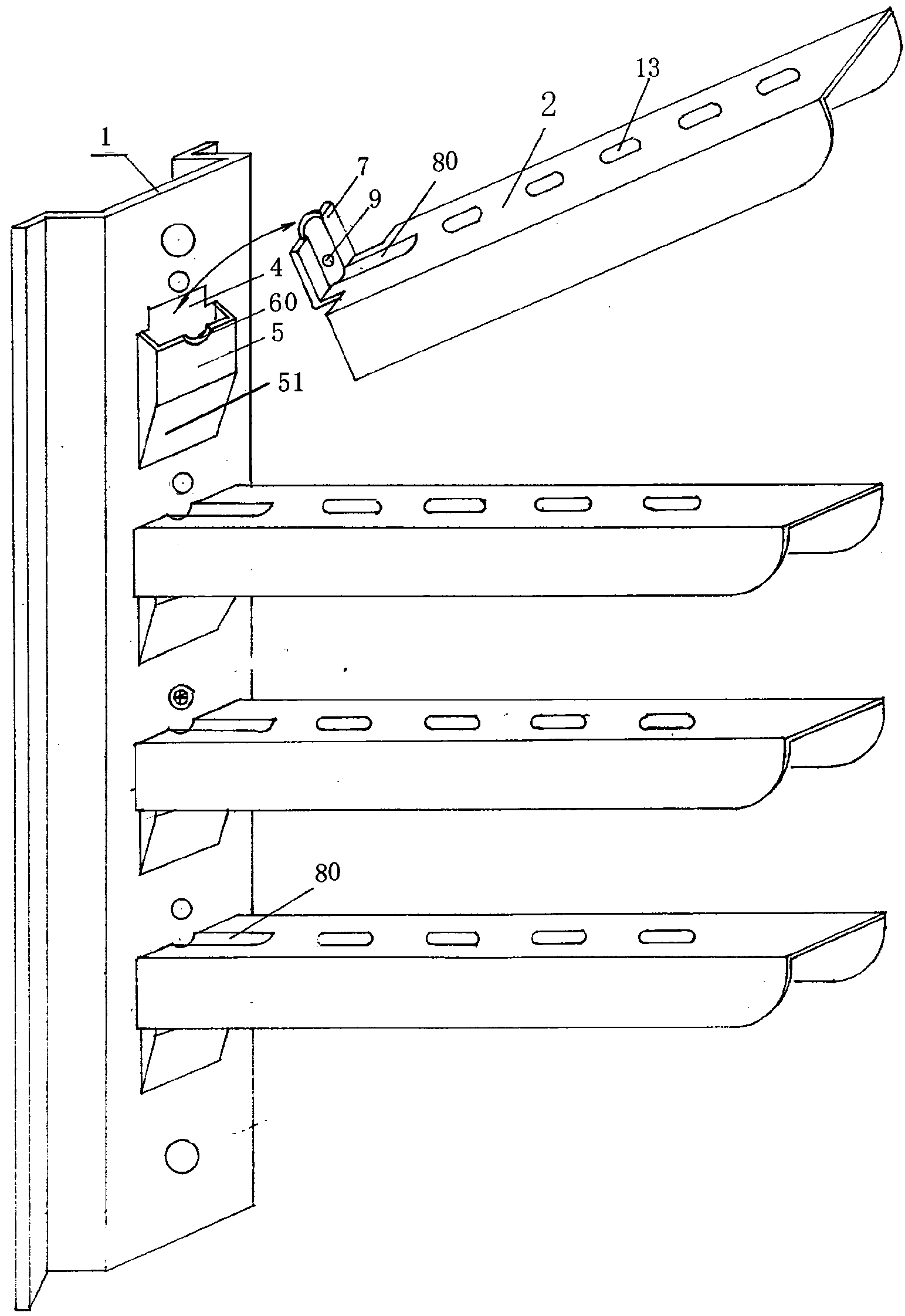

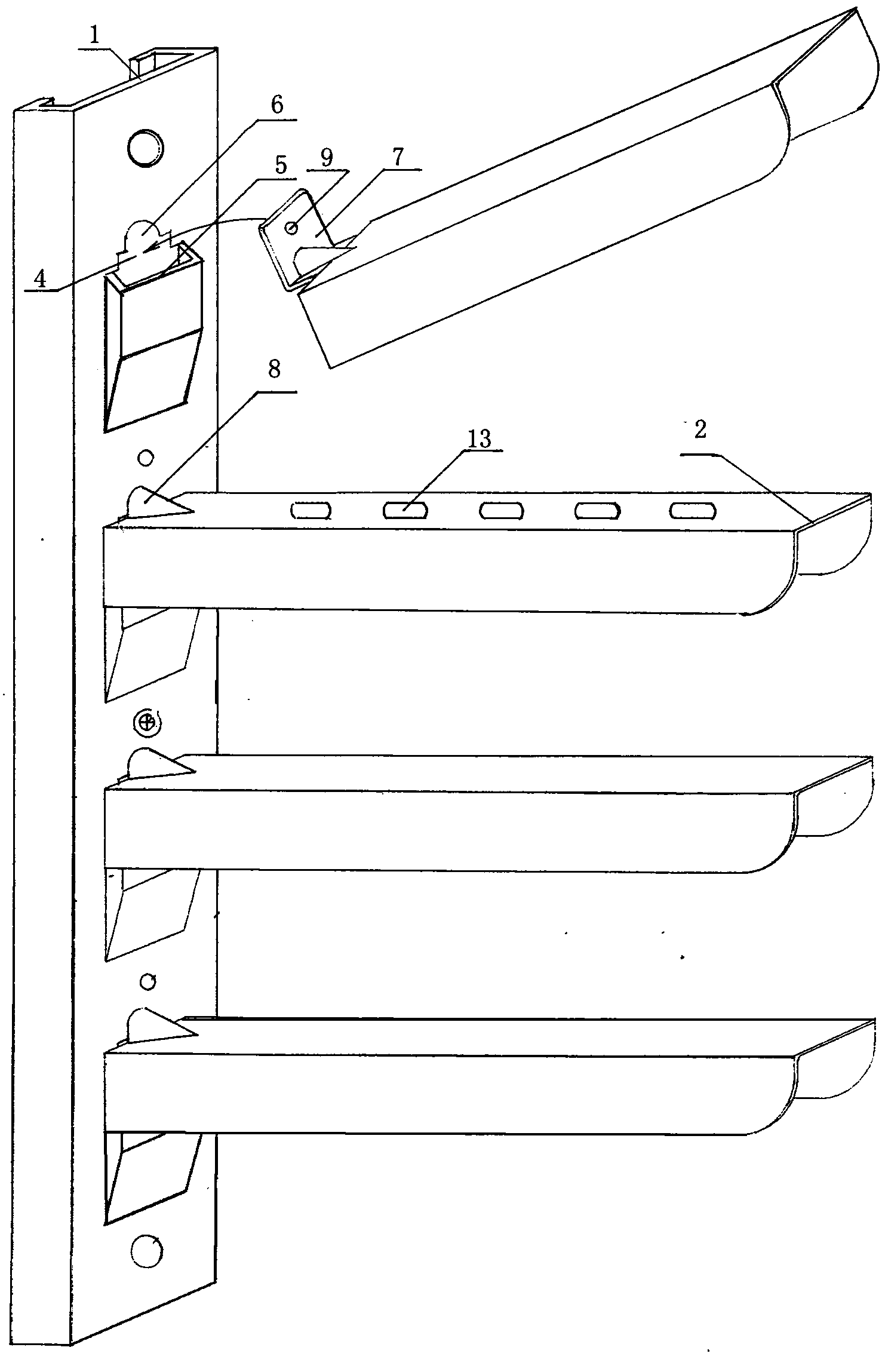

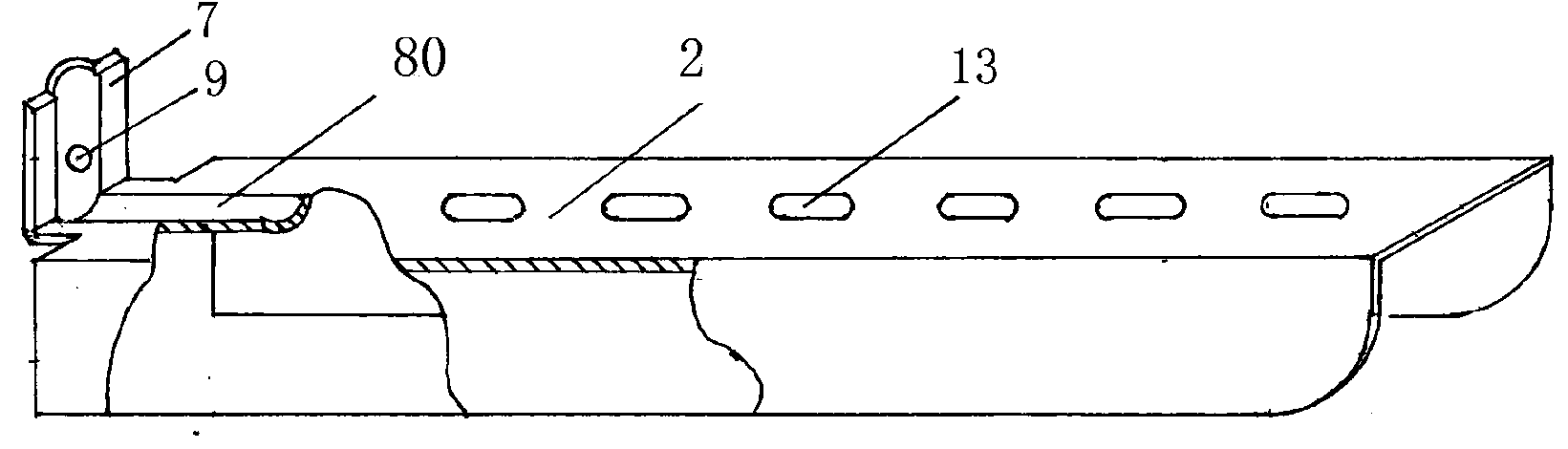

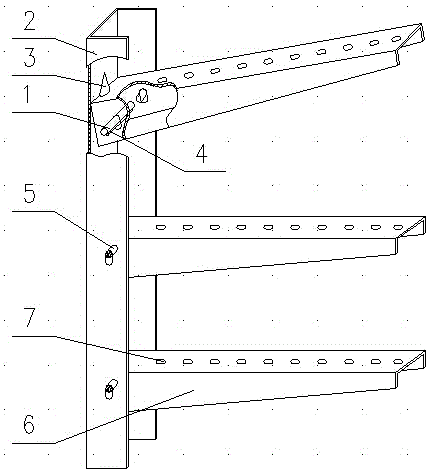

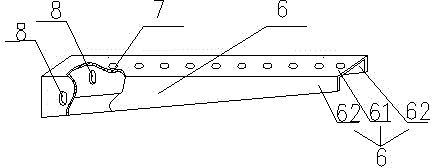

Novel welding-free detachable bracket

InactiveCN104810776AEnsure connection stabilityAvoid poor compatibilityCable installations on groundBuilding constructionWelding

The invention relates to a novel welding-free detachable bracket, which comprises a bracket vertical column and bracket support cross beams, and is characterized in that the bracket vertical column is C-shaped in cross section and of an integrated structure; the bracket vertical column is provided with convex positioning force points and hinge pin positioning force points; the convex positioning force points are located on a main body of the bracket vertical column; the hinge pin positioning force points are kidney-shaped holes and obliquely arranged at a side edge of the bracket vertical column; the cross section of each bracket support cross beam is of a U-shaped structure, a main plate of each bracket support cross beam is provided with a plurality of cable buckling holes, a protection plate of each bracket support cross beam is trapezoid-shaped, and each bracket support cross beam is provided with hinge pin locking force points; the bottom ends of the bracket support cross beams are located in the bracket vertical column in a sleeved mode, the initial end of each bracket support cross beam is located below the convex positioning force point, the bracket vertical column and the bracket support cross beam are provided with a hinge pin therebetween, the hinge pin penetrates through the hinge pin positioning force point and the hinge pin locking force point so as to enable the bracket support cross beam and the bracket vertical column to realize pressing, pulling and buckling structural connection. The bracket provided by the invention forms a detachable mode free of electrical welding, can carry out cross operations, is convenient to install, shortens the construction period, reduces the transshipment burden and has good compatibility for construction coordination.

Owner:JIANGSU TENGYU ELECTRIC ENERGY EQUIP CO LTD

Connection structure between drawer side panels and panels

The invention relates to a connecting structure for a side plate and a face plate of a drawer. The connecting structure comprises a fixed plate, a first movable seat, a second movable seat and a face plate connecting piece, wherein a screw hole, an unlocking hole, a lock tongue accommodating cavity, a sleeve and a locking mechanism are provided on the second movable seat; the locking mechanism comprises a compressed spring and a lock tongue; an opening is formed in the first end of the lock tongue accommodating cavity; the second end of the lock tongue accommodating cavity is communicated with an inner cavity of the sleeve, and the inner wall of the unlocking hole is communicated with the lock tongue accommodating cavity; the lock tongue is slidably arranged in the lock tongue accommodating cavity; a rack is arranged on the lock tongue and is positioned in the unlocking hole; the compressed spring is arranged between the lock tongue accommodating cavity and the lock tongue; the face plate connecting piece is connected with the sleeve in an insertion sleeving manner; the lock tongue extends into a lock groove so as to connect the face plate connecting piece with the second movable seat. The connecting structure is simple and reasonable, the locking mechanism has a firm locking function, unlocking is convenient and easy, and the lock tongue can stably move in or out of the lock groove of the face plate connecting piece, so that the face plate of the drawer and the side plate of the drawer can be quickly assembled and disassembled, and the practicality is high.

Owner:江门市新昊玮五金科技有限公司

Electronic drain valve assembly equipment

The invention discloses assembly equipment for an electronic drain valve. The assembly equipment for the electronic drain valve comprises a box-type rack, a body loading mechanism, a transposition mechanism, a sealing ring loading mechanism, a rotary valve column loading mechanism, a ball valve element loading mechanism, a ball valve switch loading mechanism, a process sealing head loading mechanism, a sealing head sealing ring loading mechanism, an assembly mechanism, a blow-down sealing cover loading mechanism and a filter screen loading mechanism, wherein the body loading mechanism is used for conveying a body to the transposition mechanism at the rear side of the body loading mechanism; the sealing ring loading mechanism, the rotary valve column loading mechanism, the ball valve element loading mechanism, the ball valve switch loading mechanism, the process sealing head loading mechanism and the sealing head sealing ring loading mechanism are used for sequentially conveying a workpiece to the transposition mechanism; and the transposition mechanism is used for conveying the assembled workpiece to the assembly mechanism at the front side of the transposition mechanism. Through the abovementioned manner, the assembly equipment for the electronic drain valve, which is disclosed by the invention, is capable of replacing manual operation, and automatically, efficiently and regularly completing assembly for the electronic drain valve, thus saving the labour and reducing the production cost.

Owner:JIANGSU RONGYUAN CASTING CO LTD

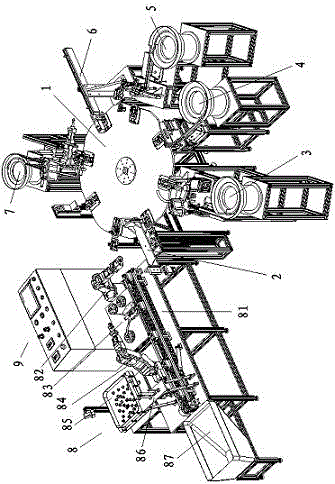

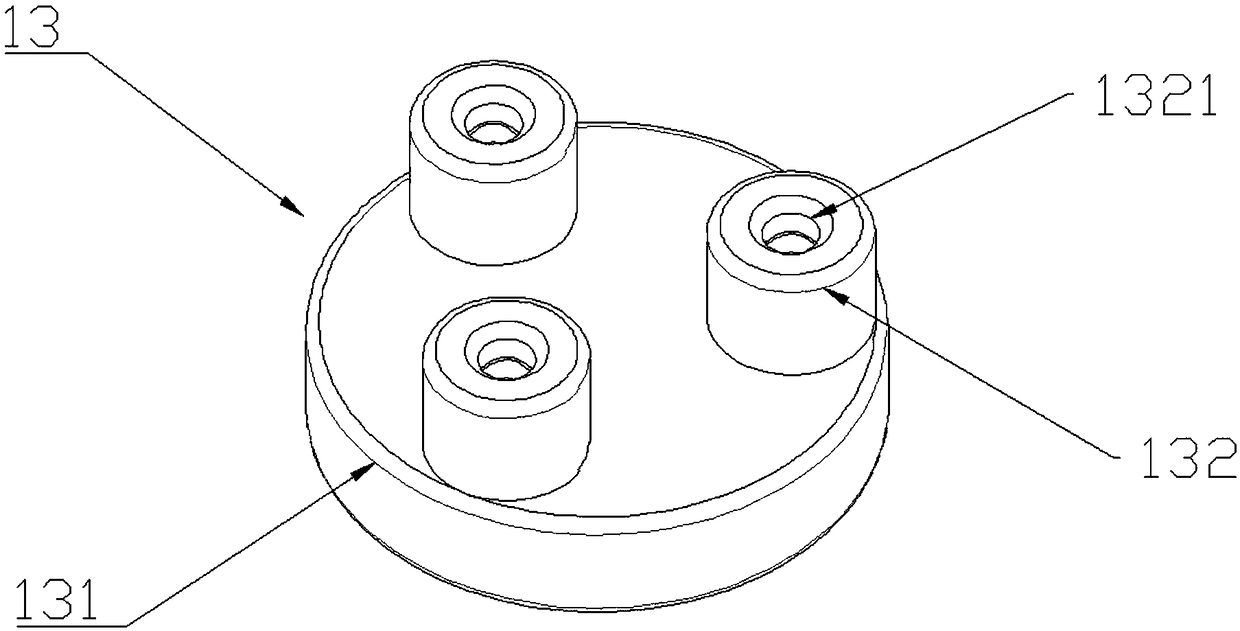

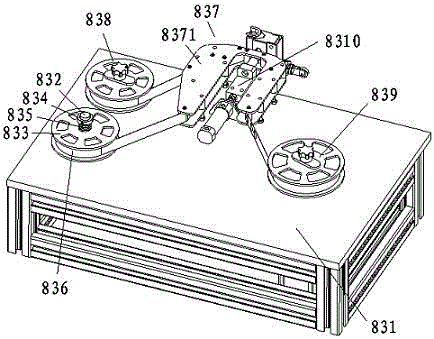

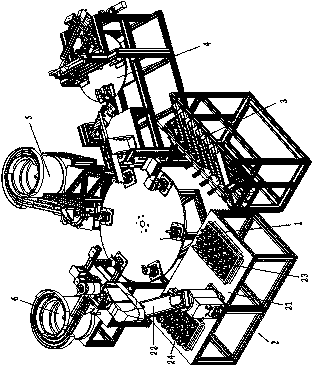

Automatic assembling machine of razor base

InactiveCN108890282AAutomate assemblyEfficient assemblyAssembly machinesMetal working apparatusElectric machineryDrive motor

A machine for automatically assemble a razor base comprises a gear shaft feeding mechanism, the automatic assembling machine further comprises an eight-station turntable mechanism (1), A load mechanism (3) for that waterproof board, A waterproof plate oiling mechanism (4) The eight-station turntable mechanism (1) comprises a direct drive motor (9) for controlling rotation, and the mechanism is annularly positioned around the eight-station turntable mechanism (1) and sequentially transports workpieces to the eight-station turntable mechanism (1). The eight-station turntable mechanism (1) comprises a water-proof ring feeding mechanism (5), a connecting bracket feeding pre-loading mechanism (6), a connecting bracket pressing mechanism (7) and a feeding mechanism (8). The invention can replacemanual automation, efficiently complete the assembly of the razor holder, save labor and reduce the production cost.

Owner:可瑞昶科技(苏州)有限公司

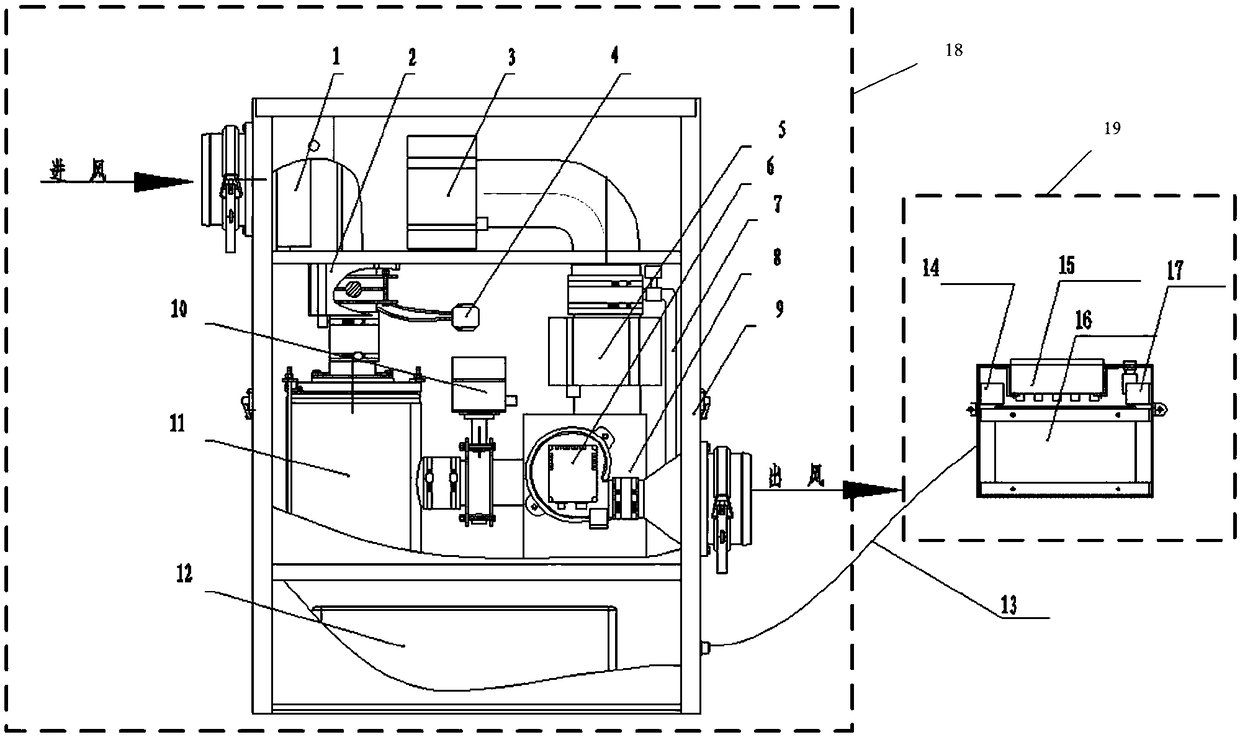

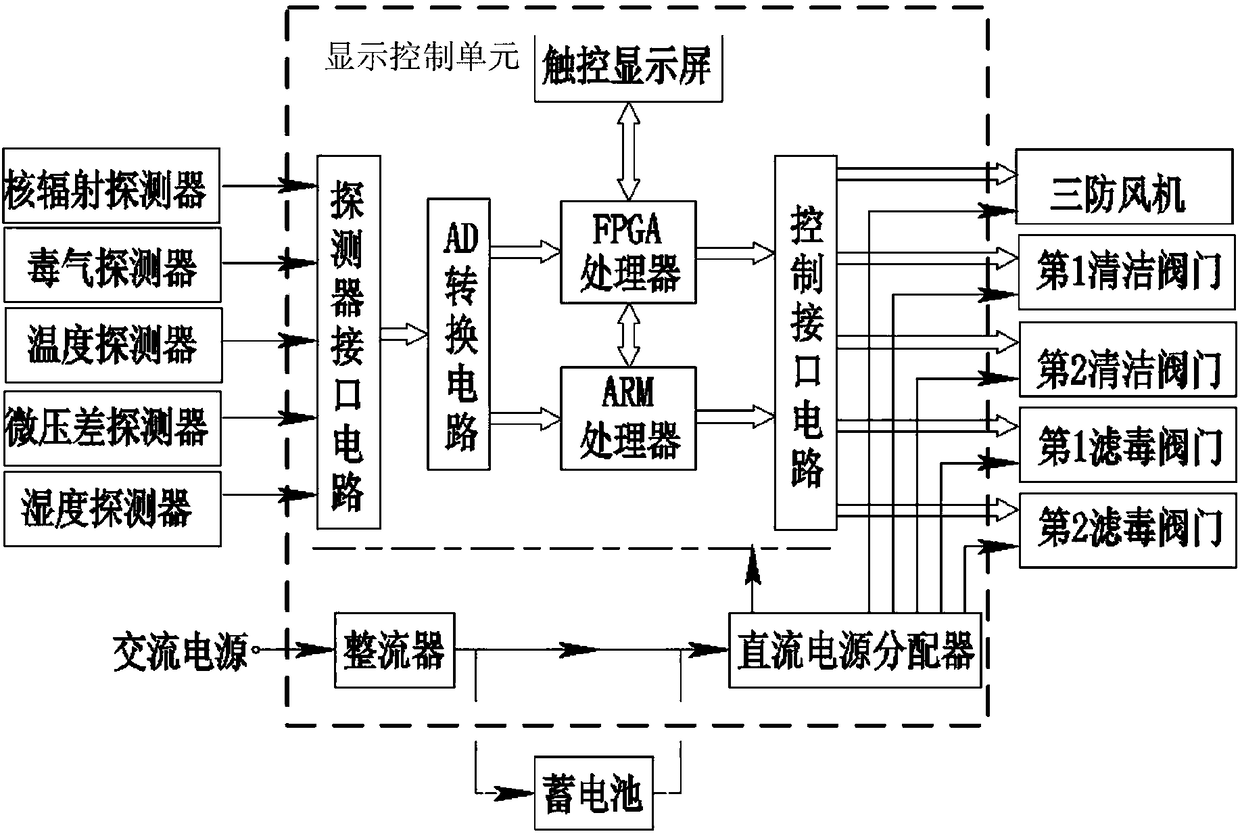

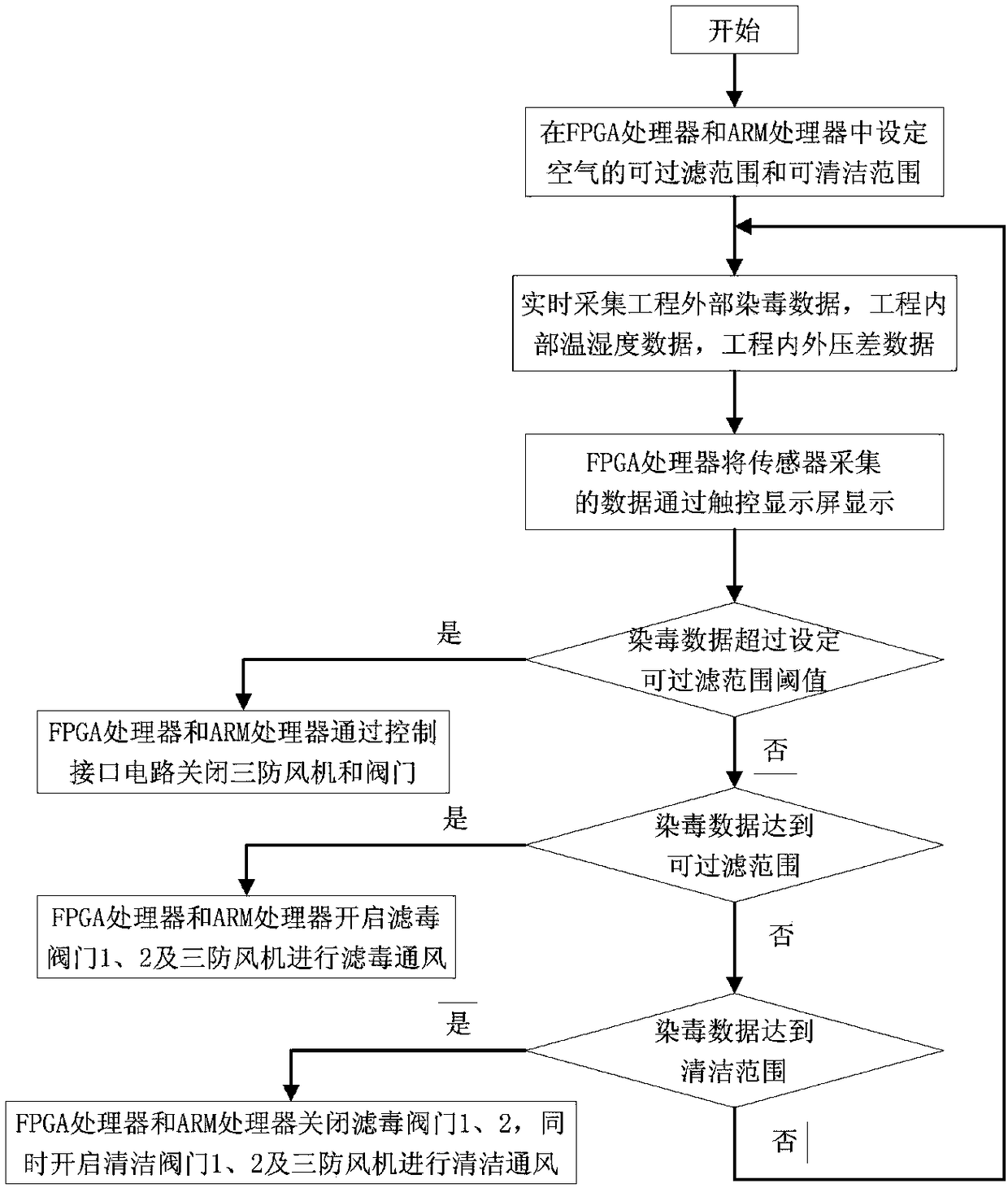

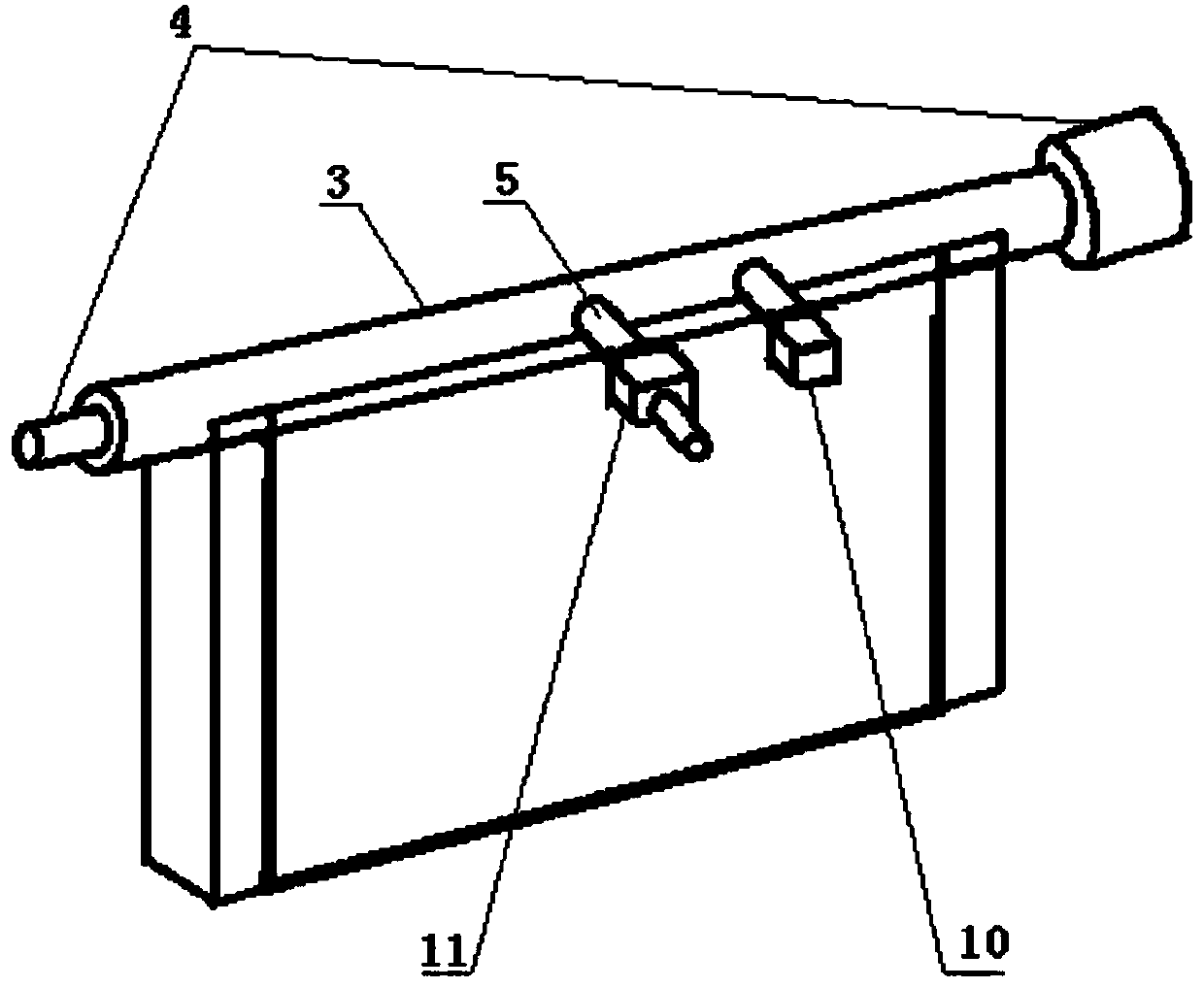

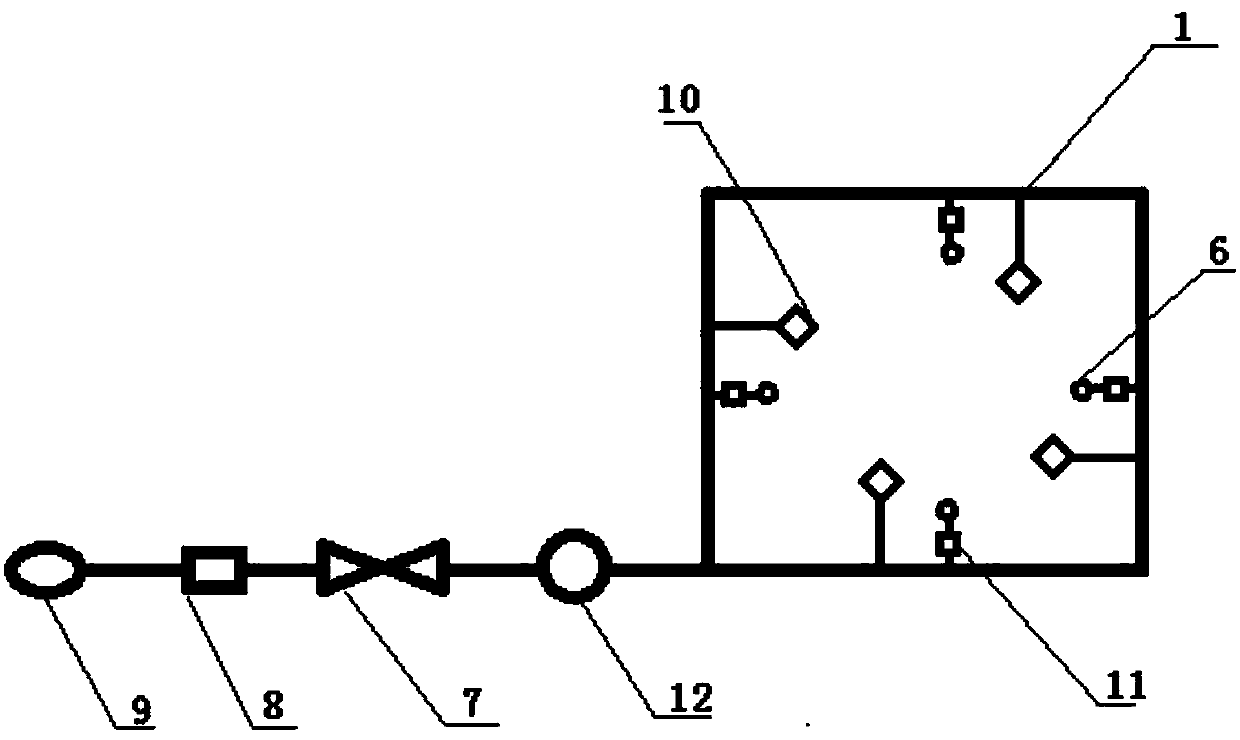

Protection ventilation device and method

PendingCN108072143AReasonable designEfficient and reliable performanceSpace heating and ventilation safety systemsLighting and heating apparatusAir filtrationControl system

The invention discloses a protection ventilation device and a method, and belongs to the technical field of protection engineering. The protection ventilation device comprises a display control unit and a ventilation cabinet unit, the display control unit comprises a control interface circuit, a rectifier and a direct-current power supply distributor, a detector interface circuit, an AD conversioncircuit, an FPGA processor, an ARM processor and a touch display screen; the ventilation cabinet unit comprises a cabinet body, a filter, a first cleaning valve, a second cleaning valve, a three-proofing machine, a three-way box assembly, a first filter valve, a second filter valve, a micro differential pressure detector and a filter absorber, wherein the first cleaning valve, the second cleaningvalve, the three-proofing machine, the three-way box assembly, the first filter valve, the second filter valve, the micro differential pressure detector and the filter absorber are arranged in the cabinet body; air filtration and ventilation equipment, the ventilation and conversion control system are integrated into a whole, the performance is efficient and reliable, and the assembly is convenient; automatic ventilation operation at ordinary time and working time of small protection engineering is achieved; various toxic agents can be effectively removed in the attack of the nuclear and biochemical weapon; the detection, the automatically converted operation modes, state display function is integrated, the intelligent degree is high, and the operation is convenient; the double-power-supply power supply is adopted, so that the operation is reliable.

Owner:中国人民解放军北部战区陆军第二工程科研设计所

Fence construction method and fence module with self-test type spraying device for pipe

The invention relates to the field of dust fall in a construction site, in particular to a fence construction method and a fence module with a self-test type spraying device for a pipe. The fence module includes at least a fence plate, fence columns and spraying pipes, the spraying pipes are hose and / or hard pipe, one or above connecting pipe is arranged in the middle of the pipe walls of the spraying pipes, and an electromagnetic valve is arranged on the connecting pipes; quick joints are arranged at both ends of the spraying pipes, the fence columns are connected with two ends of the fence plate, grooves are formed in the fence plate and the upper ends of the fence columns, the sizes of the grooves are matched with the sizes of the spraying pipes, dust sensors are arranged on the pipe walls of the spraying pipes, the spraying pipes are connected with each other to form a spraying pipeline, and a pressure sensor is installed on the spraying pipeline. The flying dust situation in the vicinity of a fence is monitored in real time by the dust sensors in the technical scheme, and dust fall can be targeted to the area requiring to be sprayed; the pressure of the spraying pipeline is monitored by the pressure sensor, when it is detected that the pressure of the spraying pipe is not within the range of normal pressure values, an intelligent terminal will have abnormal prompts, and alarms are issued by an alarm device.

Owner:WUHAN CUIYU ENVIRONMENTAL TECH

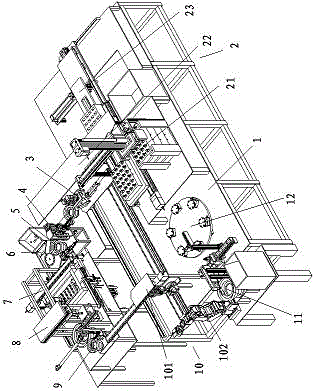

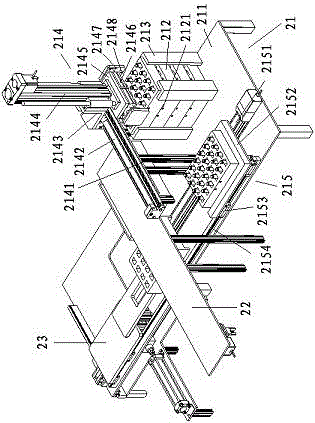

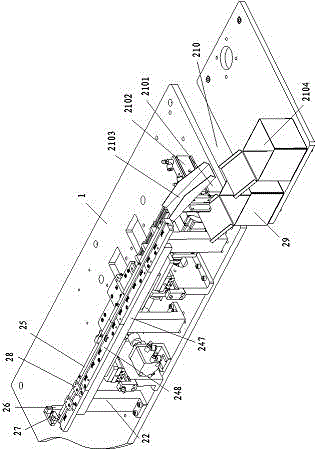

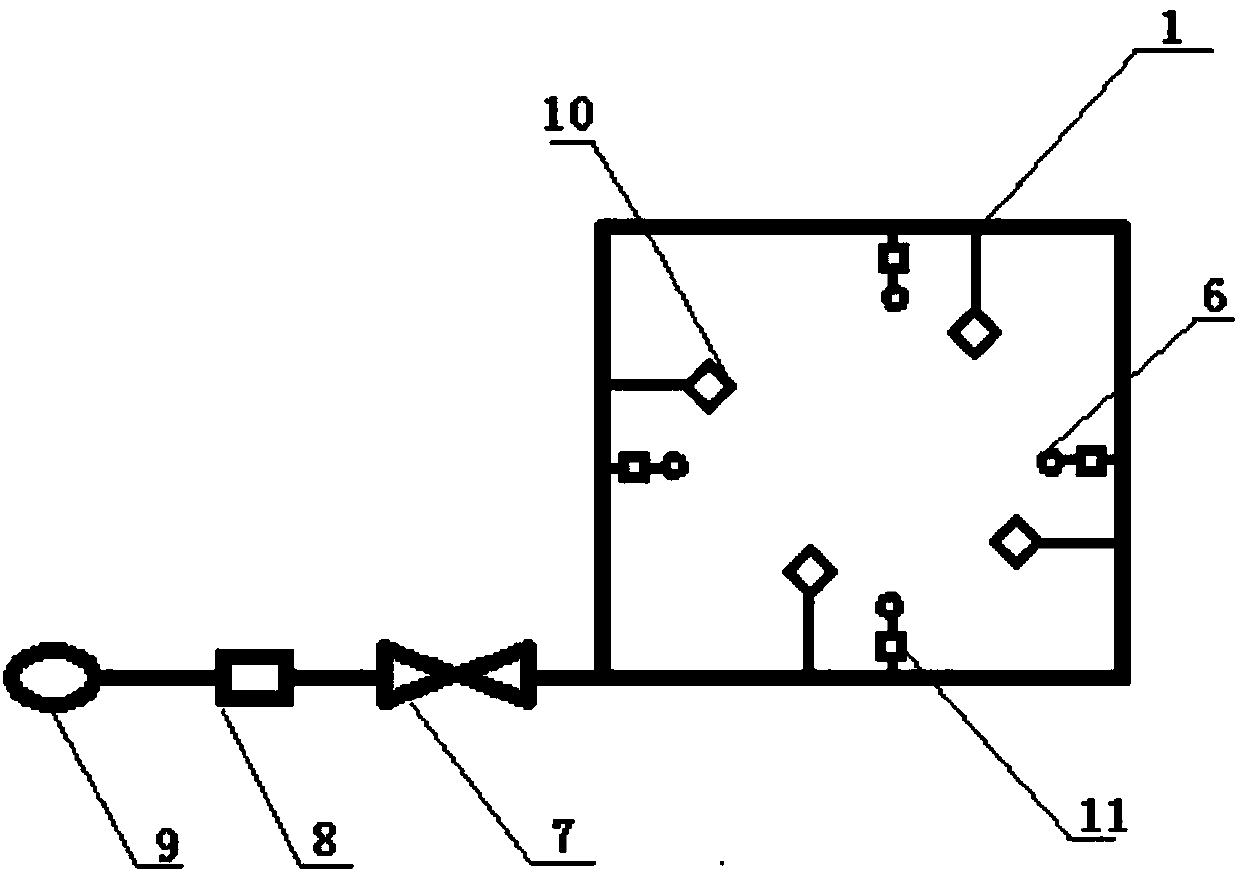

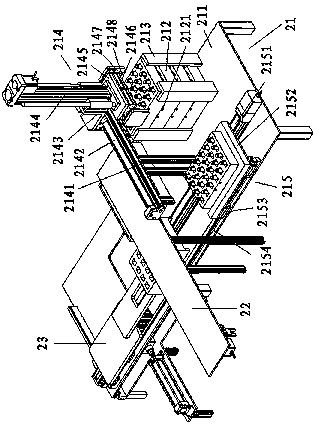

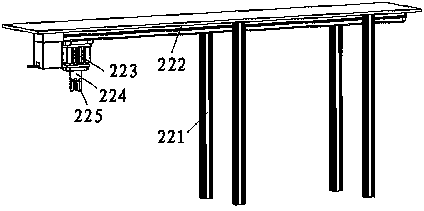

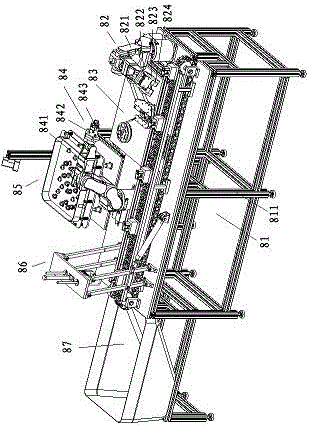

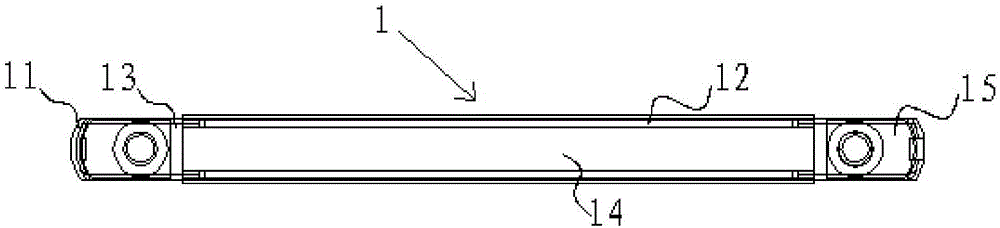

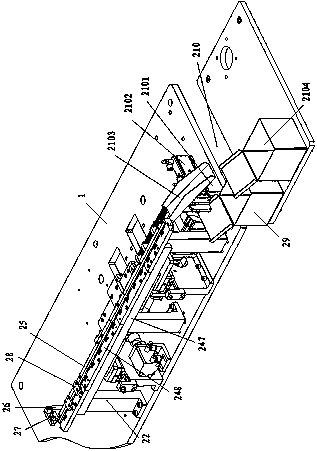

Labeling assembly line for stroke switch assembly machine

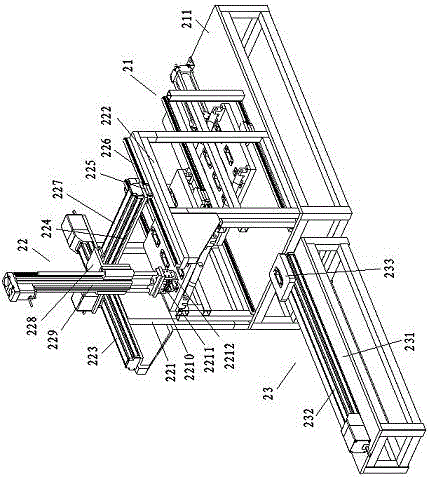

InactiveCN105990050ALabor savingReduce manufacturing costElectric switchesAssembly lineAssembly machine

The invention discloses a labeling assembly line for a stroke switch assembly machine, which comprises a feeding device, a first charging device, a labeling device, a second charging device, a protective cap feeding device, a discharging device and a finished product mounting box, wherein the feeding rack of the feeding device is provided with the first charging device, the labeling device, the second charging device and the discharging device; the rear side of the feeding rack is provided with the protective cap feeding device; the left side of the feeding rack is provided with the finished product mounting box; the first charging device conveys stroke switches to the feeding device; the labeling device carries out labeling processing on the stroke switches; the second charging device conveys protective caps at the protective cap feeding device to the feeding device; and the discharging device conveys the well-assembled stroke switches to the finished product mounting box. Through the above mode, manual labor can be replaced, assembling and labeling processing can be automatically, high efficiently and tidily carried out on the stroke switches, the labor is saved, and the production cost is reduced.

Owner:海门华夏时丽网络科技服务有限公司

Handle

ActiveCN105909059AEasy to installEasy mechanized installationHandle fastenersAlarm locksEngineeringMechanical engineering

The invention discloses a handle. The handle comprises a handle cover, a handle liner, a shifting fork, a handle gear, a handle body and a profile and further comprises a handle positioning device, a gasket, a positioning piece, a positioning sleeve and a bottom piece. The handle positioning device and the positioning piece are installed in the handle liner. The gasket is installed on the profile and is in sliding fit with the shifting fork. The positioning sleeve penetrates through the handle liner and the handle cover. The bottom piece is installed on the profile and connected with the handle liner. The handle liner is sleeved with the handle cover. The positioning sleeve is connected with the handle.

Owner:FOSHAN JINDIZHU BUILDING DECORATION MATERIALS CO LTD

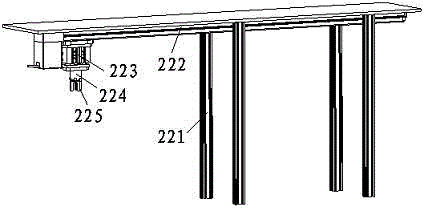

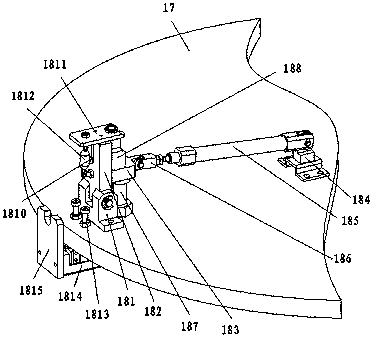

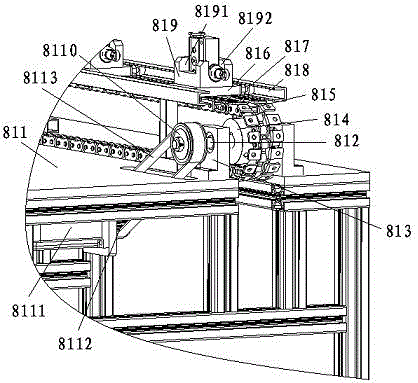

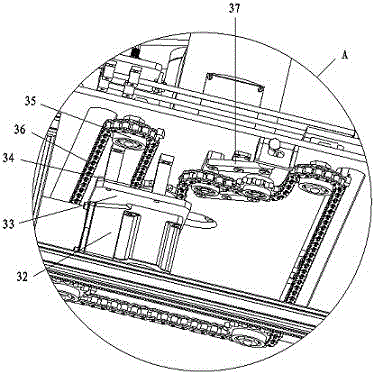

Conveying mechanism of travel switch contact part assembling machine

The invention discloses a conveying mechanism of a travel switch contact part assembling machine. The conveying mechanism of the travel switch contact part assembling machine comprises a conveying rack, a right-angled speed reduction motor, a speed reduction motor support, a driving chain wheel, synchronous chain wheels, a chain, a chain tensioning device, conveying devices, locating devices and four-axis position changing devices. A motor shaft of the right-angled speed reduction motor drives the driving chain wheel to rotate, the four synchronous chain wheels distributed in the rectangular shape are installed on the lower plane of a working table of the conveying rack and are connected with the driving chain wheel through the chain, the chain passes through the chain tensioning device, the two conveying devices are installed on the working table of the conveying rack and are distributed in a central symmetry mode, three locating devices are arranged at the side end of each conveying device, and the two four-axis position changing devices are installed on the working table of the conveying rack. By means of the mode, the conveying mechanism can replace manpower to automatically, efficiently and neatly change workpiece positions and assemble workpieces and save labor.

Owner:扬州通华电气有限公司

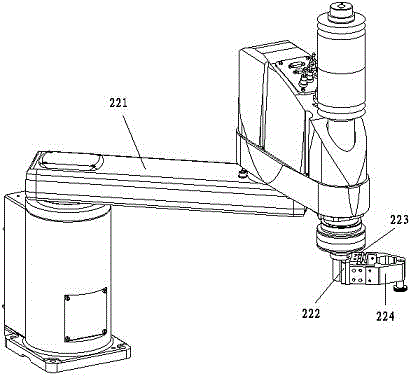

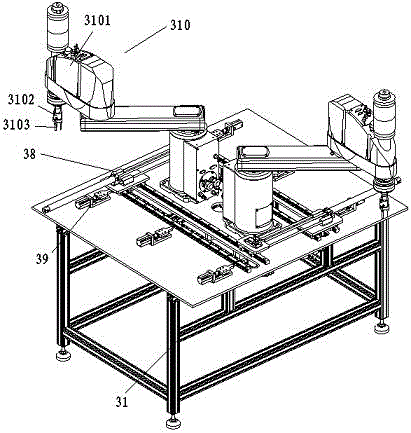

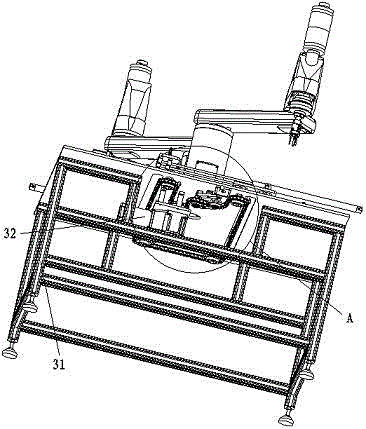

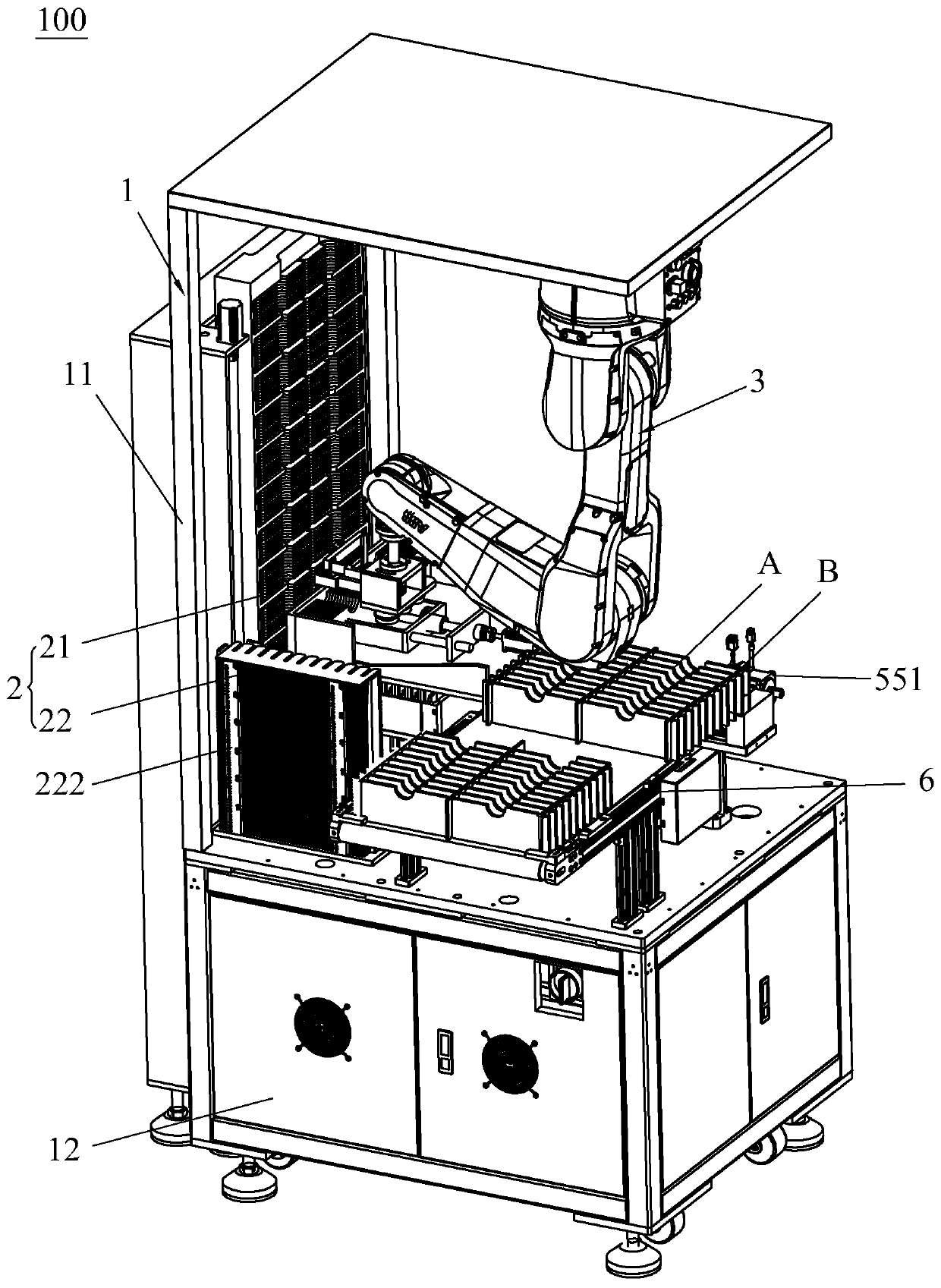

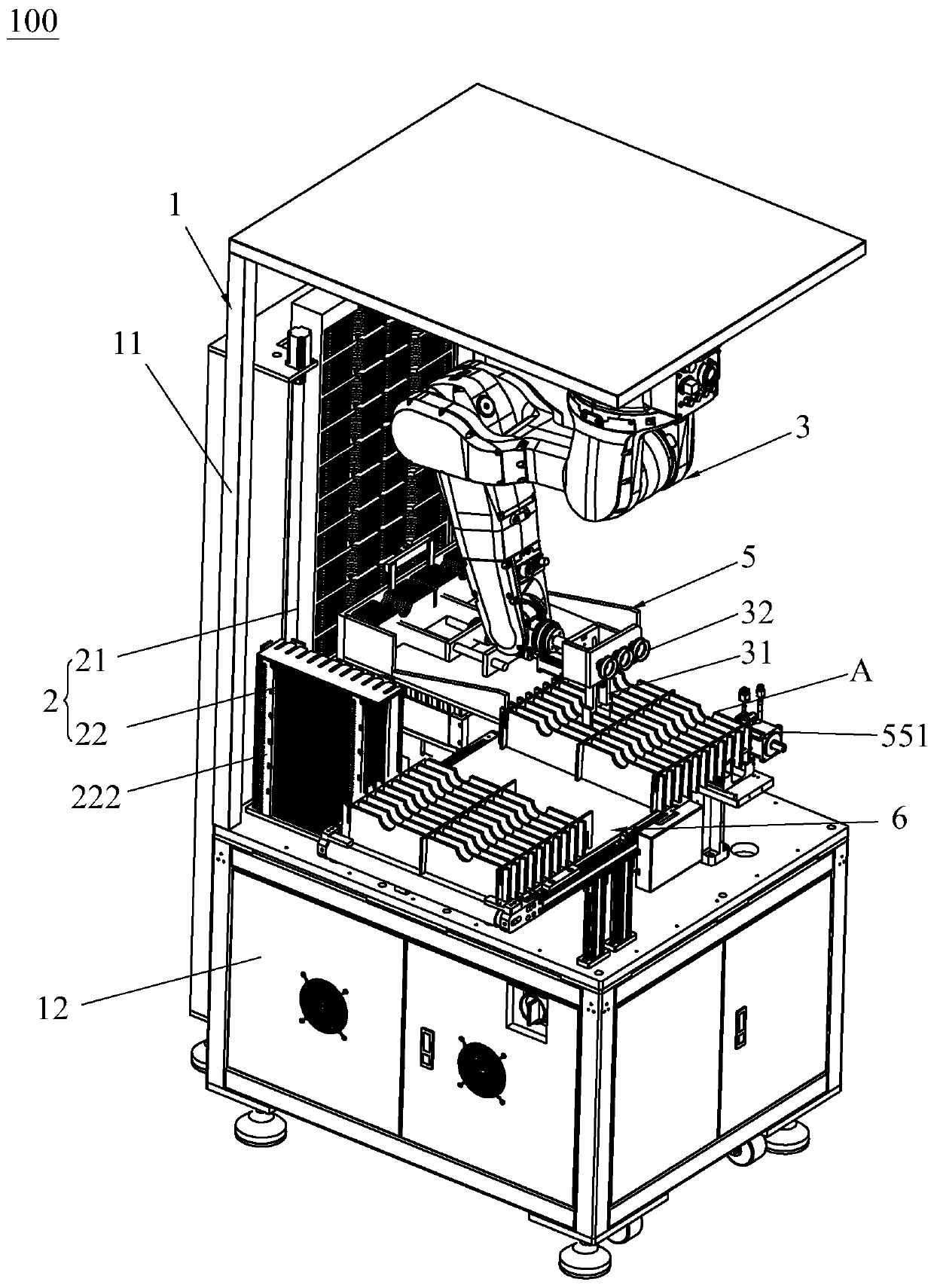

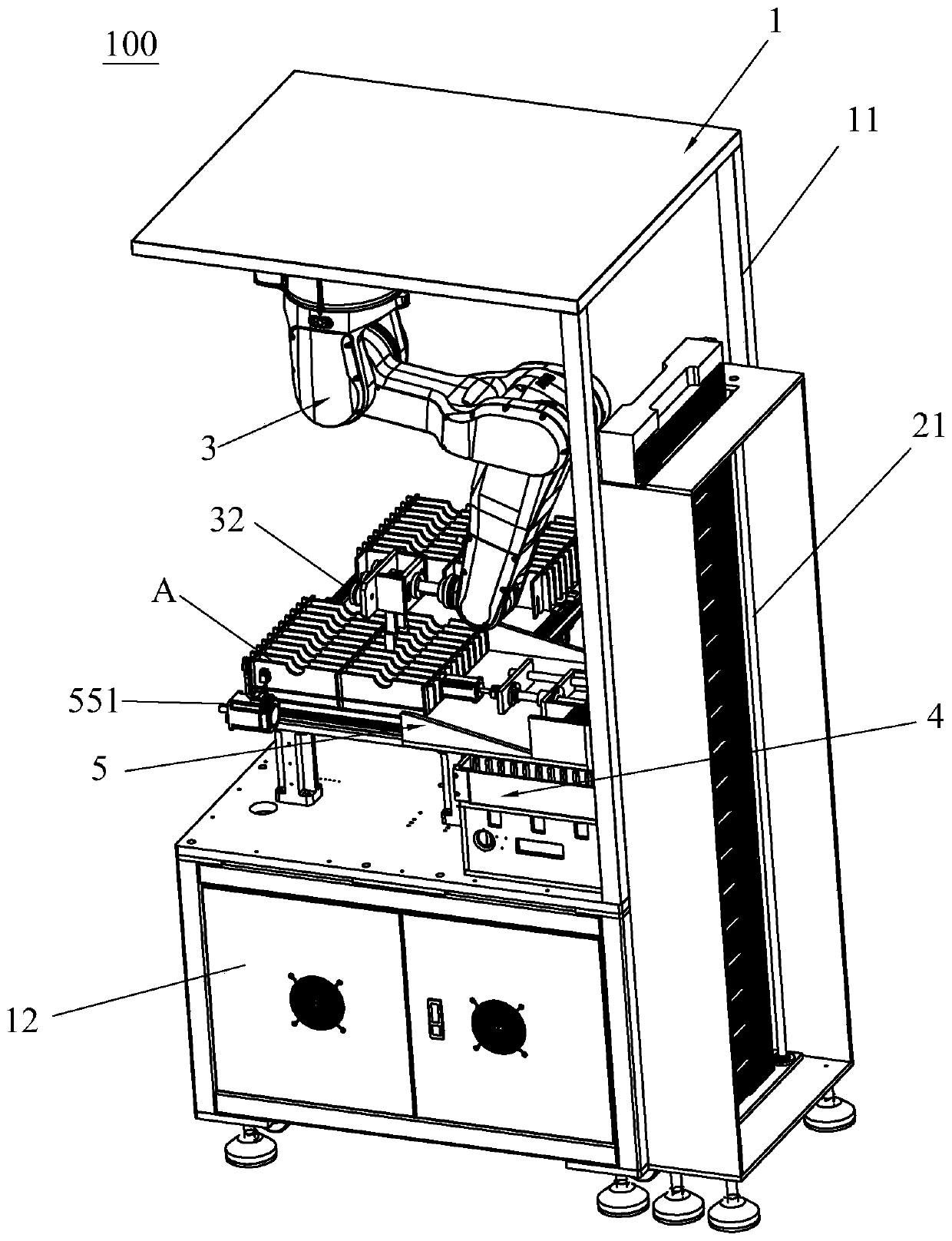

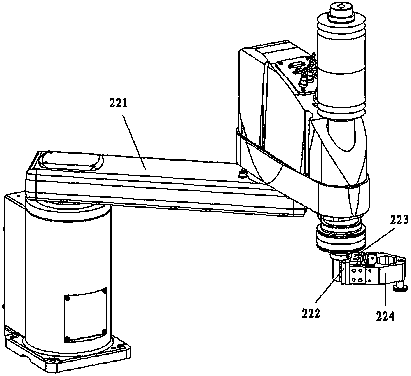

Partition plate assembling device

ActiveCN111015162ARealize automatic assemblyAutomatic assembly withoutMetal working apparatusRobot handAutomatic control

The invention discloses a partition plate assembling device. The partition plate assembling device is used for assembling a partition plate and comprises a rack, a feeding mechanism and a manipulatormechanism. The manipulator mechanism is mounted on the rack. The feeding mechanism is located on the lateral side of the rack for feeding the partition plate. The manipulator mechanism clamps the partition plate transferred by the feeding mechanism for assembly. Automatic assembling of the partition plate is achieved. Manual operation is not needed. The problems that manual assembling of partitionplates is long in time consumption and low in efficiency are solved. The whole assembling process of the partition plate is automatically controlled to be stable and tidy.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

Touch electric fireplace

ActiveUS8534855B2More and effectIncreased durabilityFurnace componentsDomestic stoves or rangesTouchpadComputer module

A touch electric fireplace comprises a housing, an imaging screen installed in the housing, a light source, a flame processing device, and a reflecting module. A window is defined on a front wall of the housing, a transparent insulator completely shields the window as well as a rim of the window, a touch area is arranged on the transparent insulator and along the rim of the window, and a touch panel is attached to a front side of the transparent insulator of the touch area; whereby, the electric fireplace is easily operated and controlled by simply touching the touch panel.

Owner:LU MIN HSUN

Micro Switch Assembly Equipment

ActiveCN105957756BNeatly assembledImprove assembly efficiencyElectric switchesMan machineEngineering

Owner:佛山市顺德区百帝电器制造有限公司

Solenoid valve assembly equipment

The invention discloses solenoid valve assembling equipment. The solenoid valve assembling equipment comprises a rotary disc mechanism, a main body transposition mechanism, an electromagnet feeding mechanism, a sign feeding mechanism, a spring washer feeding mechanism and a screw cap feeding mechanism. The main body transposition mechanism, the electromagnet feeding mechanism, the sign feeding mechanism, the spring washer feeding mechanism and the screw cap feeding mechanism are annularly located on the periphery of the rotary disc mechanism. Six main body mounting dies are mounted on a rotary disc of the rotary disc mechanism. The main body mounting dies sequentially face the main body transposition mechanism, the electromagnet feeding mechanism, the sign feeding mechanism, the spring washer feeding mechanism and the screw cap feeding mechanism. By means of the manner, the solenoid valve assembling equipment can complete assembly of solenoid valves automatically, efficiently and trimly in replacement of manpower, manpower is saved, and the production cost is lowered.

Owner:喷达汽车精密部件(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com