Novel welding-free detachable bracket

A new type of support column technology, which is applied in the installation of ground cables and cables, can solve the problems of high coordination costs and poor compatibility, and achieve the effects of shortening the production period, simple use, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

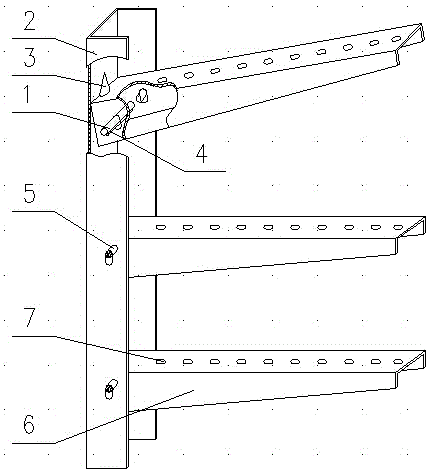

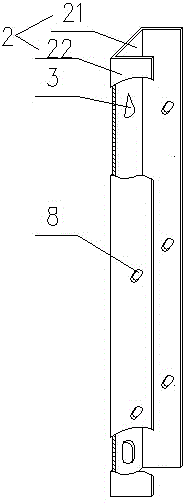

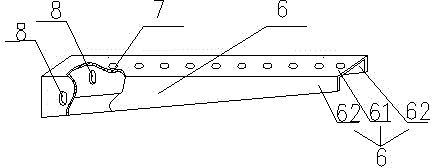

Embodiment 1

[0032] A new type of welding-free detachable bracket, comprising: a bracket column 2 and a bracket bracket 6, wherein the bracket column 2 is vertically arranged, including a column body 21 and flanges arranged on both sides of the column body 22, the The support column 2 has a C-shaped section and is an integrated structure; the support column 2 is provided with a plurality of convex positioning force points 3 and a plurality of pivot pin positioning force points 5; the convex positioning force points 3 are located on the main body of the support column 21, it is a stretched convex structure, which is vertically distributed on the bracket main body 21 according to the specification requirements, and the number of the convex positioning force points 3 is three; the shaft pin positioning force points 5 are waist-shaped holes 8, which are arranged obliquely On the side 22 of the support column of the complaint, it is vertically distributed according to the specification requireme...

Embodiment 2

[0036] A new type of welding-free detachable bracket, comprising: a bracket column 2 and a bracket bracket 6, wherein the bracket column 2 is vertically arranged, including a column body 21 and flanges arranged on both sides of the column body 22, the The support column 2 has a C-shaped section and is an integrated structure; the support column 2 is provided with a plurality of convex positioning force points 3 and a plurality of pivot pin positioning force points 5; the convex positioning force points 3 are located on the main body of the support column 21, it is a stretched convex structure, which is vertically distributed on the bracket main body 21 according to the specification requirements, and the number of the convex positioning force points 3 is three; the shaft pin positioning force points 5 are waist-shaped holes 8, which are arranged obliquely On the side 22 of the support column of the complaint, it is vertically distributed according to the specification requireme...

Embodiment 3

[0040] A new type of welding-free detachable bracket, comprising: a bracket column 2 and a bracket bracket 6, wherein the bracket column 2 is vertically arranged, including a column body 21 and flanges arranged on both sides of the column body 22, the The support column 2 has a C-shaped section and is an integrated structure; the support column 2 is provided with a plurality of convex positioning force points 3 and a plurality of pivot pin positioning force points 5; the convex positioning force points 3 are located on the main body of the support column 21, it is a stretched convex structure, which is vertically distributed on the bracket main body 21 according to the specification requirements, and the number of the convex positioning force points 3 is three; the shaft pin positioning force points 5 are waist-shaped holes 8, which are arranged obliquely On the side 22 of the support column of the complaint, it is vertically distributed according to the specification requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com