Full-automatic motor stator assembly production line

A technology for assembling production lines and motor stators, which can be used in the manufacture of motor generators, electromechanical devices, and stator/rotor bodies, etc., and can solve the problems of high labor consumption and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

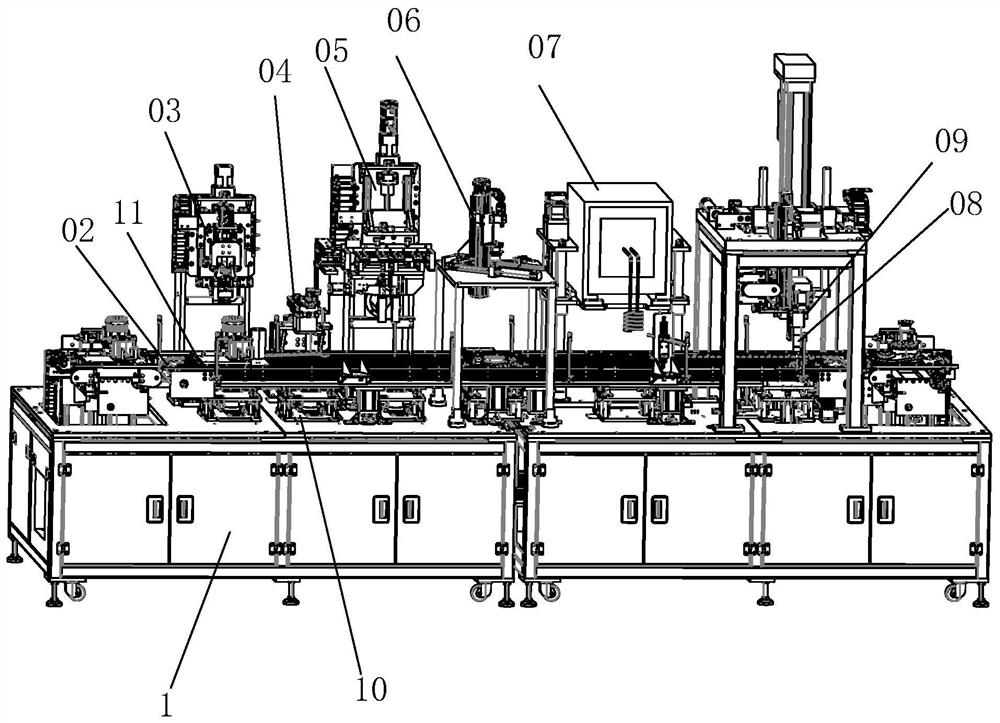

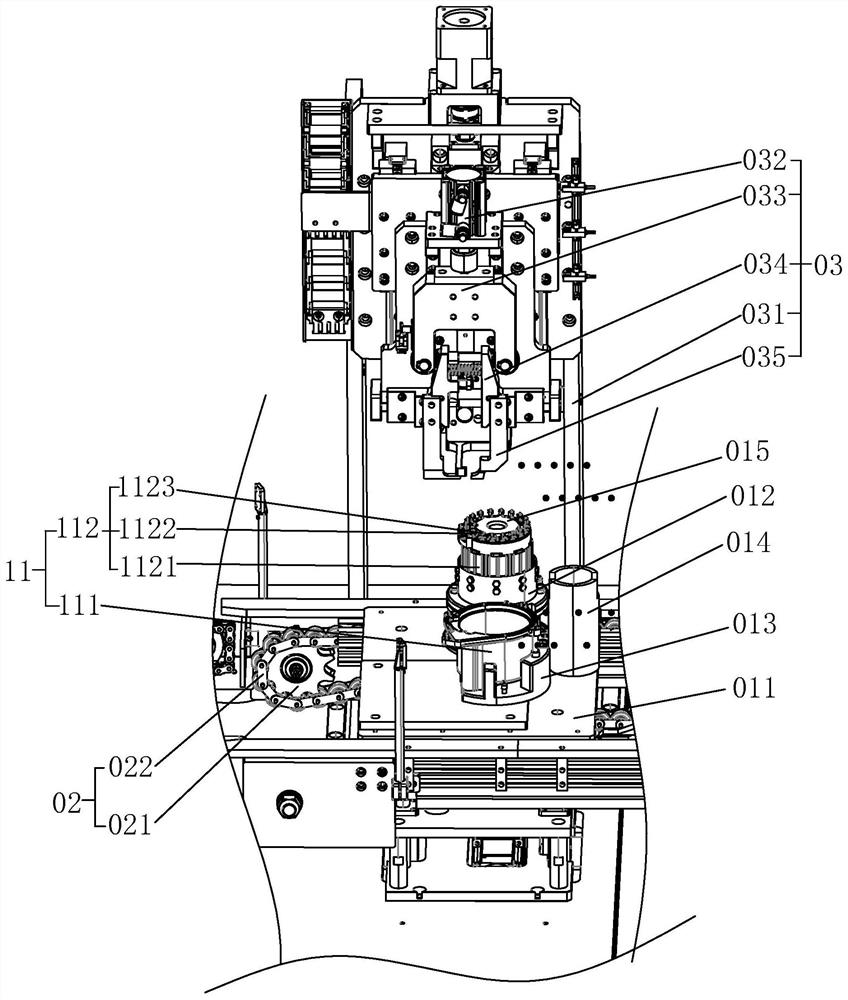

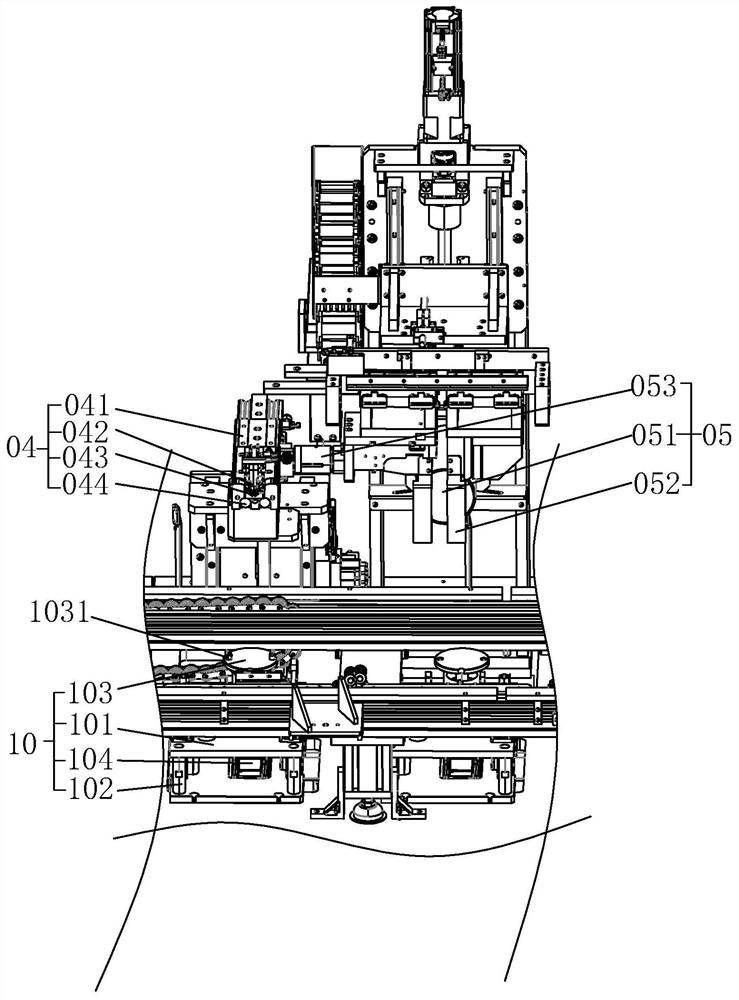

[0037] A fully automatic motor stator assembly production line, refer to figure 1 , including the frame 01 set on the level ground, the frame 01 is slidably connected with the loading plate 011 for carrying the motor casing and the motor stator, and the loading plate 011 is plugged with a mounting plate for fixing the motor stator Locate the mandrel 015, and the frame 01 is also connected with the drive assembly 02 that drives the object carrier 011 to move, and in the sliding direction of the object carrier 011, there are sequentially arranged the copper wires of the motor stator and the connectors for pre-shaping. Pre-shaping component 03, wire trimming component 04 for cutting excess copper wire, welding component 05 for welding copper wire and connector, core pulling component 06 for pulling positioning mandrel 015 out of motor stator, for The heating as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com