Solderless folding cable support frame

A cable support, folding technology, applied in the direction of pipe support, pipe/pipe joint/pipe fitting, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

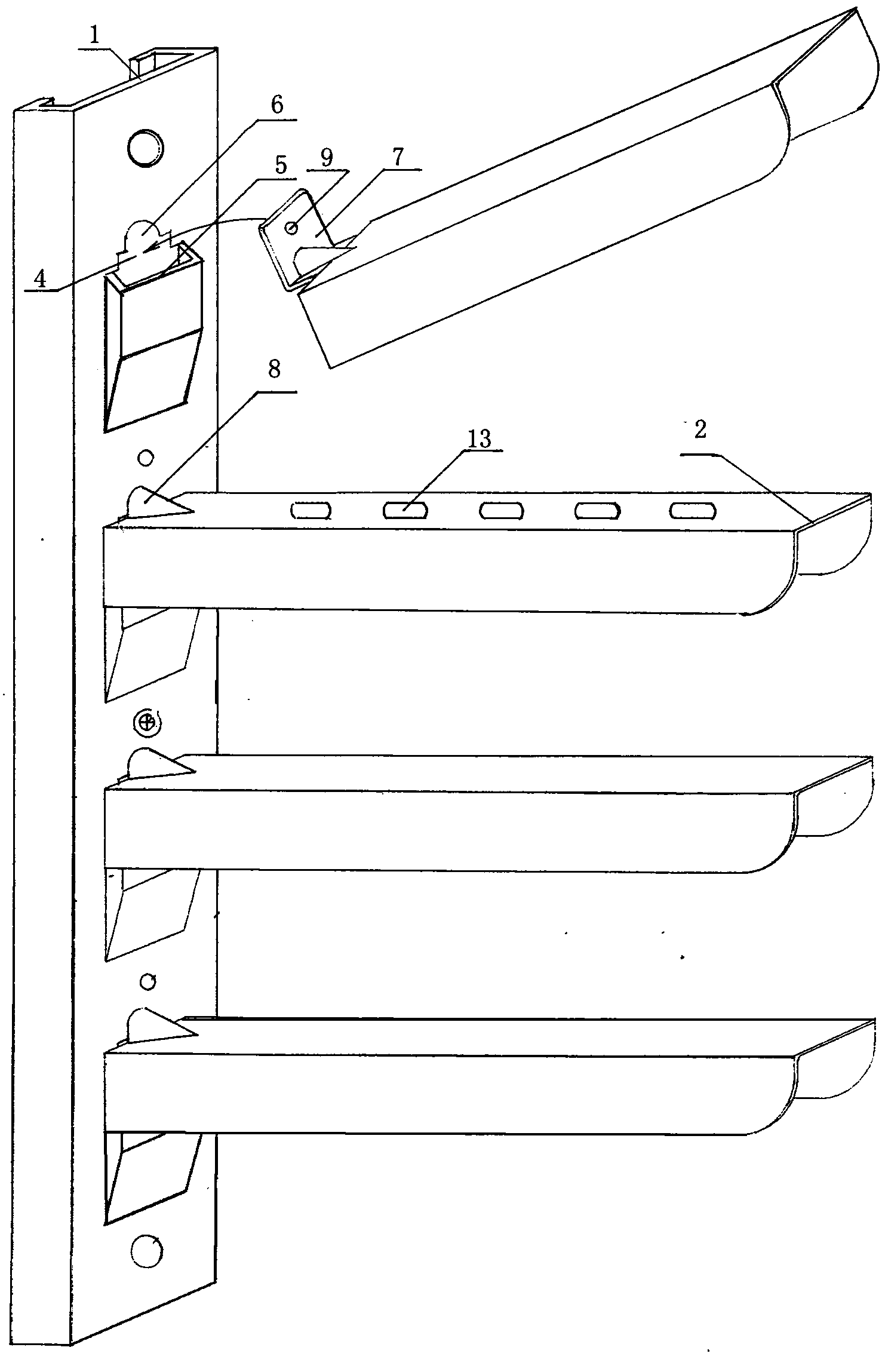

[0027] The positioning device includes a reinforcing rib 8 arranged at one end of the support 1, and is provided with a matching hole 6 on the column 1. The matching hole 6 is located at the upper end of the socket 4 and communicates with the socket 4. The increased The ribs 8 are located on the top of the buckle 4, and during installation, the reinforcing ribs 8 cooperate with the matching holes 6 to realize positioning and avoid force displacement of the bracket 2.

Embodiment 2

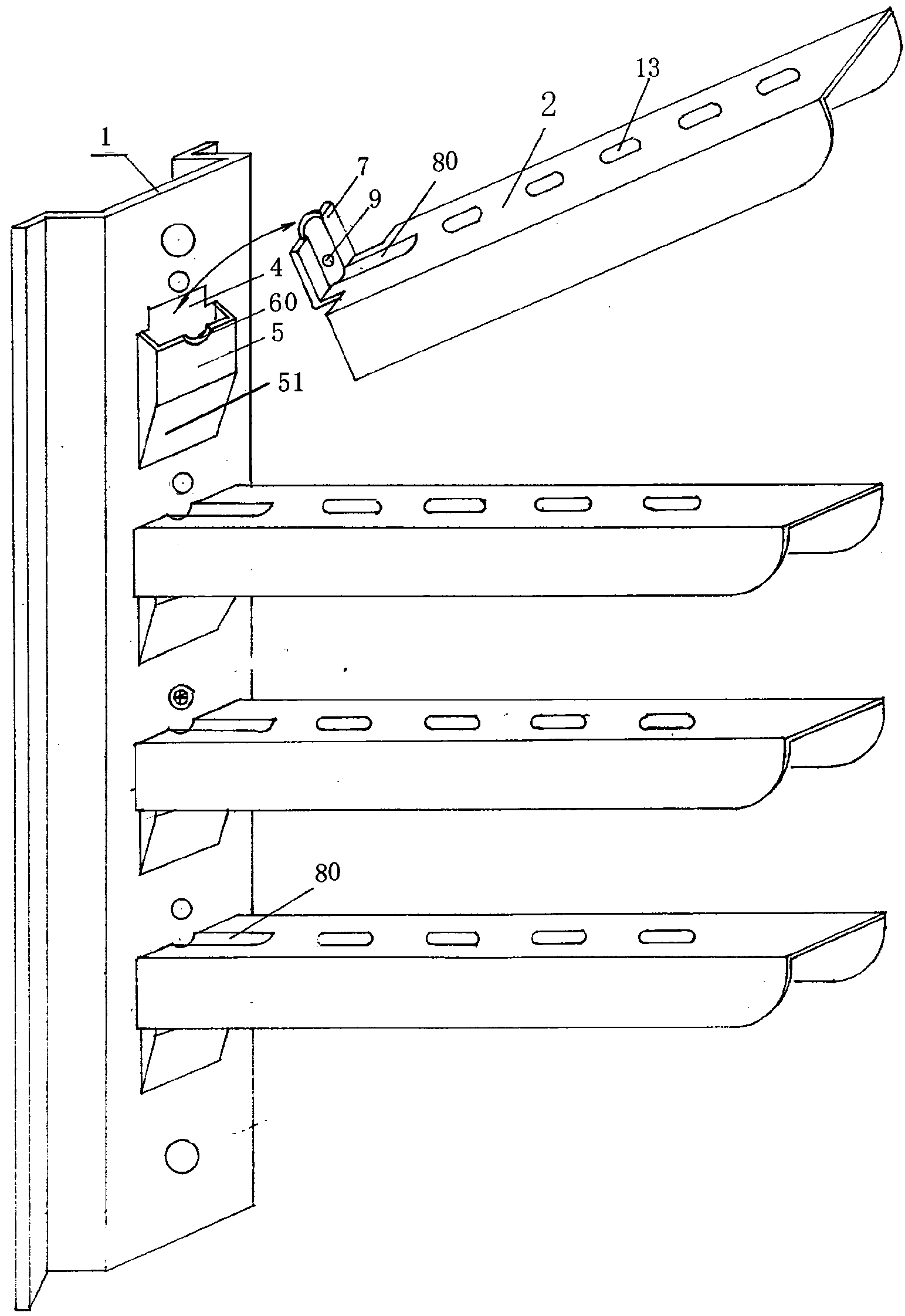

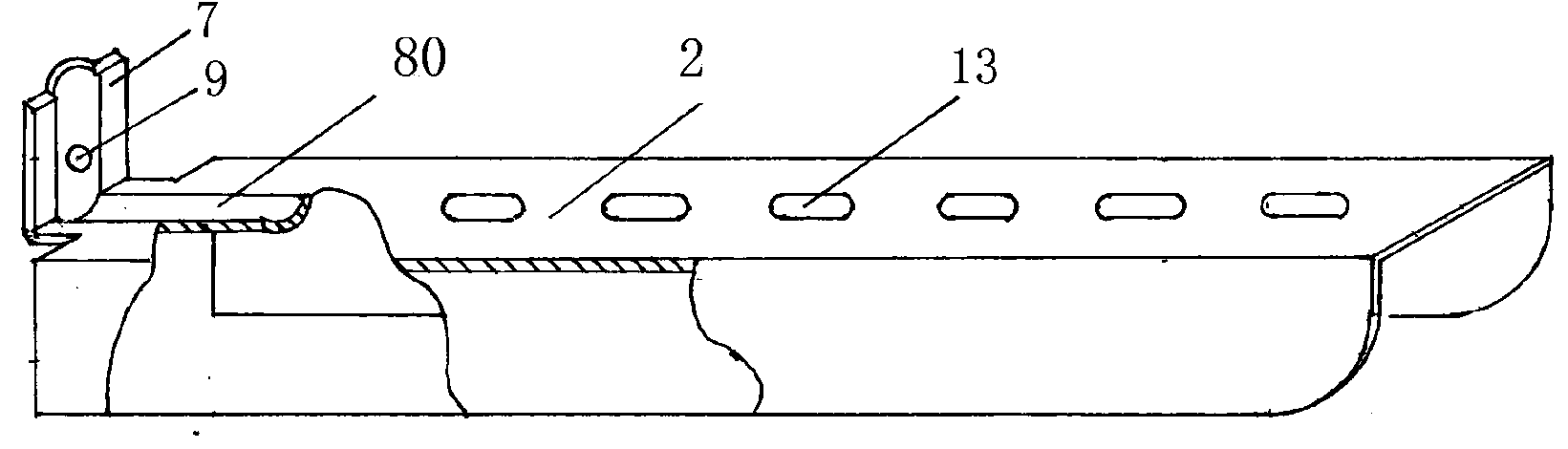

[0029] The positioning device includes a supporting plate 80 arranged at one end of the support 1 and a notch 60 arranged on the end surface of the force bearing seat 5. The supporting plate 80 is located on the bottom surface of the buckle 8. When installed, the The supporting plate 80 cooperates with the notch 60 to realize the positioning function and prevent the support 2 from shifting under force.

[0030] To sum up, the bracket has precise force-bearing components, compact structure, convenient installation, shortened construction period, good compatibility, and high efficiency and energy saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com