Automatic assembling machine of razor base

A technology for automatic assembly machines and razors, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as low efficiency, complexity, labor costs, and material costs, and achieve the goal of reducing production costs and saving labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

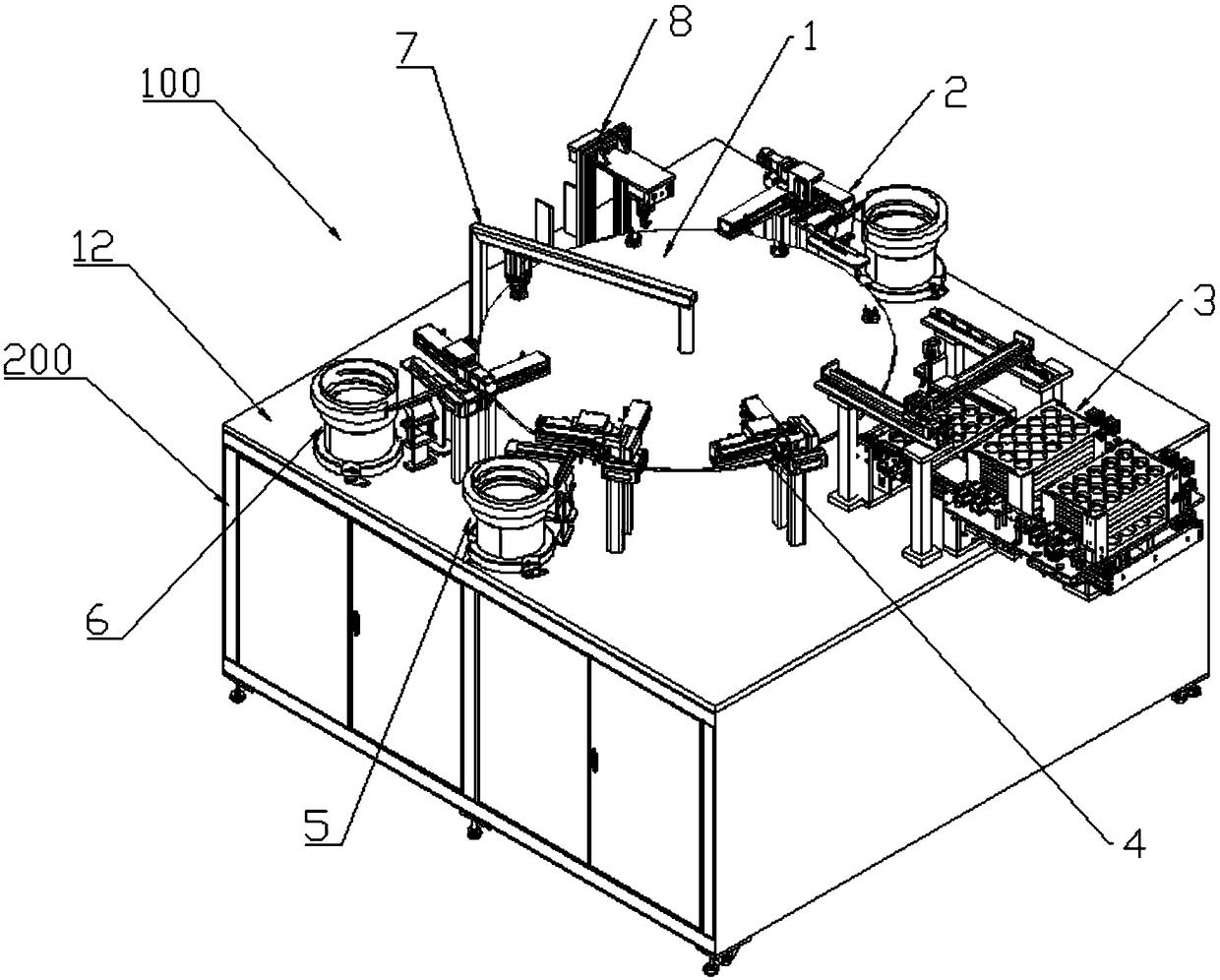

[0035] like Figures 1 to 19 As shown, a shaver holder automatic assembly machine 100 includes a frame 200, and an electric control box (not shown) is arranged in the frame 200 to control the automatic assembly machine. It also includes an eight-station turntable mechanism 1, a gear shaft feeding mechanism 2, a waterproof board feeding mechanism 3, a waterproof board oiling mechanism 4, a waterproof ring feeding mechanism 5, and a connecting bracket feeding mechanism arranged on the frame bottom plate 12. The pre-installation mechanism 6, the connecting bracket pressing mechanism 7 and the blanking mechanism 8 are located around the eight-station turntable mechanism 1 in a ring shape.

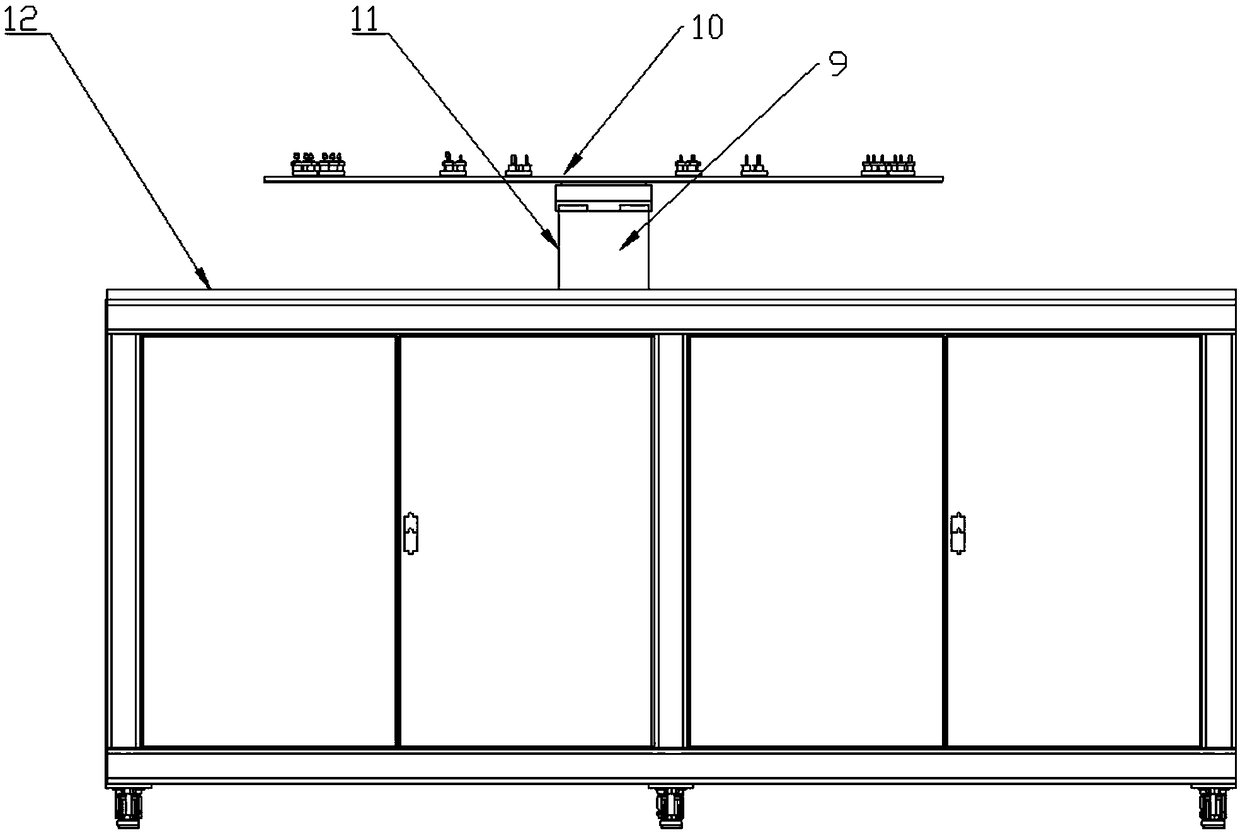

[0036] The eight-station turntable mechanism 1 includes a direct drive motor 9 and a turntable 10. The direct dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com